IMT Analytics FlowMeter F1 User manual

User Manual

FlowMeter F1, F2

Table of contents

1 Introduction 5

2 Intended use 6

3 Safety instructions 7

3.1 Representation of hazards, cautions and notes 7

3.2 Personnel 7

3.3 Responsibility and guarantee 7

3.4 Service life 8

4 Specifications 9

4.1 Measurement parameters 9

4.2 Principle of flow measurement 10

4.3 Special functions 10

4.4 Communication interfaces 10

4.5 Physical data 10

4.6 Calibration by user 11

4.7 Operating data 11

4.8 Gas standards for flow and volume measurement 12

4.9 Power supply 12

4.10 Battery operation 13

4.11 Directives and approvals 13

4.12 Device labels and symbols 14

4.13 Feature Set 15

5 Start-up 16

5.1 Individual parts in the packaging 16

5.2 Power supply 17

5.3 Mechanical connectors 17

5.4 Electrical interfaces 20

6 Operation 22

6.1 Switching the device on and off 22

6.2 Acoustic feedback 22

6.3 User control gestures 22

6.4 Screens 24

6.5 Menu 28

7 Measuring volume 39

7.1 General principle 39

7.2 Finding the correct trigger values 39

8 Servicing and care 40

8.1 Guidelines for servicing and care 40

8.2 Notes about changing parts 40

8.3 Preventive cleaning and servicing routines 40

8.4 Cleaning 41

8.5 Trouble shooting 41

8.6 Contact 43

Introduction

5

1

IMT Analytics AG

Validity

This documentation is valid for the product: FlowMeter F1 and F2

You will find the name FlowMeter on the type label on the back of your device.

Software and firmware version

This documentation applies to the following versions:

FlowMeter firmware – Version 1.0.000

In the case of older or newer versions there may be minor discrepancies in relation to

this User Manual.

Designations used in this User Manual

Buttons such as Power and indicators on the display such as Settings are printed

in boldface italics.

References to pages and sections

For references to pages and references, e.g. (4.5 Physical data), the symbol

(XY) is used.

Version information

Issue date of this User Manual: Release 01, 2023-02

Subject to technical modifications without notice.

1 Introduction

Intended use

6

2

2

IMT Analytics AG

This product is intended for testing and calibration purposes of medical – or other

devices or systems that generate Air / O2/ N2gas flows and / or gas pressures.

The device is intended for users who are trained in the use of measuring devices

and who can carry out tests, repairs, calibrations, maintenance and service work on

medical or other devices. No dedicated training on this specific device is required.

The device can be used in:

• Hospital service departments

• Clinics

• Medical and non-medical devices manufacturing facilities

• Workshop / testing / laboratory facilities of independent service companies

perfroming service and repair for medical and non-medical devices

FlowMeter is intended for use in an indoor test laboratory environment. It may only be

used outside the nursing sector. It must not be used directly on patients or devices

that are connected to patients. The FlowMeter is intended for over-the-counter sale.

FlowMeter is the solution for measurements in the following areas:

• Flow (±300L/min)

• Volume (0 L–500 000L)

• Differential pressure (±250mbar)

• Absolute pressure in the Flow channel (0.5–2bar)

• Temperature in the Flow channel (-10–50°C)

• Humidity in the Flow channel (0–100%RH, non-condensing)

FlowMeter is a measuring instrument for testing and calibrating pur-

pose on medical and non-medical devices or systems. It must not be

used for patient monitoring. FlowMeter must not be used directly on

patients or devices that are connected to patients.

This product is intended to be used at elevations of up to 5000m operation altitude

in buildings.

2 Intended use

7

Safety instructions

3

IMT Analytics AG

This User Manual uses the representation below to specifically draw attention to

residual risks during intended use and emphasize important technical requirements.

Information and/or instructions and prohibitions to prevent damage of

any kind.

Work on and with FlowMeter may only be performed by persons who

have undergone appropriate general technical training and have the

necessary experience.

Themanufacturer accepts no responsibilityor guarantee and willbe exempt fromli-

ability claims accordinglyif theoperatoror any third parties:

• fail to use the device in accordance with its intended use

• disregard the specifications

• tamper with the device in any way (conversions, modifications, etc.)

