Incon OPTImizer 2 User manual

OPTImizer®

2

On-Line Circuit Breaker Performance And SF6Gas Density Monitor

User’s Guide

52

OPTImizer

©2012 000-1530 Rev C

INCON

P.O Box 638, Saco, Me. 04072

Tel: 207-283-0156

Fax: 207-238-0158

2

This manual is written for the OPTImizer2 Circuit Breaker Monitor with rmware revision 1.0.1.

LIABILITY DISCLAIMER

INCON (Intelligent Controls) reserves the right to change this document and specications at any time without

notice. INCON makes no express or implied warranty with regard to the content of this manual. INCON assumes no

liability for errors or omissions, or for any damages, direct or consequential, that may result from the use of this

document or the equipment that it describes. This manual specically pertains to the OPTImizer2 with rmware

version 1.0.1.

Intellectual Property

This document contains proprietary information and is protected by copyright. All rights reserved. This document may

be reproduced so long as it remains in the custody of the original purchaser, and is used only by the original purchaser’s

personnel for informational purposes. OPTImizer®is a registered trademark of Intelligent Controls.

Only qualied personnel should undertake application, installation, and use of the OPTImizer²on

power systems. While applying this device on the power system, there is always the possibility of

faulty equipment operation and electrical shock. Any of these situations may result in injury or death.

Return Shipping Charges

INCON will not accept shipments of returned products without a Return Goods Authorization (RGA) number. RGAs are

obtained by contacting INCON’s Technical Service Division – NO RGAs will be given without the unit’s serial number. Return

material remains the property of the buyer until replaced or repaired.

Under Warranty: INCON will pay all freight and insurance charges for RGAs.

Non-Warranty: It is the buyer’s responsibility to prepay all freight and insurance charges for RGAs. Refer to INCON

Warranty Policy document #000-1397

CONTACT INFORMATION

Expect this OPTImizer2User’s Guide to be revised as new information is available and feedback is gathered from the

eld. We welcome and appreciate any comments. Should any questions develop during application, please contact us for

assistance.

COMMENTS ASSISTANCE

INCON - Power Reliability Systems INCON - Power Reliability Systems

Product Manager Technical Service Division

34 Spring Hill Road Tel: 800-872-3455

PO Box 638 www.incon.com / contact.aspx

Saco, ME 04072

e-mail: [email protected]

Tel: 207-283-0156 Fax: 207-283-0158

Warning

3

Contents

List of Tables........................................................................................................................... 6

1 INTRODUCTION ...........................................................................................................7

1.1 Overview.......................................................................................................................... 7

1.2 Operation Overview ........................................................................................................ 7

2 INSTALLATION ...........................................................................................................10

2.1 External Connections (Termination)............................................................................... 10

2.2 Mounting Dimensions .................................................................................................... 11

2.3 SF6Sensor Mounting .................................................................................................... 13

General Planning Considerations................................................................................................ 15

3 APPLICATION GUIDE ................................................................................................17

3.1 Breaker Wear Symptoms............................................................................................... 17

3.2 Description of Circuit Breaker Monitoring ...................................................................... 18

Interface to the Breaker Control Circuits ..................................................................................... 19

I2x T or I x T Wear Duty ................................................................................................................ 21

Time Line to Trip Trace Correlation (Examples).......................................................................... 22

Alarm Set-points.......................................................................................................................... 26

3.3 Description of SF6 Density Monitoring ......................................................................... 28

4 PROGRAMMING .......................................................................................................29

4.1 Initial Communication With the OPTImizer2 ................................................................... 29

Conguring IP Properties for Communication............................................................................. 29

Initial Set-up ................................................................................................................................ 33

4.2 General ..........................................................................................................................35

IP ADDRESS............................................................................................................................... 35

DATE / TIME............................................................................................................................... 35

DIAGNOSTICS............................................................................................................................ 35

DNP3.0 SETTINGS..................................................................................................................... 35

CIRCUIT BREAKER INFORMATION.......................................................................................... 36

4.3 Circuit Breaker Monitor Settings .................................................................................... 36

Input Mode .................................................................................................................................. 41

Contact Wear Mode ................................................................................................................... 43

If breaker is Rated in MVA, and is being Applied at Voltage other than Nameplate:................... 45

Contact Life Warning Limit ......................................................................................................... 45

Trip Time Alarm Limit................................................................................................................... 45

Arc Time Alarm Limit ................................................................................................................... 46

Clearing Time Alarm Limit ........................................................................................................... 46

Travel Time Alarm Limit............................................................................................................... 46

Closing Time Alarm Limit............................................................................................................. 46

Operations Count Alarm Limit ..................................................................................................... 47

No Operations Alarm Limit .......................................................................................................... 47

Restrike Alarm ............................................................................................................................ 47

4.4 SF6MONITOR SETTINGS ............................................................................................ 49

Low Gas Warning Limit ............................................................................................................... 49

Low Gas Alarm Limit ................................................................................................................... 49

Density or Pressure Trend Limit .................................................................................................. 49

SF6Sensor Signals ..................................................................................................................... 50

Analog Sensor - Signal Low (Milliamps) ..................................................................................... 50

Analog Sensor - Signal Low Represents (Units)......................................................................... 50

Analog Sensor - Signal High (Milliamps) .................................................................................... 50

Analog Sensor - Signal High Represents (Units) ........................................................................ 50

4.5 ACTIONS ........................................................................................................................51

Preset Remaining Contact Life.................................................................................................... 51

Preset Operation Number ........................................................................................................... 52

