Inca PSJ2 User manual

1

INCA

CONTROL PTY LTD Phone: (02) 9675 3815

UNIT 14/62 OWEN ST Fax: (02) 9675 1381

GLENDENNING NSW 2761 Email: sales@incacontrol.com.au

Web: www.incacontrol.com.au

Design & Manufacture of:

Custom-built switchboards

Electronic control equipment

AC/DC pumping controls

Installation & service

INCA MODEL

PSJ2

PRESSURE

CONTROLLER

USER MANUAL

Inca Reference PSJ2

Software Version 1.0

Technical Support

Pumps & Mechanicals –

Controls –Inca Control & Engineering Pty Ltd

Phone 02 9632 2837

2

TABLE OF CONTENTS

1.0 Control Panel Overview………………………………………………. 3

1.1 Features………………………………………………………… 3

1.2 Description……………………………………………………... 3

2.0 Installation…………………………………………………………….. 4

2.1 Mechanical installation………………………………………… 4

2.2 Sensor installation……………………………………………… 4

2.3 Electrical installation…………………………………………… 4

2.4 Maintenance…………………………………………………….. 4

3.0 Start- up………………………………………………………………… 5

3.1 Notes on value entry…………………………………………... 5

3.2 Power up display………………………………………………. 5

3.3 Screen display layout………………………………………….. 5

4.0 Calibration……………………………………………………………. 6

4.1 Setting low pressure shutdown…………………………………. 6

4.2 Setting low pressure time delay………………………………… 6

4.3 Setting high pressure shutdown……………………………….. 6

4.4 Setting high pressure time delay……………………………….. 6

4.5 Duty start pressure…………………………………………… 6

4.6 Duty stop pressure…………………………………………….. 6

4.7 Standby start pressure………………………………………… 6

4.8 Standby stop pressure………………………………………….. 6

4.9 Pressure sensor calibration.…………………………………….. 7

4.10 Total Flow setting Pump No1…………………………………. 7

4.11 Total Flow setting Pump No2…………………………………. 7

4.12 Irrigation controlled………………………………………….. 7

4.13 Reset Hour run meter………………………………………… 7

4.14 Total flow display……………………………………………… 7

4.15 Pump hour run meter…………………………………………... 7

5.0 Operation……………………………………………………………… 8

