Incon task sentinel TS-1001 Operating instructions

PageFC - 1

Part Number: 000-1053, Rev. C

Copyright

©

January 2009

Setup Programming

Guide

Tank Sentinel

®

(TS - 1001, 2001, 504, 508 & 750)

Automatic Tank Gauge

/

Leak Detection

System

Tank Sentinel Setup Programming Guide

NOTICE

INCON has strived to produce the finest possible manual for you, and to ensure

that the information contained in it is complete and accurate. However, INCON

makes no expressed or implied warranty with regard to its contents. INCON

assumes no liability for errors or omissions, or for any damages, direct or

consequential, that result from the use of this document or the equipment which

it describes.

This document contains proprietary information and is protected by copyright. All

rights are reserved. No part of this document may be reproduced in any form

without the prior written consent of INCON.

INCON reserves the right to change this document at any time without notice.

Need Help ? Contact INCON at:

INCON

INTELLIGENT CONTROLS, INC.

PO Box 638

SACO ME 04072

Office Hours: 8 a.m. to 5 p.m. EST Monday through Friday

Sales - Technical Service -

Phone: (800) 872-3455 Phone: (800) 984-6266

Fax: (207) 283-0158 Fax: (207) 282-9002

E-mail:

E-mail:

Visit our Website at: After Hours Cell Phone:

www.incon.com

(207) 229-4437

INCON is a wholly owned subsidiary of Franklin Electric and is a member of the

Franklin Fueling Systems Group

Tank Sentinel ®SCALD®Brite BriteBox®Britebus®BriteSensors®

and INCON ®are registered trademarks of Intelligent Controls, Inc.

System Sentinel™ and System Sentinel ™are trademarks of

Intelligent Controls, Inc.

Copyrighted 1997, 1998, 2003 Intelligent Controls, Inc. All rights reserved.

—❖—

Table of Contents Page TOC - 1

TOC

Table of Contents

P Preface................................................................................................... P - i

Graphic Symbol Conventions ..................................................................................... P - i

Page Numbering Convention................................................................................. P - i

Page Layout Convention ....................................................................................... P - i

Before You Begin – Read This ..................................................................................... P - ii

– Site Information Required ............................................................................. P - ii

– Other Sources of Information ....................................................................... P - ii

Scope of This Manual ................................................................................................. P - iii

Menu Conventions ......................................................................................... P - iii

Parent Menus ................................................................................................. P - iii

Key Action .................................................................................................................. P - iii

Alpha-Numeric Input ............................................................................................ P - iv

Programming Alarms, Limits, or Inputs to Output Groups.......................................... P - v

Programming Output Devices: .................................................................................. P - vi

Example Applications: ......................................................................................... P - vi

Programming I/O Module Operation .............................................................. P - vii

Interfacing TS-LLD to Tank Gauge ............................................................................ P - vii

Leaving (Exit) Setup Programming .......................................................................... P - viii

After Programming is Done ...................................................................................... P - viii

Warranty Reminder .................................................................................................. P - viii

1 SystemSetupProgramming................................................................ 1 - 1

System Menu .............................................................................................................. 1 - 1

2 Tanks Setup Programming .................................................................. 2 - 1

Tanks Menu ................................................................................................................. 2 - 1

Tanks – TANK ALARM N Menu................................................................................... 2 - 3

Tanks – SPECIAL TANK N Menu................................................................................ 2 - 5

3 LinesSetupProgramming ................................................................... 3 - 1

Lines Menu .................................................................................................................. 3 - 1

Line Data Menu ........................................................................................................... 3 - 2

4 ProbesSetup Programming ................................................................ 4 - 1

Probes Menu ............................................................................................................... 4 - 1

Probes – PRESSURE Probe Data Menu ................................................................... 4 - 3

Probes – SPECIAL Menu ........................................................................................... 4 - 4

TOC

Page TOC - 2 Tank Sentinel Setup Programming Guide

5 ProductsSetupProgramming ............................................................. 5 - 1

Products Menu ............................................................................................................ 5 - 1

SPECIAL PRODUCTS Menu ..................................................................................... 5 - 2

6 ManifoldsSetupProgramming............................................................ 6 - 1

Manifolds Menu ........................................................................................................... 6 - 1

Manifolds ALARMS Menu ........................................................................................... 6 - 2

7 ReconciliationSETUP PROGRAMMING.............................................. 7 - 1

Reconciliation Menu .................................................................................................... 7 - 1

8 DispenserInterfaceModule (DIM)SETUP PROGRAMMING .............. 8 - 1

DIM Menu .................................................................................................................... 8 - 1

9 ReportsSetupProgramming............................................................... 9 - 1

Reports Menu ............................................................................................................. 9 - 1

Reports Schedule Menu ............................................................................................. 9 - 2

Tank Inventory Detail Report: .................................................................... 9 - 2

Tank Inventory Summary Report: ............................................................. 9 - 2

Product Inventory Detail Report: ............................................................... 9 - 2

Product Inventory Summary Report:......................................................... 9 - 3

Product Usage Detail Report: ................................................................... 9 - 3

Product Usage Summary Report: ............................................................. 9 - 3

Delivery Detail Report: .............................................................................. 9 - 4

Delivery Summary Report: ........................................................................ 9 - 4

Active Alarm Report: ................................................................................. 9 - 5

Cleared Alarm Report:............................................................................... 9 - 5

Alarm History Report:................................................................................ 9 - 5

SCALD Leak Test: Report ......................................................................... 9 - 6

Sensor Status Report ................................................................................ 9 - 6