Clear Latched Alarms.................................................................................................................. 52

Reset Operations Counter........................................................................................................... 52

Reset SF6Density Trend Data .................................................................................................... 53

4

5 User Interface ............................................................................................................54

5.1 Post Maintenance Resetting / Presetting ........................................................................ 54

5.2 Periodic Data Dump........................................................................................................ 54

Alarm History Report................................................................................................................... 55

Application Event History Report................................................................................................. 56

Circuit Breaker Event History Report .......................................................................................... 57

SF6Logged History Report.......................................................................................................... 58

SF6Daily Summary Report ........................................................................................................ 58

Data Interpreting.......................................................................................................................... 58

5.3 Alarm Acknowledgement / Cancellation.......................................................................... 60

5.4 USB Scripts ...................................................................................................................60

6 COMMUNICATION DETAILS .....................................................................................61

6.1 RS-232........................................................................................................................... 61

6.2 Fiber-Optic Interconnection ............................................................................................ 63

6.3 RS-485........................................................................................................................... 63

6.4 Ethernet ........................................................................................................................63

6.5 XML ..............................................................................................................................64

6.6 DNP3.0 .........................................................................................................................66

6.6.1 Device Prole Document ............................................................................................. 66

6.6.2 DNP3.0 Implementation Table .................................................................................. 68

6.6.3 DNP3.0 Point List ..................................................................................................... 69

7 SPECIFICATIONS .......................................................................................................72

DSDP SF6 Density & Temperature Sensor Specications ................................................... 73

5

List of Figures

Figure 1: OPTImizer2Field Wiring ...................................................................................... 10

Figure 2: OPTImizer2Mounting Dimensions (Not actual size) ........................................... 11

Figure 3: OPTImizer2General Dimensions......................................................................... 12

Figure 4: DSDP Sensor Connections ................................................................................... 13

Figure 5: Breaker Cabinet and Control House Interface...................................................... 15

Figure 6: Typical Trip Trace, with Arc Duration Information Superimposed .......................... 18

Figure 6A: Trip Trace, Using Trip Coil Voltage to Start OPTImizer2.................................... 22

Figure 6B: Event to Time Correlation of Fig 4, ..................................................................... 23

Figure 6C: Event to Time Correlation of Fig 4, ..................................................................... 24

Figure 7: Trip Trace, Using Trip Initiate to Start OPTImizer2............................................... 25

Figure 8: Alarm Relay Assignments...................................................................................... 27

Figure 9: User Interface, Conguration Page ....................................................................... 33

Figure 10: User Interface, Conrming Conguration Update................................................ 34

Figure 11: User Interface, Action Page ................................................................................. 34

Figure 12: Aux A Interface, using Trip Initiate (Red Light)..................................................... 37

Figure 13: Aux A Interface, using 52 / a Contact in Trip Circuit............................................. 38

Figure 14: Aux A Interface, using Trip Coil Excitation Voltage ............................................. 38

Figure 15: Aux A Interface using Individually Wetted 52/ a Contact..................................... 39

Figure 16: Aux B Interface, using Green Light...................................................................... 39

Figure 17: Aux B Interface, using 52 / b Contact in Green Light Circuit................................ 40

Figure 18: Aux B Interface, using Individually Wetted 52/ b Contact ................................... 40

Figure 19: Trip Trace illustrating A Input Delay Setting Considerations ................................ 41

Figure 20: Estimated Trip Latch Release Times based on Nameplate Breaker Voltage ...... 43

Figure 21: Estimated Arc Time based on Nameplate Breaker Voltage................................. 44

Figure 22A: A 3-Cycle Arc, No Restrike ................................................................................ 48

Figure 22B, A 5½-Cycle Arc, No Restrike ............................................................................. 48

Figure 22C, A 5½-Cycle Arc, Restrike Detected ................................................................... 48

Figure 23: User Interface, History Page ............................................................................... 54

Figure 24: User Interface, Status Page with Active Alarms .................................................. 60

Figure 25: 9-pin to 9-pin Cable Connections ........................................................................ 61

Figure 26: 25-pin to 9-pin Cable Connections ...................................................................... 62

Figure 27: Schweitzer Fiber-Optic Interface ......................................................................... 63

Figure 28: RS-485 Full-Duplex Wiring .................................................................................. 63

Figure 29: RS-485 Half-Duplex Wiring ................................................................................. 63

Figure 30: User Interface, Preferences Page ....................................................................... 64

Figure 31: User Interface, Editing the Preferences Page ..................................................... 64

Figure 32: User Interface, XML Page ................................................................................... 65

Figure 33: User Interface, XML Command Access............................................................... 65

6

List of Tables

Table 1: Required Information for Application ....................................................................... 14

Table 2A: Breaker Cabinet Installation Considerations......................................................... 16

Table 2B: Control House Installation Considerations............................................................ 16

Table 3: Alarm Set-points...................................................................................................... 26

Table 4: Alarm Outputs, LED’s and Relays........................................................................... 26

Table 5: Impact of A Input Assertion on the A Input Delay Setting ........................................ 42

Table 6: Must-Clear Times of Breakers, Voltage Dependent ................................................ 43

Table 7: Accumulated Duty Wear Calculation Example based on Trip History ..................... 52

Table 8: Alarm Codes............................................................................................................55

Table 9: Application Event Codes ......................................................................................... 56

Table 10, OPTImizer2 Specications................................................................................... 72