5.1 System operation……………………………………………….. 8

5.2 Manual/off/auto selector………………………………………. 8

5.3 Duty Selector Switch P1/Auto/P2……………………………… 8

6.0 Trouble shooting………………………………………………………. 9

7.0 Controller settings sheet………………………………………………. 10

8.0 Warranty Statement…………………………………………………… 11

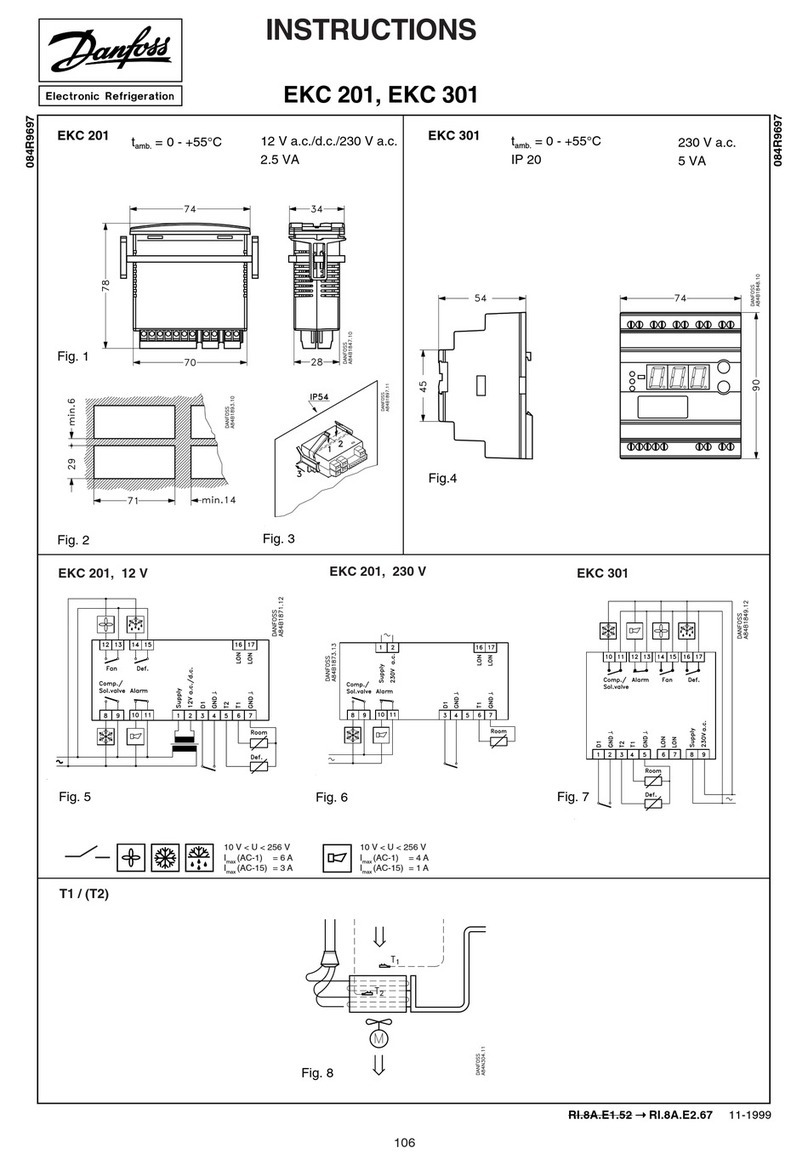

Drawing supplied separately

3

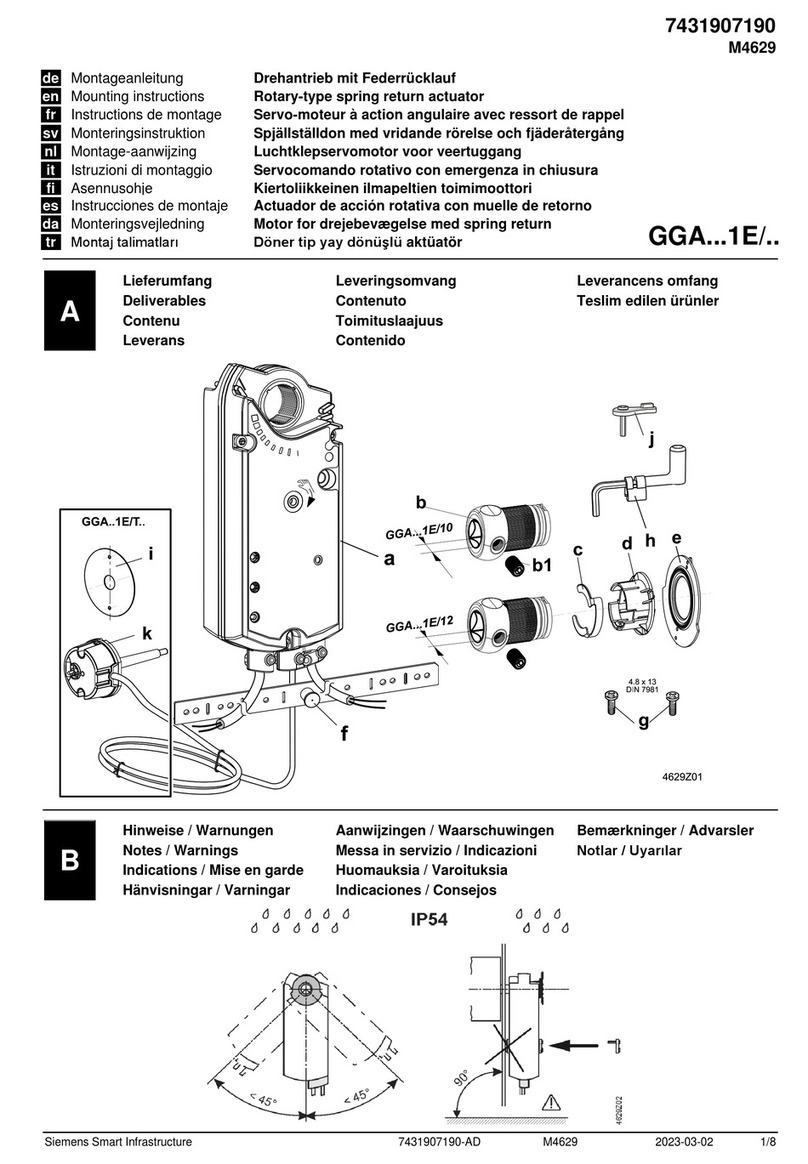

1.0 Control Panel Overview

1.1 Features

JAZZ HMIPLC with user friendly setup & display

Display of system pressure

Low & high pressure pump shutdown with reset button

Low level pump shutdown with automatic reset

Manual/off/auto selectors on JAZZ Face

Duty selector on JAZZ face

Hour run meter (resetable)

Mathematical calculation of Total flow in Kilolitres

Microprocessor controlled

Useable with any 4-20mA loop powered Pressure Transducer

Usable with Irrigation controller input

1.2 Description

The pressure control panel is designed to maintain a system discharge pressure via adjustable control points

entered by the operator. The display shows the actual live pressure input received from the system discharge

pressure transducer. It also displays the pump operating condition & alarm conditions

User Interface

Display An LCD screen displaying 2 lines of text, each 16 characters long

Keypad Operator keyboard, 16 sealed membrane keys

Performance

Range 0 –1000kpa generally, programmable to suit transducer range

Flow Totaliser up to 32000 kilolitres

Inputs 2 wire plus shield connected to terminals located on panel base plate for

pressure transducer.

2 wire plus earth connected to terminals for irrigation controller

2 wire connected to terminals for Low Level float switch

Outputs

Motors 3 wire plus earth sized to suit motor FLC connected directly to motor starters

overload terminals.

Power Supply 415V 3phase neutral & earth power supply sized to suit the total load of the