Vapor Sensor: ............................................................................................ 9 - 6

Regulatory Report: .................................................................................... 9 - 7

Line Compliance Report: ........................................................................... 9 - 7

Line Diagnostics Report: ........................................................................... 9 - 7

Line Test History Report: ........................................................................... 9 - 8

Line Test Report:....................................................................................... 9 - 8

Shift Reconciliation Report: ....................................................................... 9 - 8

Daily Reconciliation Report: ...................................................................... 9 - 9

Monthly Reconciliation Report:.................................................................. 9 - 9

Shift Reconciliation History Report: .......................................................... 9 - 9

Daily Reconciliation History Report:........................................................ 9 - 10

Shift Sales Report: .................................................................................. 9 - 10

Daily Sales Report: ................................................................................. 9 - 10

Table of Contents Page TOC - 3

TOC

Monthly Sales Report: ............................................................................. 9 - 11

Shift History Report: ................................................................................ 9 - 11

Daily History Report: ............................................................................... 9 - 11

10 LeakTest Setup Programming.......................................................... 10 - 1

Leak Test Menu (Static Tank) .................................................................................... 10 - 1

Tank Leak Test Menu................................................................................................. 10 - 2

11 SCALD ® Tank LeakTest Setup Programming.................................. 11 - 1

SCALD Tank Leak Test Menu.....................................................................................11 - 1

SCALD (tank leak) Test Menu ....................................................................................11 - 2

12 LineTests SetupProgramming .......................................................... 12 - 1

LN (Line) Tests Menu .................................................................................................12 - 1

Line Leak Test Requirements & Notes: ..........................................................12 - 2

13 Clock / Calendar Setup Programming................................................ 13 - 1

Clock / Calendar Menu...............................................................................................13 - 1

14 AnnunciatorSetup Programming ...................................................... 14 - 1

Annunciator Menu (Console Alarm Horn) ..................................................................14 - 1

Annunciator Time-out................................................................................14 - 1

Modulated Annunciator Output Group (alarm assignment)....................14 - 2

Solid Annunciator Output Group (alarm assignment) ............................14 - 2

15 RelaysSetupProgramming................................................................ 15 - 1

Relay Menu ................................................................................................................15 - 1

Relay 1 Output Group (alarm assignment) ............................................ 15 - 2

TEST Relay 1 ...........................................................................................15 - 2

Relay 2 Output Group (alarm assignment) ............................................ 15 - 3

TEST Relay 2 ...........................................................................................15 - 3

16 TS-ROM Relay Output Module Setup Programming ......................... 16 - 1

TS-ROM Menu ...........................................................................................................16 - 1

Grace Period ..................................................................................................16 - 1

TS-ROM Channel 1 Output Group (alarm assignment) .....................16 - 2

TS-ROM Channel 2 Output Group (alarm assignment) .....................16 - 2

TS-ROM Channel 3 Output Group (alarm assignment) .....................16 - 2

TS-ROM Channel 4 Output Group (alarm assignment) .....................16 - 3

TS-ROM Channel 5 Output Group (alarm assignment) .....................16 - 3

TOC

Page TOC - 4 Tank Sentinel Setup Programming Guide

TS-ROM Channel 6 Output Group (alarm assignment) .....................16 - 3

TS-ROM Channel 7 Output Group (alarm assignment) .....................16 - 3

TS-ROM Channel 8 Output Group (alarm assignment) .....................16 - 4

17 Sensors(Leak Detection)SetupProgramming ................................. 17 - 1

Sensors Menu ............................................................................................................17 - 1

Naming Sensors ....................................................................................... 17 - 1

Leak Detection Sensors ...........................................................................17 - 3

Standard Sensors (below... all Alarms = STD N) .....................................17 - 3

BriteSensors & alarms (all 3 wire – below)...............................................17 - 3

18 Auxiliary Inputs Setup Programming................................................. 18 - 1

Aux. Input Menu .........................................................................................................18 - 1

19 Cathodic Protection Monitor (CPM) SETUP PROGRAMMING .......... 19 - 1

Remember:.................................................................................................................19 - 1

CPM Menu Notes: ...................................................................................................... 19 - 1

20 I / O (Input/Output) Module Setup Programming.............................. 20 - 1

I O Module Menu ........................................................................................................20 - 1

Channel N Output Groups – Output Module Alarm Assignments ..............................20 - 4

21 CommunicationPorts Setup Programming....................................... 21 - 1

Comm Ports Menu .....................................................................................................21 - 1

COMM PORT 2 Menu................................................................................................21 - 3

DATA MODE Menu .....................................................................................................21 - 5

FAX MODE Menu ......................................................................................................21 - 8

22 ComplianceVia Sensors(CVS) SETUP PROGRAMMING.................. 22 - 1

Remember:.................................................................................................................22 - 1

Character input / editing: ............................................................................................22 - 1

Before Programming: .................................................................................................22 - 1

CVS Tanks Menu ............................................................................................ 22 - 2

CVS Lines Menu ............................................................................................22 - 3

23 UpgradeMenu ..................................................................................... 23 - 1

TS-UPGRADE ...........................................................................................................23 - 1

Upgrade Menu ................................................................................................23 - 2

Table of Contents Page TOC - 5

TOC

24 LanguageSelectionMenu................................................................... 24 - 1

Language Selection Menu ..........................................................................................24 - 1

Language Selection Notes ............................................................................. 24 - 1

25 Data Log Menu .................................................................................... 25 - 1

Data Log Menu ...........................................................................................................25 - 1

