Emerson Bettis XTE3000 User manual

Other Emerson Controllers manuals

Emerson

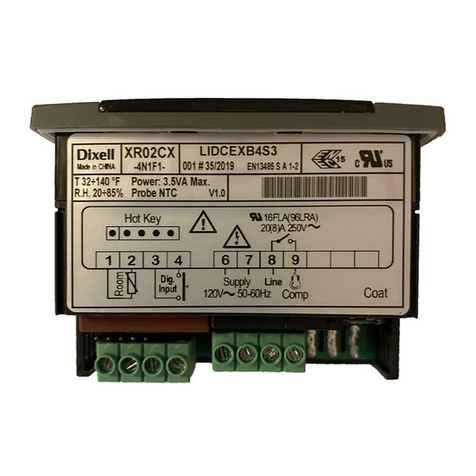

Emerson dixell XR02CX Wiring diagram

Emerson

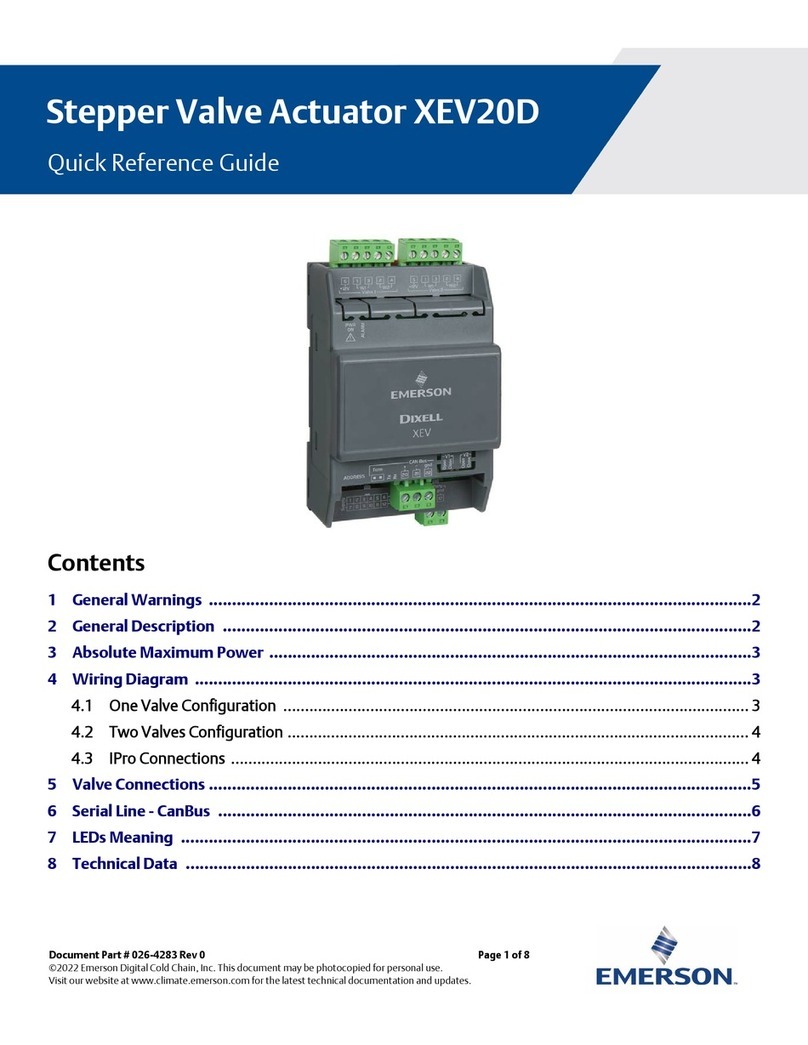

Emerson Dixell XEV20D User manual

Emerson

Emerson Dixell XM670K Wiring diagram

Emerson