three motor & must have a protection circuit breaker sized to suit the starting

characteristics of the motor

Mechanical Specification

Enclosure Mild steel powder coated RAL 7032 IP54

Stainless steel is available

Dimension Up to 4kW 400Hx400Wx150D

Larger motor sizes available

Sizes may vary for specials

Pump Unit See Pumping detail by Brooks Irrigation

Environmental Specification

Operating Temp -10 to 50deg C

Relative Humidity Do not install in areas of high humidity

Locate control panel internally where possible to help reduce heat & weather

damage & increase mechanical life.

Vibration Do not install in a location that is subject to large amounts of vibration

4

2.0 Installation

Note: If any damage to control panel if found, please notify your pump supplier or Inca Control as

soon as possible prior to installation.

The control panel can be wall mounted separately from the pumping unit; distance is governed by the cable

sizing to the motor.

It is recommended that the control panel is within view of the pumping unit for safety reasons. If not in view

lockable isolating switches must be installed at the pump motors

2.1 Mechanical Installation

Mount the control panel via the mounting holes in each corner at the back of the enclosure using minimum

6mm screws, nuts & locking washers, or masonry anchors

Install in a dry well ventilated location that matches with environmental specification in 1.2 above

2.2 Sensor Installation

Locate the pressure transducer in the discharge pipe work as close as practical to the control panel.

2.3 Electrical Installation

Note: All cable entries must enter via the bottom of the cabinet. If cables are entered via the roof Inca

Control Pty Ltd reserve the right to withdraw warranty because of the possibility of shaving entering

sensitive electronic equipment.

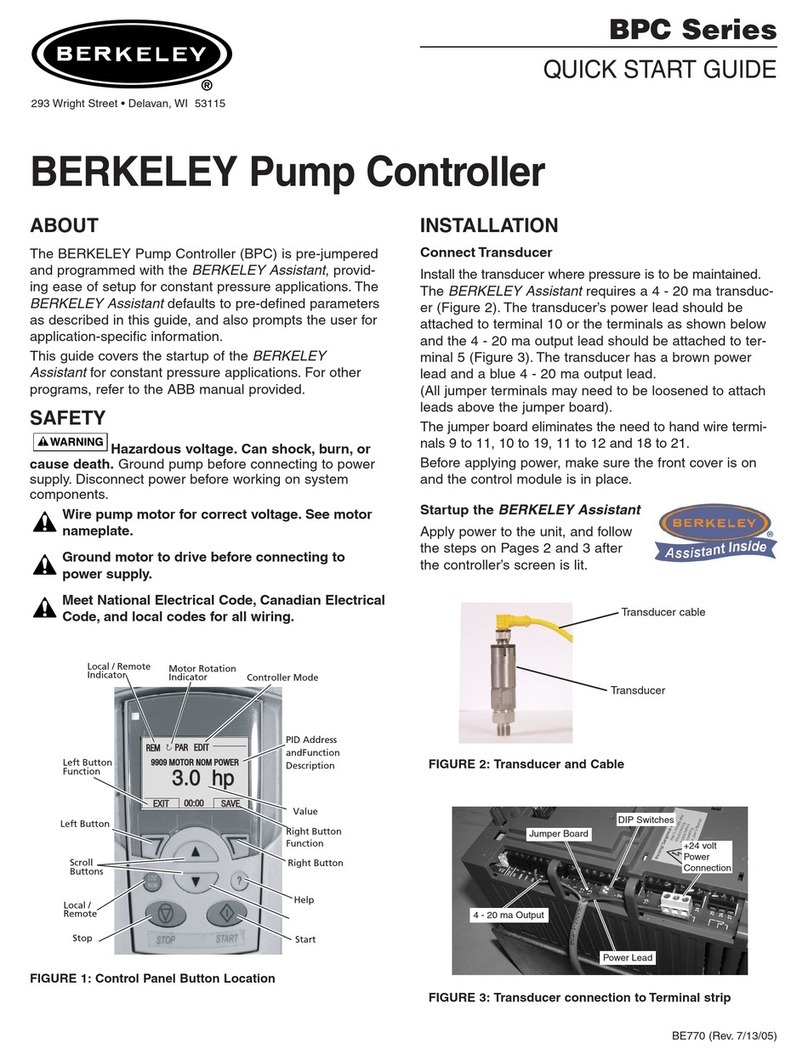

Transducer wiring

The pressure transducer must be wired in 1 pair overall screened data cable. This type of cable provides the

most protection against electrical noise & allows a more accurate outcome

Connect to the sensor as per data supplied by the sensor supplier

At the control panel connect the positive lead to terminal No10 & the return signal to terminal No12.

The screen must be solidly earthed, with a saddle clamp providing the best screening earth.

Float switch wiring

The float switch is wired in the cable supplied with switch. The cable to be connected must close the circuit

when water in the suction tank falls

Connect the float switch as per data supplied by the float switch supplier

At the control panel connect the float switch lead to terminal No10 & terminal No11.

The screen must be solidly earthed, with a saddle clamp providing the best screening earth.

Irrigation control wiring

The control signal from the irrigation controller operates the pumps start signal & must be 24VAC or DC signal

on to start pump & 24VAC/DC signal off to stop pump

At the control panel connect the 24VAC/DC Irrigation control signal directly to the coil on relay R1 at the base

of the control panel. Active lead to terminal No A1+ & the negative to terminal A2-.

Motor Wiring

The motor must be wired in cabling sized to suit the motor power requirement.

The motor is to be connected in star or delta as instructed by the nameplate on the motor.

The cabling entering into the motor terminal box shall be glanded unless a submersible motor is being used in

this case the pump lead is supplied by the pump manufacturer

The cable entering the control panel end can be glanded using standard nylon glands & run directly to the

appropriate overload terminals T1, T2, T3

2.4 Maintenance

Check that all connections are tight as copper is soft & can work loose

Check that all controls are functioning as intended

5

3.0 Start up

3.1 Notes on Value Entry

When entering a numeric value, the cursor can be backspaced to correct mistakes by pressing the LEFT

ARROW button.

Decimal points can only be entered on entries with decimal points in the display line. The decimal point is

entered by pressing the +/- . down arrow key on the bottom of the blue buttons

You can only enter a value of as many digits as is displayed on the screen. Example an input that displays 3

digits can only have 3 digit entered

3.2 Power Up Display

On power up the screen will display the main page including the pressure, switch position & operating

information.

3.3 Screen Display Layout

The screen displays two lines of information

The top line displays the live discharge pressure in kPa

The bottom line displays the manual/off/auto switch position & operating condition of the pump

6

4.0 Calibration

The calibration of the controller is carried out on pages accessed by pressing & holding in the RIGHT ARROW

Button for 5seconds. The first calibration page will appear. You can move through the calibration pages by

pressing the RETURN ARROW button & then the RIGHT ARROW button to move on. Continuing this process

will move you through the pages with out making any changes. If changes are made the inputted value is

recorded once the enter button has been pressed. The enter button is the return arrow located at the bottom

right corner of the facia. To get out of calibration pages press the RETURN ARROW button twice & return to

the main page.

4.1 Setting Low Pressure Shutdown

Press & hold the RIGHT ARROW button for 5seconds to enter calibration pages. Low pressure on will now be

displayed.

The Cursor will be flashing under the first digit of the LOW PRESSURE ON setting. Simply type in the

appropriate pressure you want the low pressure shutdown to operate at, example 200kPa Press 2, press 0,

press 0 & then press Return Arrow button.

Press the RIGHT ARROW Button to move onto the next Page

4.2 Setting Low Pressure Time Delay

Low pressure time delay will now be displayed.

The Cursor will be flashing under the first digit of the LOW PRESSURE TIME DELAY setting. Simply type in

the appropriate delay time you want after the low pressure set point has been reached, example 45sec Press

0, press 0, press 4, Press 5, & then press Return Arrow button.

Press the RIGHT ARROW Button to move onto the next Page

4.3 Setting High Pressure Shutdown

High pressure on will now be displayed.

The Cursor will be flashing under the first digit of the HIGH PRESSURE ON setting. Simply type in the

appropriate pressure you want the High pressure shutdown to operate at, example 800kPa Press 8, press 0,

press 0 & then press Return Arrow button.

Press the RIGHT ARROW Button to move onto the next Page

4.4 Setting High Pressure Time Delay

High pressure time delay will now be displayed.

The Cursor will be flashing under the first digit of the HIGH PRESSURE TIME DELAY setting. Simply type in

the appropriate delay time you want after the High pressure set point has been reached, example 45sec Press

0, press 0, press 4, Press 5, & then press Return Arrow button.

Press the RIGHT ARROW Button to move onto the next Page

4.5 Duty Pump Start Pressure

Duty pressure on will now be displayed.

The Cursor will be flashing under the first digit of the DUTY PRESSURE ON setting. Simply type in the

appropriate pressure you want the Pump start pressure to operate at, example 400kPa Press 4, press 0, press

0 & then press Return Arrow button.

Press the RIGHT ARROW Button to move onto the next Page

4.6 Duty Pump Off Pressure

Duty pressure off will now be displayed.

The Cursor will be flashing under the first digit of the DUTY PRESSURE OFF setting. Simply type in the

appropriate pressure you want the Pump stop pressure to operate at, example 500kPa Press 5, press 0, press

0 & then press Return Arrow button.

Press the RIGHT ARROW Button to move onto the next Page

4.7 Standby Pump Start Pressure

Duty pressure on will now be displayed.

The Cursor will be flashing under the first digit of the STANDBY PRESSURE ON setting. Simply type in the

appropriate pressure you want the Pump start pressure to operate at, example 400kPa Press 4, press 0, press

0 & then press Return Arrow button.

Press the RIGHT ARROW Button to move onto the next Page

4.8 Standby Pump Off Pressure

Duty pressure off will now be displayed.

The Cursor will be flashing under the first digit of the STANDBY PRESSURE OFF setting. Simply type in the

appropriate pressure you want the Pump stop pressure to operate at, example 500kPa Press 5, press 0, press

0 & then press Return Arrow button.

Press the RIGHT ARROW Button to move onto the next Page

7

4.9 Pressure Sensor Calibration

Calibrate Sensor will now be displayed.

The Cursor will be flashing under the first digit of the CALIBRATE SENSOR setting. Simply type in the 20mA

scale of the pressure transducer to be used, example 1000kPa (10bar) Press 1, Press 0, press 0, press 0 &

then press Return Arrow button.