Data Logging Notes ........................................................................................25 - 1

26 DisplayMenu ....................................................................................... 26 - 1

Display Menu .............................................................................................................26 - 1

Display Notes .................................................................................................26 - 1

27 Problem Solving (Alarms & Errors) ................................................... 27 - 1

Problem Solving .........................................................................................................27 - 1

Outputs DON’T Turn On When Expected.......................................................27 - 7

A AppendixA StandardTanks................................................................ A - 1

B AppendixBStandard Products .......................................................... B - 1

C AppendixCTypicalTankLeakTestTimes........................................... C - 1

D AppendixDPart Number Codes......................................................... D - 1

Tank Sentinel Part Numbering .................................................................................... D - 1

Example Part Numbers .................................................................................. D - 1

Part Number Codes & Meaning...................................................................... D - 2

CFF Customer Feedback Form........................................................... CFF - 1

FCC Information & Requirements ........................................................ FCC - 1

Overall Information & Requirements ...................................................................... FCC - 1

INDUSTRY CANADA Information & Requirements ............................................ FCC - 2

CP-01 Issue 8, Part I, Section 14.1 ............................................................ FCC - 2

CP-01, Issue 8, Part I, Section 14.2 ........................................................... FCC - 2

TOC

Page TOC - 6 Tank Sentinel Setup Programming Guide

Table of FIGURES andTABLES

Page Layout Convention ................................................................................. P - i

Figure 2 - 1 Typical Tank Limits....................................................................... 2 - 3

TABLE 4.1 SPECIAL PROBE RTD POSITIONS .......................................... 4 - 5

TABLE 9.1 TYPICAL REPORT SCHEDULE ................................................. 9 - 1

TABLE 9.2 24 HOUR TIME INPUT FORMAT .............................................. 9 - 1

TABLE 10.1 TYPICAL TEST SCHEDULE ................................................. 10 - 3

TABLE 10.2 24 HOUR TIME INPUT FORMAT .......................................... 10 - 3

TABLE 12.1 24 HOUR TIME INPUT FORMAT ...........................................12 - 2

TABLE 13.1 24 HOUR TIME INPUT FORMAT ...........................................13 - 2

WORKSHEET 1-1 – OUTPUT GROUPS - SYSTEM LIMITS ....................... 1 - 6

WORKSHEET 2-1 – OUTPUT GROUPS - TANKS 1 THRU 4 ...................... 2 - 8

WORKSHEET 2-2 – OUTPUT GROUPS - TANKS 5 THRU 8 ...................... 2 - 9

WORKSHEET 6-1 – OUTPUT GROUPS - MANIFOLDS 1 THRU 4 ............. 6 - 4

WORKSHEET 10-1 – OUTPUT GROUPS - TANK LEAK TESTS .............. 10 - 5

WORKSHEET 12-1 – OUTPUT GROUPS - LINE LEAK TESTS .................12 - 5

WORKSHEET 17-1 – OUTPUT GROUPS - SENSORS 1 TO 8 ..................17 - 4

WORKSHEET 17-2 – OUTPUT GROUPS - SENSORS 9 TO 16 ................17 - 5

WORKSHEET 17-3 – OUTPUT GROUPS - SENSORS 17 TO 24 ..............17 - 6

WORKSHEET 17-4 – OUTPUT GROUPS - SENSORS 25 TO 32 ..............17 - 7

WORKSHEET 17-5 – OUTPUT GROUPS - SENSORS 33 TO 40 ..............17 - 8

WORKSHEET 18-1 – OUTPUT GROUPS - AUX. INPUTS 1 AND 2...........18 - 3

WORKSHEET 19-1 – OUTPUT GROUPS - LINE LEAK TESTS .................19 - 3

WORKSHEET 20-1 – OUTPUT GROUPS - EXTERNAL INPUTS ..............20 - 6

WORKSHEET 20-2 – OUTPUT GROUPS - LINE INPUTS ......................... 20 - 7

—❖—

PREFACE Page P - i

P

Contents:

Graphic Symbol, Page #

& Layout Conventions

Before you Begin

– Site Information Required

– Other Sources of Info.

Page Number

Chapter Name

(

ODD

NUMBERED

PAGES

)

Chapter Number

Manual Name

(

EVEN

NUMBERED

PAGES

)

Page Number

Chapter Number

Scope of This Manual

Menu Conventions, Key

Action, Alpha-Numeric Input

Programming Alarm, Limits,

or Inputs to Output Groups

Programming Output Devices

Chapter Number &

Name (

TOP

LEFT

FIRST

PAGE

)

Chapter Contents

NOTE

☞

Programming I/O Module

Operation

Interfacing TS-LLD to Tank

Gauge

Leaving (Exit) Setup

Programming

P PREFACE

Graphic Symbol Conventions

Importantinformation, tips, and hints are highlightedby the NOTE graphic.

CAUTION

messages are highlighted by the

CAUTION

graphic and contain

instructions that must be followed to avoid faulty equipment operation, or hazards.

Ifignored, equipmentdamage or personnelinjury

could

result!

WARNING

messages are highlighted by the

WARNING

graphic and contain

instructionsthat must be followed to avoid faultyequipment operation,or anexplosion or

shock hazards. If ignored, severe injury or death

may

result !

DANGER

messagesarehighlightedbythe

DANGER

graphicandcontaininstructions

thatmustbefollowedtoavoidan explosionorelectricalshock hazard.If ignored,severe

injury or death

will

result !