Emerson FieldQ Series Operational manual

Emerson

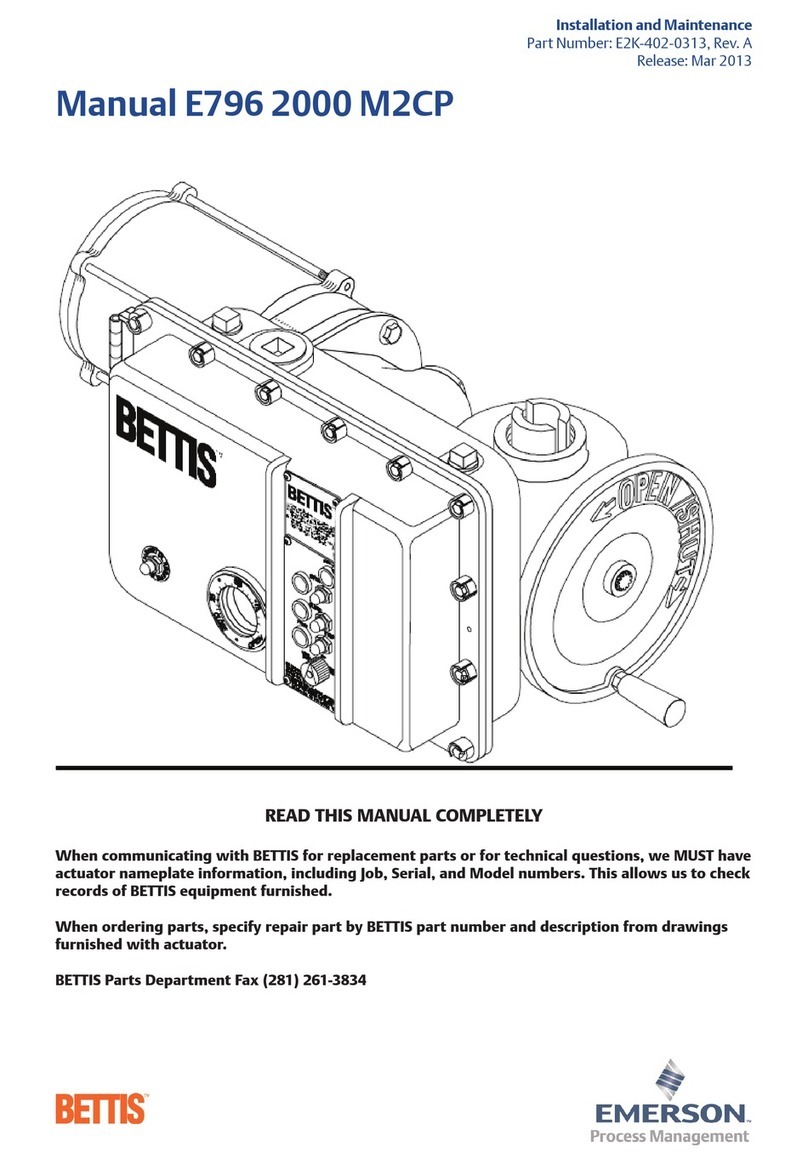

Emerson BETTIS E796 2000 M2CP User manual

Emerson

Emerson EC3-X32 User manual

Emerson

Emerson Asset Management Tag User manual

Emerson

Emerson Dixell XRB Wiring diagram

Emerson

Emerson Digistart CS User manual

Emerson