7

1 INTRODUCTION

1.1 Overview

The OPTImizer2is an On-Line Circuit Breaker

Performance and SF6Gas Density Monitor that is used

for implementing predictive maintenance, maintenance

deferral, just-in-time (JIT) maintenance and environmental

protection. This intelligent electronic device (IED) monitors

the condition of the main contacts, mechanism and

dielectric; and logs the following information during CB

operation:

• Trip Time (mS) (also known as Opening Time)

• Arc duration (mS) (phase segregated)

• Clearing Time (mS) (also known as Interrupting Time)

• Cumulative I2xT or I xT on the main contacts (phase-

segregated) from arcing

• Restrike Occurrence (phase segregated)

• Mechanism opening travel time (mS)

• Mechanism closing travel time (mS)

• Operation Counts

The OPTImizer2continuously monitors SF6(Sulfur

hexauoride) gas density and temperature, and then

calculates gas pressure, density and pressure trend rates

and changes in mass. The present density, pressure,

mass, density and pressure trend rates, and temperature

are recorded in the history log at regular intervals. There

are alarms for low density and high density or pressure

trend rate.

In addition to alarming of anomalies by LEDs and contact

alarms, digital information is available for retrieval through

a DNP3.0 network or a web browser. The ability to provide

historical data, in addition to alarming at setpoints, makes

the OPTImizer2ideal for reliability centered maintenance

(RCM) programs.

The OPTImizer2has passed rigorous standards for

survivability in the electric utility substation environment. It

may be mounted directly in the circuit breaker cabinet, or

in the control house.

A minimal interface to the breaker control and secondary

current circuits is used, employing snap-on CT pickup coils

and two parallel wiring connections. This minimal interface

to the power circuit breaker makes the OPTImizer2ideal

for both retrot and new applications. One, two or three

SF6gas density sensors may be used.

The OPTImizer2 is specically designed for use on gas

(SF6) circuit breakers, but can be used on oil and vacuum

breakers.

The wear models used in the OPTImizer2are valid for any

voltage class and correspond to ANSI / IEEE C37.06-1989.

1.2 Operation Overview

CONDITION and WEAR LOGGING

• SF6Density (g / L), Pressure (PSIG, BAR, Kilopascals)

Mass (Pounds, Kilograms)

• SF6Trend Rate (units / day) Mass Loss (Pounds,

Kilograms, Pounds CO2, Metric Tonnes CO2)

• Trip Time (mS)

• Duration of the arcs (by phase) during tripping (mS)

• Clearing Time (mS)

• Cumulative I2xT or I xT on the contacts (phase

segregated) from the arcs during tripping

• Restrike Occurrence (by phase)

• Mechanism opening travel time (mS)

• Mechanism closing travel time (mS)

• Operation Counts (Time and Date Stamping is provided

for each trip operation.)

Alarm set-points may be entered against these items.

SENSING INPUTS

AC Current Input Channels

Three signals (one per phase) from split-core CT pickup

coils placed around the secondary of each circuit breaker

primary phase CT. The signal is proportional to 0-(Max) A

in the primary CT’s secondary circuit (where “Max”= 20,

30, 50, 100,160, 250, 400 or 800 Amps depending upon

the CT range chosen).

System frequency may be at 50 or 60 Hz. These signals

are used to record the arc duration and cumulative I2xT or

I x T contact duty. I2x T or I xT calculations are accurate in

the presence of DC offset and sinusoidal harmonics up to

the 16th.

Split-Core CTs

The OPTImizer2is designed to be used with INCON

Split-Core pickup coils only. Models CT-20, CT-30,

CT-50, CT-100, CT-160, CT-250, CT-400 and CT-800

are custom designed for the accuracy required by the

OPTImizer2. Range is 1.4-20A, 2.1-30A, 3.5-50A, 7.0-

100A, 11.2-160A, 17.5-250A, 28.0-400A and 56.0-800A

respectively. Three CT’s (one per phase) are provided in a

CT kit. These split-core CT pickup coils snap-on for easy,

non-intrusive installation to the circuit breaker secondary

current circuits. Burden is 0.05VA @ 5 amp.

SF6 Input Channels

Two types of SF6gas density sensors may be used:

2-wire 4-20mA “analog” or INCON Model DSSP “digital”

type sensor. This input is user-congurable for up to

three sensors. For analog sensors, the density units

(grams / liter) are scalable over all or a portion of the

4-20mA signal range. Sensor power of 20VDC is provided

for each channel. SF6gas temperature can also be

measured if the “digital” sensor is used.

8

DC Input Channels

Two discrete voltage signals, 48-250 VDC. The “Aux A”

input is used to initiate the trip time log, the mechanism

time log, the arc duration time log, and the cumulative

I2T or IT duty log. The “Aux B” input is used to stop the

mechanism time log.

A continuous interrogation process detects Aux input logic

failure when both inputs are asserted or de-asserted at

the same time for longer than 3 seconds. This conicting

input would indicate a serious problem with the circuit, DC

power has been lost, a wire is broken, etc. This condition

causes an “A-B Logic” alarm.

EVENT TRIGGERING

• TRIP TIME (opening time log) – (Available in

INPUT MODEs 2 & 4 only.) The start is triggered by

a positive assertion (rising edge) to the Aux A input.

The stop is triggered by the de-assertion (falling

edge) of the Aux A input, with the actual buffer stop

time adjusted by the software setting A INPUT

DELAY, which accounts for the time difference

between the Aux A de-assertion and the actual

parting of the main contacts.

