Industrial Scientific DSX User manual

Product

Manual

DSX Standalone Mode

DSXi Cloud-connected Mode

iNet® Accounts

Edition: 1

May 4, 2015

Part Number: 17156005-1

Industrial Scientific Corporation.

Pittsburgh, PA USA

Shanghai, China

© 2015 Industrial Scientific Corporation

All rights reserved. Published 2015

Revision 0

Contents

Warnings and Cautionary Statements.............................................................................................................................................. 1

General Information .......................................................................................................................................................................... 3

Introduction ................................................................................................................................................................................... 3

Capabilities ................................................................................................................................................................................... 3

Compatibilities............................................................................................................................................................................... 5

System Requirements and Supplies............................................................................................................................................. 5

Certifications ................................................................................................................................................................................. 5

Care and Operating Guidelines .................................................................................................................................................... 5

Training......................................................................................................................................................................................... 6

Getting Started.................................................................................................................................................................................. 7

Work-space Checklist ................................................................................................................................................................... 7

Unpack.......................................................................................................................................................................................... 7

Hardware Overview ...................................................................................................................................................................... 8

Specifications................................................................................................................................................................................ 9

Setup............................................................................................................................................................................................... 11

Introduction ................................................................................................................................................................................. 11

Setup Instruction......................................................................................................................................................................... 11

Use.................................................................................................................................................................................................. 19

Use Instruction............................................................................................................................................................................ 19

Error Messages........................................................................................................................................................................... 20

Warranty and Limitation of Liability............................................................................................................................................. 23

Contact Information......................................................................................................................................................................... 28

1

Warnings and Cautionary Statements

Failure to perform certain procedures or note certain conditions may impair the performance of this product. For

maximum safety and optimal performance, please read and follow the procedures and conditions listed below.

Use only in a clean-air environment known to be nonhazardous.

Use of this product in areas where it may be subject to large amounts of electromagnetic interference

may affect the reliable operation of this device and should be avoided. Sources of large amounts of

interference could be and are not limited to:

Operation near high radio frequency (RF) fields (near 2-way radio transmission antennas where the RF

fields may greatly exceed 10 V/M, etc.).

AC Power Mains that may have excessive power surges, spikes, or transients (from large AC motors

operating heavy loads, which may induce voltage sags, etc.).

Use only at altitudes below 2,000 m (6,000 ').

NOTE: This product has been tested to, and passes all EMC requirements to EN 61326:1998 Electrical

Equipment for Measurement, Control and Laboratory Use for Type 2 (Industrial) Apparatus, as well as

FCC Part 15, Class A emissions levels when installed to the requirements outlined within this manual.

Mandatory compliance to these standards helps to ensure controlled, reliable operation of this device

when exposed to typical levels of electromagnetic interference as well as ensuring that this device is not

the source of emissions that might interfere with other equipment installed nearby.

NOTE: Per 30 CFR 75.320(b), the product tests for oxygen deficiency of MSHA-approved oxygen

detectors compatible with the product that can detect 19.5% oxygen with an accuracy of ±0.5%.

NOTE: Per 30 CFR 22.7(d)(2)(i), the acceptable limit during calibration and bump testing with 2.5%

methane must be 10% for MSHA-approved instruments using Industrial Scientific certified calibration gas.

NOTE: This product has an internal pump that controls the flow of gas delivered to the system. As a

result of the internal pump, a demand-flow regulator must be used in conjunction with this product.

