INDCO HS-5 Series User manual

INDCO, Inc. M-M-30118 mixer manual HS-5 date: 3/8/05

HS-5 SERIES

DISPERSER

Contents Page

Safety, General & Installation ... 3

Operation ...... 4

Maintenance ...... 5

Electric Motor Data & Troubleshooting . . 6

Parts List ......10

HS-5

Series

Disperser

OWNERS

MANUAL

INDCO, Inc.

4040 Earnings Way

New Albany, IN 47150

phone: 812-941-5954

fax: 812-944-9742

web: www.indco.com

Warranty

Our products are guaranteed against

defective materials and workmanship, we will

repair or replace such items as may prove

defective at our option. Warranty period is

one year on items manufactured by INDCO.

On items not manufactured by INDCO, the

manufactures warranty applies. All

component parts of our products are covered

by this warranty, except for normal wear items

such as belts or impellers. We cannot be

responsible for damage or abuse to equipment

caused by improper installation or operation.

Warranties can also be voided by

unauthorized disassembly of equipment. For

warranty repairs, equipment is returned to

INDCO at the customer’s expense; we will

repair and return to customer at our expense.

Under no circumstances will we allow labor

charges or other expense to repair defective

merchandise. This warranty is exclusive and

is in lieu of all other warranties, whether

express or implied. INDCO shall not be liable

for any other damages, whether

consequential, indirect, or incidental, arising

from the sale or use of its products.

page 1 of 11

INDCO, Inc. M-M-30118 mixer manual HS-5 date: 3/8/05 page 2 of 11

Dispersers - Variable Speed Electric

Model:

Serial No.:

Date:

Order No.:

