Impulse ECOMIZER-PRO User manual

Introduction

Congratulations on your purchase of an Impulse Pump unit with ECOMIZER-PRO

control technology.

The ECOMIZER-PRO is an emissions-reducing and fuel-saving mobile pump and engine

controller that can automatically handle the unit's performance based on the changing

conditions in a pump pit. Adjusting the revolution cycles depends directly on the

amount of supplied medium that needs to be pumped.

Pump units equipped with the ECOMIZER-PRO offer the best of both worlds - the

mobility of a self-operating diesel pump set with the full flexibility of a frequency-

controlled electric fixed installation. With the ECOMIZER-PRO control technology, both

diesel and electric driven mobile pumps can achieve significant emissions reductions

and fuel savings of up to 55% when compared to similar equipment without this

technology.

The ECOMIZER-PRO achieves full automation with comprehensive log data on the

pump's use, such as operating hours, production days, hours until the next service,

and/or time-related warnings or alarms when exceeding adjustable limits. The user can

choose some limits and/or parameters attuned to their own operations.

The ECOMIZER-PRO, with optional internet connection, allows you to remotely monitor

and even operate the pump set from any computer with internet connection.

Introduction

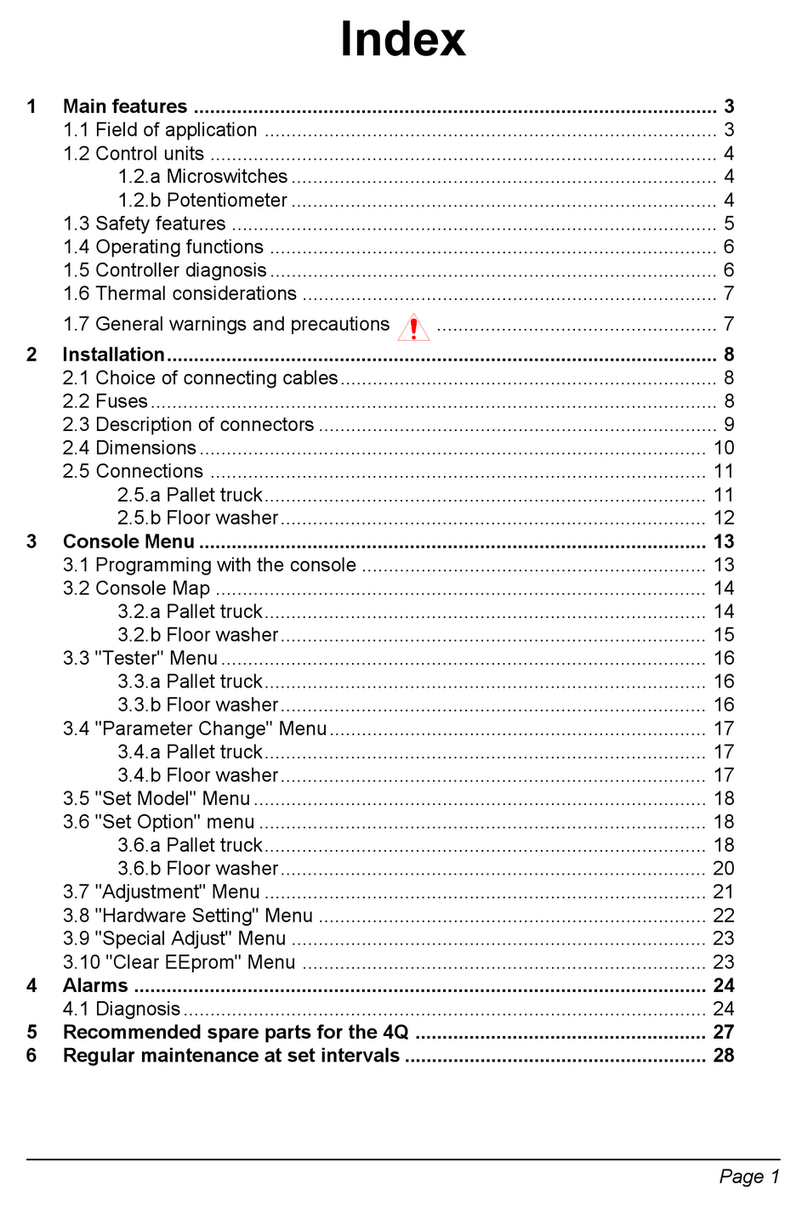

INDEX ECOMIZER-PRO

4. Manual Control

5. Level Control

1. Screen Activation

2. Starting Screen

3. Ecomizer-Pro Explanation

p. 1

p. 2

p. 3

7. Fault Codes

8. Info Screens

9. Login Screen

p. 4

p. 7

p. 20

p. 22

p. 25

6. Battery Recharge

10. Time Settings

p. 19

p. 29

1

1. Screen Activation

All Impulse Pumps equipped with ECOMIZER-PRO are operated using only a single

switch. To activate the display, keep the switch in the “Start” position until the display

lights up (approximately 5 seconds). Once it has lit up, you can release the switch, which

will return to the “On” position. In the “On” position, the unit is active for remote

operation.

Please be aware that the pump is in Stand-By mode as soon as the switch is in “On”

position. Maintenance, repair, and/or transportation should never be done with the

switch in “On” position.

1. To start the ECOMIZER-PRO: Hold the “Off-On-Start” switch on the control box in

the “Start” position, and wait until the Touch Screen display appears.

2. After these 3 seconds the switch can be released, and it return to its “on” position.

When no further actions are made during the shutdown delay (standard on 2

minutes) the ECOMIZER-PRO will switch itself into Stand-By. To reactivate the

