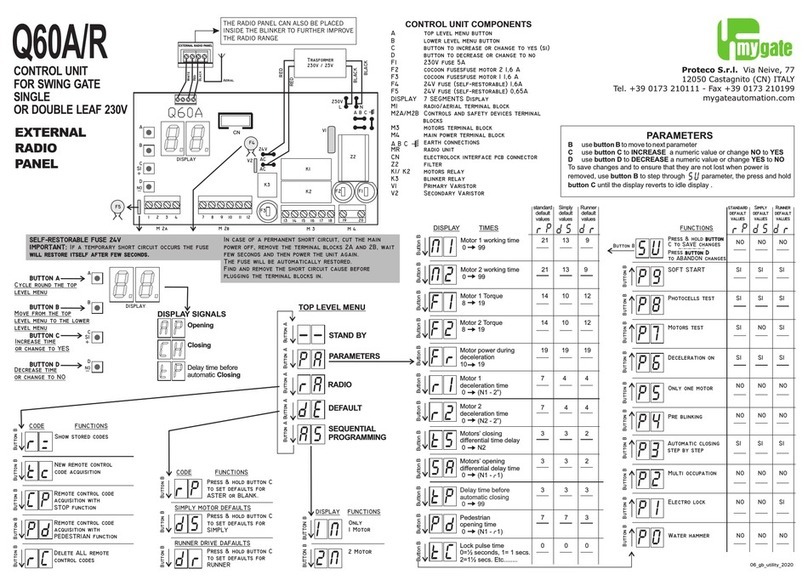

Imtex-Controls VSD-IOM-002 User manual

!

7b

7c

7d

11

10

17

16

12

5

7

1

2

2a

9

20

15

19

14

13

14a

15a

15b

18

Button A

Button B

3

4

Type VSD Valve Controllers are designed to provide high accuracy feedback of valve position with comprehensive diagnostics, including Partial

Stroke Testing (PST). This document, outlines the essential safety information for installing the device, connecting into the device (including

connecting the primary solenoid) and the connection to and setting of the independent feedback systems. Additional connections to and operation

of the Valve Diagnostic/PST system within the device are covered by document VSD-IOM-001.

Installation - Mounting

Attach mounting plate (1) to the actuator using fasteners (2) and lockwashers (2a) provided with mounting kit (if supplied by Imtex).

Loosen indicator cover set screw (3) and rotate indicator cover (4) to desired viewing angle. Retighten set screw (3).

Fit VSD assembly to actuator ensuring that the NAMUR coupler (7) engages the shaft of the actuator (9). If a torque coupler (7a) is

used instead of the NAMUR Coupler on Non-NAMUR actuators, ensure this is securely fitted to the underside of the controller using the screw,

flatwasher and lockwasher supplied (7b/7c/7d) before fitting over the flats on the actuator shaft (9).Secure the assembly using the screws (10) and

lockwashers (11) provided with the mounting kit. Eccentricity of the shaft must not exceed 0.25mm.

If it should be necessary, re-align controller by loosening mount screws (10). Retighten screws when satisfied with alignment.

Fine tune the indicator cover (4) by loosening set screw (3). Retighten set screw when completed.

Installation - Wiring and Setting Internally Wired Transmitter and Independent Switches

Once the controller is fitted to the actuator, remove cover (12) by loosening 2 x cover lock screws (13).

Bring field wiring into the enclosure via the conduit entries (14) fitted with a suitable cable gland. Use blanking plugs to block off any un-used cable

entries. If wiring in the actuator solenoid(s) or additional components, bring these into the enclosure using conduit entries 14a to facilitate wiring.

NOTE: Suitable IP6x rated cable glands, blanking plugs and thread adaptors must be used to maintain controller IP rating. On flameproof enclosures,

only ATEX/IECEx certified Exd cable gland, blanking plugs and thread adaptors can be used. Blanking plugs must not be used with a gland adaptor.