—❖—EndofChapter symbol

Page Numbering Convention – Example:

Page 4 - 1 = Chapter 4 page 1

Page Layout Convention – Example:

P

Page P - ii Tank Sentinel Setup Programming Guide

BeforeYouBegin–ReadThis

CAUTION

Leakingundergroundstoragetanks ( USTs )and fuellinescause serious

environmentalandhealthhazards. TheTankSentinel

®

systemisdesignedtodetectleaks

intanks bytank tightness/ leaktesting withliquid levelprobes, and/orwith leakdetection

sensors. You must follow the instructions in this manual carefully to ensure that the

system is programmed properly and is effective in detecting leaks.

–SiteInformationRequired

• Site Plan? — showing the location, size, and model #s of all tanks, probes and sensors

•DispenserManufacturerDocumentation?

• Pump Manufacturer Documentation? — Type, Model #s, and suction inlet

distance off

the bottom

of each tank (to determine the lowest product level and highest water level)

• Pump Control Required ? — enable / disable pumping... TS-IEM Output modules (for

TS-2001/508consoles only),or aTS-ROM1 BriteBox

•Remote Device Control Required? — useTS-IEM (see above), or a TS-ROM2BriteBox

• Remote Tank Overfill Alarm / Acknowledge Installed ? — (TS-RA1 or TS-RA2 / TS-RK)

Type, Model, Size and Manufacturer of each Tank

• Tank Manufacturers’ Tank Chart / Strapping Table (s)? — for each tank or the diameter

and length of each tank

• Are any tanks identical ? — (tanks, probe data, and alarm limits can be copied)

•Standard ProbeData? — (model number, shaftlength, gradient, serial number)

• Special Probe Data? — (ie RTD / Temperature sensor locations)

• Tank # & Probe # — model number assignments and input channels for each tank

• Leak Detection Sensors? — installed in or near or associated with each tank including

inputchannelnumberassignments

• Product? — in each tank (API specific gravity) and the type & number of float(s) / probe

•State andLocal Regulations?— (testingrequirements, reportingrequirements, and

hotlinenumbers, and otherinformation that you and/or the customer will need)

– Other Sources of Information

Use the TOC (Table of Contents) to find information within this manual and see the

following INCON documentation:

•

Installation Guide

•

Operator’s Guide

•

TroubleShooting Guide

•

Leak Detection Sensor – Installation Guides (one per type / family of sensor)

•

Tech Service Bulletins •Application Bulletins

•

ApplicationNotes

PREFACE Page P - iii

P

ScopeofThisManual

Thismanual shows the setup-programmingof Tank Sentinel system. Each Chapter is

dedicatedto a specific parent menu (see ParentMenus below).

Menu Conventions

The menu structure in this manual is shown in an indented format:

PARENT MENUs are above and to the left of sub-menus and

SUB-MENUs are below and to the right of parent menus.

Default VALUES, SETPOINTS, & LIMITS are shown first and in ITALIC text.

Parent Menus

UPPER ROW – DISPLAY TEXT

LOWER ROW – DISPLAY TEXT

MENU keys M1 thru M4

Numbers within boxes are

Chapter #s. Some parent menus, or

sub-menus will not appear unless:

*

a related setup menu / feature is selected

**

the accessory (hardware) is installed and the

system is powered up

***

the appropriate options have been purchased

Key Action

MENU keys

– use (press) to:

•

choose / display other menus or sub-menus

or exit SETUP mode

•

move the cursor left or right through a text

string (

M1

=

left,

M2

= right)

•

backspace over / delete a character in a text

string (

M4

backspaces from the right)

KEY PAD keys

– use (press):

•

ï

CANCEL

to cancel an input or to exit out

of a menu

•

▲

UP

or

DOWN

▼to display more menus

when (MORE) is shown, or other selections

from a sub-menu when (UP/DN) is shown

•

Use the

ENTER

key to accept the displayed

choice or value for storage into setup memory

SELECT MENU OPTION (MORE)

SETUP UPGRADE LANGUAGE DATALOG

M1 M2 M3 M4 NOTES

☞

SETUP MENU (MORE)

EXIT SYSTEM TANKS LINES

M1 M2 M3 M4

SETUP MENU (MORE)

PROBES PRODUCTS RECONCILE DIM

M1 M2 M3 M4

SETUP MENU (MORE)

REPORTS LK TESTS SCLD TEST LN TESTS

M1 M2 M3 M4

SETUP MENU (MORE)

CLK/CAL ANNUNC RELAYS SENSORS

M1 M2 M3 M4

SETUP MENU (MORE)

AUX INPUT CPM COM PORTS CVS

M1 M2 M3 M4

12* 3***

20

5* 6* 7

4*

9*** 10*** 11

8***

13 15*

12

16

14**

18

17** 19

21 22

P

Page P - iv Tank Sentinel Setup Programming Guide

KeyAction(C

ONTINUED

FROM

PREVIOUS

PAGE

...)

•

ACKSHIFT

key is used to change the preconditioned

input character type...

the display

shows either an

A...M

or the word NUMERIC when an alphanumeric or numericinput is

expected. Press the

ACKSHIFTkey N times

to change the current input character type

to another type (look at the upper right corner of display while doing this).

See the

Operator’s manual about using the ACKSHIFTkey to silence and acknowledge alarms,

andto start an outputgrace period (programmable length oftime).

