Ref. FTA_GS_M_ST-GPX_H-en Rev: 0 23/06/23 1of 12

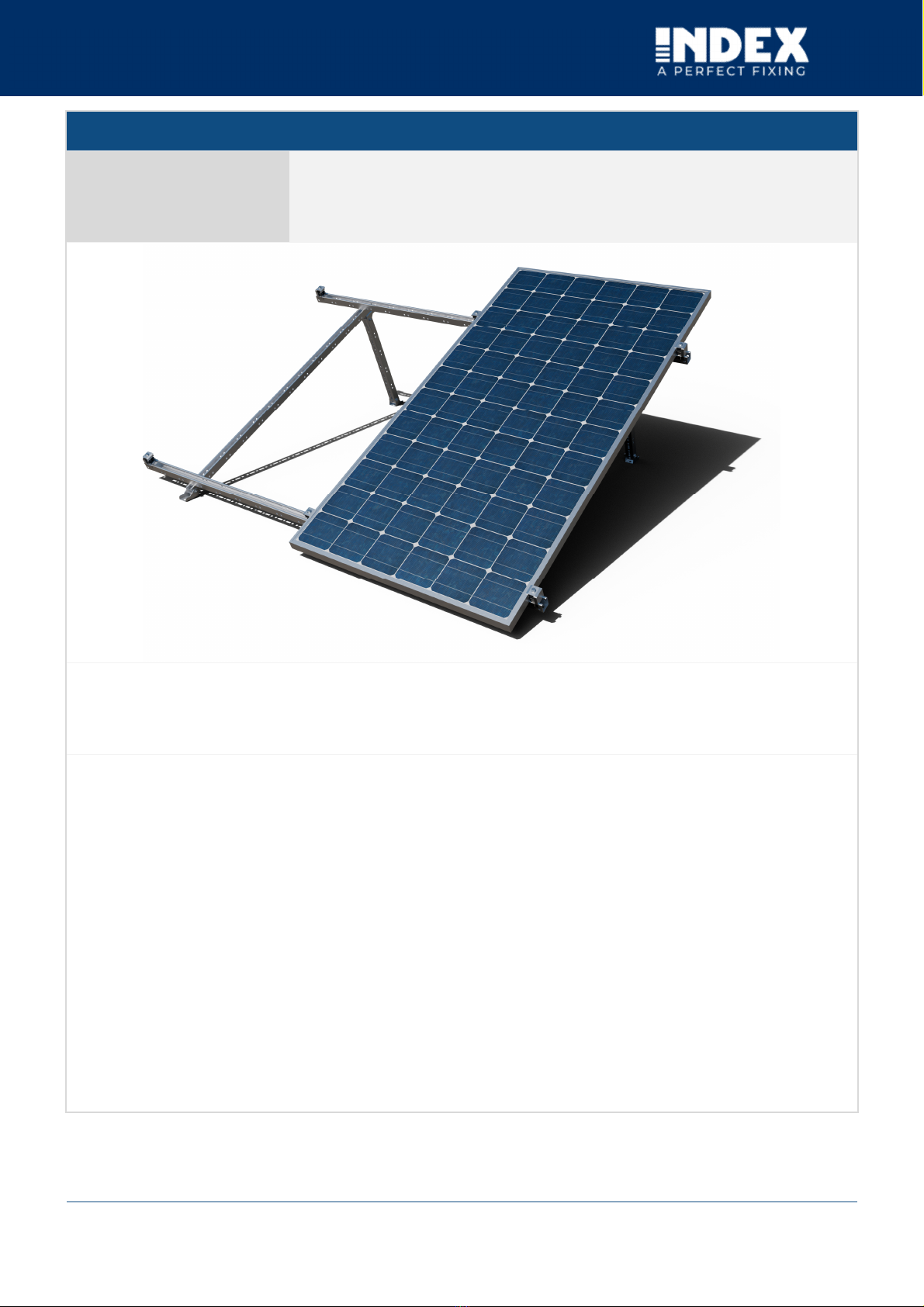

ST-GPX INSTALLATION MANUAL ON CONCRETE

1. CHARACTERISTICS

Description:

Coplanar mounting system on GP-XS Atlantis C4-M perforated guide

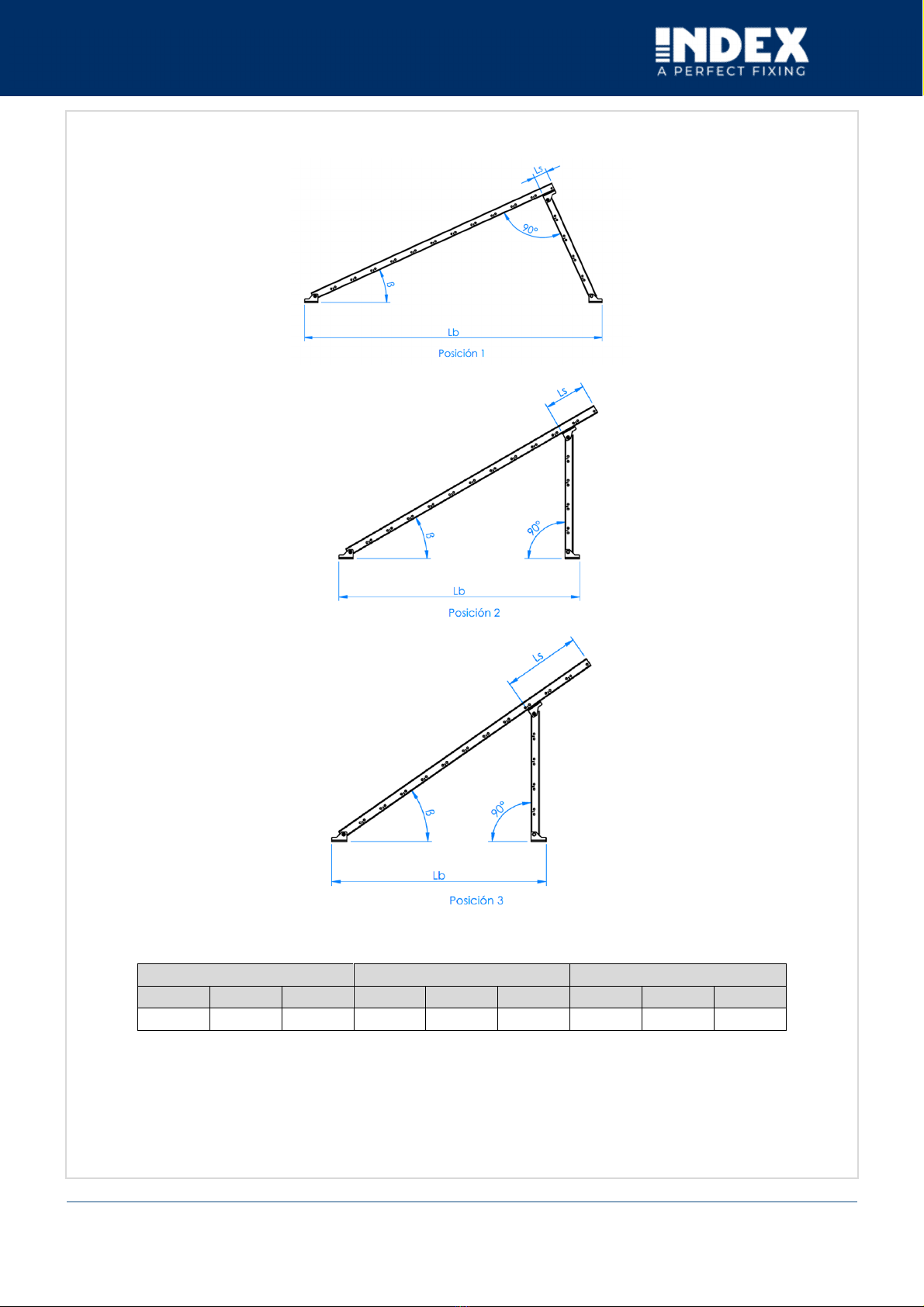

System inclination:

Triangular mounting on pre-assembled triangles with adjustable inclination at 25°, 30° and 35°.

System orientation:

Facing SOUTH, EAST OR WEST depending on the roof orientation.

System materials:

Aluminium, stainless Steel and EPDM.

Warranty:

Until 10 years depending on environmental conditions (excluding environments exposed to hydrogen

sulphide). The warranty is only valid if the complete ST-GPX system is used.

Compatible solar panels:

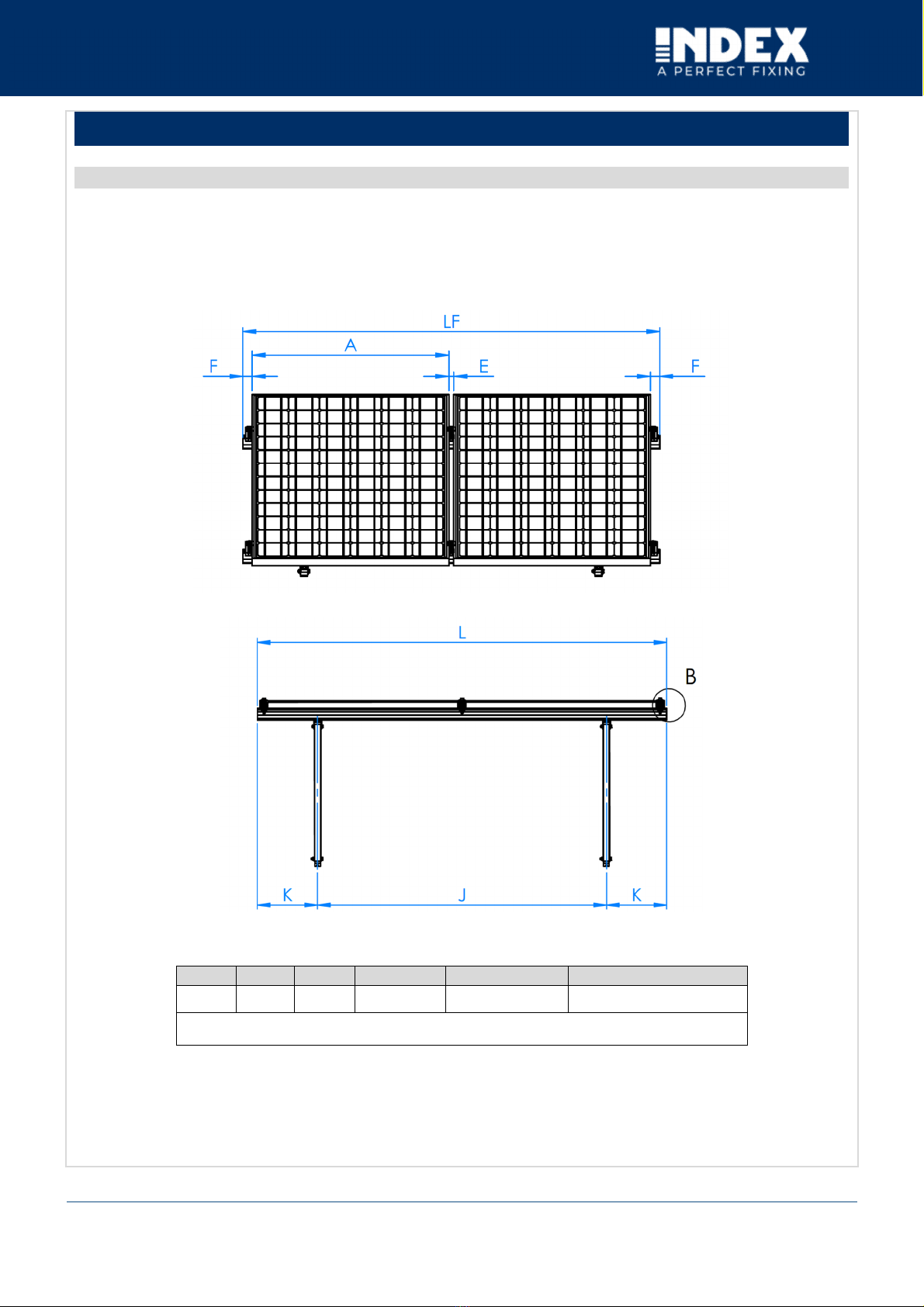

Solar panels type:

Solar panels with frame height between 30mm and 40mm.

Solar panels orientation:

Mounting orientation of portrait (vertical)

Solar panel size

Panel length less than 1150 mm

Application area:

Application area: Flat and low-slope roofs.

Roof slope: Up to 240 km/h. The structure and fixing must be calculated according to local and roof conditions.

Wind load: Up to 2 kN/m². The structure and fixing must be calculated according to local and roof conditions.

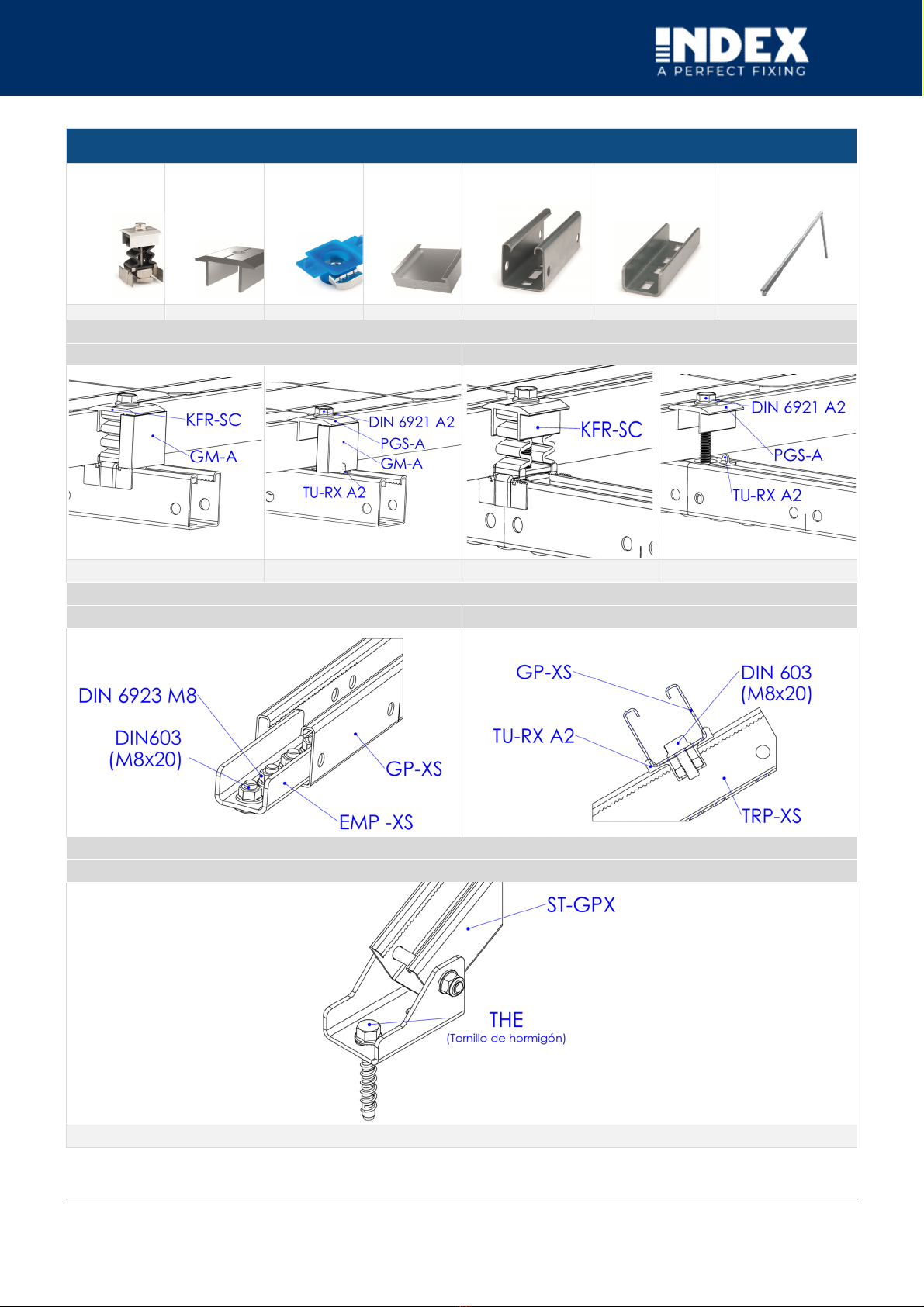

ST-GPX SYSTEM DESCRIPTION

Triangular mounting system with GP-XS “guía perforada INDEXTRUT

solar. Acero Atlantis C4-M”, para instalación de placas solares.