2

General Information

Introduction

Capabilities

Compatibilities

System Requirements and Supplies

Certifications

Care and Operating Guidelines

Training

Introduction

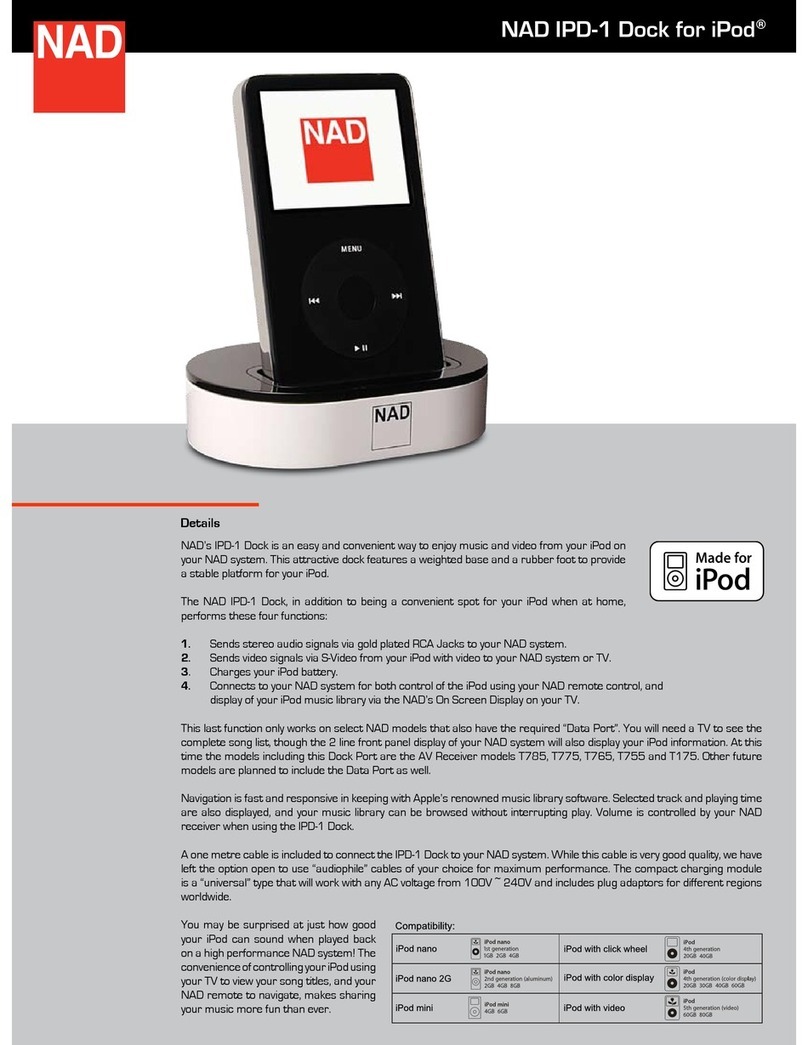

The DSX™Docking Station can be installed for use with the gas detection instruments and program

platforms of Industrial Scientific. Within this manual, the docking station is referred by order type or the

references noted below:

Order type

Reference

DSX Standalone Mode

Standalone Mode (unit, order, etc.)

DSXi Cloud-connected Mode (DSXi)

DSXi (unit, order, etc.)

DSX-to-DSXi upgrade (DSXi)

DSXi (unit, order, etc.)

iNet® Account (replacement or add-on equipment)

iNet Account (unit)

Capabilities

The DSX Docking Station order types named above each provide the following.

Choice of 3 or 6 gas intake ports

Charging of compatible instruments

Choice of display-screen language: English, French, German, Portuguese (Brazilian), or Spanish

Automated and on-demand (“forced”) bump tests and calibrations

Each order type offers additional functionality as summarized below.

DSX Standalone Mode

Automatically performs one on-dock task (bump test [default setting] or calibration).

When a USB data storage device (included) is connected, the following are automatically downloaded to

the device when an instrument is docked:

Records for station-performed bump tests

Records for station-performed calibrations

General Information

4

Instrument data logs

Downloaded data are saved to the USB in CSV (comma separated values) file format, which can be

opened with (or imported to) a spreadsheet.

DSXi Cloud-connected Mode

Automatically performs all scheduled instrument tasks on-dock including bump tests, calibrations, firmware

updates, and settings changes.

Instrument data logs and station-performed bump tests and calibrations are automatically uploaded to the

cloud-based Gas Detection Program Platform, iNet Control.

Access to the iNet Control software interface, which provides these capabilities:

View your gas detection program summary and learn of specific issues that need attention.

View alarm events, other instrument data, reports, and alerts.

Take care of basic Account administration including global (fleet) event settings and special events.

Use organizational tools to create equipment groups, and assign settings to equipment groups or

equipment items.

Set up users for iNet Control access; limit or expand a user’s access level and set up users for the

automatic receipt of reports and alerts.