Alpha-Numeric Input (example)

The example below is what you would see when

programmingSYSTEM ID... (press keys:

MENU M1 M2 M2 M1

) to display:

A...M means that the system is conditioned to

input the upper left letter of any key (A B C D

E F G H I J K L M)... see below:

Press

ACK SHIFT

key once again to display:

N...Z means that the system is conditioned to

input the upper left letter of any key (N O P Q R S T U V W X Y Z)

–conditions remain until changed– see below:

Press

ACK SHIFT

key once again to display:

NUMERIC means that the system is conditioned to input the lower character of

any key (numbers 1 2 3 4 5 6 7 8 9 0 . +/–or a SPACE)... see above.

COMMAND

(#3)

N

UMERIC

number or special character

(# 2 )

N...Z

(# 1 )

A...M

input a

letter

Press the

ACK SHIFT

key

N

times to DISPLAY the

input character type ( #__ )

then press the

Key

of choice.

Upper right

DISPLAY

shows the

input

selection

...shown

here

within

dashed

lines

Typical

Key

LOCATION LINE 1 A...M

INCON BACKSPACE

M1 M2 M3 M4

A

N

PRODUCT

1

LOCATION LINE 1 N...Z

A BACKSPACE

M1 M2 M3 M4

LOCATION LINE 1 NUMERIC

AN 0.1 BACKSPACE

M1 M2 M3 M4

NOTE

The shift

function will remain in the

current input character

mode (or position) until

the ACK SHIFT key is

pressed again

.

PREFACEPage P - v

P

Programming Alarms, Limits, or Inputs to Output Groups

TheTS-1001/504 / 2001/508 / 750 Tank Sentinels includes a powerfulsetup feature called

Output Groups

(OGs). Alarms, limits, and inputs (Aux. or

I/O

Module inputs) can be

assigned/programmedtooutputgroups(OUTGROUP orOG). Anoutputdevicewillturn

on or off when an alarm is active in any of its assigned output group(s). Up to 32 output

group(s)canbe assignedorprogrammed toanyoutput device...also seeProgramming

Output Devices.

The

standard

outputdevices are annunciators and relays. Other

outputdevices

can be

optionally

addedtothe system.Theseare

:

TS-ROM BriteBox

relays,

TS-CIMBriteBox

outputmodules

,andTS-IEMinternalexpansionPCBoard

outputmodules

—forTS-2001/

508consoles only.

Example:

TANK 1, ALARMS and the H LIM OG (high product level limit) menus:

The HIGH LIM (high product

level limit) has an associated H

LIM OG – high limit output

group near it.

In an 8 tank system

there are 8

H LIM OG s (one under

each tank menu).

Each limit, alarm or input can

be assigned to oneof the 34

Output Group choices —

GROUP A thru FF, or to ALL

output GROUPS, or to

NONE

( nooutput group =default )

.

Recordoutputgroup

assignmentsfor each alarm,

limit, or input in theprovided

OGWorksheets.

Example Output Group Assignment WORKSHEET

(partial)

HIGH PRODUCT OUTPUT GROUP 1 (UP/DN)

NONE

M1 M2 M3 M4

HIGH PRODUCT OUTPUT GROUP 1 (UP/DN)

GROUP A

M1 M2 M3 M4

HIGH PRODUCT OUTPUT GROUP 1 (UP/DN)

ALLGROUPS

M1 M2 M3 M4

NOTE

OG = OutputGroup- Out

p

ut Grou

p

Assi

g

nment WORKSHEETOut

p

ut Grou

p

choices -

Example - System:

NONE

= default setting (others are: GROUP A thru FF & ALL GROUPS)

NONE

LEAK OG ATank Leak turns on Modulated Annunciator, Relay 2 for external leak light A

THEFT OG TSentinel Mode Theft Limit (turns on external product theft light) B

SYSFL OG FSystem Fail - software or hardware failures - (activates solid annunciator) C

E

F

Output Devices:Modulated Annunciator, Solid Annunciator, Relay 1, Relay 2, I /O Output Module

Channel # 1 to # __ (record all OG Assignments in the vertical column)

TANK ALARM 1 (MORE)

COPY HIGH LIM H LIM OG HIGH HIGH

M1 M2 M3 M4

P

Page P - vi Tank Sentinel Setup Programming Guide

ProgrammingOutputDevices:

After assigning alarms and limits to output group(s), program the appropriate

output devices to respond to any or all output groups (OGs)

Example Applications:

Turn on external Tank Overfill Alarm & solid console annunciator

(when a high or high high product level –alarm limit is reached)

Program the

(above)

alarm limits for each tank. Assign the associated H LIM OG or HH

LIMOGoutputgroupstoonealarmgroupforeachtank

(ieGROUPO).

Programthesolid

annunciator (alarm horn) and relay 1

output devices

to react to any

GROUP O

alarm by

assignment...changeGROUP O–(dash) toa Y. The externalTS-RA2 orRA1 alarmunit

(wired to relay 1) will turn on / off with relay 1.

This way a high level condition in any tank will activate the solid annunciator and the

externalalarm connected to relay1.

To disable a STP & turn on the modulated console annunciator

(when a low low product or high water –alarm limit is reached)

Programthe

(above)

alarmlimits foreach tank.Assign theassociated LL LIMOG andW

LIM OG output groups toa

unique

alarmgroup

foreachtank

(ie GROUP P for TANK

1&GROUPSforTANK4)

. ProgramtheTS-ROMchannelrelays

outputdevice

(CHANNEL

N —OUT GRPS) to respond to a unique tank alarm

GROUP __

. The line power, that

activatestheSTP motorrelay,is wiredbetweenthe TS-ROMrelaycontacts. Whenthese

alarmsoccur, the uniqueoutput group activates the appropriate TS-ROM channel relay

whichinterrupts theSTP power anddisables dispensing.

