IMT Analytics FlowAnalyser Series User manual

User Manual

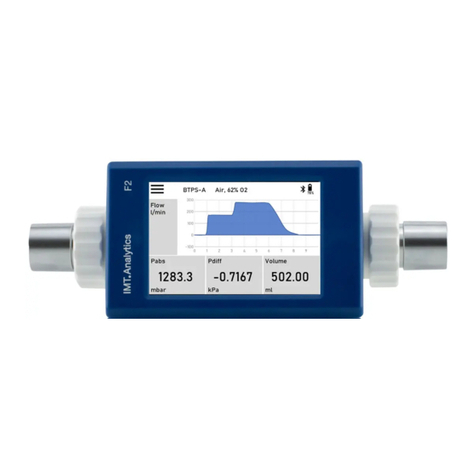

FlowAnalyser

Table of contents

1 Introduction 5

2 Intended use 6

3 Safety instructions 7

3.1 Representation of hazards, cautions and notes 7

3.2 Personnel 7

3.3 Responsibility and guarantee 7

3.4 Service life 7

4 Specifications 8

4.1 Measurement parameters 8

4.2 Gas standards for flow and volume measurement 11

4.3 Power supply 12

4.4 Battery operation 12

4.5 Directives and approvals 13

4.6 Device labels and symbols 13

4.7 PC minimum requirements 13

5 Start-up 14

5.1 Individual parts in the packaging 14

5.2 Power supply 15

5.3 Mechanical connectors 15

5.4 Electrical interfaces 20

6 Operation 23

6.1 Switching the device on/off 23

6.2 The Start screen 23

6.3 Change contrast 23

6.4 User controls terminology 24

6.5 Specification of user controls 24

6.6 Numerical display 25

6.7 Configuration display 27

6.8 Statistics display 28

6.9 Menu display 29

6.10 Data storage 30

6.11 RT-200 emulation mode 32

6.12 Calibrations 34

6.13 Gas type and standard 36

6.14 Set trigger 37

6.15 Filter 40

6.16 Set language 40

6.17 HW activation 41

6.18 Call up system info 41

6.19 Hidden menu options 42

6.20 Factory defaults 42

7 MultiGasAnalyser OR-703 43

7.1 Description 43

7.2 Use 43

7.3 Warning 43

7.4 Principle 44

7.5 Connection 44

7.6 LED signal 45

7.7 OR sensor calibration 46

7.8 Servicing and care 47

7.9 Technical specifications 47

IMT Analytics AG

8 Measuring ventilation ratios 48

8.1 General 48

8.2 Connecting to the ventilator 49

8.3 Standard trigger values 50

8.4 Base flow 50

8.5 Finding the correct trigger values 51

8.6 Special cases 52

9 Servicing and care 54

9.1 Guidelines for servicing and care 54

9.2 Notes about changing parts 54

9.3 Preventive cleaning and servicing routines 54

9.4 Contact 57

10 Accessories and spare parts 58

10.1 Ordering address 58

10.2 Device variants 58

10.3 Options 58

11 Disposal 59

11.1 Disposal 59

12 Appendix 60

12.1 Abbreviations and glossary 60

12.2 Measurement parameters and units 62

Introduction

5

1

IMT Analytics AG

Validity

This documentation is valid for the product with the designation:

• FlowAnalyser PF-300, FlowAnalyser PF-301, FlowAnalyser PF-302

• MultiGasAnalyser OR-703

You will find the name FlowAnalyser on the rating plate on the back of your device.

The FlowAnalyser designation used in this manual applies to the models

FlowAnalyser PF-300, FlowAnalyser PF-301 and FlowAnalyser PF-302.

Software and firmware version

This documentation applies to the following versions:

FlowAnalyser firmware – version 4.3.3

In the case of older or newer versions there may be minor discrepancies in relation

to this User Manual.

Designations used in this User Manual

Buttons and indicators on the display

Buttons such as Power and indicators on the display such as Change Settings are

printed in boldface italics.