• ARC TIME (arc duration log) – maximum duration

is 10 cycles per trip operation; the start time is

indexed by an assertion of the Aux A input, with the

actual buffer start time adjusted by the software

setting A INPUT DELAY, which accounts for

the time difference between the Aux A assertion

and the actual parting of the main contacts. A

proprietary algorithm that detects the end of arc

current in all three phases triggers the stop. See

Figure 6.

• CLEARING TIME (interrupting time log) –

(Available in INPUT MODEs 2 & 4 only.) The start

is triggered by the assertion (rising edge) of the Aux

A input. A proprietary algorithm that detects the end

of arc current in all three phases triggers the stop.

• TRAVEL TIME (mechanism time log) – (Available

in INPUT MODEs 1 & 4 only.) maximum duration is

10 cycles per trip operation; the start is triggered by

a change in state of the Aux A input. An assertion to

the Aux B input triggers the stop.

• CLOSING TIME (mechanism time log) – (Available

in INPUT MODE 1 only.) maximum duration is 10

cycles per trip operation; the start is triggered by

an assertion to the Aux B input. An assertion to the

Aux A input triggers the stop.

• MAIN CONTACT ARCING DUTY LIFE (phase

segregated I2T or I T per trip operation and phase

cumulative I2T or I T data log); A mathematically

calculated value representative of the destructive

arc energy.

FIELD OUTPUTS

Visual Display

On-board LEDs will illuminate and latch when reaching an

alarm setpoint or detecting a failure mode. These may be

reset by software command.

The circuit breaker OPEN / CLOSED status is also

shown by green and red LEDs on the OPTImizer2. This

OPEN / CLOSED status indicator should only be used as a

secondary indication and to verify correct programming of

A INPUT POLARITY and B INPUT POLARITY assertion

states.

An LED bar graph alternates every 10 seconds between

indicating the remaining contact life and the SF6gas level.

In both cases, the condition of the worst phase is displayed.

When more than one LED is lit, the contact life is being

displayed. When a single LED is lit, the SF6level is being

displayed.

The scale is -50% to +100% for contact life. The scale for SF6

gas level is based upon the programmed SF6Fill (density

or pressure), the Low Gas Warning Limit and the low Gas

Alarm Limit.

When displaying remaining contact life, the green zone is

scaled from 100% remaining life to the Warning Limit. The

yellow zone is scaled from the Warning Limit to the Danger

Limit (0% life). The red zone is scaled from the Danger Limit

to 50% below the Limit.

When displaying

SF6

gas level, the green zone is scaled from

the Fill (density or pressure) value to the Low Gas Warning

Limit. The yellow zone is scaled from the Low Gas Warning

Limit to the Low Gas Alarm Limit. The red zone is scaled from

the Low Gas Alarm Limit to zero (pressure or density).

When the display is in the green zone, the LED(s) will be

lit continuously. When the display is in the yellow zone, the

LED(s) will ash slowly to indicate an approaching alarm

condition. When the display is in the red zone, the LED(s) will

ash rapidly to indicate an alarm condition exists.

A slowly

ashing green heartbeat LED indicates that the OPTImizer²

system is functioning normally.

Relay Contacts

Two Form C relays and one Form A relay are provided

for alarms. The dry contacts are rated for 3A at 250 VAC

or 1 / 2A at 125VDC. These contacts are not intended

for breaking DC inductive loads. (For Alarm / relay

assignments, see Figure 8):

• The “RED” relay asserts when a Restrike or excess arc

duration is detected, or when the Contact Life Danger

limit is reached.

• The “YELLOW” relay asserts when a failed CT pickup

coil is detected, the Contact Life Warning limit is

reached, the Operations Count limit is reached, the

open or close mechanism time limit is reached, the Trip

Time limit is reached, the Clearing Time limit is reached,

the No Operations time limit is reached, or an A-B Logic

Alarm condition occurs.

• The SF6relay asserts when a Low Gas Alarm limit or

Trend Alarm limit is reached or if there is a malfunction

of the SF6sensor.

9

POWER INPUT

The OPTImizer2operates from station battery DC or from

AC station service power. Input Range: 110 to 250VDC, 90

to 264VAC. Power Consumption: 15 VA maximum.

COMMUNICATION PORTS

These ports are for setting, alarm acknowledgment, history

reset, and data viewing / dumping using the DNP3.0 protocol.

RS-232:

Connection: RS-232C, 9-pin female, DCE. A “straight

through” cable should be used for connection to a DTE

device, such as a PC. (Note: The ASCII protocol is no

longer supported on this port.)

Factory preprogrammed settings for RS-232 and RS-

485 communication:

Data bits: 8

Stop bits: 1

Parity: None

Baud rate: 9600 bps

Flow control: None

RS-485:

The port is full-duplex and un-terminated. The port can

be congured for half-duplex by adding jumpers from Tx+

to Rx+ and from Tx- to Rx-. If the OPTImizer² is the last

device in a network, the Transmit and Receive lines need

to be properly terminated with a 120 ohm resistor.

Ethernet:

This port is can be used with DNP3.0 and TCP/ IP

protocols simultaneously (in multi-sessions). When

connected to a secure local area network (LAN) the

OPTImizer² can be accessed remotely with a web browser,

providing the correct IP address is given. Firmware

upgrades can also be performed through this port using a

special upgrade tool (contact INCON Technical Services).

