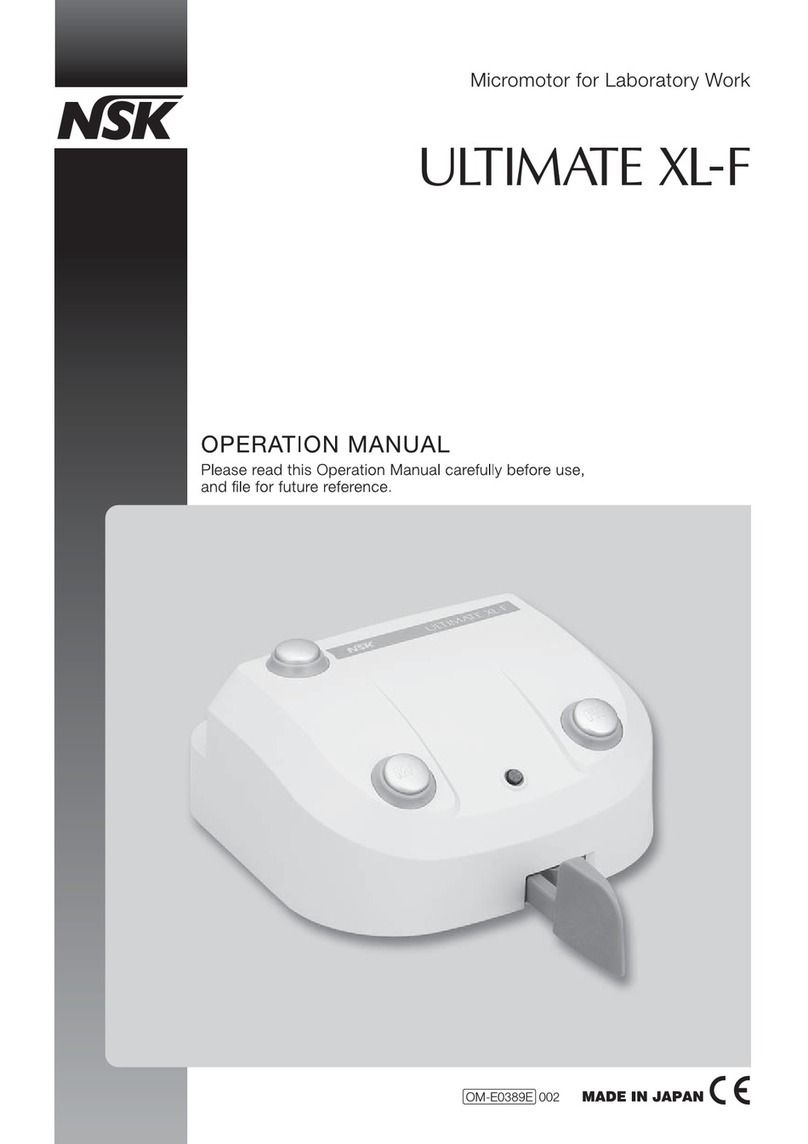

⑨StartSwitch

Startsandstopsmotorrotation

⑩Forward/ReverseSwitch

Thisswitchcontrolsthedirectionofrotation,

forward(FWD)orreverse(REV).Withthecutting

toolfacingtheoperatorrighthandrotation(FWD)

willbeclockwiserotation.

⑪ControllerSwitch(AUTOーMANUAL)

Thisswitchselectsmotor/spindlecontrolfromthe

ControlPanelorfromanexternalsource.

●MANUAL:ControlPanel

●AUTO :Externalcontrolthroughtheinput/

outputconnectorCN2②

⑫MotorSpeedSelectionSwitch

Selectthemotorspeedcontrolmode.Internalunit

(INT),External(EXT),Centering(500)

⑬SpeedAdjustmentKnob

Steplesslyadjustablespeedcontrol.Iftheknobis

turnedclockwise,thiswillincreasemotorspeed.

Motorspeedisadjustable:2,000-40,000min-1

(400Z),2,000-50,000min-1(500Z)and20,000-

80,000min-1(800Z).

⑭DigitalSpeedIndicator(SPEED)

PresetSpeed,ActualSpeed,WarningandError

Codesaredisplayedto2digits.

ErrorLamp:Whenanerrorexiststhislamplights

andtheerrorcodeisshownonthedigitaldisplay.

PowerLamp:PowerSwitchisintheONposition.

MotorLamp:Motorisrotating(exceptatthe

minimumofspeedadjustmentknob)

FWD.Lamp:Forwardrotationiscounter-clockwise

rotationwhenthecuttingtoolisfacingtheoperator.

REV.Lamp:Reverserotationisclockwiserotation

whenthecuttingtoolisfacingtheoperator.

ManualLamp:Manualoperation

AUTOLamp:Autooperation

500Lamp:500min-1operationforcentering

EXTLamp:MotorControlbyexternalsignal

source.

INTLamp:MotorControlbyfrontpanelcontrols.

LoadMonitorLamp(LOAD):Realtimeload

monitoringdisplay.

(

)

⑩Forward/ReverseSwitch

⑪ControllerSwitch(AUTOーMANUAL)

⑨StartSwitch

⑬SpeedAdjustmentKnob

BPowerLamp

GAutoLamp AErrorLamp

CMotorLamp

DFWD.Lamp

EREV.Lamp

FManualLamp

KLoadMonitorLamp(LOAD)

I

ExternalLamp

H500Lamp

JInternalLamp

⑭DigitalSpeedIndicator(Speed)

⑫

MotorSpeedSelectionSwitch

A

B

C

D

E

F

G

H

I

J

K