Connect wiring to the terminals (15, 15a, 15b) within the enclosure according to the wiring diagram and terminal labelling. Connect earth conductor

(which forms part of the supply cable and MUST be at least equal to the size of the phase conductors ) to the internal earth points (18). Connect

the external earth/equipotential bonding conductor to the controller using the external earth clamp assembly(19). Conductor should be 4mm2 (min)

The next stage of the installation requires the actuator to be stroked. This can be done in a number of ways depending on the configuration of the

controller installed. Document VSD-IOM-001 covers how the actuator might be stroked using the controller. Otherwise, the actuator canbe stroked

using the solenoid(s) backwired into the controller as operated from the control room, (may require a seperate 24VDC power supply to be connected

depending on unit supplied).

The internally wired transmitter is factory set to provide feedback for 90 degree rotation - clockwise to close. If required, the internally wired transmitter

can be re-programmed.

NOTE: THIS SHOULD ONLY BE DONE IF CONFIDENT THE TRANSMITTERREQUIRES RESETTING BECAUSE IT IS

PROVIDING AN INVERTED SIGNAL.

Clear the transmitter (20) programming by pressing and holding buttons 'A' and 'B' for 2 seconds until the LED

blinks. Drive the actuator to closed position. Press and hold button 'A' for 2 sec until it blinks. Drive the actuator to open position. Press and hold

button 'B' for 2 sec until it blinks.

For controllers fitted with standard cam/spline activated switches/sensors, drive the actuator to the first required indication position and

set the bottom switch by lifting and rotating the bottom cam (16). Secure the cam by allowing it to fully re-engage with the spline (17).

Repeat the process for each switch in-turn by lifting/pushing down the appropriate cam, rotating and re-engaging as desired position is reached.

For controllers with barrel or slotted sensors, or with a transmitter, consult page 2 of these instructions for 'Further Setting Instructions'.

Once completed, verify that indication is as required by fully stroking the actuator. Then refit cover (12) and secure using the 2 x cover lock screws (13).

SPECIAL CONDITIONS FOR SAFE USE OF CERTIFIED ENCLOSURES - ATEX / IECEx

Installation should be carried out by suitably trained personnel to an applicable Code of Practice (eg IEC/EN60079-14 & IEC/EN61241-14).

Only suitably IP and Exd certified and temperature rated cable glands, thread adaptors and blanking plugs are permitted for use

with ATEX/IECEx flameproof enclosures.

The equipment shall not be subjected to a build up of dust and is to be cleaned regularly to prevent dust build up forming on the enclosure.

Where intrinsically safe components are fitted and are to be used within an Intrinsically Safe Circuit, they MUST be supplied by an

ATEX/IECEx approved barrier that is suitable to work with Input Parameters of the respective components

WARNING - For units operating at +85

C, cable, cable glands or conductors in conduit shall be rated +100

C (minimum).

WARNING - Monitor includes external plastic parts and presents an Electrostatic Hazard: Clean Only with a Damp Cloth.

WARNING - Do not install on an external source of heating or cooling e.g. by hot/cold air blowing temperature units

WARNING - Locate monitor to prevent propagating brush discharges

WARNING - Monitor should not be opened when energised or an explosive atmosphere may be present. The cover

screws (13) must be loosened before opening and re-tightened before the controller re-enters service.

The maximum constructional gap (i

C

) is less than that required by

Table 1 of IEC 60079-1:2007 clause 5.2.2 as detailed below:

Flamepath - Through Shaft

Max Gap (mm) - 0.07

Comment - Cylindrical Spigot Joint

Item 7a

REV

DATE

TITLE:

DWG NO.

SHEET 1 OF 3

VSD-IOM-002

Installation, Operating & Maintenance

VSD - IECEx/ATEX

Imtex Controls Limited

CHK'D

ECO

Tel:+44(0)8700-340002

Website: www.imtex-controls.com

13-2019

Additional Instructions for Safe Use

The certification for this monitor relies upon the following materials used in its construction:

- Stainless Steel

- EDPM 70

If the equipment is likely to come into contact with aggressive substances, then it is the responsibility

of the user to take suitable precautions that prevent it from being adversely affected, thus ensuring

that the type of protection provided by the equipment is not compromised. Aggressive substances

might be: acidic liquids or gases that attack Stainless Steel, or direct and prolonged contact with some

Hydrocarbons that could affect the seals. Regular checks/inspections should be carried out if aggressive

substances are present.

Instructions

Reference Diagram

DRAWN

28.2.13

PT

B

17-2618

14.2.17

A

PT

REV

STATUS

R

18-2692

1.2.18

PT

B

!