ECOMIZER-PRO the user has to turn the switch on “start” again, or when applied

(optional), the pump can be started by Remote Control.

3. The “Off” position will shut down the Pump Unit completely. This position can be

used as emergency stop. Make sure the ECOMIZER-PRO is on “Off” while

maintaining, repairing, transporting or being stored.

Screen Activation

Switching to “Off” Position has the same working as an

emergency stop

2

2. Starting Screen

Depending on the purchased software version there are three possible starting screens

available:

Starting Screen

Manual Control (Only)

The Manual Control (Only) software option is mostly used on smaller pump sets which

are generally operated on site. See Manual Control section to discover all advantages.

Level Control (Only)

The Level Control (Only) software option is mostly used for larger pump sets for which

Ecomizer-Pro can help reduce mistakes caused by human error.

Ecomizer-Pro

The Ecomizer-Pro software option gives the user the choice of using either manual

control or level control.

The pump will

automatically shut down

in Stand-By mode as soon

as there are no further

interactions with the

display for more than 120

seconds.

3

From this point on the manual is based on the Ecomizer-Pro software version. The

Manual Control Only and Level Control Only are both explained separately.

Starting Screen

To change the Touch Screen language, press the [Language] button.

Select the preferred language by pressing the flag on the pop-up.

3. Ecomizer-Pro Explanation

Note:

USA flag uses the Imperial system (PSI, Inch, Ft, and Gallons/h).

All other flags use the Metric system (Bar, Metre, Litre, m3/h).

4

4. Manual Control

Manual Control

Be aware that RPM adjustment is only possible as soon as the system has been primed

(full of water). As long as there is no water present, the REV UP and REV DOWN buttons

are not being displayed on the screen.

As soon as “START MANUAL CONTROL” has been selected the following screen

appears:

The pump starts up after 5 seconds and a warning beep is given. You can stop the start-

up procedure at any time by pressing the red “STOP” button.

In manual control you can activate the pump unit and set the RPM value according to

your preferences.

Activate Manual Control by pressing START MANUAL CONTROL

5Manual Control

As soon as the pump has started the following screen appears:

Air in suction hose is

displayed by “AIR

DETECTED” and a blue dot.

Vacuum pump is active.

General Data

As soon as the pump has been primed “REV UP” and “REV DOWN” buttons appear.