• operate the device with accessories that are not listed in theassociatedsets

of product documentation

• Report any serious incident that has occurred in relation to the

medical device to the manufacturer (8.6.2 Technical support)

and the authority having jurisdiction in their locale

• The device has user replaceable parts (8.3 Preventive cleaning

and servicing routines)

• Neligence of warning and error messages can lead to damage of

the device

• The device including the measurement channel shall not be ex-

posed to high level of volatile organic compounds (VOC). Doing

so may lead to permanent offset of the humidity sensor.

• Only use original packaging in good condition for transport or

storage

• The device must not be placed in a pressure chamber

• The device is not intended to measure flammable or combustible

gases

• The device is not intended to measure liquids

• The device must not be connected to a telecom network

• The device must only be connect to approved equipment with

CE, CSA, UL or other equivalent safety mark to ensure double

insulation

3.1 Representation of hazards,

cautions and notes

3 Safety instructions

3.2 Personnel

3.3 Responsibility and guarantee

8

Safety instructions

3

IMT Analytics AG

Although the devicemeets high quality and safety standards andhas

beenconstructed and tested according to the current state of the

art,it is not possible to rule outthe risk of injuries withseriousconse-

quencesif the device is not used in compliance with the intended use

(improperly) or is misused. Therefore, please read this User Manual

carefully and keep this documentation in a readily accessible place

close to your device.

The typical service life of the device is specified as 10 (ten) years, provided it

is handled properly in accordance with this User Manual.

3.4 Service life

Specifications

9

4

IMT Analytics AG

Parameter Value

Flow1

(4.13 Feature Set)

Range

Accuracy

±300L/min

FlowMeter F1:

±1.9% or ±0.05L/min

FlowMeter F2:

±1.7% or ±0.05L/min

Volume Range

Accuracy

0L–500 000L

±4% or ±0.01mL

Differential pressure2Range

Accuracy

±250mbar

±0.5% or ±0.15mbar

Absolute pressure in the

Flow channel

Range

Accuracy

0.5–2bar

±10mbar

Temperature3Range

Accuracy

-10–50°C

±1°C

Humidity2Range

Accuracy

0–100%RH*

<20%RH: ±5%RH*

20%–80%RH: ±3%RH*

>80%RH: ±5%RH*

Accuracy valid

• between 10 °C and 30 °C (channel temperature)

• between 950 hPa and 1250 hPa

• zero offset calibration performed after warm-up

• for measurements performed within 4 h after last zero offset calibration at

same ambient conditions

1

Flow accuracy specified is valid under the above mentioned general conditions and for an air flow in

positive flow direction.

• Add 0.05 % of reading per 1°C outside the range of 10 °C to 30 °C (channel temperature)

• Add 0.005 % of reading per 10 hPa above 1250 hPa

• Add 0.01 % of reading per 10 hPa below 950 hPa

• Add 0.05 % of reading per 10 % oxygen concentration above 21 %

• Add 0.2 % of reading for negative flow direction

Flow accuracy stated with gas (channel) temperature and ambient temperature within 10 °C of each

other. Add 0.05 % of reading per 1 °C above 10 °C temperature difference.

2Only available for the model FlowMeter F2

3At flow rate ≥ 50 L/min, screen brightness ≤ 30 %, battery not charging

* Non-condensing

All flow and volume specifications are based on STP gas standard at

21.1 °C and 1013.25 mbar.

For all specifications with absolute and relative tolerances, the greater

value applies (for example: ±1.9% of reading or ±0.05L/min abso-

lute, whichever is greater).

4 Specifications

4.1 Measurement parameters

Specifications

10

4

IMT Analytics AG

Flow in the flow channel is determined by differential pressure measurement. To build

up differencial pressure Δp, a measuring disc is used to provide flow resistance. For

flow rates >50 L/min the differential pressure Δp2 is used. For lower flows, the Flow-

Meter uses Δp1 to improve the accuracy at lower flow rates.

ƞ: dynamic viscosity of the gas [Pa s]

ρ: gas density [kg/m3]

c1, c2: device-specific constants (channel geometry)

Dynamic viscosity

The viscosity of a medium is its resistance to the flow and shear of the current. Vis-

cosity is extremely dependent on temperature. The viscosity of a medium is slightly

dependent on the pressure and moisture content of the medium.

Density

Density is the unit for the mass per unit volume of the medium. Density is very de-

pendent on pressure and temperature.

The impact of ambient conditions is hence the reason why flow is occasionally con-

verted to standard conditions.