!

Warning: Electrostatic Hazard - See Instructions

Model:

Serial:

IQ

INTRINSICALLY SAFE COMPONENTS (connect to safe area via Certified Barrier):

WARNING: DO NOT OPEN WHEN ENERGISED OR WHEN AN

EXPLOSIVE ATMOSPHERE MAY BE PRESENT.

TYPE VSD

Valve Controller

IEC CERTIFICATE NO: IECEx TRC 13.0004X

ATEX CERTIFICATE NO: TRAC13ATEX0005X

Tonbridge - TN11 0AH - UK

www.imtex-controls.com

WARNING: FOR T

amb

+85

C, CABLE GLANDS OR CONDUCTORS IN

CONDUIT ENTRIES SHALL BE RATED +100

C (MIN)

II 2 GD

CONSULT INSTRUCTIONS PRIOR

TO INSTALLATION, OPERATION

or MAINTENANCE

0518

Exd [ib] IIC T4 Tamb = -

C to +85

C Gb & Ex tb IIIC T135

C Db IP6X

Exd [ib] IIC T6 Tamb = -

C to +60

C Gb & Ex tb IIIC T85

C Db IP6X

INTRINSICALLY SAFE INFORMATION:

U

i

I

i

P

i

C

i

L

i

V

mA

W

nF

µH

(1) 3/4"NPT / (5) 1/2" NPT

(3) 3/4"NPT / (3) 1/2" NPT

(1) M25 x 1.5 / (5) M20 x 1.5

(2) M25 x 1.5 / (4) M20 x 1.5

T

(2) 3/4"NPT / (4) 1/2" NPT

S

U

ENTRIES SUPPLIED

DIGIT

Y

(3) M25 x 1.5 / (3) M20 x 1.5

V

(6) 1/2" NPT

W

(6) M20 x 1.5

X

Z

ENTRIES SUPPLIED

DIGIT

CABLE ENTRY GUIDE

A

Barrel Sensor

16

Barrel/Slot Sensor Setting

Drive the actuator to the first required indication position and set the first switch

by pushing round the lower metal shim on the shaft (16) to cover the sensor.

Repeat the process for each sensor in-turn by driving the actuator to the indication

position and adjusting the appropriate shim to cover the corresponding sensor.

Independent Transmitter Setting

NOTE: The Type VSD Transmitter is factory set to provide position information over

a 90 Degree span. The Transmitter type and setting is done following the same

method as the internally wired transmitter. The independent transmitter will be

located above the internally wired transmitter.

Clear the transmitter programming by pressing and holding buttons 'A' and 'B' for 2

seconds until the LED blinks. Drive the actuator to closed position. Press and hold

button 'A' for 2 sec until it blinks. Drive the actuator to open position. Press and hold

button 'B' for 2 sec until it blinks. For controllers fitted with standard cam/spline

activated switches/sensors, drive the actuator to the first required indication position

and set the bottom switch by lifting and rotating the bottom cam (16). Secure the cam

by allowing it to fully re-engage with the spline (17).

Maintenance

The Type VSD requires no servicing during normal working life, if installed correctly.

However, it is advisable to check mounting screws/bolts, o-rings and terminal wiring

for signs of loosening or corrosion as part of the routine plant maintenance to ensure

continued operation. Ensure safety warnings are observed during maintenance.

Inspection & maintenance to ATEX/IECEx flameproof enclosures to be carried out by

suitably trained personnel with applicable code of practice

(eg IEC/EN60079-17). Repairs to Type SRX ATEX/IECEx

flameproof enclosures are not permitted. Please consult factory.

DRAWN

REV

DATE

TITLE:

DWG NO.

SHEET 2 OF 3

VSD-IOM-002

Installation, Operating & Maintenance

VSD - IECEx/ATEX

Imtex Controls Limited

CHK'D

ECO

Tel:+44(0)8700-340002

Website: www.imtex-controls.com

This private & confidential drawing is the property

of Imtex Controls Limited, Tonbridge, UK and cannot

be copied or reproduced without the express

written permission of the Company.