Vacuum pump is active and

will turn off when the pump

is primed (full of fluid) for

more than 20s.

REV UP and REV DOWN

buttons together with

setpoint.

Air in system

System

primed

Slide show:

•Flow rate

•Pressure

•Vacuum

6Manual Control

4.1 Main screen during operation (Manual Control)

Vacuum pump

is not active

(system is fully

primed)

Manual set

setpoint (RPM)

RPM bar. In this unit from

1000 RPM to 1800 RPM.

1000 1800

RPM

If air is detected and the pump starts snoring/slobbering the RPM will automatically fall

down to idle RPM (in this case 1000 RPM). The setpoint is still in memory and as soon as

the system is fully primed again, the unit will automatically rev up to its setpoint.

Remarkable Advantages:

4.3 Intelligent Manual Control by ECOMIZER-PRO

4.2 Air Snoring in Manual Control

In manual control the pump will keep on running even when air is detected.

The automatic shut-down of the unit after 900s of priming air is ONLY in this

mode not activated. As air is detected the unit will rev down to 1000 RPM,

vacuum pump will be activated, and the pump will keep on priming/snoring.

•Fuel Reduction

•Emission Reduction

•Noise Reduction

•Wear Reduction

•Extended Lifetime

7

5. Level Control

Level Control

Level Control provides the advantage that the pump performance is automatically adjusted

to the available amount of medium (flow). The units come equipped with a hydrostatic

pressure sensor and/or a ball float switch. The two connectors for the sensors have different

connection points (4 pins or 5 pins), eliminating the possibility of connection mistakes. This

needs to be connected in the pump set.

Activate Level Control

If there are no sensors connected the following screen appears indicating that the level

sensor needs to be connected.

There are three possible ways of connecting the level sensors. Every sensor is creating

its own distinct display.

8Level Control

5.1 Installing/positioning of the Ball Float Switch

2. Secure the Ball Float Switch using a tie-wrap or tape on a (sinking) tube as shown below.

1. Put a tube (longer than total pit depth) inside the well. Now mark the level at which the

pump needs to start pumping. This is the position at which the ball float should be mounted.

The ball float switch will float (up) as soon as the water level rises above this point. As soon as the

float stays up the pump will be activated.

Please make sure the Ball Float Switch is secured in such a way that the float can not interfere

anywhere.

Keep distance

between float

and tie-wrap

small to avoid

getting

tangled.

Ball Float Up (activated). On screen:Ball Float Down. On screen:

9Level Control

5.2 Connecting Ball Float Switch Only

The following screen appears:

In this mode ensure that the ball float is positioned (floating) at the desired level at

which you want the pump to start. After installing the ball float, activate the pump by

pressing the START button.

Active pump unit on ball float switch waiting for fluid (ball float switch down).

Ball Float

Switch

Connected

(Down)

10 Level Control

As soon as the water level will activate the pump by lifting the float switch up, the following

screen appears:

The vacuum pump is active and will prime the system. After full activation the following

screen appears:

As long as the float switch is up the engine will slowly rev up to maximum RPM.

Ball Float

Switch

Connected

(Up)

11 Level Control

If the water level comes down and the float switch will be down the unit will slowly rev

down to a minimum of 1400 RPM.

As soon as the water level comes up to a level that the float switch will come up again the

pump will rev up again.

As soon as air enters the suction line the pump will shut itself off (stops) and will be waiting

until the time the float switch will be up again.

12 Level Control

5.3 Installing/positioning of the Hydrostatic Pressure Sensor (HPS)

1. Put a filter/well point tube with end cap (longer than total pit depth) inside the well.

2. Place the HPS inside the filter well point tube and sink it completely to the bottom.

Filter/well-

point tube.

Placed at the

bottom of the

pit.

Hydrostatic

Pressure

Sensor (HPS)

TIP:

If you expect a lot of sludge at the bottom of the pit

then place the HPS a little bit higher to avoid clogging

of the holes of the sensor. The HPS cable has a small air

line inside and may never kink. However, it is important

to check and maintain the HPS regularly and put it back

at the same position after maintenance.