USB COMMUNICATION PORT

This port is for data dumping (BIN les and ASCII text

les), alarm acknowledgement or rmware upgrades. It

will Interface only to a USB memory stick. A memory stick

with a special software tool can be used to acknowledge

alarms. This software tool can be downloaded from the

OPTImizer2 Product CD. A memory stick containing a

special upgrade script and les can be used to upgrade

the rmware (contact INCON Technical Services). (See

section 6)

COMMUNICATIONS SOFTWARE

The OPTImizer² is equipped as a web server. A common

web browser is all that is needed to communicate to the

OPTImizer² using the TCP/ IP protocol. If DNP3.0 protocol

is used, the DNP Master device will have the proper

software for network communication. The OPTImizer²

will respond to properly addressed and validated DNP

commands.

DATA STORAGE

Data is stored in non-volatile memory. The memory holds

the most recent 5000 records in a database. A “record” will

be made of events that include: program settings changes,

CB opening, CB closing, alarm occurrences and scheduled

data logs.

SELF DIAGNOSTICS

A blinking green “power on” LED indicates satisfactory

operation of the microprocessor system. An "Input Signal"

LED indicates the malfunction of a CT Pickup Coil or

SF6

sensor.

PHYSICAL

Size: 8.69W x 5.63H x 2.75D, Inches Nominal

Weight: 4 Lbs. 8 Oz.

PERFORMANCE

• Temperature: -20 to +150°F

• Surge Withstand: ANSI C37.90.1, SWC Test

• Electrostatic Dissipation: IEC 810-2

• Environmental: ANSI C37.1

10

2 INSTALLATION

2.1 External Connections (Termination)

Figure 1: OPTImizer²Field Wiring

110-250 VDC (Twisted Pair Recommended)

90-264 VAC 50/60Hz

Use Twisted Pair Cable

Contact Rating: 3A @ 250 VAC or

1/2A @ 125VDC

The OPTImizer2should be installed

as close to the CT Pickup Coils as

possible. Cut any excess cable from the

Pickup Coils. It is not recommended to

extend the Pickup Coil cables.

SF6Density Sensors

Terminal Screw

maximum torque

12 inch-Lbs

11

2.2 Mounting Dimensions

Figure 2: OPTImizer²Mounting Dimensions (Not actual size)

12

Figure 3: OPTImizer² General Dimensions

13

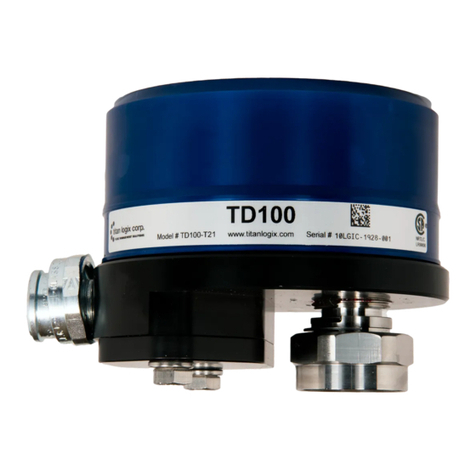

2.3 SF6Sensor Mounting

Pipe Thread

INCON offers an SF6density sensor as an accessory to

the OPTImizer²: The Model DSDP with digital output

signal. This sensor uses a G 3/ 8” British Standard parallel

pipe thread with an O-ring seal. An appropriate adaptor

tting will be required when installing one of these sensors

into a manifold or vessel with a different thread.

Other brands of SF6density sensor are available

with many other pipe thread options. Be sure you are

combining the appropriate sensor threads with the

appropriate adaptor tting threads.

Location

It is always preferable that the

SF6

density sensor be

mounted as close to the gas vessel as possible, so that the

sensor can be close to the same temperature as the vessel.

The INCON DSDP is a “true density” sensor, not a

temperature-compensated pressure sensor. For this

reason, it is less critical that it be mounted as close as

possible to the SF6gas vessel. The density measurement

is not as affected by temperature.

Other brands of SF6density sensor may be used. Virtually

all other brands are temperature-compensated-pressure-

type sensors. It is more critical to mount this type of sensor

as close as possible to the SF6gas vessel, so that the

temperature of the SF6gas can properly affect the sensor.

A difference in temperature between the SF6gas in the

vessel and a sensor of this type will cause an error in the

density output signal.

The SF6density sensor may be installed alongside an

existing SF6density switch or gauge. If only one opening

is available, a “T” tting may be used to create a second

opening for the sensor.

Any air in the piping to the sensor can delay accurate

density measurement for up to two weeks. The sensor

should be installed with the gas port facing upward if

possible. A SMALL amount of SF6can be bled past the

sensor threads before tightening the sensor to purge

trapped air.

Extreme care must be taken when

installing sensors. A gas-tight seal

must be achieved on all pipe tting and

sensor threads.

Vacuum

If a vacuum is used to extract air before lling a breaker

with SF6gas, do not expose the density sensor to vacuum

greater than one atmosphere.

1 2

3

4

Viewed from end

SF6Sensor Connections

Pin 1: Connect to Optimizer²+ Terminal (Red Wire)

Pin 2: Connect to Optimizer²— Terminal (Black Wire)

Pins 3 & 4: No Connection

1.06" Dia.