13-2019

28.2.13

PT

Product Markings

Further Setting Instructions

Cable Entries

Referenced Standards

The number and type of cable entry on the Controller can be determined by reference

to the 7th digit of the monitor part number. For example, in part number -

VSD16SYSR0-IOO

the seven digit is a 'Y' which corresponds to the monitor having 3 off M25 x 1.5 cable entry

and 3 off M20 x 1.5 cable entry. Refer to table below for details.

The following standards have been referred to in

these instructions and are applicable to the use

of this product when used in an environment

where an explosive atmosphere may be present:

IEC 60079-0:2017 7th Ed

IEC60079-1:2014 7th Ed

IEC60079-11:2011 6th Ed

IEC 60079-31:2014 2nd Ed

EN60079-0:2012

EN60079-1:2014

EN60079-11:2012

EN60079-31:2014

The label on the controller should be as below:

NPT Threads conform to ANSI/ASME B1.20.1 and shall be made up wrench tight

Metric Thread tolerance to ISO 965-1 and ISO 965-3

NOTE: The year of manufacture of the monitor can

be obtained from the last 2 digits of the serial number

STATUS

REV

R

B

17-2618

14.2.17

A

PT

18-2692

1.2.18

PT

B

CC

BOT SWITCH

TOP SWITCH

CONDUIT

ENTRIES

NO

NO

NC

NC

BOTTOM

or RIGHT

SENSOR

TOP or

LEFT

SENSOR

CONTROLLER - 2 x 2-Wire Prox Sensor

VSD42, 43

CONDUIT

ENTRIES

SENSOR 1

SENSOR 2

TOP/LEFT SENSOR

BOTTOM/RIGHT SENSOR

BU

-

A

+

BU

BK

BN

-

+

A

BN

CONTROLLER - 2 x 3-Wire Prox Sensor

VSD42, 43

SENSOR 1

CONDUIT

ENTRIES

BK

SENSOR 2

CONDUIT

ENTRIES

+

-

CONTROLLER - w/ 2 WIRE

TRANSMITTER - VSD70

TRANS

EMERGENCY SHUTDOWN OUTPUT (-)

EMERGENCY SHUTDOWN OUTPUT (+)

EMERGENCY SHUTDOWN INPUT (-)

EMERGENCY SHUTDOWN INPUT (+)

'-' ACTIVE ANALOGUE INPUT 2

'+' ACTIVE ANALOGUE INPUT 2

'-' ACTIVE ANALOGUE INPUT 1

'+' ACTIVE ANALOGUE INPUT 1

NOT USED

EXTERNAL. 24VDC POWER SUPPLY (-)

2412

11

14

23

22

21

13

ALLOCATION

TERMINAL

'-' PASSIVE ANALOGUE OUTPUT (OPTIONAL)

'+' PASSIVE ANALOGUE OUTPUT (OPTIONAL)

'-' PASSIVE ANALOGUE INPUT (OPTIONAL)

10

9

NOT USED

EXTERNAL POWER SUPPLY - GROUND

7

NOT USED

8

6

ALLOCATION

TERMINAL

2

5

EXTERNAL. 24VDC POWER SUPPLY (+)

4

'+' PASSIVE ANALOGUE INPUT (OPTIONAL)

3

1

ALLOCATION

TERMINAL

VALVE CONTROLLER BOARD - NOTE: TERMINAL 7 MUST BE CONNECTED TO GROUND. ALL OTHER GROUNDS ARE INTERNALLY CONNECTED

TERMINAL

ALLOCATION

27

29

28

30

31

'+' DIGITAL OUTPUT 1

'-' DIGITAL OUTPUT 1

32

GROUND

'+' DIGITAL OUTPUT 2

'-' DIGITAL OUTPUT 2

GROUND

'+' DIGITAL OUTPUT 3

'-' DIGITAL OUTPUT 3

TERMINAL

ALLOCATION

33

39

34

40

41

42

'+' DIGITAL INPUT 1

'-' DIGITAL INPUT 1

'+' DIGITAL INPUT 2

'-' DIGITAL INPUT 2

TERMINAL

ALLOCATION

43

39

44

40

41

42

'+' DIGITAL INPUT 3

'-' DIGITAL INPUT 3

SPECIAL NOTE:

Installation of Reed Switches (without Choke):

Where reed

switches (particularly low power, Rhodium contact versions) are

installed at the end of long cable runs, it is the responsibility of the

installer to ensure suitable precautions are taken to ensure cable

capacitance does not induce premature switch failure.