Press the RIGHT ARROW Button to move onto the next Page

4.10 Total flow Setting Pump No1

Litres per second will now be displayed.

The Cursor will be flashing under the first digit of the LITRES PER SECOND P#1 setting. Simply type in the

flow rate of the pump delivery, example 10l/s Press 1, press 0 & then press Return Arrow button.

With this setting, the JAZZ HMIPLC will display a mathematical calculation of total flow in kilolitres. (Flow is

reset to zero when 32000k/l is displayed)

Press the RIGHT ARROW Button to move onto the next Page

4.11 Total flow Setting Pump No2

Litres per second will now be displayed.

The Cursor will be flashing under the first digit of the LITRES PER SECOND P#2 setting. Simply type in the

flow rate of the pump delivery, example 10l/s Press 1, press 0 & then press Return Arrow button.

With this setting, the JAZZ HMIPLC will display a mathematical calculation of total flow in kilolitres. (Flow is

reset to zero when 32000k/l is displayed)

Press the RIGHT ARROW Button to move onto the next Page

4.12 Irrigation Controlled

Irrigation will now be displayed.

The Cursor will be flashing under the digit identifying on or off.

If selected to ON, pump will only run in auto when a 24VAC/DC input has been received from the irrigation

controller. The pump will then be controlled via the duty pressure on & off settings

If selected to OFF, the pump will run via the duty pressure on & off settings.

To select the Irrigation control enter 1 in the & status Press Return Arrow to accept

To select NO irrigation control enter 0 in the status & press return arrow to accept

Press the RIGHT ARROW Button to move onto the next Page

4.13 Reset Hours run meter

Reset Hours run meter will now be displayed.

To reset the hour meter press & hold #5 button for 5second.There will be no change on the screen so you will

need to check that the reset has been achieved

Press the RETURN ARROW Button to move back to the main page

4.14 Total Flow displays

The JAZZ HMIPLC has a mathematical display of total Flow. This flow is calculated using the litre/second rate

of the pump which is set in 4.10 & 4.11 above.

To access the total flow meters, from the main page press the ARROW UP button. The total flow for Pump

No1 is now displayed.

Press the ARROW UP button again will display the total hours run for pump No1

Press the ARROW UP button again will display the total flow for pump No2

Note, Total flow before display returns to zero is 32000k/l

4.15 Pump Hours run meter

The JAZZ HMIPLC has a pump hour’s run display.

To access the total hours run meter for pump No1, from the main page press the ARROW UP button. The

total flow for Pump No1 is now displayed. Press the ARROW Up button again the total hour run meter for

Pump No1 will now be displayed

Press the ARROW UP button again will display the total flow for pump No2

Press the ARROW UP button again will display the total hours run for pump No2

Note, Total hours run before display returns to zero is 32000Hours.

To reset the hour meter press & hold #5 button for 5second.

8

5 Operation

5.1 System Operation

The system is designed to maintain a pressure in the discharge line of a pumping system relating to the

settings entered by the operator. The pump will start when the pressure falls to the duty start set point & will

run until the pump stop set point is reached

If the pressure continues to fall & reaches the standby start pressure the standby pump will be started & will

run until the standby stop pressure has been reached

If the irrigation input signal is to be used the pump will not operate until this signal is on and will then operate

between the start & stop set points.

If the system pressure falls to the low set point for an adjustable time period the pump will be locked out until

manually reset.

If the pressure continues to rise to the high pressure set point for an adjustable time the pump will be locked

out until manually reset

If a low level float switch is connected & closes this input the pump will be shutdown until the level rises to

reset the float switch & automatically restart the pump

5.2 Manual/Off/Auto Selector Switches

Each pump has a Manual/Off/Auto selector switch. Each function of the switch is selected by touching on the

appropriate button on the JAZZ facia.

ManualTouching the MAN button will turn the pump on continuously

Off Touching the OFF button will turn the pump off.

Auto Touching the AUTO button will select the pump on automatic & is then controlled via the set

points within the JAZZ HMIPLC

5.3 Duty Selector (P1 / AUTO / P2) Switch

The panel has a Pump 1/Auto/ Pump2 selector switch. Each function of the switch is selected by touching on

the appropriate button on the JAZZ facia.