Docking station firmware is automatically updated.

iGas cylinder compatibility data is automatically updated..

iNet Accounts

Automatically performs all scheduled instrument tasks on-dock including bump tests, calibrations, firmware

updates, and settings changes.

Instrument data logs and station-performed bump tests and calibrations are automatically uploaded to the

cloud-based Gas Detection Program Platform, iNet Control.

Access to the iNet Control software interface, which provides these capabilities:

View your gas detection program summary and learn of specific issues that need attention.

View alarm events, other instrument data, reports, and alerts.

Take care of basic Account administration including global (fleet) event settings and special events.

Use organizational tools to create equipment groups, and assign settings to equipment groups or

equipment items.

Set up users for iNet Control access; limit or expand a user’s access level and set up users for the

automatic receipt of reports and alerts.

Docking station firmware is automatically updated.

iGas cylinder compatibility data is automatically updated..

All iNet docking stations and instruments are leased from and maintained by Industrial Scientific. When an

equipment item is in need of service, iNet Control notifies the account administrators, removes the item

from service, and ships a replacement item.

Compatibilities

5

Compatibilities

Each docking station is compatible with one of the following Industrial Scientific instruments:

GasBadge® Pro

MX6 iBrid™ Multigas Monitor

Tango™ TX1 Single-gas Monitor

Ventis™ LS Multigas Monitor

Ventis™ MX4 Multigas Monitor

The docking station is compatible with only iGas™cylinders used with demand-flow regulators and card-

reader-and-tubing assemblies, all from Industrial Scientific. The use of demand-flow regulators that have an

iGas pressure switch is recommended for DSXi units and required for iNet Accounts.

DSXi units are compatible with iNet for the cloud-based storage of and access to data. Standalone Mode

units use a USB storage device for data storage and access, and are compatible with some printers (HP

OfficeJet 100 Mobile Printer recommended).

System Requirements and Supplies

DSX Standalone Mode

A PC and Ethernet cable is recommended for setup.

DSXi Cloud-connected Mode and iNet Accounts

A network connection is required for setup and operation.

The network connection must provide 10/100 Ethernet support using an Ethernet cable that comprises

RJ45 connectors and is of the cable type Cat5 or greater. For longer cables, 14−110 m (46–360 '), use a

solid conductor shielded twisted pair cable.

The docking station does not natively support wireless networking. If a wireless connection is desired, it can

be established through third-party hardware solutions such as wireless bridges or mobile broadband

routers plugged into the unit’s LAN port. Use of such a wireless solution will not affect docking station

operation.

Certifications

The product is certified for use as indicated on the labels affixed to the docking station.

Care and Operating Guidelines

Use the following guidelines to enhance personal safety and protection of the docking station and working

environment.

The unit should be serviced by qualified personnel only. Contact Industrial Scientific for troubleshooting,

examination, or repair.

The unit is equipped with a fixed-voltage power supply and will operate at only one voltage (see the

regulatory label on the outside of the unit for its operating voltage).

To help protect the unit from sudden, transient increases or decreases in electrical power, use a surge

suppressor, line conditioner, or uninterruptible power supply (UPS).

General Information

6

To reduce the risk of electric shock or fire:

Do not use the unit during an electrical storm without proper protection.

Do not connect or disconnect any cables to or from the unit during an electrical storm.

Do not expose the unit to rain or moisture.

Do not push any objects into the openings of the unit.

To avoid possible damage to the unit's system board, wait 5 seconds after powering off the unit before

restarting.

To avoid shorting the unit when disconnecting a network cable, first unplug the cable from the unit, and

then from the network jack. When connecting a network cable, first plug the cable into the network jack,

then the other end into the unit.

Be sure nothing rests on the unit's cables or tubing. Ensure cables and tubing are not located where they

can be stepped on, cut, tripped over, loosened, or disconnected.

Do not place the unit on or near flammable materials.

Do not use corrosive chemicals or vapors near the unit.

Do not immerse the power cable or plug in water.

Do not drop the unit.

Before cleaning the unit, disconnect the power supply from the power source.

Clean the unit with a soft cloth dampened with water.

Do not spray water directly onto the unit.

Do not use liquid or aerosol cleaners, which may contain flammable substances.

Compressed gas cylinders and their contents may present specific hazards to the user. Use only in a well-

ventilated area. Use only in accordance with the instructions and warnings as marked on the cylinder and

the appropriate Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS).

Training

Industrial Scientific offers classroom and self-guided online training options for a variety of topics,

including the setup and operation of the docking station.

3

Getting Started

Work-space Checklist

Unpack

Hardware Overview

Specifications

Work-space Checklist

Set up and use the docking station in an area that is known to be nonhazardous.

Choose a work space that is large enough to accommodate the units and their accessories, and is in

close proximity to an accessible power source.

For DSXi and iNet Account units, choose a work space that is in close proximity to a network

connection; for DSX Standalone Mode units, a computer connection.

As needed, mount cylinder holders to the desired desk or wall locations.

Abide by all care and operating guidelines during setup and operation.

Unpack

The box contains those items listed and shown below (as ordered). Each ordered item should be

accounted for in the unpacking process.

After unpacking, if any item is missing or appears to have been damaged, contact Industrial Scientific

or a local distributor of Industrial Scientific products.

Item (part number)

DSX Docking Station

GasBadge® Pro (18109331)

MX6 iBrid™(18109329)

Tango™TX1 (18109330)

Ventis™LS (18109328)

Ventis MX4 (18109327; shown here)

Getting Started

8

Item (part number)

iGas Card-reader-and-tubing Assembly (17155785)

Power Supply (17136623)

With adapters for Australia, Europlug, North America, and UK and Ireland

Power Cord, Dedicated (optional; use with power supply in place of adapter)

Australia (17155001)

Europlug (17155003)

North America (17155000)

UK and Ireland (17155005)

Fresh-air fitting (factory installed)

USB Data Storage Device (17156585; for DSX Standalone Mode orders only)

see hardware overview

Flipper Lock (17155133; for Ventis MX4 docking stations only)

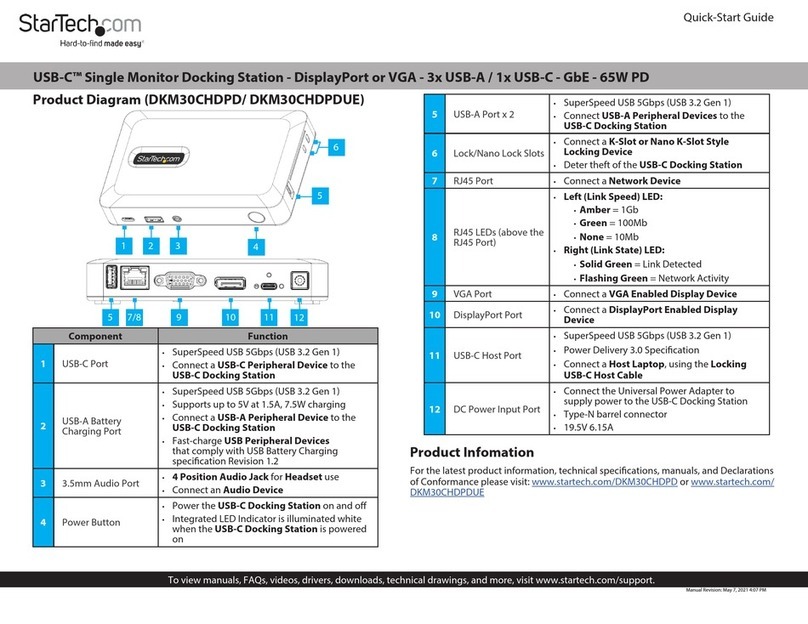

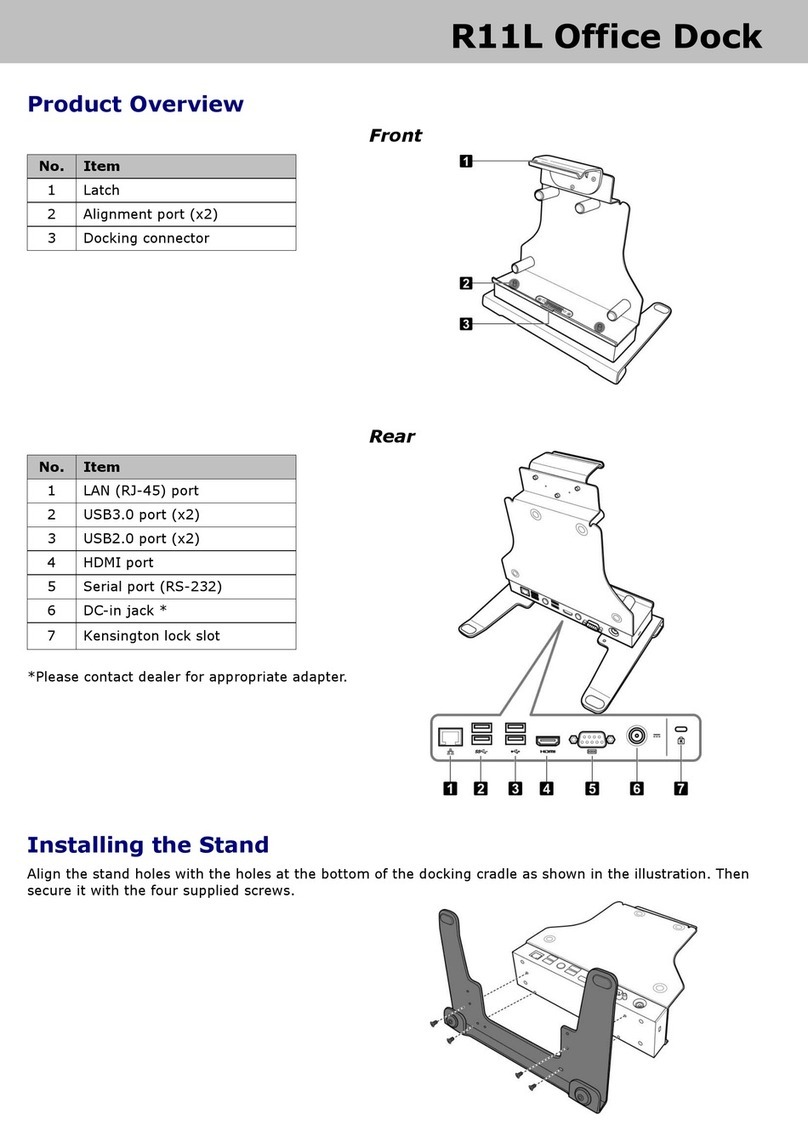

Hardware Overview

Front(Ventis MX4 diffusion model shown)

Cradle lid (shown open)

Flipper lock

for use with Ventis MX4 diffusion

instruments only

Cradle

LCD

LEDs

From top to bottom:

green, amber, and red

Keypad

From left to right:

left arrow key (), enter key (),

and right arrow key ()

Specifications

9

Back

Back panel (six port-set unit shown)

iGas port sets

From left to right:

Port set 4

Port set 5

Port set 6

Power supply port

(12 VDC)

Network connection

(LAN PORT)

From left to right:

Port set 1

Port set 2

Port set 3

Note: The port sets 1, 2, and

3 are positioned in the same

location on the three port-set

unit.

USB port, type A

(USB)

For use with Standalone Mode units

(USB data storage device or

compatible printer)

Specifications

Physical Specifications

Instruments supported

GasBadge Pro, MX6 iBrid, Tango TX1, or Ventis LS, or Ventis MX4

Dimensions

GasBadge Pro, Tango TX1: H: 22.66 cm (8.92 "); W: 16.89 cm (6.65 "); D: 27.31

cm (10.75 ")

Ventis MX4, Ventis LS: H: 24.97 cm (9.83 "); W: 16.89 cm (6.65 "); D: 27.31 cm

(10.75 ")

MX6 iBrid: H: 25.3 cm (9.96 "); W: 16.89 cm (6.65 "); D: 27.31 cm (10.75 ")

Gas and fresh-air intake ports

3-port configuration: two gas and one fresh air

6-port configuration: five gas and one fresh air

Pump flow rate

1.2 SCFH (550 mL/min)

Communication

10/100 Ethernet support using an Ethernet cable that comprises RJ45

connectors and is of the cable type Cat5 or greater (for longer cables, 14−110 m

[46–360 '], a solid conductor shielded twisted pair cable).