Consult Imtex for further information

VSD16 - Mechanical w/ Silver Contacts

Electrical Ratings: 10.0A @ 125/250VAC

0.5A @ 125 VDC

Temp Range: -40 to +60

C

Operating Life: 400,000 Cycles

Not recommended for circuits operating less than

20mA @24VDC

VSD17 - Mechanical w/ Gold Contacts

Electrical Ratings: 1.0A @ 125VAC

0.5A @ 30 VDC

Temp Range: -40 to +60

C

Operating Life: 100,000 Cycles

Recommended for use in 24VDC computer input circuits

VSD42 - NAMUR Proximity Sensor

Current Ratings: Target Present - Current < 1.0mA

Target Absent - Current > 3.0mA

Voltage Range: 5 to 25VDC (nominal 8VDC)

Temp. Range: -25 to +60

C (T6) or +72

C (T4)

Operating Life: Unlimited Cycles

Use with intrinsically safe repeater barrier. Namur

sensors fully conform to EN60947-5-6 (VDE0660

Part 212) standard.

CONTROLLER - 2 x SPST/SPDT Switch

VSD16,17,25 & 40

For SPST Switch NC contact is not available

BL(-)

BR(+) BR(+)

BL(-)

VSD70 - Analogue Transmitter -

Non-Contact Style

Supply Voltage: 12 to 24VDC

Load Impedance: R< (U - 9) / 0.02

Linearity: < 1% of FS

Repeatability: < 0.36

Op Temp Range: -40 to +85 Deg C

BASE BOARD

Supply Voltage: 24VDC

Max Dissipated

Power under Max

Load Conditions: 3.57 Watts

Op Temp Range: -40 to +85 Deg C

See Unit Title Plate

NOTE: Terminal 7 must be connected to Ground. All other

Electronic Board grounds are connected internally

NOTE 2:If VSD is fitted to actuator with 2 Solenoids but where only one is backwired into the

Controller, Terminals 21 to 24 would be for Power and Connections to the PST Solenoid.

VSD25 (A140077) - SPDT (Rhodium) Reed Switch

Electrical Ratings: 0.5A (Switching Current)

1.0A (Steady State Current)

120V Max (Voltage)

10W/VA Max (Power)

Temp. Range: -50 to +60

C (T6) or +85

C (T4)

Operating Life: 5,000,000 Cycles

VSD25 (A140077-SU) - SPDT(Hermetically Sealed

Reed)- w/ Choke

Electrical Ratings: 0.15A @ 125VAC / 30VDC

Inductance: 680 µH

Resistance: 10 Ohms

Temp. Range: -40 to +60

C (T6) or +85

C (T4)

Operating Life: 5,000,000 Cycles

VSD40 (A140077-SU) - SPST(Hermetically Sealed

Reed - w/ Choke)

Electrical Ratings: 0.15A @ 125VAC / 30VDC

Inductance: 680 µH

Resistance: 10 Ohms

Temp. Range: -40 to +60

C (T6) or +85

C (T4)

Operating Life: 5,000,000 Cycles

VSD25 (A140088) - High Power SPDT(Hermetically

Sealed Reed - Tungsten)

Electrical Ratings: Max Current: 3 Amps

Max Power: 100 Watts/VA

Min Power: 2 Watts

Temp. Range: -40 to +60

C (T6) or +85

C (T4)

Operating Life: 5,000,000 Cycles

Not recommended for use in 24VDC operating at <20mA

DRAWN

REV

DATE

TITLE:

DWG NO.

SHEET 3 OF 3

A4

VSD-IOM-002

Installation, Operating & Maintenance

VSD - IECEx/ATEX

Imtex Controls Limited

CHK'D

ECO

Tel:+44(0)8700-340002

Website: www.imtex-controls.com

This private & confidential drawing is the property

of Imtex Controls Limited, Tonbridge, UK and cannot

be copied or reproduced without the express

written permission of the Company.

