IMS ROBOTICS DRIVE plus Operating instructions

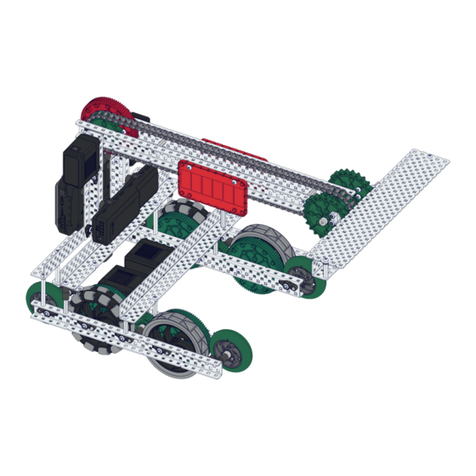

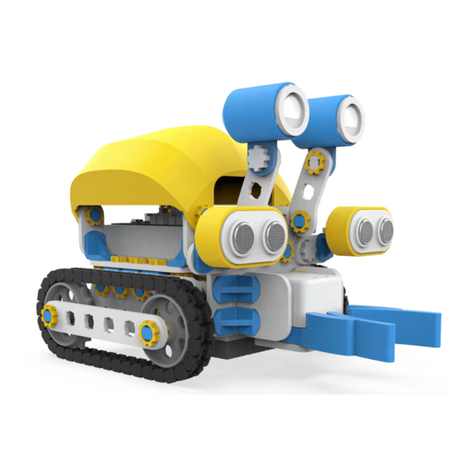

DRIVE plus carriage and cutter drive

Number:

RH-11.010.A

Scope:

IMS Robotics

Document managment

Date:

28.03.2022

Created:

00145

Checked:

00047

Page:

1 of 8

DRIVE plus

carriage und cutter drive

Repair manual

DRIVE plus carriage and cutter drive

Number:

RH-11.010.A

Scope:

IMS Robotics

Document managment

Date:

28.03.2022

Created:

00145

Checked:

00047

Page:

2 of 8

Foreword

This Repair Manual provides the technical description of our cutter motors and important

information to have them independently repaired by professionals.

We recommend reading the Repair Manual thoroughly before carrying out the respective

repairs.

IMS Robotics GmbH owns all rights to this Repair Manual as well as to its enclosures/pictures.

All details and information are entrusted to the recipient for personal use only.

Information from this Repair Manual must not be disclosed or handed over to third parties, in

particular, to competitors. Therefore, reproduction of this Repair Manual in any form is not

permitted.

Liability

IMS Robotics GmbH assumes no liability for direct damage or consequential damage resulting

from improper repair.

In addition, please use only spare parts supplied by IMS Robotics GmbH. IMS Robotics GmbH

also assumes no liability for the use of other products and any resulting damage.

IMS Robotics GmbH reserves the right to make changes to this Repair Manual at any time and

without notice in the event of any technical or typing errors contained in it.

DRIVE plus carriage and cutter drive

Number:

RH-11.010.A

Scope:

IMS Robotics

Document managment

Date:

28.03.2022

Created:

00145

Checked:

00047

Page:

3 of 8

Table of contents

Preface ....................................................................................Fehler! Textmarke nicht definiert.

Liability ...............................................................................................Fehler! Textmarke nicht definiert.

1. Removal and assembly instructions.................................................................................................... 3

2. Dismanteling of the carriage ............................................................................................................... 4

3. Assembly of the carriage..................................................................................................................... 7

4. Resources ............................................................................................................................................ 8

1. Removal and assembly instructions

•When dismantling the carriage to replace the drive shaft (034 11 312), the cutter arm can

and should remain mounted on the carriage. The cutter arm serves as a "lever" when pulling

the cover off the housing. Great care must be taken to ensure that the sealing surfaces and

above all, the O-ring are not damaged.

➢If the O-ring is damaged, the cutter arm must be detached from the carriage and all

cable connections disconnected. This is the only way to mount a new O-ring.