Programthemodulatedannunciator(alarmhorn)

outputdevice

toactivateandreacttoany

alarm by assignment... change GROUP P Q R S –(dash) to a Y.

ExampleOutput Device –OUTPUT GROUP Assignments

(shown filled-in)

NOTE

☞

The 24

TH

group

(Group X) is shown

assigned Y

Output Device —OUTPUT GROUP Assignment

ABCDEFGHI JKLMNOPQRSTUVWXYZAABBCCDDEEFF

Y YYY YYYYY Y

OUTPUT GROUP GROUP

Y– – YYY– ––– – – – –YYYYY

– – – – Y– – – – – – – – X

132

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z AA BB CC DD EE FF

Press:

M1

to move the cursor left

ï

M2

to move the cursor right

ð

M4

to backspace (delete) one character to the left

ï

UP / DOWN

▲▼ to select (Yfor yes assigned, or

–

(dash) for no not assigned)

ENTER

to store the setup into the system memory

PREFACEPage P - vii

P

Standard and

Optional

Output Devices

NOTE

Programming

I/O

ModuleOperation

TheTS-CIM/ TS-IEMchannels* canfunctioneither asan inputor an outputmodule. The

modemenuoptionallowsselectionofthechanneloperation—thismustcorrespondtothe

type of module that is inserted into the channel. Input mode must be selected for input

modules,and output modemust beselected foroutput modules.

Referencethe Chapter

about

IOMODULE

setupprogramming.

Aux. Inputs are always inputs and cannot be changed because the input circuitry

is hard-wired.Reference the Chapter about

AUX INPUT

setup programming.

InterfacingTS-LLD toTank Gauge

In order to interface the INCON TS-LLD line leak detector(s) to the TS-1001/504 / 2001/

508 / TankSentinel consoles —

Use the

TS-LLD

interface terminals within the console(providingRS-485bidirectional

communication).ThefirstTS-LLDiswired tothetankgaugeand the othersareconnected

to each other (1 to 2, 2 to 3... ).

LLD

is available with Tank Sentinel software version #

1.10 and higher ( check options – Lmust be in the part number ).

StandardOutput Devices:

Modulated Annunciator

Solid Annunciator

Relay 1

Relay 2

Optional Output Devices:

TS-ROM Relay 1

TS-ROM Relay 2

TS-ROM Relay 3

TS-ROM Relay 4

TS-ROM Relay 5

TS-ROM Relay 6

TS-ROM Relay 7

TS-ROM Relay 8

Optional (TS-CIM / TS-IEM) Output Devices

:

I/O Module Output 1*

I/O Module Output 2*

I/O Module Output 3*

I/O Module Output 4*

I/O Module Output 5*

I/O Module Output 6*

I/O Module Output 7*

I/O Module Output 8*

I/O Module Output # 9* I/O Module Output # 10*

I/O Module Output # 11* I/O Module Output # 12*

I/O Module Output # 13* I/O Module Output # 14*

I/O Module Output # 15* I/O Module Output # 16*

I/O Module Output # 17* I/O Module Output # 18*

Note: The TS-2001 will list the

TS-CIM Output Modules as I/0

Module - Outputs # 17 through

#24 (if installed).

I/O Module Output # 19* I/O Module Output # 20*

I/O Module Output # 21* I/O Module Output # 22*

I/O Module Output # 23*

I/O Module Output # 24*

P

Page P - viii Tank Sentinel Setup Programming Guide

Leaving(Exit)SetupProgramming

There are two ways to leave the setup mode. These are:

1.) Use (press) the

CANCEL

key until the exit choice appears, then press the

M1

key to

exit the setup mode.

–or –

2.) Wait until the Tank Sentinel console

autoexits

.

Theunitwillautomaticallyleave/exitthesetupmode

( autoexit )

afterthreeorfourminutes

ofinactivity(ifno keyispressed). Thisfeature preventstheunitfrom beingleftinthe setup

modefor longperiods of time...

leaktestingandleakdetectionarenotactivewhilein

thesetupmode.

Whileviewingdatainthenormalrunmode,thedisplaywillalsorevert to thenormaldisplay

after shorter period of key inactivity (20 or 30 seconds).

AfterProgrammingisDone

After the system is custom-programmed and tested, printout or Fax a hard copy of the:

system setup report, and a setup report for each tank for your records. Please give a

copy of these reports to the customer for his records.

WarrantyReminder

Afterinstallation, make sure to sign the completed Warranty Registration form and

return it to INCON. This form validates the express warranty stated here !

—❖—

NOTE

☞

SETUP MENU (MORE)

EXIT

SYSTEM TANKS PROBES

M1 M2 M3 M4

SystemSetup Page 1 - 1

1

1 System SETUP PROGRAMMING

SystemMenu

H U

MENU

×Press this key and follow the

7highlighted sequence shown below

Contents:

System Menu

Worksheet 1-1 — System Output

Groups

See the Table of Contents to find topics in

this manual. See the Preface for general

information about this manual. See the

Installation, Operator’s, TroubleShooting

Guides and Application Notes for other

reference sources.

NOTE

☞

SELECT MENU OPTION (MORE)

SETUP

UPGRADE LANGUAGE DATALOG

M1 M2 M3 M4

SETUP MENU (MORE)

EXIT

SYSTEM

TANKS LINES

M1 M2 M3 M4

SYSTEM INFO (MORE)

PASSWORDS SYSTEM ID UNITS NO. TANKS

M1 M2 M3 M4

The NO. (of) TANKS set in the system menu

is shown in the TANKS, PROBES and

PRODUCTS menus !

