IMS ROBOTICS MICRO S Operating instructions

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

1 of 113

MICRO S automatic

Cutter motor

Repair Manual

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

2 of 113

Foreword

This Repair Manual provides the technical description of our cutter motors and important information to have

them independently repaired by professionals.

We recommend reading the Repair Manual thoroughly before carrying out the respective repairs.

IMS Robotics GmbH owns all rights to this Repair Manual as well as to its enclosures/pictures. All details and

information are entrusted to the recipient for personal use only.

Information from this Repair Manual must not be disclosed or handed over to third parties, in particular, to

competitors. Therefore, reproduction of this Repair Manual in any form is not permitted.

Liability

IMS Robotics GmbH assumes no liability for direct damage or consequential damage resulting from improper

repair.

In addition, please use only spare parts supplied by IMS Robotics GmbH. IMS Robotics GmbH also assumes no

liability for the use of other products and any resulting damage.

IMS Robotics GmbH reserves the right to make changes to this Repair Manual at any time and without notice in

the event of any technical or typing errors contained in it.

Technical data

Area of application: DN75 - DN150 - with DN250 extension

Power supply: 100 - 240 VAC, 50/60 Hz, max. 1.6 A

Supply air: Free of dirt (particles < 5 micrometres)

Temperature range: +5 °C to max. +40 °C

(41 °F to max. 104 °F)

Residual water separated

Residual oil < 5 mg/m3

Supply pressure max. 10 bar (145 PSI)

min. Flow rate: 1 m3/min (35 CFM)

Water supply: distilled water

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

3 of 113

Important information on repair

Before starting to repair the MICRO S light plus cutter motor, please read this repair information in detail.

Cables and quick-release couplings as well as standard screws have to be glued with Loctite (274, 574, 577) at

the required points. The use of the appropriate Loctite can be found in the Repair Manual or as an overview in

the corresponding exploded drawings of the respective component sections.

1. Replace cable/quick-release couplings

when they are loosened.

2. Deburr the cable/quick-release couplings

before assembly.

3. Remove LOCTITE completely from

internal threads of the housing parts

4. Remove grease/ clean the internal

thread.

Before mounting the lifting and radial air bag, it is necessary to check if all cables and quick-release couplings

are tight and leak-proof.

When removing any components, pay attention to the O-rings which need to be reassembled. When

assembling the cutter motor, always make sure that all the necessary O-rings are installed. To fix the O-rings in

the O-ring groove, Energrease MP-MG 2 is applied to all the O-rings and then used.

When removing housing parts, it is advisable to mark the previously installed position. This helps in finding the

previous installation position when reassembling.

When crimping ferrules, it is important to ensure that the ring of the ferrule sits in the groove provided in the

housing. This groove is located at the end of a series of grooves which should provide better support for the air

bag. You can identify it by the fact that it is deeper and wider than the other grooves.

Groove for crimp ferrule (example for all housings)

deburring

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

4 of 113

Table of Contents

Foreword ............................................................................................................................................................................. 2

Liability................................................................................................................................................................................. 2

Technical data...................................................................................................................................................................... 2

Important information on repair......................................................................................................................................... 3

1. Assembly and testing equipment.................................................................................................................................... 6

2. Replacing the air motor................................................................................................................................................. 11

3. Exchange air motor housing .......................................................................................................................................... 16

4. Removing the lifting air bag........................................................................................................................................... 19

5. Mounting the lifting air bag........................................................................................................................................... 21

6. Removing the front radial air bag................................................................................................................................ 26

7. Mounting the front radial air bag ................................................................................................................................ 29

8. Removing the rear radial air bag ................................................................................................................................. 32

9. Mounting the rear radial air bag ................................................................................................................................. 38

10. Removing the axial movement mechanism............................................................................................................... 47

11. Mounting the axial movement mechanism ............................................................................................................... 50

12. Compress axial hose .................................................................................................................................................... 53

13. Replacing the DN 8 axial hose ..................................................................................................................................... 56

14. Removing the front rotary unit.................................................................................................................................... 61

15. Mounting the front rotary unit.................................................................................................................................... 63

16. Replacing the brush unit in the rotary unit ................................................................................................................. 67

17. Removing the disc grinding ring .................................................................................................................................. 71

18. Mounting the disc grinding ring .................................................................................................................................. 72

19. Motor unit assembly.................................................................................................................................................... 75

20. Soldering the 8-pole cable connector.......................................................................................................................... 81

21. Replacing the spring contact PCB camera................................................................................................................... 83

22. Replacing sapphire glass panes in front cover ............................................................................................................ 87

23. Intermediate inspection/leak detection...................................................................................................................... 90

23.1 Change lifting bladder ........................................................................................................................................... 90

23.2 Change axial muscle .............................................................................................................................................. 92

23.3 Change radial bubble............................................................................................................................................. 93