Emerson Branson 2000X ae User manual

Emerson

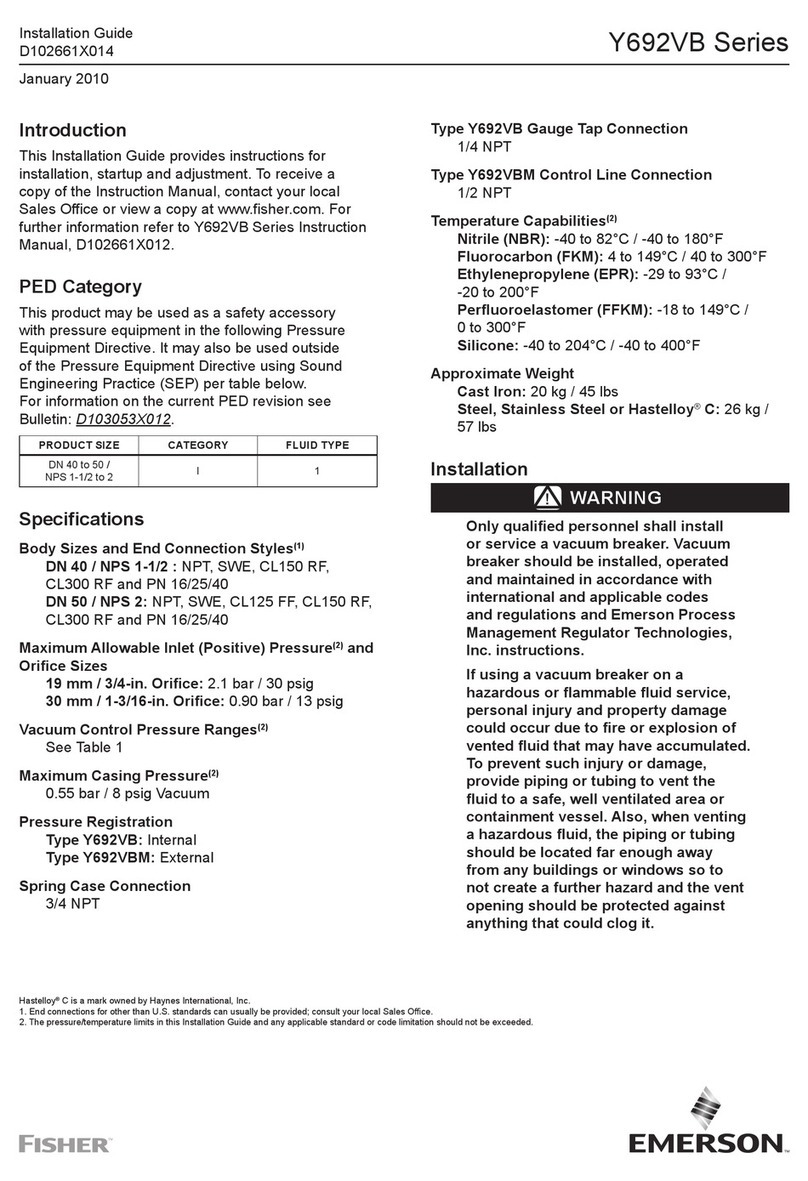

Emerson Fisher Y692VB Series User manual

Emerson

Emerson DSM314 User manual

Emerson

Emerson Bettis 500 User manual

Emerson

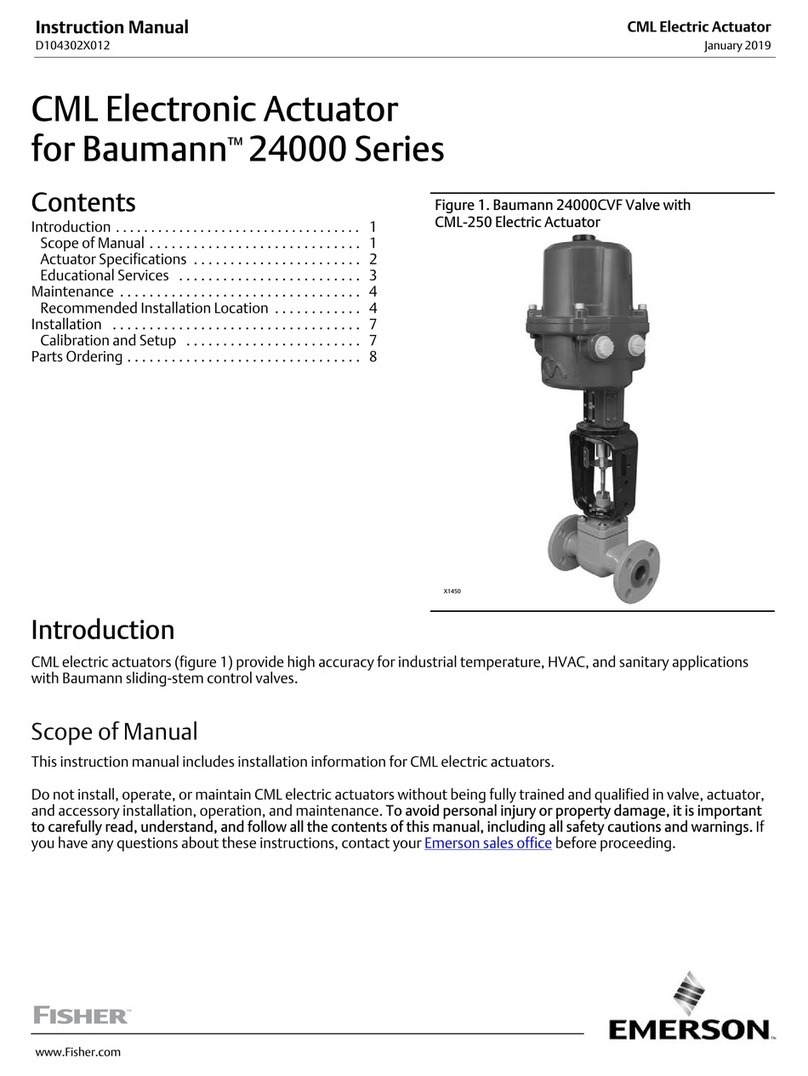

Emerson Fisher CML-750 User manual

Emerson

Emerson Leroy-Somer R220 Instruction Manual