B

13-2019

28.2.13

PT

A

STATUS

R

REV

B

1.2.18

18-2692

WIRING DIAGRAMS ('X' Indicates the applicable Diagram)

ELECTRICAL CHARACTERISTICS - NON-I.S. COMPONENTS ('X' Indicates the applicable Rating(s))

INTRINSICALLY SAFE PARAMETERS

17-2618

14.2.17

PT

PT

Popular Control Unit manuals by other brands

Unical

Unical PANEL BOARD MODULATING MASTER operating instructions

schmersal

schmersal PROTECT-IE Series operating instructions

Flowserve

Flowserve Edward 602Y Maintenance manual

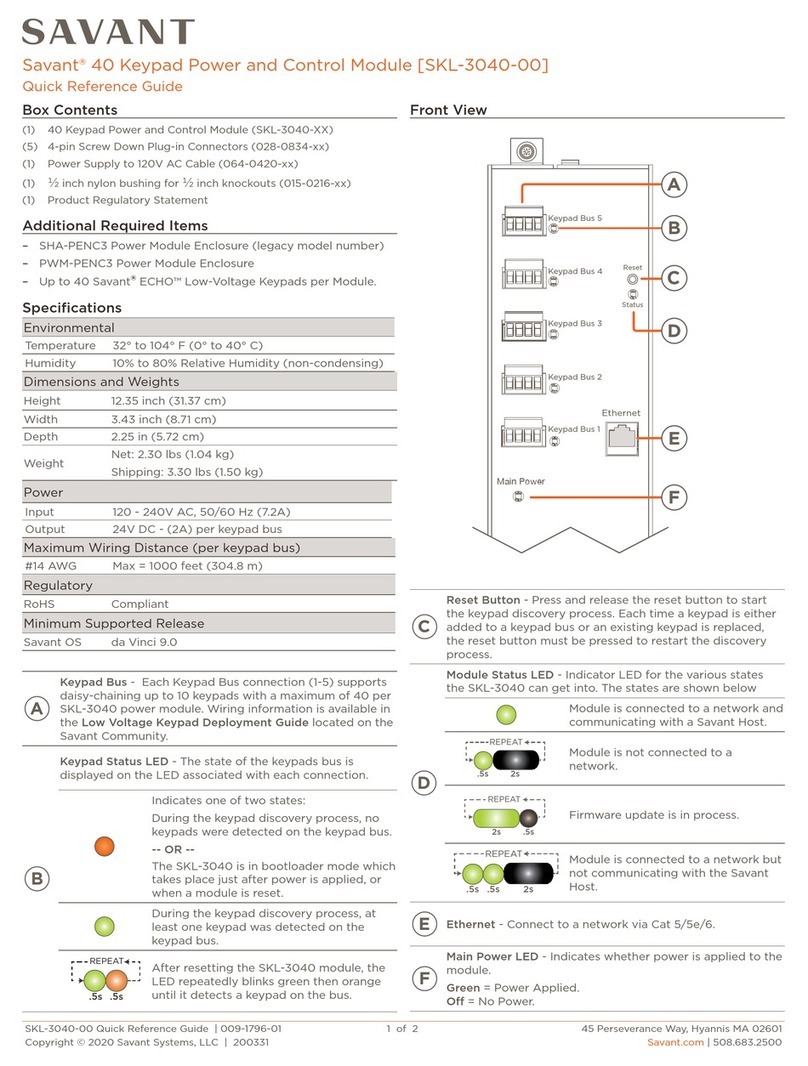

Savant

Savant SKL-3040-00 Quick reference guide

Dickert Electronic

Dickert Electronic DCM31 manual

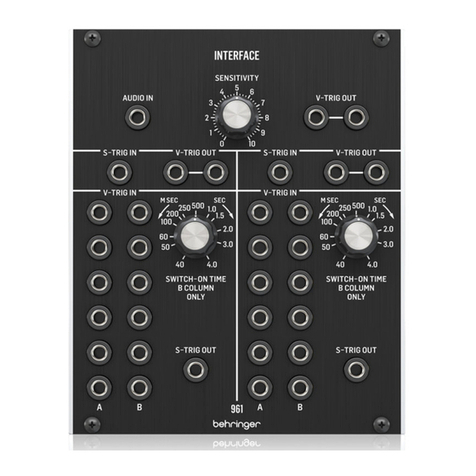

Behringer

Behringer 961 Interface quick start guide