(4.8 Gas standards for flow and volume measurement)

Automatic battery operation in the event of a power failure.

• USB-A: for data recording and software updates

• USB-C: no communication, used only for charging

• RJ-10 (serial port) to stream measurement values and set up the device

Weight: 350g

Size (l × w × h): 200×80×60 mm

Gas types: Air, O2, N2and mixtures: Air/O2

4.2 Principle of flow

measurement

4.3 Special functions

4.4 Communication interfaces

4.5 Physical data

Specifications

11

4

IMT Analytics AG

Offset calibration of the pressure and flow sensors (6.5.7 Zero offset calibration).

Degree of protection, against water and dust, according to IEC 60529: IP 20

The two devices FlowMeter F1 and FlowMeter F2 have 3 different modes:

• Battery operated

• Mains supplied / battery charging

• Switched off / storage

Please note the different ambient condition for the different modes. The allowed con-

ditions for the Flow channel and the device enclosure are different.

Battery operated

Environment conditions Allowed range

Temperature (flow channel/enclosure) -10–50°C (14–122°F)

Air humidity (enclosure) 10%–90%RH*

Air humidity (flow channel) 0%–100%RH*

Absolute pressure in flow channel 50kPa–200kPa

Atmospheric pressure 54kPa–120kPa

Mains operated

Environment conditions Allowed range

Temperature (flow channel/enclosure) 5–40°C (41–104°F)

Air humidity (enclosure) 10%–90%RH*

Air humidity (flow channel) 0%–100%RH*

Absolute pressure in flow channel 50kPa–200kPa

Atmospheric pressure 54kPa–120kPa

4.6 Calibration by user

4.7 Operating data

Specifications

12

4

IMT Analytics AG

Switched off / storage

Environment conditions Allowed range

Temperature (flow channel/enclosure) -10–60°C (14–140°F)

Air humidity (flow channel/enclosure) 5 – 95 % RH*

Absolute pressure in flow channel 50kPa–200kPa

Atmospheric pressure 54kPa–110kPa

* Non-condensing

FlowMeter converts the flow and volume readings measured in the device to match

the conditions of the standard selected. The following gas standards are supported

by FlowMeter:

Gas standard Temperature Pressure Relative

humidity

Ambient Temperature and

Pressure

ATP Current gas

temperature

Current

ambient pressure

Current

gas humidity

Channel Temperature and

Pressure

CTP Current gas

temperature

Current

channel pressure

Current

gas humidity

Standard Conditions USA STP 21.1°C (70°F) 1013.25mbar

(760mmHg)

0%

Body Temperature and

(Ambient) Pressure Sat-

urated according to ISO

80601-2-12:2011

BTPS-A 37°C (99°F) Current

ambient pressure

100%

Please refer to 11 Measurement parameters and units. Here, you

will also find the conversion factors for the units of measurement.

Input voltage of the power supply: 100–240VAC (±10%), 50–60Hz, 0.6A

Output voltage of the power supply: 5VDC, 3.0A

FlowMeter input voltage: 5VDC, 2.5A

The original power supply from IMT Analytics must be used for trouble-free and relia-

ble operation. It is power tested and approved according to IEC 62368-1.

4.8 Gas standards for flow and

volume measurement

4.9 Power supply

Specifications

13

4

IMT Analytics AG

Operating time during battery operation: at least 4 hours.

Charging the battery

A complete charging process takes about 4 hours in normal conditions. The service

life of the battery is extended if the battery is not completely discharged. Do not store

the device with a discharged battery. Optimal state of charge for long term storage

is 80%.

The battery is not user replaceable and must not be replaced with a

different type. Doing so may lead to an explosion, burn or fire hazard.

The device indicates visually and audibly when the battery must be

charged. Please do not store the device if the battery is in a depleted

state.

Caution:Complete depletion can damage the battery beyond

repair!

• IEC 61010-1

• IEC 61326-1

• CAN/CSA-C22.2 No. 61010-1-12

• UL 61010-1 3rd Edition

The device is classified as Pollution Degree 2.

The device is classified as Overvoltage Category II.

For the USB connection

V1.1 is used (12Mbit)

For RJ-10 connection

If the device is to be actuated via the RS-232 interface, your dealer will be pleased to

provide you with a detailed protocol.

The device is not intended for use outside a building.