Remember:

• Use

UP

or

DOWN

▲ ▼ key to display

more menus (MORE shown) or selec

tions (UP/DN shown)

• Press

CANCEL

to cancel data entry

• Use the

ENTER

key to accept data

Character input / editing:

• Press

M1

to move the cursor left

ï

• Use

M2

to move the cursor right

ð

• Press

M4

to backspace (delete) one

or more characters to the left

ï

PASSWORDS

(none / empty)

enter up to 12 characters max.

Press

ENTER

to accept this data.

(Secures access to setup mode or acknowledging alarms and/or starting grace periods.

A setup password is recommended for security.)

SETUP

SETUP PASSWORD

ACK

(also see ANNUNC [IATOR] menu for time-out)

ACKNOWLEDGE PASSWORD

(none / empty)

enter up to 12 characters max.

Press

ENTER

to accept this data.

— Continued on next page —

1

Page 1 - 2 Tank Sentinel Setup Programming Guide

S

YSTEM

Menu(C

ONTINUED

...

FROM

PREVIOUS

PAGE

)

SYSTEM ID

(enter new 5 line report header, see below)

Default Report Header Ø

LINE 1

LOCATION LINE 1

INCON

enter up to 24 characters max.

Press

ENTER

to accept this data.

LINE 2

LOCATION LINE 2

INTELLIGENT CONTROLS

enter up to 24 characters max.

Press

ENTER

to accept this data.

LINE 3

LOCATION LINE 3

P. O. BOX 638

enter up to 24 characters max.

Press

ENTER

to accept this data.

LINE 4

LOCATION LINE 4

SACO ME 04072

enter up to 24 characters max.

Press

ENTER

to accept this data.

LINE 5

LOCATION LINE 5

1-800-984-6266

enter up to 24 characters max.

Press

ENTER

to accept this data.

UNITS

(Units are set in either US Standard or Metric)

MEASUREMENT UNITS

VOLUME

(– change if not using the default US units)

VOLUME UNITS

(volume measurement units)

GALLONS

Use

UP/DOWN

▲

▼keys to choose units.

LITERS

Press

ENTER

to accept this data.

LEVEL

(– change if not using the default US units)

LEVEL UNITS

(level and length units)

INCHES

Use

UP/DOWN

▲

▼keys to choose.

CM

(Metric - Centimeters)

Press

ENTER

to accept this data.

TEMP

(– change if not using the default US units)

TEMPERATURE UNITS

(Prints F for Fahrenheit, or C for Celsius on reports)

FAHRENHEIT

Use

UP/DOWN

▲

▼keys to choose units.

CELSIUS

Press

ENTER

to accept this data.

NO. TANKS

(enter total number of tanks in the system)

NUMBER OF TANKS

1

enter number of tanks.

Press

ENTER

to accept this data.

............... LINE 1

:

:

:

..... LINE 5

System Setup Page 1 - 3

1

S

YSTEM

Menu (C

ONTINUED

...

FROM PREVIOUS PAGE

)

NO.SENSORS

(enter the number of Leak Detection Sensors)

NUMBEROFSENSORS

12(for TS-1001,504, 750)

(0 thru N) enter the total number of Sensors.

24(for TS-2001,508)

(also enter all unused channels between the lowest to

highest channel (also see SENSORS menu)

Press

ENTER

to accept this data.

NO.METERS

(devices used with TS-DIM)

NUMBEROFMETERS

0

enter number of meters.

Press

ENTER

to accept this data.

BUSY ENA

BUSYENABLED

(dispenser supports ‘busy’ signal to ATG)

NO

Use

UP/DOWN

keys to choose setting.

YES

Press

ENTER

to accept this data.

UTHRESH

(volume allowed pumped before Catastrophic Leak alarm)

USER THRESHOLD

+0

1 to +9999 volume units.

Press

ENTER

to accept this data.

LIMITS

LIMITS

(set leak limits for after hours sentinel mode – also see

LEAKLIM

menu)

LEAKLIMIT

+2.0

0.2 to +10.0 volume units.

Use keypad to input sentinel mode leak rate.

Press

ENTER

to accept this data.

LEAK OG

(assign leak alarm to an OG (

NONE

, A to FF, or ALL)

LEAKLIMITOUTPUTGROUP

(32 OGs available... see Worksheet #1-1 )

NONE

Not assigned to an Output Group (OG)

GROUPA

thru

FF

One OG selected (

A = 1

ST

OG, FF = 32

ND OG

)

ALLGROUPS

All OGs selected

Use

UP/DOWN

keys to choose an OG.

Press

ENTER

to accept this data.

THEFT LIM

(enter theft limit for all tanks)

THEFTLIMIT

+10.0

1 to +9999 volume units.

Press

ENTER

to accept this data.

THEFT OG

(assign theft limit alarm to an OG (

NONE

, A to FF, or ALL

THEFTLIMITOUTPUTGROUP

Output Groups)(32 OGs available... see Worksheet #1-1 )

NONE

Not assigned to an Output Group (OG)

GROUPA

thru

FF

One OG selected (

A = 1

ST

OG, FF = 32

ND OG

)

ALL

GROUPS All OGs selected

Use

UP/DOWN

keys to choose an OG.

Press

ENTER

to accept this data.

1

Page 1 - 4 Tank Sentinel Setup Programming Guide

S

YSTEM

Menu(C

ONTINUED

...