(27 mm)

2.00"

(50.8 mm)

1.135"

(28.8 mm)

3.24"

(82.3 mm)

0.454"

(11.5 mm)

G ⅜" Thread

Figure 4: DSDP Sensor Connections

Caution

14

2.4 Planning for Installation and Programming, Required Field Documentation

The OPTImizer2application should be planned, much like the application of other IEDs, such as a protective relay, fault

recorder, or monitor. Actual programming and installation can be accomplished in a few hours (typically 2 hours) after the

setpoints are calculated and determined. The required information is tabulated below:

Information Source(s) AffecTed SeTTINgS / USe

CT Primary Coil Ratio One Line Diagram, Visual Inspection of

Applied CT Ratio

• Bushing CT Ratio

Logic and Assertion Levels of

Aux A and Aux B inputs Circuit Breaker Elementary Diagram

• Input Mode

• A Input Polarity

• B Input Polarity

Time Difference Between Aux

A input Assertion and Parting

of Main Contacts

Trip Trace, ANSI Standards (C37.06)

•A Input Delay

(Time Difference between Aux A input and

the main contacts parting)

Breaker Nameplate Data

Breaker Manufacturer’s Data Sheets,

Breaker Nameplate, ANSI Standards

(C37.06)

• Contact Life Mode

(I2x T or I x T)

• Contact Life Danger Limit

• Contact Life Warning Limit (%)

• Operations Count Limit

• SF6Gas Fill Weight

• SF6Gas Fill Pressure

• SF6Gas Fill Temperature

• Breaker Volume

Breaker Trip History

Operations Logs, Relay Fault Records,

Digital Fault Recorders, Oscillographs,

Estimation

• Preset Remaining Contact Life

(% for each phase)

Type of Breaker for employing

Restrike Detection Generally used on SF6Gas Breakers • Restrike Alarm (Enable / Disable)

System Frequency • Power System Frequency

Date • DATE

Time • TIME

Site Identication System Topology, Mapping • Site Name

Baud Rate, Parity, Flow

Control, Stop Bits

Pre-programmed Setting, Interfaced

Communication Equipment if Networked • Port Settings

Table 1: Required Information for Application

15

General Planning Considerations

The OPTImizer2 may be installed in a control house or breaker cabinet. The required interfaces can be obtained at either

location. The SF6sensors must be installed on the circuit breaker itself. Sensor accuracy is best when installed nearest to

the interrupter vessel.

The OPTImizer2should be installed as close to the CT Pickup Coils as possible. Cut any excess cable from the Pickup

Coils. It is not recommended to extend the Pickup Coil cables.

A

B

C

Aux B Interface

Aux A Interface

Phase A, Snap-on CT

Phase B, Snap-on CT

Phase C, Snap-on CT

Phase A, Snap-on CT

Phase B, Snap-on CT

Phase C, Snap-on CT

RG

Aux A Interface

Aux B Interface

Bushing CT (Typ.)

Phase Relay (Typ.)

Ground Relay

(Typ.)

BREAKER CABINET

CONTROL HOUSE

or TI

TI

b

a

or

Figure 5: Breaker Cabinet and Control House Interface

Phase B, CT Pickup Coil

Phase B, CT Pickup Coil

Phase A, CT Pickup Coil

Phase A, CT Pickup Coil

Phase C, CT Pickup Coil

Phase C, CT Pickup Coil

16

The actual installation location may be determined after review of many factors, some of which are outlined below:

Circuit Breaker Cabinet Mounting

Pros Cons

Readily accessible to Maintenance personnel.

Trip initiate signal may not be available should

it be the desired interface for the Aux A input

assertion.

A 52 / a contact (in the actual trip circuit or

individually wetted) for asserting the Aux A input,

and a 52 / b contact (in the actual green light circuit

or individually wetted) signal for asserting the Aux

B input are readily available. A trip initiate signal

may also be available for the Aux A input assertion if

desired.

May be environmentally unfriendly (temperature,

humidity, electrical noise, transients) for both the

equipment and personnel.

Secondary current circuit interface is readily

available (from bushing CTs).

Integration may be more difcult (long distances,

electrical noise, step potential).

Table 2A: Breaker Cabinet Installation Considerations

Control House Mounting

Pros Cons

Centralized location for multiple unit installations. May lie within an area not readily accessible to

Maintenance personnel.

Trip Initiates (red light) signal for asserting the Aux

A input, and an end of mechanism travel (green

light) signal for asserting the Aux B interfaces are

readily available. A 52 / a contact signal may also

be available for the Aux A input assertion if desired.

The 52/a and 52/b may not be available if they

are the desired interface for the Aux A and Aux

B input assertion.

Secondary current circuit interface is readily

available (from relays).

Usually easier to integrate (short physical wiring

runs in close proximity to an RTU, PLC, substation

computer, modem, port switcher, etc.).

Not near SF6ports on circuit breaker, long cable

runs from sensors may increase noise.

Environmentally friendly (temperature, humidity,

electrical noise, transients) for both the equipment

and personnel.

Table 2B: Control House Installation Considerations

17

3 APPLICATION GUIDE

3.1 Breaker Wear Symptoms

Breaker Wear Symptoms

Power circuit breakers exhibit symptoms of wear from

the stresses of operation. The wearing of a breaker may

adversely affect the mechanism, the dielectric capabilities

for extinguishing an arc, and the main contacts by erosion

due to duty (wear).

Mechanism Condition

The mechanism operation during a trip essentially consists

of three events:

• Trip Latch Operation

• Travel Mechanism Operation

• End of Travel Mechanism (dashpot, including

preparation for closing)

• Closing Mechanism Operation

Samples of issues that may cause problems within the

mechanism are:

• Poor trip coil action due to high impedance or

shorted turns

• Sticking in the latch

• Lack of lubrication

• Binding of components

• Bearing wear or seizure

• Compromise in the stored energy system (spring,

pneumatics)

Any of these may manifest themselves as a decrease

in the breaker travel velocity. Accompanying a slowing

in velocity would be a detectable increase in transit time

from the closed to tripped (open) position. This is due to

the relationship of V T = D, where V is velocity, or rate

(in. / sec.), T is time (secs.), and D is distance (in.).