INDCO, Inc. M-M-30118 mixer manual HS-5 date: 3/8/05

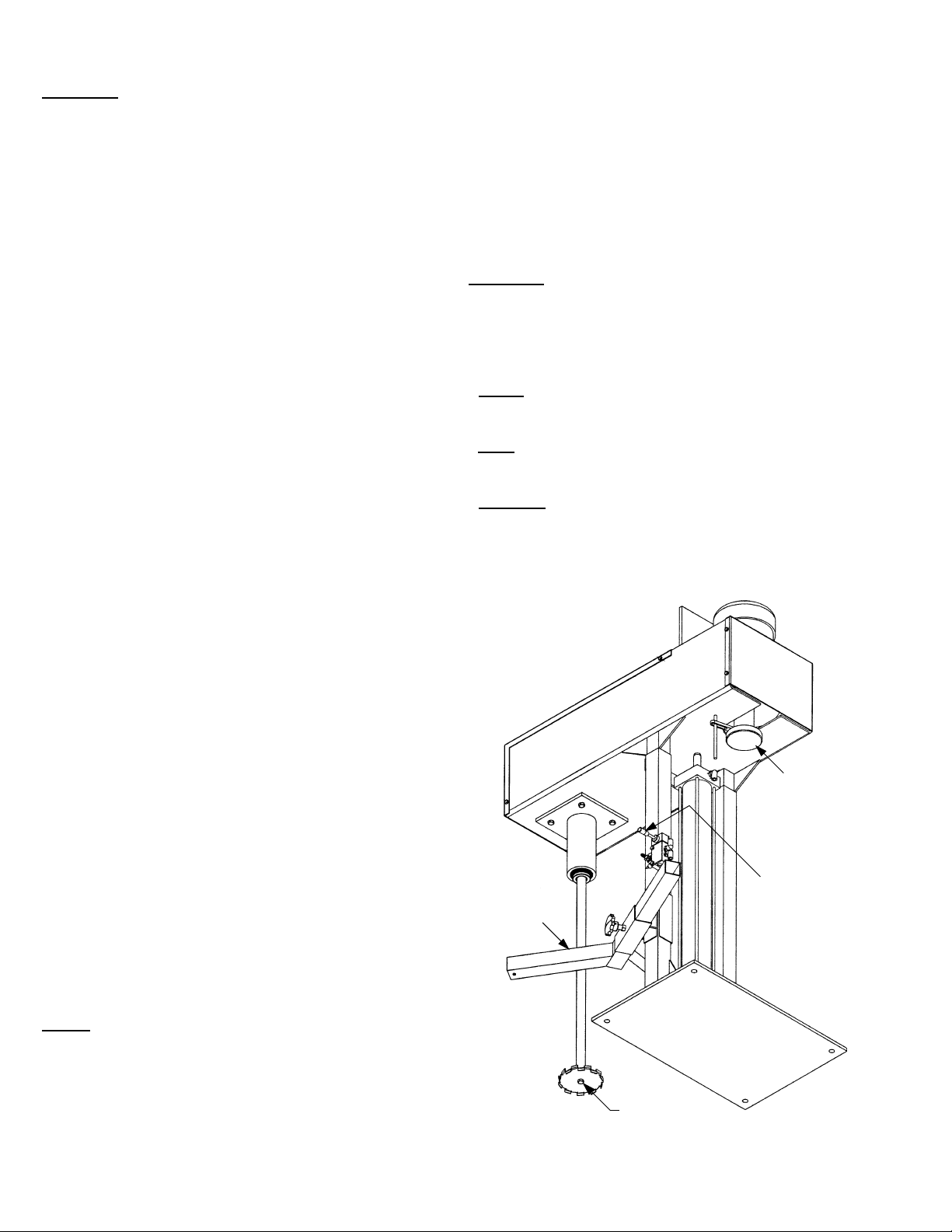

General

The HS-5 series 5-horsepower electric powered high-speed

dispersers are designed for small production batches.

Each model comes complete with following features:

• Variable speed:

- Mechanical belt drive: 600 to 4000 RPM.

- Electronic inverter drive: 180 to 3600 RPM.

• Impeller shaft: 1.25” dia. - 316 stainless steel.

• 6” design ‘A’ disperser blade - 304 stainless steel.

• Pneumatic cylinder lift mechanism, 36” travel range.

• Container holder with capacity for 55-gallon drum.

• TEFC or Explosion-Proof electric motor.

• Optional tachometer.

Installation

Receiving:

Before removing any packing, visually inspect the exterior

of the shipment for any sign of damage. Should there be

any damage, bring it to the attention of the delivering UPS

or truck line and note the same on the receiving ticket.

Should there be damage you must place a claim with the

truck line. They are the only ones who will pay for the

damage done and you are the only one who can place that

claim.

Mounting:

Ensure the unit is securely bolted to your floor and is level,

square, and plumb. Leave space around the unit for

cleaning, inspection and maintenance.

Pre-Start Up Check List:

1. Are all mounting bolts tight?

2. Is disperser blade mounting bolt tight?

3. Has electric motor been wired according to the diagram

on the motor label? Is motor grounded?

4. Does motor have emergency stop located as per local

code?

5. Bump motor and check rotation, looking down into the

container, shaft should rotate clock-wise. If direction is

incorrect reverse motor as explained on the motor label.

Safety

Please follow the below safety precautions. Read this

complete manual before trying to operate your mixer.

Failure to follow these instructions could result in serious

bodily injury or death.

• Never move the unit without a suitable lifting device.

• Have a qualified individual bring power to your unit.

• Always ground the unit.

• Never run the unit in open air.

• Never adjust the speed without the unit running.

• Always lockout the power when working on the unit.

• Always use the container holder to restrain the container

during operation.

Electric Motor Safety:

Motors should be installed, protected and fused in

accordance with latest issue of National Electrical Code,

NEMA Standard Publication No. MG 2 and local codes.

Eyebolts or lifting lugs are intended for lifting the motor

only. These lifting provisions should never be used when

lifting or handling the motor with other equipment (i.e.

gearboxes or other driven equipment) as a single unit. Be

sure eyebolt is fully threaded and tight in its mounting hole.

Eyebolt lifting capacity rating is based on a lifting alignment

coincident with the eyebolt center-line.

Eyebolt capacity decreases as deviation from this alignment

increases. See NEMA MG 2.

Frames and accessories of motors should be grounded in

accordance with National Electrical Code (NEC) Article 430.

For general information on grounding refer to NEC Article

250.

Rotating parts such as pulleys, couplings, external fans,

unusual shaft extensions should be permanently guarded.

Keep hands and clothing away from moving parts. Trained,

qualified personnel should make electrical repairs only.

Mechanical Variable Speed Drive Safety:

When maintenance is required in the area of the equipment

necessitating removal of the guarding, the prime mover

should be turned off and “locked out”.

The user of variable speed belt drives should be aware of

the hazards through misuse of the product or failure to

protect against contact with moving parts.

Spring-loaded pulleys should never be disassembled without

first receiving instruction from factory.

Rapid acceleration or braking, or shock loading may cause

a shaft to fracture due to torsional twist beyond its capacity.

All mounting screws on the pulleys must be kept tight.

Even though each pulley is individually balanced at the

factory the system in which the pulleys operate may

resonate, particularly at high RPM’s over 1800. Sometimes

a new belt will reduce vibration levels in a system.

page 3 of 11

INDCO, Inc. M-M-30118 mixer manual HS-5 date: 3/8/05

CAUTION:

• Never run mixer without an impeller.