References to pages and sections

For references to pages and references, e.g. (4.1.6 Physical data), the symbol

(XY) is used.

Version information

Issue date of this User Manual: Release 02, 2019-03

Subject to technical modifications without notice.

1 Introduction

Intended use

6

2

2

IMT Analytics AG

This product is intended for testing and calibration purposes on medical devices

orsystems thatgenerate gas flows or gas pressures. That includes ventilators and

anaesthetic machines. The user of the device has received training on how to use

medical equipment and can perform repairs, maintenance and servicing on medical

devices. The device can be used in hospitals, in clinics, at device manufacturers or at

independent service companies that perform repairs or servicing on medical devices.

FlowAnalyser is intended for use in a laboratory environment. It may only be used

outside the nursing sector. It must not be used directly on patients or devices that

are connected to patients. The measuring instrument FlowAnalyser is intended for

over-the-counter sale.

FlowAnalyser is the solution for measurements in the following areas:

• Flow Low (-20 – 20 L/min)

• Flow High (-300 – 300 L/min)

• Volume

• Differential pressure

• High pressure

• Ambient pressure

• Oxygen

• Temperature

• Air humidity

• Dew point temperature

In addition, variousventilation parameters can be measured:

• Inspiratory volume, expiratory volume

• Ventilation rate

• I:E

• Inspiratory time, expiratory time

• Ppeak

• Pmean

• Pplateau

• PEEP

• PF Insp (inspiratory peak flow)

• PF Exp (expiratory peak flow)

• Ti/TCycle

• Cstat

• Delta P

FlowAnalyser is a measuring instrument for checking and calibrating

ventilators and anaesthetic machines. It must not be used for patient

monitoring. During patient treatment by the ventilator it is not allowed

to connect to FlowAnalyser.

2 Intended use

7

Safety instructions

3

IMT Analytics AG

This User Manual uses the representation below to specifically draw attention to

residual risksduring intended use andemphasise important technical requirements.

Information and/or instructions and prohibitions to prevent damage of

any kind.

Work on and with FlowAnalysermay only be performed by persons

whohave undergone appropriate technical training andhave the

necessary experience.

Themanufacturer accepts no responsibilityor guarantee and willexempt itself fromli-

ability claims accordinglyif theoperatoror any third parties:

• fail to use the device in accordance with its intended use

• disregard the specifications

• tamper with the device in any way (conversions, modifications, etc.)

• operate the device with accessories that are not listed in theassociatedsets

of product documentation.

Although the devicemeets high quality and safety standards andit

has beenconstructed and tested according to the current state

of the art,it is not possible to rule outthe risk of injuries withseri-

ousconsequencesif the device is usedinnon-compliance with the

intended use (improperly) or is misused.

Therefore please read through this User Manual carefully and keep

this documentation in a readily accessible place close to your device.

Themaximum service life of the devicehas been specified as 10(ten)years,provided

it is handled properly in accordance with this User Manual.

3.1 Representation of hazards,

cautions and notes

3 Safety instructions

3.2 Personnel

3.3 Responsibility and guarantee

3.4 Service life

Specifications

8

4

IMT Analytics AG

4.1.1 Measuring instrument values1

Flow Low Range

Accuracy

-20 – 20 nL/min

± 1.75% of reading or ± 0.04 nL/min

Flow High Range

Accuracy

-300 – 300 nL/min

± 1.75% of reading or ± 0.1 nL/min

Volume Range

Accuracy

-100 – 100 nL

± 2% of reading ± 0.02 nL (Flow

High) or ± 0.01 nL (Flow Low)