Emerson

Emerson Digitax ST User manual

Emerson

Emerson Dixell XRi77CX Wiring diagram

Emerson

Emerson digitax st series User manual

Emerson

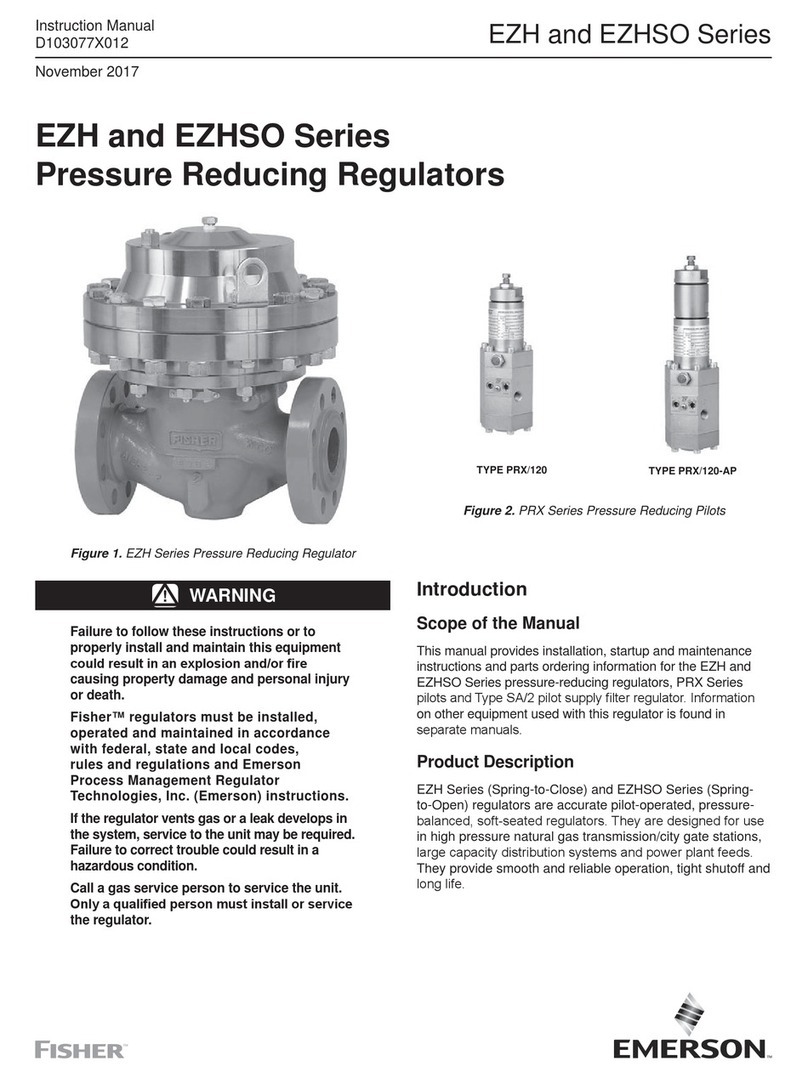

Emerson EZH Series User manual

Emerson

Emerson Bettis RTS User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions