Inception Machines ARCMILL User manual

Assembly Instruction

Guide

03/06/2019 Version 1.3

Part Number Descripon Quanty

S1 40x40 Cross Beam 2

S2 40x40 1N Cross Beam 1

S3 40x80 Y-Axis Beam w/linear rail assembly 2

S4 40x120 Gantry Beam w/linear rail assembly 1

S5 4080 End Plate Standard 2

S6 4080 End Plate Reverse 2

S7 Gantry Upright Plate Le1

S8 Gantry Upright Plate Right 1

S9 Z-Axis Rear Rail Mounng Plate 1

S10 Z-Axis Sffening Brace 2

S11 Spindle Mounng Plate 1

S12 Z-Axis Lead Screw Mounng Plate 1

S13 Y-Axis Lower Cable Chain Mount (fied with DC power enclosure) 1

S14 Y-Axis Lower Cable Chain Rest 3

S15 Y-Axis Rail Cover Le1

S16 Y-Axis Rail Cover Right 1

S17 Gantry Top Dust Cover 1

S18 Gantry Lower Dust Cover 1

S19 Gantry Side Skirt 2

S20 Y-Axis Motor Cover 2

S21 Dewalt Spindle Mount 2

S22 MDF Wasteboard (half) 2

T1 Z-Axis MGN15H 250mm Linear Rail Assembly 2

T2 Z-Axis Lower Bearing Block 1

T3 HTD3M 15 Tooth Timing Pulley 3

T4 HTD3m 15mm Wide Timing Belt Set (823mm x2) (830mm x1) 1

T5 HTD3M Belt End Clamp w/nuts and set screws installed 6

T6 9mm 150-GT2 Belt 1

T7 GT2 20T 9mm 6.35mm Bore Pulley 1

T8 Z-Axis leadscrew assembly (nut, FK06 bearing, gt2 pulley) 1

E1 XY Axis Limit Switch PCB Assembly Standard 2

E2 XY Axis Limit Switch PCB Assembly Reverse 3

E3 XY Axis Limit Switch PCB Assembly Standard Angled Socket 1

E4 Controller Assembly (w/enclosure, base plate, m3x8 buon head, F2F spacers, end plates, fan) 1

E5 USB Cable 1

E6 Nema 23 Stepper Motor X 1

E7 Nema 23 Stepper Motor Z 1

E8 Cable Conduit Set (980mm x2) (700mm x1) 1

E9 Cable Carrier Mount Open 6

E10 Cable Carrier Mount Standard 3

E11 Gantry Conduit Hook 1

E12 Z-Axis Microswitch Cable Retaining Clip 2

E13 Cable Tie Mount Base 3

E14 Power Supply 1

E15 Power Supply Mains Lead 1

E16 Microswitch Cable X-Axis 1

E17 Microswitch Cable Y-Axis 1

E18 Microswitch Cable Z-Axis 1

E19 Nema 23 Stepper Motor Y1 1

E20 Nema 23 Stepper Motor Y2 1

ARCMILL Kit Contents

1

Part Number Descripon Quanty

F1 M3x12mm Cap Head Screw (40 screws used to install rails) 107

F2 M3x30mm Cap Head Screw 10

F3 M3x10mm Countersunk Screw 12

F4 M3x8mm Cap Head Screw 36

F5 M3x6mm Socket Buon Head Flange Screw 6

F6 M3 Penny Washer 2

F9 M3x12mm Buon Head Screw 4

F10 M4x12mm Set Screw 2

F11 M4x20mm Set Screw 4

F12 M4x8mm Countersunk Screw 7

F13 M4 Full Nut 8

F14 M4x35mm Set Screw 2

F15 M5x25mm Cap Head Screw 4

F16 M5x35mm Cap Head Screw 4

F17 M5x16mm Cap Head Screw 14

F18 M6x16mm Cap Head Screw 16

F19 M6x10mm Cap Head Screw 4

F20 M6x55mm Cap Head Screw 2

F21 M8x20mm Buon Head Screw 6

F22 M8x25mm Countersunk Screw 14

F23 HNTT6-3 Misumi M3 T-Nut Pre Inseron (40 used to install rails) 38

F24 HNTT6-6 Misumi M6 T-Nut Pre Inseron (-1 assembly error) 13

F25 M6x12mm Pronged T-Nut 64

F26 M3x10mm Nylon Screw 4

F28 Y-Axis M5x10mm Spacers 8

F29 Nema 23 Idler Bearing Block Assembly (bearings, shims, screws fied) 2

F30 X-Axis Motor Mount Bearing Spacer (2x bearings, circlips fied) 4

F31 XYZ Axis Limit Switch PCB Spacer 6

F32 Z-Axis Microswitch Striker 1

F33 3x7x20mm Hollow Spacer 4

F34 M5x10mm Set Screw

A1 Extrusion Alignment Jig 1

A2 Cross Beam Spacer 1

A3 Cable Ties 10

A4 1mm Spindle Mount Spacer 2

Tools Required

ARCMILL Kit Contents

- 1.5mm hex key

- 2.0mm hex key

- 2.5mm hex key

- 3.0mm hex key

- 4.0mm hex key

- 5.0mm hex key

- 7.0mm spanner

- Small flat blade screwdriver

2

Base Frame Assembly

3

Step 1: Cross Beam Screws

Step 2: Cross Beam Wasteboard Nuts

S1

S2

F21

S1 (x2)

S2 (x1)

F21 (x3)

Insert (F21) screws into end holes in (S1) and (S2) beams

approximately 6mm from fully tight

Insert 4x (F24) T-nuts into bottom slot of each cross beam

F24

F24 (x12)

4

Step 3a: Cross Beam Install

Step 3b: Cross Beam Install Positions

S3

S3 (x2)

Start with Y-Axis beams (S3) inverted slide all cross beams into

upper slot of the Y-Axis beams

Align cross beams with side access holes in (S3) Y-Axis beams

5

Step 4: Front Cross Beam Tightening

Step 5: Middle Cross Beam Position

S3

Position front cross beam (S2) flush with front of Y-axis beam (S3),

while applying upward pressure against (A1) tighten end screw

While applying upward pressure on cross beam (S1) tighten end

screw through access hole, repeat process at remaining 3 positions

A2 (x1)

S2

A2

A1

S3 (x1)

S2 (x1)

A1 (x1)

Use (A1) jig at all 6

cross beam

positions

A1 (x1)

A1

6

Step 6: Cable Carrier Nuts

Step 7: Cable Carrier Mounting Brackets

Slide 4x (F23) T-nuts into upper slot of each Y-Axis beam (S3)

Position (S14) approximately 25mm/1 inch away from middle cross

beam, (S13) 10mm from end of beam, screw in place with (F1)

S14 (x1)

F23

S13

F23 (x8)

S3

S14

F1

S13 (x1)

F1 (x4)

7

Step 8: Side 2 Cable Chain Mounting Brackets

Step 9: Y-Axis Dust Covers Preparation

Partially screw in (F1) screws though (S15) cover into (F23) T-nuts,

repeat for opposite cover (S16)

S16 (x1)

S15

F1 (x8)

S14

F1

F15 (x1)

F1 (x5)

S14 (x2)

Position (S14) approximately 25mm/1 inch away from middle cross

beam, (Rear S14) 10mm from end of beam, screw in place with (F1)

F23

F1

F23 (x5)

8

Step 10: Y-Axis Dust Cover Install

Step 11: Belt Tensioning Clamps

Slide on (T5) belt tensioning clamp into Base frame top slot, set

screw holes facing inwards. Repeat for all 4 corners.

T5 (x4)

T5

Turn over base frame, slide both Y-Axis dust covers into the top

slot of the Y-Axis beams, align larger notch to front (circled)

Left Right

9

Step 12: Foot End Plates

Step 13: Belt Tensioning Screw

Using (F2) belt tensioning screw partially tighten in front end, fully

tighten rear belt clamps

F2 (x4)

S5

Screw on 4 end plates (S5 and S6) into Y-Axis beams using (F22)

screws. Tip: use foam packaging block to jack up frame

F22

F22 (x8)

S6 (x2)

S5 (x2)

F2

S6

S5

S6

10

Step 14: Wasteboard Mounting

Step 15: Cable Carrier Mounts

Attach (E9) open cable carrier mount to lower brackets using (F12)

countersunk screws

F12 (x2)

Inset all (F25) wasteboard T-nuts prior to mounting to base. Screw

wasteboards (S22) down to cross beams using (F18) screws

F18

S22 (x2)

F18 (x12)

F12

S22

E9

E9 (x2)

11

Step 16: Complete Base Assembly

Set completed base assembly aside while assembling remaining

parts

Step 17: Belt Clamp Adjustment

Attach (E9) open cable carrier mount to lower brackets using (F12)

countersunk screws

T5 (x4)

T5

12

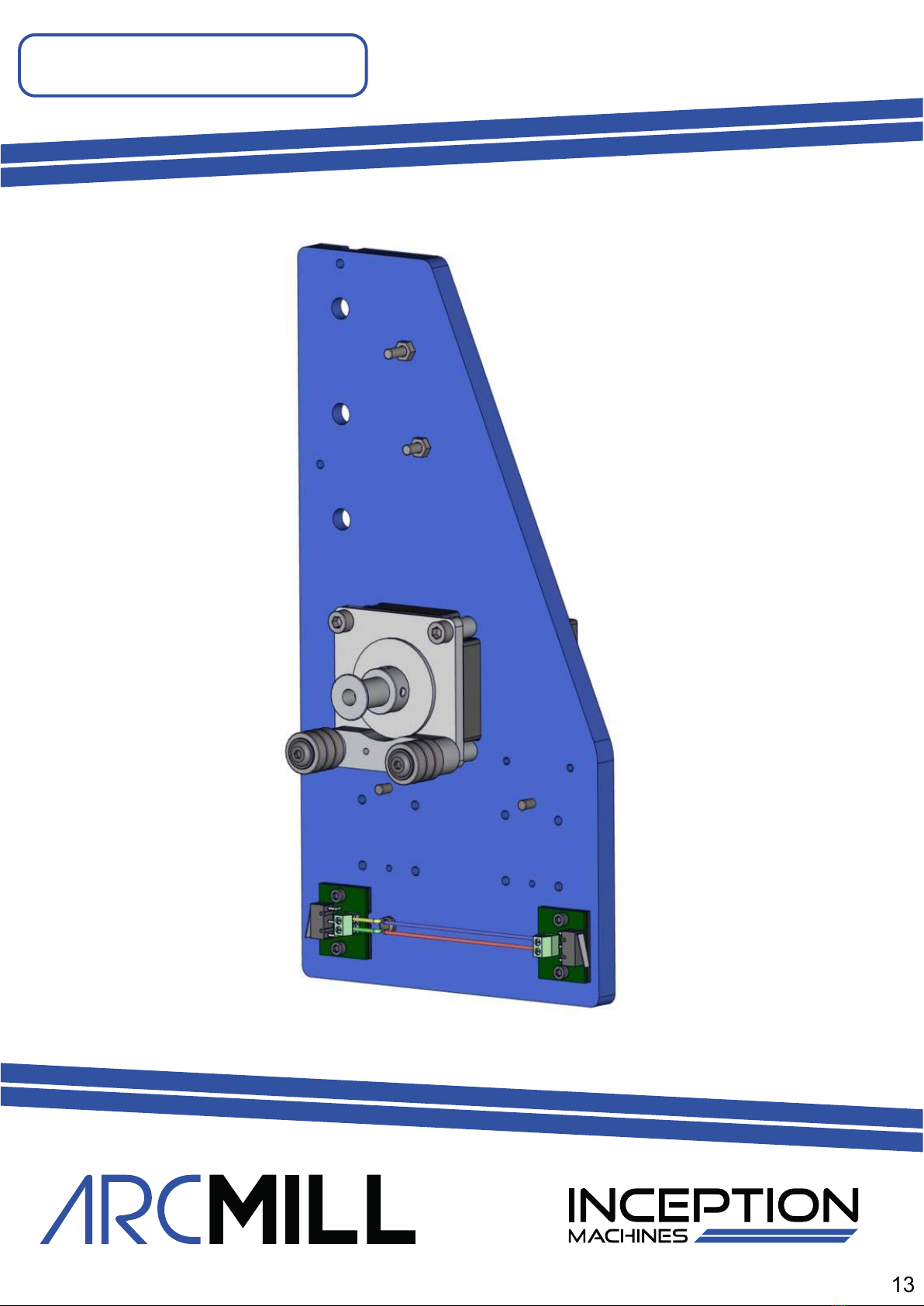

Gantry Upright Assembly

13

Step 1: Stepper Motor Install

Step 2: Stepper Motor and Bearing Block Mounting

S8

E19

S8 (x1)

E19 (x1)

Pass (E19) Y-Axis Motor and cable through portal in right hand

gantry plate (S8), orienting cable with rear notch

Insert spacers (F28) behind stepper motor flange, bolt though top

holes using (F15). Attach (F29) through bottom holes with (F16)

F28

F29 (x1)

F28 (x4)

F16 (x2)

F16

F15

F29

F15 (x2)

14

Step 3: Pulley Install

Step 4: Limit Switch Mounting

T3

T3 (x1)