Pressure (at high flow) Range

Accuracy

0 – 150 mbar

± 0.75% of reading or ± 0.1 mbar

Differential pressure Range

Accuracy

-150 – 150 mbar

± 0.75% of reading or ± 0.1 mbar

High pressure Range

Accuracy

0 – 10 bar

± 1% of reading or ± 10 mbar

Ambient pressure Range

Accuracy

0 – 1150 mbar

± 1% of reading or ± 5 mbar

Oxygen Range

Accuracy

0 – 100 vol%

± 1 vol%

Humidity Range

Accuracy

0 – 100% RH (non-condensing)

± 3% RH

Temperature Range

Accuracy

0 – 50°C

± 1.75% of reading or ± 0.5°C

Dew point temperature Range

Accuracy

-10 – 50°C

± 2% of reading or ± 1°C

Additional pressure sensors For details please refer to the sections 5.3.6 Low pres-

sure (PF-302 LOW) and 5.3.7 Pressure sensor ±1bar

(PF-301 VAC).

1

Standard litres per minute (converted to STP conditions of 21.1°C and 1013 mbar)

4 Specifications

4.1 Measurement parameters

Specifications

9

4

IMT Analytics AG

4.1.2 Ventilation parameters

Vti, Vte Tidal volume of inspiration

and expiration

Range

Accuracy

± 10 nL

Flow High: ± 1.75% or

0.20 mL (>6.0 nL/min)

Flow Low: ± 1.75% or

0.10 mL (>2.4 nL/min)

Vi, Ve Minute volume of

inspiration and expiration

Range

Accuracy

± 300 nL/min.

± 2.5% or 0.02 nL (Flow High)

0.01 nL (Flow Low)

Ti, Te Inspiratory and

expiratory time

Range

Accuracy

0.05 – 60 s

± 0.02 s

Ti/Ttotal Ratio of inspiratory time to

time of a respiratory cycle

Range

Accuracy

0 – 100%

± 5%

Ppeak Maximum pressure Range

Accuracy

0 – 150 mbar

± 0.75% or ± 0.1 mbar

Pmean Mean pressure Range

Accuracy

0 – 150 mbar

± 0.75% or ± 0.1 mbar

I:E Inspiratory/expiratory ratio Range

Accuracy

1:300 – 300:1

± 2.5%

PEEP Positive end-expiratory

pressure

Range

Accuracy

0 – 150 mbar

± 0.75% or ± 0.1 mbar

Rate Ventilation rate Range

Accuracy

1 – 1000 bpm

± 2.5% or ± 1 bpm

PF Insp. Peak flow during

inspiration

Range

Accuracy

± 300 nL/min

± 1.75% or ± 0.1 nL/min

PF Exp. Peak flow during

expiration

Range

Accuracy

± 300 nL/min

± 1.75% or ± 0.1 nL/min

Cstat Static compliance Range

Accuracy

0 – 1000 mL/mbar

± 3% or ± 1 mL/mbar

Pplateau Plateau pressure Range

Accuracy

0 – 150 mbar

± 0.75% or ± 0.1 mbar

Delta P Pressure amplitude

(Ppeak – PEEP)

Range

Accuracy

0 – 150 mbar

± 0.75% or ± 0.1 mbar

Specifications

10

4

IMT Analytics AG

4.1.3 Principle of flow measurement

Flow in the flow channel is determinedbydifferential pressure measurement. To build

up differential pressure a plastic screen is used to provide flow resistance.

ƞ: dynamic viscosity of the gas [Pa s]

ρ: gas density [kg/m3]

c1, c2: device-specific constants (channel geometry)

Dynamic viscosity

Theviscosity of a medium is its resistance tothe flow and shear

of the current. Viscosity is extremely dependent on temperature. Theviscosity of a

medium isslightly dependent on the pressure andmoisture content of the medium.

Density

Density is the unit for the mass per unit volume of the medium. Density is very de-

pendent on pressure and temperature.

The impact of ambient conditions is hence the reason why flow is occasionally con-

verted to standard conditions.