Simplified EU Declaration of Conformity

Hereby, IMT Analytics AG declares that the radio equipment types FlowMeter F1 and

FlowMeter F2 are in compliance with Directive 2014/53/EU.

The full text of the EU declaration of conformity is available at the following internet

address: www.imtanalytics.com

4.10 Battery operation

4.11 Directives and approvals

Specifications

14

4

IMT Analytics AG

The following labels and symbols can be found on FlowMeter, packaging or

accessories:

Symbol Description

Warning notice

Power button

Alternating current

Class II equipment

For indoor use only

Direct current

Power input

USB Port to connect an USB flash drive

Serial interface

Conforms to CE Directives and Regulations

Safety Mark for North America for FlowMeter

Mark for proof of product compliance to North American safety stand-

ards

Manufacturer

Date of Manufacture

The operating instructions should be considered when

operating the device

Serial Number

Waste Electrical and Electronic Equipment

Conformity with Low Voltage Directive 2014/35/EU

Mark for United Kingdom Conformity Assessment

This equipment contains specified radio equipment that has been

certified to the Technical Regulation Conformity Certification under the

Radio Law

UDI Data

Matrix Code

Unique Device Identification

(01) GTIN-No.

(11) Production Date

(21) Serial No.

4.12 Device labels and symbols

Specifications

15

4

IMT Analytics AG

Symbol Description

Catalog number

Keep dry

Protect from sunlight

Temperature for transport and storage

Humidity range for transport and storage

Atmospheric pressure for transport and storage

The two devices FlowMeter F1 and FlowMeter F2 differ from each other in terms of

the available features.

The models can be easily distinguished by the color of the top cover.

FlowMeter F1 FlowMeter F2

Top cover Black Blue

Flow measurement ±300L/min

±1.9% or ±0.05L/min

±300L/min

±1.7% or ±0.05L/min

Volume measurement available available

Absolute pressure in flow channel available available

Differential pressure ports not available available

Temperature measurement available available

Humidity measurement not available available

Bluetooth available in subsequent

software release

available in subsequent

software release

Statistic screen not available available

4.13 Feature Set

Start-up

16

5

IMT Analytics AG

Picture Description

FlowMeter

Power supply

Protection Filter RT019

Calibration certificate

5.1 Individual parts in the

packaging

5 Start-up

Start-up

17

5

IMT Analytics AG

The power supply socket is located at the rear of FlowMeter.

The device can be disconnected from the mains by disconnecting the

power supply. The power supply should therefore be easily accessible.

5.2.1 Supply voltage

The mains voltage of the power supply is 100–240VAC at 50–60Hz.

Before switching on, make sure the operating voltage of the power

supply is compatible with the local mains voltage. You will find this

information on the rating plate on the back of the power supply.

5.3.1 Protection Filter RT019

To protect the device against contaminants and particles in the flow channel, the

Protection Filter RT019, must be used for flow measurements. Connect the

Protection Filter RT019 to the flow channel inlet port before connecting the device

under test.

Particles of dirt in the air can clog the measuring system and thus

lead to incorrect measurements. The Protection Filter RT019 must be

checked regularly (8.3 Preventive cleaning and servicing routines).

5.2 Power supply

5.3 Mechanical connectors

Start-up

18

5

IMT Analytics AG

5.3.2 Flow channel

The flow channel can be used to perform gas flow measurements from -300L/min

to 300L/min. The channel includes pressure, temperature and humidity1sensors.

Flow channelFlow channel

Measuring range: ±300L/min

Accuracy: FlowMeter F1: ±1.9% or ±0.05L/min

FlowMeter F2: ±1.7% or ± 0.05L/min

When working with relatively high humidity, ensure that condensation

does not form in the unit! Water can irreparably damage the sensors!

The device including the measurement channel shall not be exposed

to high level of volatile organic compounds (VOC). Doing so may lead

to permanent offset of the humidity sensor.

1Only available for the model FlowMeter F2

Start-up

19

5

IMT Analytics AG

5.3.3 Differential pressure1

The differential pressure connectors can be used for differential pressure measure-

ments.

Differential pressure ports

+ −

Measuring range: ±250mbar

Accuracy: ±0.5% or ±0.15mbar

1Only available for the model FlowMeter F2

Start-up

20

5

IMT Analytics AG

5.4.1 USB connection for charging

The USB-C port is used to connect the power supply. The port is located at the rear

of the device.