Slide (T3) pulley onto motor shaft, finger tighten set screws the

position of the pulley can be adjusted later

Mount Limit Switch (E1 and E2) to gantry plate (S8 only) using (F4)

screws, place (F31) behind limit switches

F4

F31 (x2)

F4 (x4)

E2 (x1)

E1

F31

E2

E1 (x1)

15

Step 5: Limit Switch Wiring

Step 6: Limit Switch Striker

E17

E17 (x1)

Pass (E17) limit switch cable through hole in gantry plate, connect

up coloured wires to limit switch terminal blocks

Wind (F11) screws until flush with back side of gantry plate, attach

(F13) nuts, leave loose for fine adjustment later

F13 (x2)

F11 (x2)

F13

F11

Repeat steps 1,2,3,6 for

opposite gantry upright (S9)

and (E20) motor

16

Gantry Beam Assembly

17

Step 1: Gantry Beam Assembly Start Point

Step 2: Lower Dust Cover Preparation

S4

S4 (x1)

Partially screw in (F1) screws though (S18) cover into (F23) T-nuts

F23 (x5)

S18 (x1)

F1

F23

S18

F1 (x5)

18

Step 3: Top Dust Cover Preparation

Step 4: Dust Cover Mounting

Slide both dust covers (S17 and S18) onto gantry beam, ensure

flush with end of beam

S18 (x1)

S17 (x1)

S17

F23 (x5)

S17 (x1)

F1 (x5)

Partially screw in (F1) screws though (S17) cover into (F23) T-nuts

F1

F23

S17

S18

19

Table of contents

Popular Power Tools manuals by other brands

Metabo

Metabo MT 18 LTX Original instructions

Raider

Raider RDP-SPSH20 solo user manual

Makita

Makita DHR242ZJW instruction manual

Sparky Group

Sparky Group K 306E Original instructions

One Stop Gardens

One Stop Gardens 94593 Assembly and operating instructions

SCHUNK

SCHUNK VERO-S WDM-5X Assembly and operating manual