(4.2 Gas standards for flow and volume measurement)

4.1.4 Special functions

Automatic battery operation in the event of a power failure

4.1.5 Communication interfaces

USB, RS-232 port for firmware download, remote control functions and connection

to MultiGasAnalyser OR-703 (optional), trigger input (digital) for external trigger

4.1.6 Physical data

Weight: 3.7 kg

Size (l × w × h): 22 × 25 × 12 cm

Gas types: Air, O2, N2O, He, N2, CO2and

mixtures: Air/O2, N2O/O2, He/O2

4.1.7 Calibration by user

Offset calibration of the pressure sensors, calibration of the oxygen sensor.

Specifications

11

4

IMT Analytics AG

4.1.8 Operating data

Temperature: 15 – 40°C (59 – 104°F)

Air humidity: 10% – 90% RH

Atmospheric pressure: 700 – 1060 mbar

Storage and transport conditions: -10 – 60°C (14 – 140°F) at 5 – 95% RH

4.1.9 Extensions

• FlowLab software

• MultiGasAnalyser OR-703

FlowAnalyser converts the flow and volume readings measured in the device to

match the conditions of the standard selected. The following gas standards are sup-

ported by FlowAnalyser:

Gas standard Temperature Pressure Relative

humidity

Ambient Temperature and

Pressure

ATP Current gas

temperature

Current

Ambient pressure

Current

gas humidity

Ambient Temperature and

Pressure Dry

ATPD Current gas

temperature

Current

Ambient pressure

0%

Ambient Temperature and

Pressure Saturated

ATPS Current gas

temperature

Current

Ambient pressure

100%

Ambient Pressure at 21°C AP21 21.0°C (70°F) Current

Ambient pressure

Current

gas humidity

Standard Conditions USA STP 21.1°C (70°F) 1013.25 mbar

(760 mmHg)

0%

Standard Conditions USA

Humid

STPH 21.1°C (70°F) 1013.25 mbar

(760 mmHg)

Current

gas humidity

Body Temperature and

Pressure Saturated

BTPS 37°C (99°F) Current ambient

pressure and chan-

nel pressure (HF)2

100%

Body Temperature and

(Ambient) Pressure Sat-

urated according to ISO

80601-2-12:2011

BTPS-A 37°C (99°F) Current

ambient pressure

100%

Body Temperature and

Pressure Dry

BTPD 37°C (99°F) Current ambient

pressure and chan-

nel pressure (HF)2

0%

Body Temperature and

(Ambient) Pressure Dry

BTPD-A 37°C (99°F) Current

ambient pressure

0%

Standard condition ac-

cording to DIN 1343

0/1013 0°C (32°F) 1013.25 mbar

(760 mmHg)

0%

Standard condition

according to ISO 1-1975

(DIN 102)

20/981 20°C (68°F) 981 mbar

(736 mmHg)

0%

2In order to measure BTPS / BTPD at channel pressure in the high flow channel, the rear end of the low

flow channel has to be connected to the high flow channel. See section (5.3.3 Flow Low 1F)

4.2 Gas standards for flow and

volume measurement

Specifications

12

4

IMT Analytics AG

Gas standard Temperature Pressure Relative

humidity

API Standard Conditions 15/1013 15°C (60°F) 1013.25 mbar

(14.7 psia)

0%

Cummings Standard 25/991 25°C (77°F) 991 mbar

(500 ft altitude)

0%

20°C/1013 mbar 20/1013 20°C (68°F) 1013.25 mbar

(760 mmHg)

0%

Normal Temperature and

Pressure

NTPD 20.0°C (68°F) 1013.25 mbar

(760mmHg)

0%

Normal Temperature and

Pressure, Saturated

NTPS 20.0°C (68°F) 1013.25 mbar

(760mmHg)

100%

In this User manual the unit sL/min is based on ambient conditions of

0°C and 1013 mbar (DIN 1343).

Please refer to Appendix B: Measurement parameters and units.