Solving for T, the equation transforms to T = V / D. Any

decrease in velocity must be accompanied by an increase

in time. In the case of a power circuit breaker, if the time

interval between two signals is monitored, one being

the beginning of travel and the other the end of travel,

increases in transit time can be detected.

The OPTImizer2monitors trip response time and

mechanism travel transit times (open and close) to aid in

determining the condition of the mechanism, and predicting

when maintenance is needed.

Dielectric Capability

The ability of a circuit breaker to extinguish an arc can

be monitored by examining the amount of time an arc is

present after a trip command to the breaker is given. If the

mechanism transit time remains constant, but an increase

in arc duration is noted from a baseline level, some

“dielectric” compromise can be assumed to have occurred

in the arc chamber. Samples of issues that may cause

problems in the ability of a circuit breaker to extinguish an

arc are:

• Contaminated oil

• Contaminated gas

• Low gas density

• Worn bafes

• Nozzle ablation

The OPTImizer2monitors SF6gas density to aid in

determining if maintenance is needed to prevent loss of

dielectric and to predict when gas needs to be added.

The OPTImizer2monitors arc duration time to aid in

determining the condition of the dielectric quality within the

arc chamber, and predicting when maintenance is needed.

The OPTImizer2monitors phase segregated I2xT or

I xT values from each operation, and maintains a phase

segregated summation log of the cumulative duty that each

pole has undergone to aid in determining the condition of

the main contacts within the arc chamber.

Main Contacts Erosion Due to Duty

The main contacts of a circuit breaker erode (wear) from

the heat present during the arc interval. The relationship

for breakers with a medium (air, gas, oil) is expressed

in ANSI C37.06, Rating of Power Circuit Breakers on a

Symmetrical Basis, as a dI / dT function, which can be

reduced to an I2xT expression.

The erosion of the main circuit breaker contacts is directly

proportional to the I2xT present during each arc. To

effectively measure the I2xT during the arc interval, steps

must be taken to insure that DC offset is included in the

calculation, and the sampling rate is high enough to insure

that harmonics present within the arc are also accounted

for in the calculation.

18

3.2 Description of Circuit Breaker Monitoring

Typical Trip Trace Example

A typical trip trace is illustrated in Figure 6. The OPTImizer2, by examining signals corresponding the start of the trip (trip

initiate or the 52 / a contact opening), the end of mechanism travel (green light or 52 / b contact closing), and secondary

phase currents can obtain a wealth of information about the power circuit breaker.

Figure 6: Typical Trip Trace, with Arc Duration Information Superimposed

General Comments

Examination of a typical trip trace allows the quantities the

OPTImizer2records to be visualized. Arc duration (ARC),

although not possible to record during a de-energized trip

test using conventional test equipment, is shown here for

illustration.

The time line corresponding to the parting of the main

contacts (mains) is used to determine the time difference

between this event and either the trip initiate or the 52 / a

contact opening. In each case the A INPUT DELAY time

will be different. The choice to use the trip initiate or the

parting of the 52 / a will depend on where the OPTImizer’s

Aux A input is wired in the circuit. The proper A INPUT

DELAY must be programmed accordingly. The ability

to know this time difference allows the OPTImizer2to

precisely start timing the arc for both the arc duration

record and the wear duty (I2xT or I xT) calculations.

Reference for the following function descriptions in this

section should be made to Figure 6A, Typical Trip Trace

Diagram.

Interface to Breaker Secondary Current

Secondary Current Interface - The per phase (fA,

fB, fC) interrupting duty information and arc duration

information is ascertained by interfacing to the bushing

CT secondary current circuits using snap-on CT Pickup

Coils. The acquisition of interrupting current information

is therefore non-intrusive, as the CT secondary current

circuits do not have to be cut or otherwise modied. No

shunts are required.

The CT secondary circuits are available at the breaker

cabinet and the control house, (if there is a control house).

The Protective Relay Bushing CT’s secondary circuits

should be used, since Metering CTs may saturate at high

current levels associated with fault duty.

19

Interface to the Breaker Control Circuits

Two discrete voltage inputs are used to obtain information

to determine the start of the trip (AuxA) and the end of

mechanism travel (Aux B). These two inputs may be

directly coupled, using parallel wiring connections, to

the breaker control circuit or separately wetted breaker

auxiliary contacts. Additionally, auxiliary relays or diodes

may be used for isolation or to accommodate dual trip

circuits. No shunts are required.

Depending on the application, the voltage state can

change from no-voltage to voltage, or voltage to no-

voltage. The OPTImizer² is programmed to react to one

of the changes as an assertion to an input. De-bounce

circuitry is employed, and input assertions are dened as

the rst transition point in voltage.

Aux A Input Interface

The Aux A input is the starting trigger for the Trip Time log

and the mechanism time log. With the time adjustment

from the A INPUT DELAY setting, the Aux A starts the arc

duration log and the wear duty logs.

The Aux A input interface is made using a parallel connection

in the actual breaker control circuit: to the trip initiate

(shunting of the red light or the Trip Coil); to the 52 / a

contact (closed to opened), or an individually wetted 52 / a

contact (closed to opened) that is not in the actual trip circuit.

There are other possibilities using additional interface

devices, such as isolating relays and diodes.

There are advantages to using the Trip Coil signal for

assertion of the AuxA input:

• Allows capture of the latch time in the Trip Time log.