USB port for data storage device or printer (for use with Standalone Mode units

only).

Display

128 x 64 dot matrix LCD

Language options: English, French, German, Portuguese (Brazil), or Spanish

Performance Specifications

Getting Started

10

Operating temperature range

0–50 ºC (32–122 ºF)

Operating humidity range

0–80% relative humidity (RH) up to 30 ºC (86 ºF), decreasing linearly to 50% RH

at 50 ºC (122 ºF)

External power supply ratings

Supply voltage: 100–240 VAC/12 VDC

Frequency range: 50–60 Hz

Current rating: 5A

4

Setup

Introduction

Setup Instruction

Introduction

Based on your order type, complete the instruction steps noted

below. It is important to complete these tasks in the stated

order.

Order type

Complete these

steps*

DSX Standalone Mode

2–16

DSXi Cloud-connected Mode

1A and 2–14

DSX-to-DSXi upgrade

1B and 2–14

iNet Account (replacement or add-on

equipment)

2–14

*If the docking station will be dedicated to service only Ventis MX4

diffusion units, also complete step 17.

When setup is completed, your docking station will look similar

to the image shown here. It may differ based on the number or

type of connected cylinders and whether the unit is or is not

connected to a network or computer. If you have any questions

during setup, contact Industrial Scientific.

Setup Instruction

Step

Task

1

Activation for the order types:

DSXi Cloud-connected Mode

DSX-to-DSXi upgrade

You will need your Activation Certificate.

Reminder: Complete 1A or 1B, but not both,

depending on whether you ordered a DSXi unit (1A)

or a DSX-to-DSXi upgrade (1B).

1A

If you ordered a DSXi Cloud-connected unit, find its Activation Certificate in your docking station shipment.

To install your first unit, go to www.indsci.com/mydsx and follow the instructions provided there.

To install additional units, log into iNet Control. Click on the “Fleet” tab: from the drop-down menu, select

“Activate a Docking Station” and follow the on-screen instructions.

Setup

12

1B

If you ordered the DSX-to-DSXi upgrade, you will receive an Activation Certificate from Industrial Scientific for each

unit you are upgrading. Go to www.indsci.com/mydsx and, with your certificate(s), follow the instructions

provided there.

The remaining setup steps are shown below in detail. Those pertaining to the back of the docking station

(steps 2-15) can also be viewed as part of a completed docking station setup on page 18.

2

Network connection for DSXi units and iNet Accounts

PC connection for Standalone Mode units

For DSXi units and iNet Accounts, a network

connection is required for setup and operation.

For Standalone Mode units, a PC connection is

recommended for setup. This allows you to access

and adjust the unit’s settings through the on-board,

easy-to-use DSX Configurator. For example, you

can change the unit’s date and time setting to match

your time zone so that bump test and calibration

records have accurate date-time stamps. Once

setup is completed, Standalone Mode units can be

disconnected from the computer.

─

Plug the cable into the

Network (or PC for

Standalone Mode orders).

Connect the other end to the

docking station’s LAN

PORT.