P1 Touching the P1 button will select Pump No1 to be duty & Pump No2 to be standby

continuously

Auto Touching the AUTO button will allow the pumps to automatically alternate.

P2 Touching the P2 button will select Pump No2 to be duty & Pump No1 to be standby

continuously

9

6 Trouble Shooting

Condition

Do This

1. Unit does not power up.

Check that power supply is on to panel and isolator

is on.

Check that control circuit breaker is on.

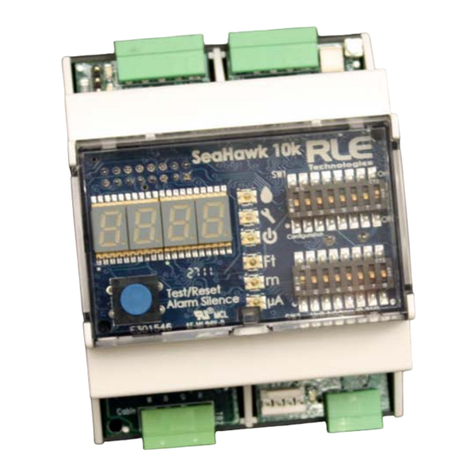

2. PLC Controller does not power up but

power is on.

Check that 24VDC power supply is operating, &

power supply plug on PLC controller is fully inserted.

3. Pump does not run but Starter is operating.

Check that all pump circuit breakers are on

4. Pump Fail displayed on screen.

Reset pump overload by pressing overload reset

button on to of overload. If problem continues call for

service

5. System Produces a Low Pressure shutdown.

Press the reset button & allow system to re-

pressurize. If problem continues call for service.

6. System Produces a High Pressure shutdown.

Press the reset button & allow system to re-

pressurize. If problem continues call for service.

7. Pressure displaying a negative value.

Pressure transducer has open circuit 4-20mA loop

or is faulty. Check pressure transducer cabling

connections, replace transducer with the same unit

or call for service

10

7 Controller settings sheet

Parameter

Description

Factory settings

User Setting

Low pressure

Shutdown

Pressure at which pumps are

shutdown for low discharge pressure

100kPa

Low pressure Timer

Time delay before pump shuts down

5sec

High pressure

Shutdown

Pressure at which pumps are

shutdown for high discharge pressure

600kPa

High pressure Timer

Time delay before pump shuts down

5sec

Duty Pump on

Duty Pump start set point

400kPa

Duty Pump off

Duty Pump stop set point

500kPa

Standby Pump on

Standby Pump Start set Point

350kpa

Standby Pump off

Standby Pump Stop Set Point

500kpa

Sensor calibration

Sensor 100% (20mA) Pressure

1000kpa

Litres per second Pump

No1

Pump No1 output in litre per second

for total flow calculation

4l/s

Litres per second Pump

No2

Pump No2 output in litre per second

for total flow calculation

4l/s

Irrigation Control

Irrigation control (1) or pressure only

control (0)

0

11

9.0 Warranty Statement

The Products manufactured by Inca Control Pty Ltd is guaranteed against faulty workmanship for a period of 12months

from the date of delivery.

Our obligation assumed under this guarantee is limited to the replacement of parts which, by our examination are

proved to be defective & have not been misused, carelessly handled, defaced or damaged. This guarantee is VOID

where the purchaser has modified or repairs have been made or attempted by anyone except an authorised

representative of Inca Control Pty Ltd.

Products for attention under guarantee (unless otherwise agreed) must be returned to the factory freight paid and, if

accepted for free repair, will be returned to the customers address in Australia free of charge.

Equipment supplied by Inca Control Pty Ltd, but manufactured by others is covered by their manufacturers warranty

only.

When returning the product for service or repair, a full description of the fault must be given and the mode of operation

used when the product failed.

In addition to the above, equipment manufactured, installed & commissioned by Inca Control Pty Ltd, within the Sydney

Metropolitan Area, includes onsite replacement.

In any event Inca Control Pty Ltd has no other obligation or liability beyond replacement or repair of this product.

NOTES:

Table of contents