Rating: 5V, 2.5A

The device must only be connect to approved equipment with CE, CSA, UL or other

equivalent safety mark to ensure double insulation.

5.4.2 RS-232

The RS-232 interface is used for remote monitoring or control.

4 3 2 1

Actuation of the RS-232 port takes place via a special RS-232 cable. If the device

shall be actuated via the RS-232 interface, your dealer will be pleased to provide you

with a detailed protocol.

FlowMeter pin assignment (RJ-10 connector):

Pin 1 NC

Pin 2 RxD (Input of FlowMeter)

Pin 3 TxD (Output of FlowMeter)

Pin 4 GND

5.4 Electrical interfaces

This manual suits for next models

1

Table of contents

Other IMT Analytics Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

ATI Technologies

ATI Technologies Scorpion X2 installation instructions

Milwaukee

Milwaukee REDLITHIUM Operator's manual

Tektronix

Tektronix FiberMaster TFP2A Service manual

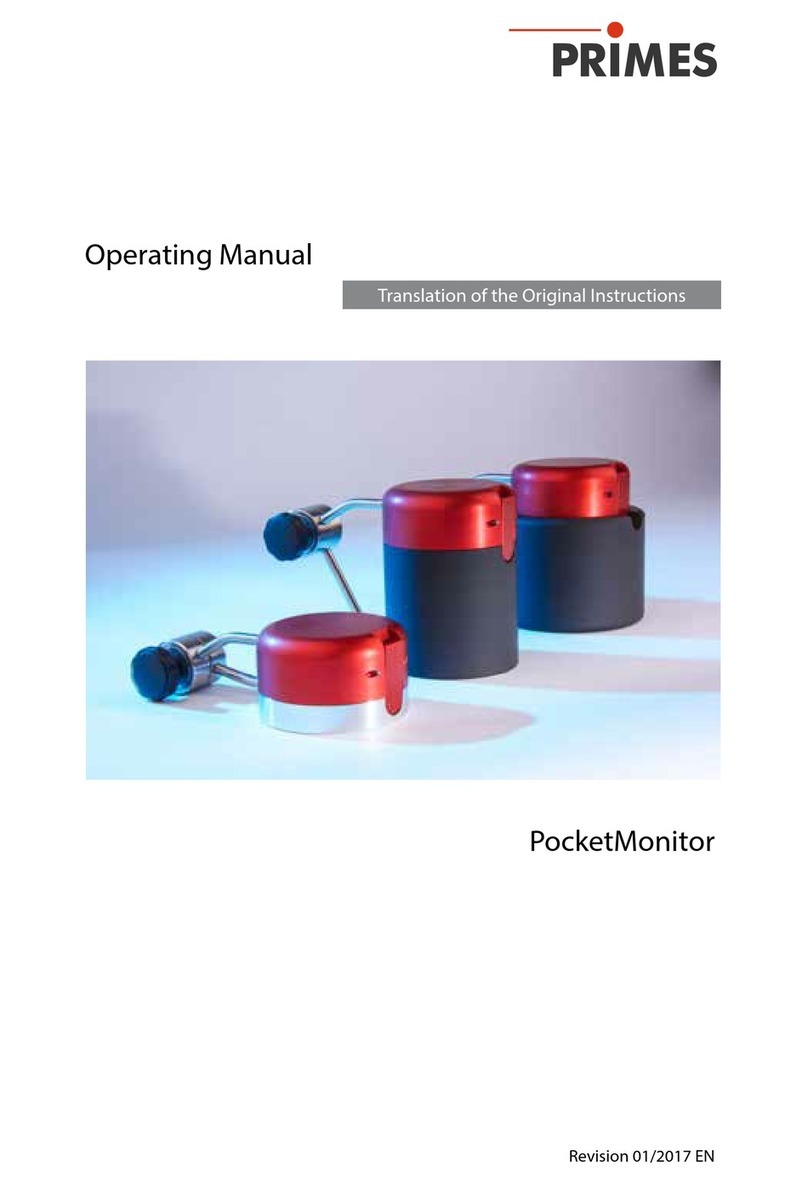

Primes

Primes PocketMonitor operating manual

KPS

KPS KPS-PA20 MINI instruction manual

Auber Instruments

Auber Instruments SYL-1813 instruction manual