• Never run the impeller in open air.

• Never run impeller outside a container.

Dispersion “rules of thumb” include:

10-HP is required for every 100-gallons, under 20,000-cPs.

Single shaft dispersers are not recommended for product

over 50,000-cPs. The liquid level should equal the liquid

diameter. In general the disperser is run at blade tip speeds

of 4,000 to 6,000 Feet-Per-Minute. FPM = rpm x 0.262 x

blade diameter, in inches. The lower ranges are used for

agitation or blending operations while the upper ranges are

used for dispersions of difficult materials. The middle range

is adaptable to a great many solutions and easier

dispersions. Experience by the operator will be the best

key as to what speed to try first on materials handled at

your facility.

The blade should equal 1/3rd the tank diameter and be

center, vertical mounted. Under normal operation the blade

is located from 1 to 1.5 blade diameters from the bottom.

If this results in an excessive vortex, the blade may be

lowered. If the action is a little slow at the above location,

the blade may be raised to a limit of 2.5 diameters to obtain

a good flow providing the amount of material over the blade

is greater than the amount of material beneath. At this

point, good action is usually assured in the bottom of the

container.

When adding materials to the container for a test, always

introduce the liquid phase first. In most cases, the disperser

should be started and solid phase added. However, on

some formulations such as enamel, particularly those of

colored pigments, it has been found most satisfactory to

add vehicle in tank and then add all pigments before turning

on motor.

Air Cylinder Operation:

Before connecting your air supply ensure the lift control

valve is in the center (off) position. The valve lever is spring

loaded to rest in the center position. Connect your air supply

to the quick connector on the 3-position control valve.

Maximum air pressure is 100 PSI. Note that air pressure is

used to both raise and lower the cylinder. The following will

enable you to adjust the height of the impeller or to install

and remove your batch container:

CAUTION: After the air line is installed and before operating

the machine for the first time, move the lift control valve to

the downward position. This will charge the air cylinder

and prevent surging when the lift control valve is moved to

the upward position.

• Lifting:

Move the lift control valve to the up most position. To

stop upward motion move valve to center (off) position.

• Hold:

To hold the impeller at any height move the lift control

valve to the center (off) position.

• Lowering:

Move the lift control valve to the down most position.

To stop downward motion move valve to center (off)

position.

Electronic Speed Control:

Baldor SmartMotor® Inverter-Duty models have an

electronic keypad variable speed control. Speed range is

180 to 3600 RPM.

Mechanical Speed Control:

Units with the mechanical variable speed belt drive have a

speed range of 600 to 4000 RPM.

Turning the hand-wheel at the rear of the disperser varies

the speed. For best results always stop and start the

disperser in the lowest variable speed hand-wheel setting.

NOTE:

DO NOT TURN THE HAND-WHEEL KNOB WHEN THE

DISPERSER IS NOT RUNNING !

Operation

page 4 of 11

mechanical

speed

control

hand-wheel

lift cylinder

control valve

blade bolt

container

holder

Operation, continued

INDCO, Inc. M-M-30118 mixer manual HS-5 date: 3/8/05

Maintenance

Maintaining your mixer is not difficult if you follow these

guidelines:

• Keep the mixer clean.

• Check all wiring on a regular basis and repair as needed.

• Unit fails to start: Check power source to unit, check

-and/or- reset breaker. If problem continues, disconnect

power and have a qualified person make proper repairs.

• Ensure the dispersion blade is fastened securely to the

shaft.