24. Final inspection/testing of all functions ...................................................................................................................... 96

24.1 Check nitrogen system for leaks............................................................................................................................ 96

24.2 Error events and their causes................................................................................................................................ 97

24.3 Check the compressed air system for leaks .......................................................................................................... 99

25. Check electrical assemblies ....................................................................................................................................... 101

26. Problems, possible causes, test methods and remedies........................................................................................... 103

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

5 of 113

27. Hazard labelling ............................................................................................................................................................. 1

28. Revision history............................................................................................................................................................. 2

29. Technical changes ......................................................................................................................................................... 3

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

6 of 113

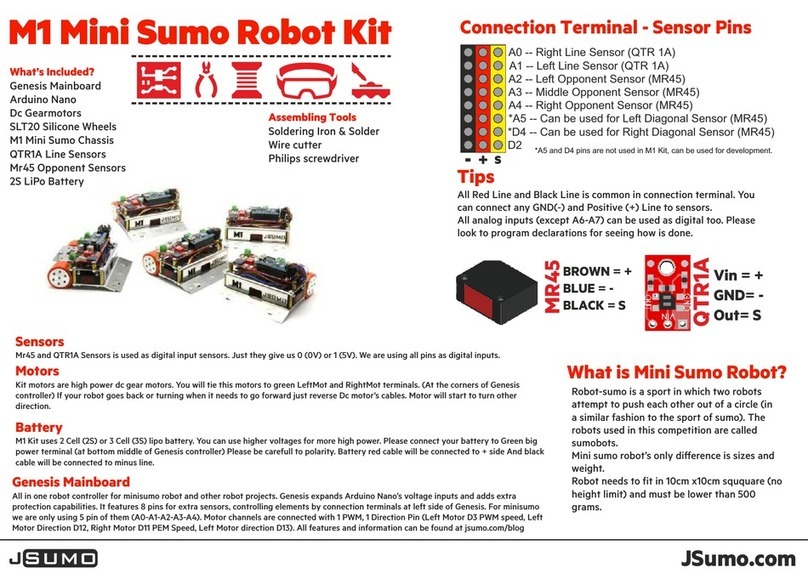

1. Assembly and testing equipment

Hinge bolt clamp

(005 30 010)

Turned socket wrench. (For mounting the cutter

air hose with the distributor)

(005 45 001)

Spring tensioner for axial spring

(005 30 014)

Threaded rods

(005 30 018)

Mounting ring for lifting air bag

(005 30 022)

Tip

For better handling, a handle can be attached to

one of the threaded rods

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

7 of 113

Nitrogen testing connection (individual strands)

(005 45 006)

Motor housing dummy

(005 45 121)

Dowel pins for removing the cutter

(030 01 757)

Wiring tool

(005 45 009)

Mounting aid press sleeve clamping bubble 8pin.

Bayonet

(005 45 013)

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

8 of 113

M3 - Pin

Soldering tool plug

(005 45 011)

Articulated hook wrench with pin

(005 45 052)

Cone for brush ring assembly

(005 45 010)

Test cables

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

9 of 113

Adapter pipe M8x1 G1/8

(005 45 007)

Camera dummy

(005 45 002)

Test kit

(005 45 300)

Compressed air control unit with gauge

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

10 of 113

Assembling tool (rear distributor)

(005 45 008)

Alignment aid cutter plug 8pin

(005 45 040)

Vehicle pliers

(005 45 031)

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

11 of 113

2. Replacing the air motor

Remove the cutter tool using the two dowel

pins

1. Loosen the air motor cover (four cylindrical

screws).

2. Pull the rotor and cylinder out of air motor

housing.

3. Replace the air motor components as required.

1 Cylinder 021 01 027

2 Ball bearing 030 01 070

3 Venting ring 030 01 032

4 Rotor with air motor ring 006 30 002

5 Shim 030 01 074

6 Ball bearing 030 01 071

7 Circlip 030 01 272

8 Set of vanes 021 01 053

3

4

8

7

6

5

1

2

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

12 of 113

1. Clamp the rotor in a vice or something similar

2. Using a plastic hammer, remove the rotor out

of the large ball bearing.

3. Replace the ball bearing and/or venting ring if

necessary.

1. Remove the circlip (on the side opposite to the

rotor)

2. Remove the rotor using a mandrel/pin punch

(identical to the large ball bearing)

1. Mount the shim and small ball bearing onto

the rotor.

Caution

Pay attention to the shim beneath the

small ball bearing!

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

13 of 113

2. Mount the ball bearings onto the rotor as fas

as it goes by hitting it lightly (with plastic

hammer).

3. Mount the circlip in the rotor groove.

1. Mount the venting ring on the rotor

(air motor ring).

2. Mount the ball bearing on the rotor and lightly

tap using the plastic hammer.