There you will also find the conversion factors for the units of meas-

urement

Input voltage of the power supply unit: 100 – 240 VAC, 50 – 60 Hz

Supply voltage: 15 V DC

Power input: 25 V A

Operating time in battery operation: 3 hours

Operating time in battery operation

with MultiGasAnalyser 2 hours

Charging the battery

A complete charging process takes 8 h. The service life of the battery is extended if

the battery is charged completely only after a prompt by the device.

Thedevice indicates visually and audiblywhen the battery has to be

charged. Please do not store the battery in the depleted state. Cau-

tion:depletion can damage the battery beyond repair!

4.3 Power supply

4.4 Battery operation

Specifications

13

4

IMT Analytics AG

• IEC 1010-1 (Safety)

• EN 61326-1 (EMC)

• CAN/CSA-C22.2 No. 0-M91 (General)

• CAN/CSA-C22.2 No. 1010.1-92 (Safety)

• CAN/CSA-C22.2 No. 1010.1 B-97 (Safety)

• UL Std. No. 61010B-1. 1st Ed. (General)

The device falls under Installation Category II.

The device is classified as Pollution Degree 2.

Thedevice is notintended for useoutside a building.

The following labels and symbols can be found on FlowAnalyser:

RS232 interface (for service)

USB port (for PC communication)

SN XXXX Serial number

Caution: observe the safety instructions in the User Manual

Production date Month – Year

Earthing

Intel® Pentium® 4 2.4 GHz

(Intel® Core TM2 Duo recommended)

Microsoft® Windows® XP, Vista, 7, 8 (32 bit / 64 bit)

Microsoft® .NET Framework 3.5 or higher

128 MB RAM (512 MB recommended)

160 MB storage space on hard disk (full installation)

CD-ROM drive

Monitor 800 × 600 (1024 × 768 recommended)

4.5 Directives and approvals

4.6 Device labels and symbols

4.7 PC minimum requirements

Start-up

14

5

IMT Analytics AG

FlowAnalyser

Power supply

USB cable

Calibration certificate

Filter

Adapter set

5.1 Individual parts in the

packaging

5 Start-up

Start-up

15

5

IMT Analytics AG

The power supply socket is located at the back of FlowAnalyser. The master switch

is used to switch the device on and off. The LED, labelled Charging, is lit when the

battery is being charged. This also takes place if the device is switched off.

5.2.1 Supply voltage

The mains voltage of the power supply unit included is 100 – 240 VAC at 50 – 60 Hz.

Before switching on, make sure the operating voltage of the power

supply unit agrees with the local mains voltage.

You will find this information on the rating plate on the back of the

power supply unit.

Only operate FlowAnalyser with the original power supply unit included!

To protect the device against interference from electromagnetic fields

and static it is necessary to earth the device using the corresponding

earthing stud.

5.3.1 Filter

To protect the device against soiling due to contaminants and particles in the air the

filter included must be used for every measurement of flow (Flow High and Flow Low).

Particles of dirt in the air can clog the measuring system and thus

lead to incorrect measurements. The filter must be checked regularly

(9.3 Preventive cleaning and servicing routines).

5.2 Power supply

5.3 Mechanical connectors

Start-up

16

5

IMT Analytics AG

5.3.2 Adapter set

The adapters enclosed help to connect the test specimen to

FlowAnalyser. Minimising dead volume and differences in the diameter of the flow

stream helps to increase the accuracy of measurement. When using the LowFlow

channel, the positive connector of the differential pressure sensor is used for pressure

measurements. With the tee enclosed and the connecting tube the relevant ports can

be connected to one another.

5.3.3 Flow Low

3

The Flow Low connector is used for measuring small flows. For calculating the venti-

lation parameters in this measurement channel the trigger must be set to "Pediatric"

(8.3 Standard trigger values). The positive connector of the differential pressure

sensor will then be automatically used for pressure measurements. To connect the

two ports the tee can be used with the connecting tube from the adapter set.