Do not over-clamp the tie-wrap in a way that the inside

air tube could be blocked.

Inspect the camp for

clogged holes on a

regular basis.

13 Level Control

5.4 Connecting Hydrostatic Pressure Sensor Only

The following screen appears:

The HPS sensor should be positioned at the bottom or just above the bottom (to avoid

sludge) of the pump pit. Make sure that the sensor is always leveled below the suction

hose/strainer of the pump. The best way is to install the HSP inside a well point (filter

tube) and as far away as possible from suction inlet/strainer.

After the HPS has been installed in the pit, the column of fluid above the sensor is given

on the screen in the green highlighted “Actual level” bar. This value given is the vertical

distance from the bottom of sensor up till the water surface level above the sensor.

Hydrostatic

Pressure

Sensor

Connected

Knowing this value already, all parameters needed to let the pump unit work fully

automatically and independently have to be set.

14 Level Control

5.5 Level Control Settings (HPS Connected):

1. Pit depth:

The pit depth value is only needed to obtain a properly scaled view of the pit on the right

side of the screen. You need to measure the distance from the fluid level in the pit to the

upper surface of the pit (ground level) or estimate it. The pit depth is the sum of the

distance from the fluid level to the ground level and the actual level, which is shown in the

green bar.

2. Alarm Level:

The alarm level is the level at which a time-stamped fault code will be registered in the

controller's list. When the alarm level is reached, the blue color of the fluid in the schematic

pit view on the screen will change to red.

3. Desired level above sensor:

The desired level above the sensor is the level that needs to be maintained in the pit. It's

important to use as much of the (sewer) pipelines' volume as possible for optimal efficiency

in over pumping. Always try to set a significant distance between the desired level above

the sensor and the set stop level.

4. Stop Level: (READ THIS SECTION CAREFULLY, MOST ISSUES ARISE HERE!!!)

•The stop level should preferably be 5 times the inner diameter (ID) of the suction

hose/pipe above the inlet of the suction hose/strainer.

•If the stop level is set too low, it can create a "Suction Vortex," causing air to be sucked

into the system, and the vacuum pump to activate continuously.

•If the vacuum pump operates continuously in level mode for more than 900 seconds

because it cannot reach the stop level due to air, it will activate an alarm and directly

shut off the pump unit (hard stop).

•Even if the fluid level rises above the desired level above the sensor later on, the pump

will not start automatically anymore but remain in an alarm state until a complete reset

is performed (set switch to "0" and restart the pump unit).

1.

2.

3.

4.

15 Level Control

The parameters for level control can be set by pressing the blue activation box for the level

that needs to be changed/adjusted.

After the activation box for a required level has been selected the screen below appears.

The required level can be set in the range as given.

Every time the level is adjusted, activate this new level by pressing the enter button. When

all levels have been set, the next screen appears showing the green start button:

PLEASE BE AWARE THAT LEVEL CONTROL IS ONLY ACTIVATED AFTER PRESSING

THE START BUTTON

16 Level Control

5.6 Screen of fully activated Level Control (waiting mode)

After pressing the START button the STOP button appears, indicating that the pump is

active. Depending on the Desired Level Above Sensor in combination with the actual level

the pump may not start directly. The Desired Level above Sensor is above the actual level.

5.7 Screen of fully activated Level Control (start mode)

After pressing the START button the pump will start directly if the actual level is above the

desired level. The following screen pops up:

17 Level Control

5.8 Main screen of Level Control (pumping mode)

Table of contents

Popular Controllers manuals by other brands

Rauch

Rauch quantron e Operator's manual

KSB

KSB EA-C Installation & operating manual

Zapi

Zapi 4Q Operating and users manual

Emerson

Emerson Bettis XTE3000 Installation, operation and maintenance manual

Mtroniks

Mtroniks True Torque DCI120-24 quick start guide

OJ Electronics

OJ Electronics OJ-Air2-WP55 instructions