1. Insert the cylinder into the air motor housing;

check if the cylinder moves freely in the axial

and radial direction; remove any unevenness

using fine sandpaper.

2. Insert new vanes into the rotor; insert the

vanes with the radius in the direction of the

rotor.

Caution

Cutter collar on one side of the venting

ring has to point towards the large ball

bearing!

Caution

It is important to ensure that the ball

bearings are mounted properly! Do not

tilt them!

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

14 of 113

1. Insert the cutter motor onto the cylinder and

guide it into air motor housing

2. Slide the cylinder with cutter motor in; the

notch on the cylinder has to be aligned with

the upper right threaded hole on the air motor

housing (notch shows the installation position

of the cylinder pin inside the air motor

housing)

Tip

Slide the cylinder and cutter motor into

air motor housing simultaneously! Hold

the cutter motor at the rotor thread,

keep it centered and insert it along with

the cylinder. The end position is reached

when the rear ball bearing sits in the air

motor housing!

Caution

Do not use any tools for inserting. It

should be possible to insert/position the

cylinder by hand!

When inserting, make sure that the

notch on the cylinder points towards the

rotor thread!

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

15 of 113

1. Replace the air motor cover

2. Screw the cover back on;

(M3x8 Cylinder screws)

3. Mount the cutter head back.

Caution

Do not tighten the screws excessively.

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

16 of 113

3. Exchange air motor housing

or

Changing the cylindrical pin for air motor

Remove the lifting air bag according to

instructions

"Removing the lifting air bag"

1. Desolder the wires from the spring

contact PCB

2. Loosening the cylinder screws

M 4x16.

3. Pulling off the air motor housing from

the cap and the sheet metal.

Installation of a new air motor housing

the following are necessary:

•Air motor housing (030 37 003)

•Stainless steel cylindrical pin 2.5x10 mm

•Stainless steel grub screw M3x5 mm

A cylindrical pin must be fitted into the air motor

housing which engages in the air motor cylinder

to hold it in position when the air motor is

installed.

(Pictures once with and once without cylindrical

pin.)

Tip

Use a suitable wire hook to get under the

individual wires and pull them carefully

upwards while desoldering.

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

17 of 113

1. Thoroughly degrease the threaded holes

in the air motor housing.

2. Insert the cylindrical pin with Loctite 574

"orange" into the hole provided and

knock it into the housing with a punch so

far..

until it protrudes approx. 2 mm in the

interior.

These parts are required when installing the

cylindrical pin in the air motor housing.

1. Cylinder (021 01 027)

2. Cover (030 01 004)

In order to achieve a better camera image, the

cover is now only installed in black under the

same item number.

3. Insert air motor cylinder into air motor

housing.

4. Screw on the air motor cover

(by fastening the cover, the guide pin is

pressed into correct position; the guide

pin should then protrude ≈ 2 mm in the

air motor housing).

5. Screw in grub screw M3x4

with LOCTITE 574 "orange".

Pin must not protrude.

Tip

Install the cylinder and cover so as to create

counterpressure when screwing in the grub screw

so that the cylindrical pin does not slip. Then check

the 2mm pin protrusion.

1

2

Bore for cylindrical pin

Tip

If it is difficult to move, ream either the pin or the

bore (Ø 2.5 H7)

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

18 of 113

Gluing in the spring contact board according to

instructions

"Replacing the spring contact PCB camera"

Change the cylindrical pin and reuse the used

air motor housing.

1. Remove the M3x5 mm grub screw.

2. Remove the old cylindrical pin from the

housing with a punch.

3. Re-cut the thread with an M3 tap to

remove any adhesive residue.

4. Insert a new cylindrical pin and continue

as described above.

Assembly of the air motor housing –see

instructions

"Mounting the front rotary unit"

Assembly of lifting bubble –see instructions

"Mounting the lifting air bag"

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

19 of 113

4. Removing the lifting air bag

1. Remove the air motor, camera and camera

ring.

2. Remove the fitting (045 01 032)

(2 M3x6 cylinder crews).

1. Carefully cut open both the crimp ferrules

on the lifting unit using DREMEL.

Removal

Caution

Do not cut into the rubber if you are

reusing the lifting air bag.

MICRO S automatic Cutter motor

Number:

RH-11.014 A

Scope:

IMS Robotics

Document Management

Date:

08 July 2022

Author:

00145

Checked:

Page:

20 of 113

2. Use a screwdriver to break open/pry open

the crimp ferrules.

1. Carefully remove the lifting air bag from the

front.

Tip

Cover the spring contact PCB of the camera

with adhesive tape to protect it from dust

and damage.

Caution

When removing the lifting air bag, the

adhesive tape used for protecting the

spring contact PCB has to be removed

again. Be very careful so as not to damage

it!

Table of contents

Other IMS ROBOTICS Robotics manuals