As many mechanism problems are in the latch, this

is the most important advantage. Use of the 52 / a

contact for interface will not allow capture of the

latch time in the mechanism time log.

• Repeatable signal with no “slop” issues as can occur

with mechanically linked auxiliary contacts.

The OPTImizer²’s AuxA input is fused, optically isolated

and transient protected. If it fails, it will be open, therefore

it cannot cause a false trip or short circuit when applied in

actual breaker control circuits.

Aux B Input Interface

The Aux B input is the stopping trigger for the mechanism

time log. The Aux B input assertion can be made using

either a green light signal (off to on) or a 52/ b contact

state change (opened to closed). There are other

possibilities using additional interface, such as isolating

relays and diodes.

The Aux B input is fused, optically isolated and transient

protected. If it fails, it will be open, therefore it cannot

cause a false indication or short circuit when applied in

actual breaker control circuits.

INPUT MODE

The Aux Input logic mode can be programmed for one of

four conditions:

Mode 1: Use this mode when the Aux A & B Input voltages

remain continuously high or low until a breaker event

occurs (as when wired across the red and green lights),

then change to the opposite state and remain constant

until the breaker is reset. In this mode, TRIP TIME and

CLEARING TIME are not logged and their alarms are

disabled.

Mode 2: Use this mode when the Aux A Input voltage

changes state momentarily, when a breaker event occurs

(as when wired to the trip coil signal), but Aux B is not

wired. In this mode, TRAVEL TIME and CLOSING TIME ,

and A-B LOGIC data are not recorded and their alarms are

disabled. The circuit breaker OPEN and CLOSED states

cannot be indicated in this mode. The red “CLOSED” LED

will be lit continuously.

Mode 3: Use this mode when the Aux A Input voltage is

continuous, as in Mode 1, but Aux B is not wired . (Used

in cases where there is no Aux B switch available) In

this mode, TRIP TIME, CLEARING TIME, TRAVEL TIME,

CLOSING TIME, and A-B LOGIC data are not logged and

their alarms are disabled.

Mode 4: Use this mode when the Aux A Input voltage

changes state momentarily, when a breaker event occurs

(as when wired to the trip coil signal) and the Aux B input

voltage remains continuously high or low until a breaker

event occurs, then changes to the opposite state and

remains constant until the breaker is reset. In this mode,

the OPTImizer²can record TRIP TIME, CLEARING TIME,

TRAVEL TIME and A-B LOGIC data and their alarms can

be active. Closing Time cannot be recorded and its alarm

will be disabled.

TRIP TIME (Trip Mechanism Time Log) (Input Modes 2

& 4 only)

When INPUT MODE 2 or 4 is selected and the "Aux A"

input is wired as shown in Figure 14, the OPTImizer²

will record TRIP TIME. The TRIP TIME log consists of a

timer. The timer starts from an assertion of the “Aux A”

input, and stops with the de-assertion of the “Aux A” input,

adjusted by the A INPUT DELAY value. The assertion

level is dened in software (A INPUT POLARITY), and

is application-dependent. The TRIP TIME measurement

starts with the Trip Initiate voltage application to the Trip

Coil and ends when the 52a contact opens (+ / - A Input

Delay value), de-energizing the Trip Coil.

20

TRAVEL TIME (Mechanism Time Log) (Input Modes 1 & 4 only)

When INPUT MODE 1 or 4 is selected, the OPTImizer²will record mechanism TRAVEL TIME. The mechanism time log

consists of a timer. The timer starts from an assertion (or de-assertion in Mode 4) of the “Aux A” input, and stops with an

assertion to the “Aux B” input. The assertion levels are dened in software (A INPUT POLARITY & B INPUT POLARITY),

and are application-dependent.

It is possible to start the mechanism trip transit time log from one of two instances, either the trip initiate signal, or the

opening of the 52 / a contact.

Note: The “Aux A” input is the common start for both the mechanism time log and the arc time log functions.

ARC TIME (Arc Time Log)

The individual, phase-segregated Arc Time logs employ a timer, starting with the main breaker contacts parting and

ending with the cessation of current in each phase.

Starting of the Arc Time Log

The arc time log is indexed to start with an assertion (or de-assertion in Modes 2 & 4) of the “Aux A” input. The assertion

level is dened in software (A INPUT POLARITY), and is application dependent. The actual starting of the log is

dependent on a setting used to adjust the time interval difference between the “Aux A” assertion and the actual parting of

the mains. This adjustment time is referred to as A INPUT DELAY in Figure 6.

The A INPUT DELAY value may be either positive or negative, depending on if the “Aux A” assertion is later or earlier than

the mains parting:

• The adjustment time (A INPUT DELAY) is positive (+), if the mains part later than the “Aux A” assertion

• The adjustment time (A INPUT DELAY) is negative (-), if the mains part earlier than the “Aux A” assertion

Note: The “Aux A” input is the common start for both the mechanism time log and the arc time log functions.

Stopping of the Arc Time Log

The arc time logs stop with the cessation of current in each phase. The cessation of current is determined by a proprietary

software algorithm which does waveform analysis in addition to checking for CT Secondary current falling below 7% of the

Pickup Coil full scale current rating for more than 8 consecutive samples (1 / 4 cycle).

Note: In instances where the CT Secondary phase currents are less than 7% of Pickup Coil full-scale current rating and

the breaker trips, an ARC TIME of 000 mS will be recorded.

Table of contents

Other Incon Measuring Instrument manuals