FROM

PREVIOUS

PAGE

)

SENTINEL

(after hours theft monitoring / tank leak detection)

SENTINEL MODE

MODE

SENTINEL MODE

OFF

Use

UP/DOWN

▲

▼keys to choose mode.

SCHEDULED

Press

ENTER

to accept this data.

Select SCHEDULED to enable Sentinel Mode —

START TIM

SENTINEL START TIME

00.00.00

up to 23.59.59

END TIME

SENTINEL END TIME

00.00.00

up to 23.59.59

DEL DELAY

(delay tank delivery reports by minutes)

DELIVERY DELAY

15

(minutes) 1 to 240 minute input range.

Press

ENTER

to accept this data.

REP DELIV

REPORT DELIVERIES

Use

UP/DOWN

▲

▼keys to choose.

Press

ENTER

to accept this data.

ENABLED

(enabled = yes, report deliveries)

DISABLED

(disabled = no, don’t report deliveries)

REP ALARM

REPORT ALARMS

Use

UP/DOWN

▲

▼keys to choose.

Press

ENTER

to accept this data.

ENABLED

(enabled = yes, report alarms)

DISABLED

disabled = no, don’t report alarms)

REP LEAK

REPORT LEAK TESTS

Use

UP/DOWN

▲

▼keys to choose.

Press

ENTER

to accept this data.

ENABLED

(enabled = yes, report leak test results)

DISABLED

(disabled = no don’t report leak test results)

REP SCALD

(Appears only if an S is present in the TS Part

REPORT SCALD TEST

Number (press CHECK and M4 to view OPTIONS)

Use

UP/DOWN

▲

▼keys to choose.

Press

ENTER

to accept this data.

DISABLED

(disabled = no, don’t report SCALD leak tests)

ENABLED

(enabled = yes, report SCALD leak tests)

Input

time in 24 hour format:

00.00.00 = midnight

22.00.00 = 10:00:00 pm

+ 12

(add 12 hours to pm times

from 1 pm to 11:59 pm

)

02.05.00 = 2:05:00 am

This manual suits for next models

4

Table of contents

Other Incon Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Master Meter System operating instructions

LOVATO ELECTRIC

LOVATO ELECTRIC DMED320 instruction manual

HiTec Systems

HiTec Systems AtmoCheck operating manual

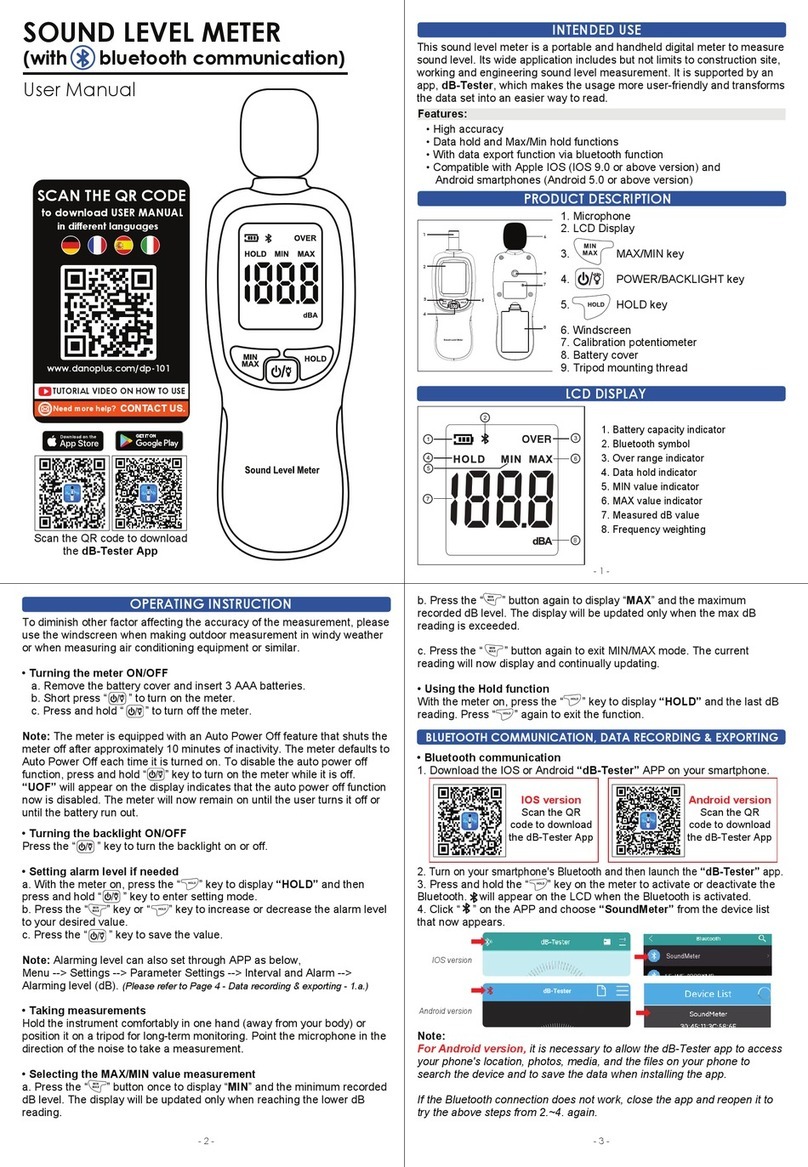

DANOPLUS

DANOPLUS DP-101 user manual

Screening Eagle

Screening Eagle Profometer PM8000 Pro user manual

Hitachi

Hitachi LM-C300 Series user manual