•Remove the housing cover (011 35 310) a maximum of 100 mm from the housing (011 42

623), otherwise the cabling can be damaged.

•When dismantling and assembling, always make sure that no cables or hoses are pinched or

damaged.

➢When reassembling everything must be fastened back in the same way as it was

before dismantling. (Photo documentation of the condition before dismantling)

•Check sealing surfaces and O-rings for intactness before assembly.

•When assembling, clean all sealing surfaces and bearings with brake cleaner or white spiritus

and grease again if necessary.

•Re-grease all moving parts.

•Secure all screw connections with Loctite 274 blue.

DRIVE plus carriage and cutter drive

Number:

RH-11.010.A

Scope:

IMS Robotics

Document managment

Date:

28.03.2022

Created:

00145

Checked:

00047

Page:

4 of 8

2. Disassembly of the carriage

1. Dismantling the pressure bar

2. Dismantling of the cutting air hoses and

the associated swivel screw

connections

3. Disassembly of the housing cover

4. Removing the cover 1

Attention

The cover is produced in 3D printing

and is very fragile

DRIVE plus carriage and cutter drive

Number:

RH-11.010.A

Scope:

IMS Robotics

Document managment

Date:

28.03.2022

Created:

00145

Checked:

00047

Page:

5 of 8

5. Loosen the fastening screws on the

housing cover (6 pieces in total)

Before removing the cover from the

housing, the ring nut must be brought into

the appropriate position by turning the

cutting arm.

blob:file:///cdd06f6b-ef26-4a8a-a5a5-

38d740b815e6

Attention

The screws are secured with Loctite 274

blue during manufacture and can be

heated with a heat gun for better

dismantling

Attention

When separating the cover from the

housing, observe the assembly instructions.

Should it be necessary to use a lever tool

between the cover and the housing, only

lever it at the points where the O-ring

cannot be damaged.

wrong

right

DRIVE plus carriage and cutter drive

Number:

RH-11.010.A

Scope:

IMS Robotics

Document managment

Date:

28.03.2022

Created:

00145

Checked:

00047

Page:

6 of 8

In the sectional drawing you can see the position of the shaft (1) with the associated

Gears (2, 3) and the two ball bearings (4, 5).

A = Cover (011 35 310)

B = Housing (011 42 623) (Unfortunately no longer available in the 3D image)

Shaft via the gear on

fix the bearing flange

6. Loosen both fitting screws on the left

and right of the housing to loosen the

bearing flange

A 4 2 1 3 5 B

Tipp

When the two parts (housing and cover) are separated, the axle (1) is pulled out of the

bearing (4). The bearing remains in the cover, the axle (1) and the gear (2) are separated

from the cover and remain in the housing.

In order to protect the gear (3) and the bearing (5) from damage during this operation,

the shaft should be held towards the housing.

Bearing flange

DRIVE plus carriage and cutter drive

Number:

RH-11.010.A

Scope:

IMS Robotics

Document managment

Date:

28.03.2022

Created:

00145

Checked:

00047

Page:

7 of 8

7. Set the bearing flange at a slight angle

8. Pull the axle together with the ball

bearing out of the flange

3. Assembley of the carriage

New SBG drive shaft to be installed 1

(034 11 312)

completely laser-welded with pinion

•Check the drive shaft and correct any irregularities.

Attention! Pinions must be free of machining residues and impacts

•Assemble the drive shaft and the carriage in reverse order to disassembly

•Observe the assembly instructions from Section 1

Hint

If the ball bearing is not damaged, it can

be used again. If it is new - deep groove

ball bearings (030 01 071)

DRIVE plus carriage and cutter drive

Number:

RH-11.010.A

Scope:

IMS Robotics

Document managment

Date:

28.03.2022

Created:

00145

Checked:

00047

Page:

8 of 8

4. Resources

Loctite 274 (blue)

For securing screw connections

Petrol or brake cleaner

for degreasing and cleaning all metallic

parts

Table of contents

Other IMS ROBOTICS Robotics manuals