Flow Low

Measuring range: -20 – 20 nL/min

Accuracy: ± 1.75% of reading or ± 0.05nL/min

The measurement channel of Flow Low does not have any additional

sensors for temperature, air humidity or oxygen concentration. For

flow calculation the current readings are transferred from the

Flow High channel. For accurate measurements it therefore makes

sense to connect the Flow Low channel to the Flow High channel

using a tube. As a result the missing values can be measured.

For flows above 20 nL/min measurement in the low flow channel is

not accurate enough.

3 Standard litres per minute (converted to STP conditions of 21.1°C and 1013 mbar)

Start-up

17

5

IMT Analytics AG

5.3.4 Flow High4

The Flow High connector can be used for the following measurements:

• Large flows (-300 – 300nL/min)

• Volume

• Temperature

• Humidity

• Oxygen

• Pressure in the channel

Measurements can be conducted bidirectionally.

Flow High

Flow High Measuring range

Accuracy

-300 – 300 nL/min

± 1.75% of reading or ± 0.1 nL/min

Volume Measuring range

Accuracy

0 – 10 nL

± 2% of reading or ± 0.02 nL

Temperature Measuring range

Accuracy

0 – 50°C

± 1.75% of reading or ± 0.5°C

Humidity Measuring range

Accuracy

0 – 100% (non-condensing)

± 3% RH

Oxygen Measuring range

Accuracy

0 – 100%

± 1% O2

Pressure in the

channel

Measuring range

Accuracy

0 – 150 mbar

± 0.75% of reading or ± 0.1 mbar

If work is being performed at a relatively high level of air humidity,

care must be taken to ensure that no condensation forms in the

device. Water can damage the sensors beyond repair!

4Standard litres per minute (converted to STP conditions of 21.1°C and 1013 mbar)

Start-up

18

5

IMT Analytics AG

5.3.5 Differential pressure

The Differential pressure connectors can be used for differential pressure measure-

ments.

Differential pressure

Measuring range: -150 –150 mbar

Accuracy: ± 0.75% of reading or ± 0.1 mbar

5.3.6 Low pressure (PF-302 LOW)

For PF-302 LOW there is an additional sensor that is connected to the designated

port. The connecting nipple is marked with a blue ring.

Low pressure

Measuring range: 0 – 5 mbar

Accuracy: ± 1% of reading or ± 0.01 mbar

With the low-pressure variant a port of the differential pressure sen-

sor (± 150 mbar) is connected to the remaining connector and the

second one is connected to the environment. The measuring range

remains the same.

Start-up

19

5

IMT Analytics AG

5.3.7 ±1 bar pressure sensor (PF-301 VAC)

With FlowAnalyser PF-301 VAC there is an additional ± 1 bar sensor that is connect-

ed to the designated port. The connecting nipple is marked with a yellow ring.

±1 bar pressure sensor

Measuring range: -1000 – 1000 mbar

Accuracy: ± 0.5% of reading or 2 mbar

With the ± 1 bar pressure sensor variant a port of the differential

pressure sensor (± 150 mbar) is connected to the remaining con-

nector and the second one is connected to the environment. The

measuring range remains the same.

Start-up

20

5

IMT Analytics AG

5.3.8 High pressure

The high-pressure port can be used for measuring pressures above 150 mbar. If a

DISS-O2connector is required for the port, an appropriate adapter can be ordered.

High pressure

Measuring range: 0 – 10 bar

Accuracy: ± 1% of reading or 10 mbar

With measurements up to 150 mbar it is recommended that the

differential pressure connector be used because there the accuracy is

up to 100 times higher. Pressures above 15 bar damage the sensor

beyond repair!

5.4.1 USB

The USB port is used for connecting FlowAnalyser to the PC. The port is located at

the back of the device.

If the device was ordered together with the FlowLab software, the measured values

can be displayed graphically on the computer. On devices without software the USB

port is disabled. It can be enabled with an activation code at any time.

USB

5.4 Electrical interfaces

This manual suits for next models

4

Table of contents

Other IMT Analytics Measuring Instrument manuals