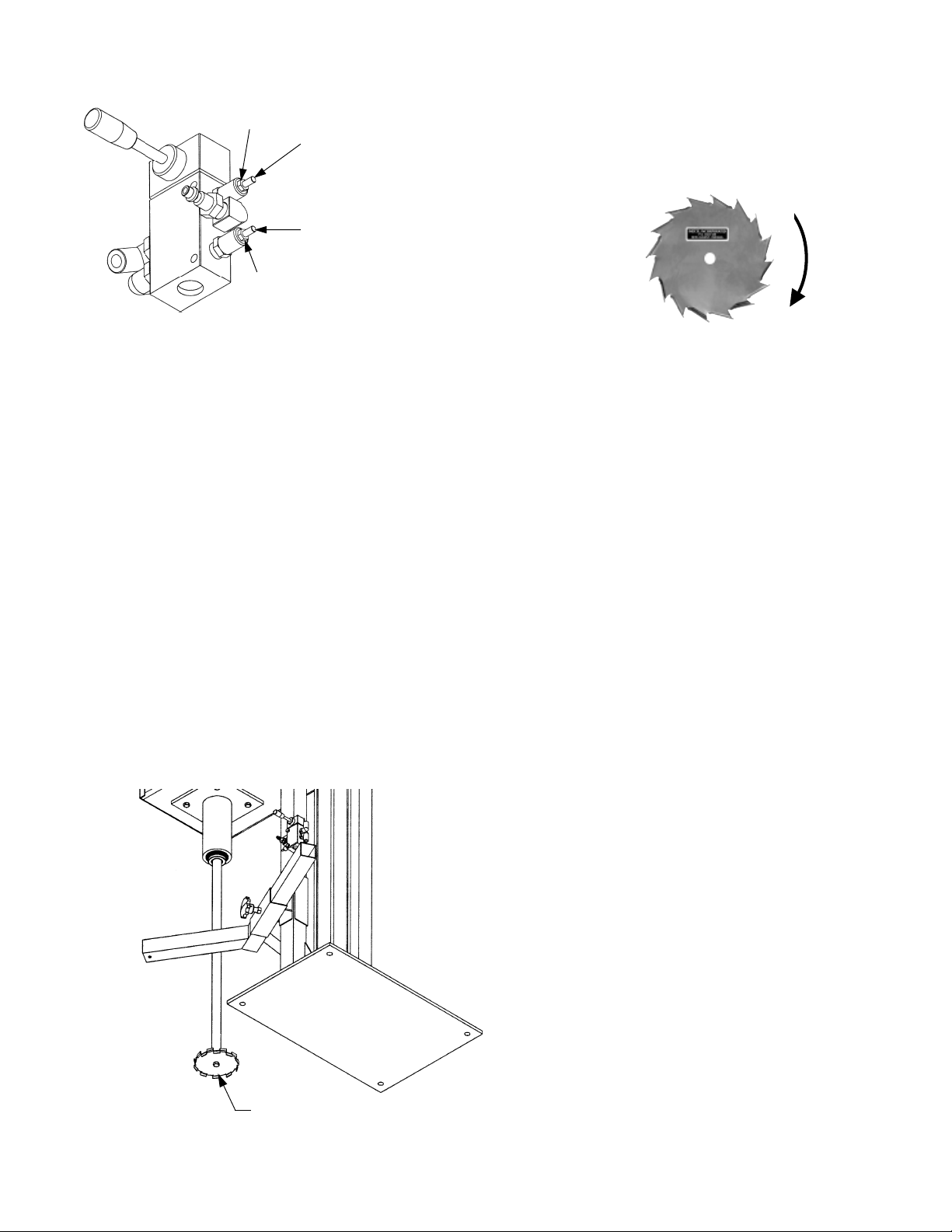

design A

(top view)

Blade Rotation:

Ensure the mixer shaft will rotate in a clock-wise direction,

looking downward into the container. Care must be taken

to ensure blade is rotating in the correct direction. Look for

arrow on blade or consult factory.

page 5 of 11

Blade Changing:

ENSURE POWER TO UNIT IS OFF OR DISCONNECTED!

Remove the bolt from the bottom of the shaft, remove and

replace the blade and replace the bolt.

blade bolt

Mechanical Variable Speed Drive

• Avoid using automotive chassis and other non-

interchangeable lubricants. Lubricated pulleys will stick

or freeze if not lubricated properly. The most frequent

cause is failure to run the drive through part of its range

at the time it is lubricated. The pulley must be lubricated

periodically and pulley adjustment opened and closed to

distribute the grease inside. Small amounts of grease

will do. Wipe excess off of belt faces.

• Check belt alignment. Misalignment will cause the belt

to overheat and wear rapidly.

• Watch for overload conditions. If the belt loops out or

squeals the drive is overloaded. This condition will

frequently exist during start-up but should not continue

for more than a few seconds. When starting up,

particularly if starting several times a day, try to start

up slowly by jogging the machine to bring the speed up

gradually.

• Excessive vibration will cause damage to all of the

equipment in the drive system. If any doubt exists as

to the safe levels of vibration a qualified person should

be called in to examine the drive.

• Use Loctite on set screws where necessary to prevent

screws from backing out due to vibration in machine.

• Air Valve ~ Cylinder speed control adjustment:

Air flow adjusting screw:

- screw in until desired

lowering speed is

obtained.

Air flow adjusting screw:

- screw out until desired

lifting speed is obtained.

Once desired raise &

lowering speeds are

obtained, tighten lock-nuts.

lock-nut

lock-nut

Operation, continued Maintenance, continued

Table of contents