3-7

Start-up

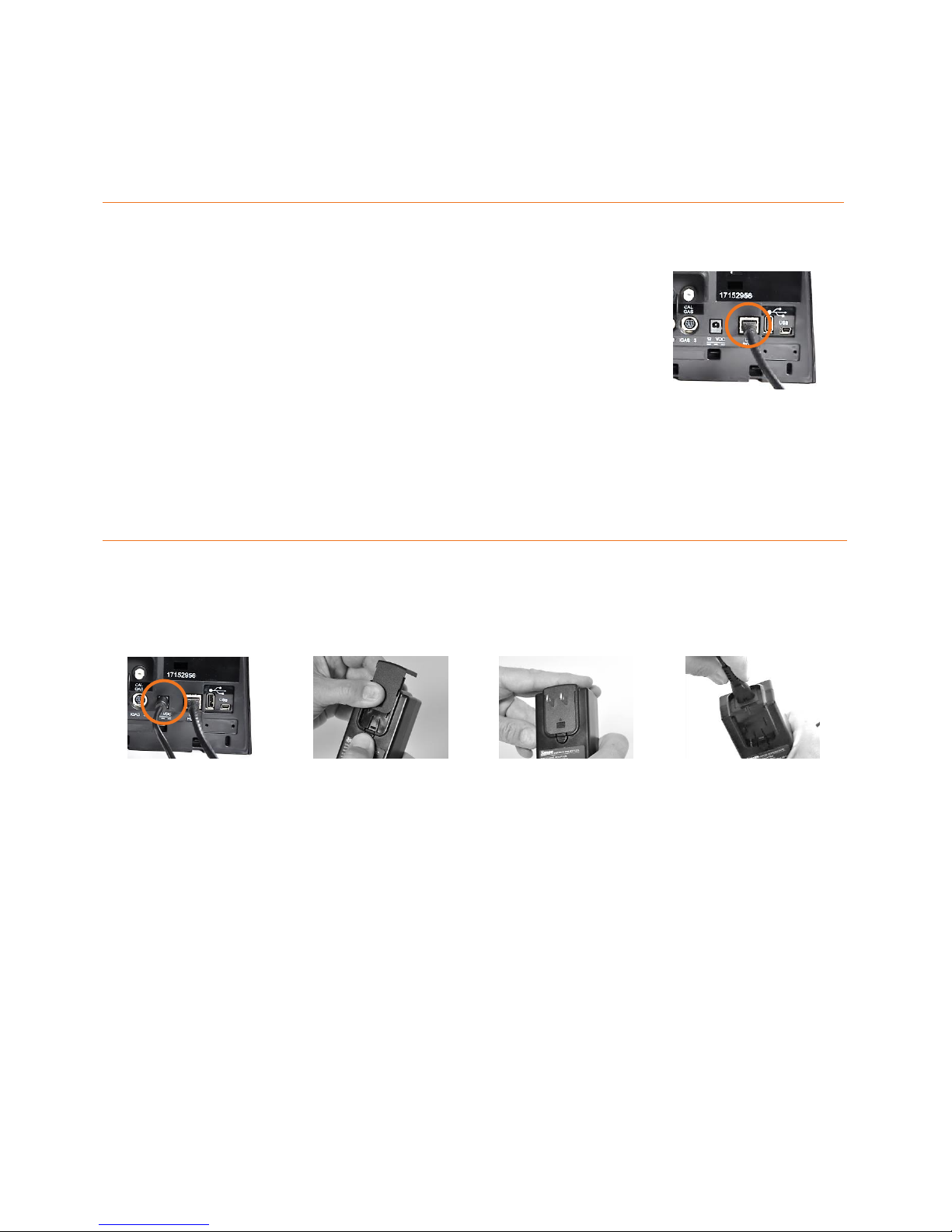

The docking station comes with a power supply and plug adapters. If ordered, a dedicated power cord can

be used in place of the adapter, an option that works well with narrow power strips. Instruction is provided

for using either option.

3. Connect the power supply

to the docking station’s 12

VDC port.

4. From the other end of the

power supply, remove its

cover: press the release tab

and slide the cover in the

direction indicated. Store the

cover for possible future use.

5. In the manner the cover was removed, replace it with the

adapter that is suitable for your outlet (above left). If a

dedicated power cord was ordered, use it in place of the

adapter (above right).

Setup Instruction

13

There is no power switch on the docking station. The unit is powered on and off at the power source.

─

6. Plug the power cord into a suitable outlet.

7. Check the docking station’s display panel.

A series of start-up messages appear on the docking station’s

display screen to indicate the unit is receiving power.

The LEDs turn on to verify they are functioning and a chirp

will sound.

Note: If the unit doesn’t power on, check the power connections at

the back of the unit, power supply, and power source.

When start-up is successfully completed, the green LED will

be on and the “ready screen” should display this text:

For Standalone Mode units, “Cal Station” (above right).

For DSXi units and iNet Accounts, “Docking Station” and

“√ iNet” (above left). Note: If these messages don’t display

within 15 minutes, the unit is not cloud-connected. DSXi users,

recheck the work you did in Step 1, “Activation”. For iNet

Accounts, contact Industrial Scientific.

i

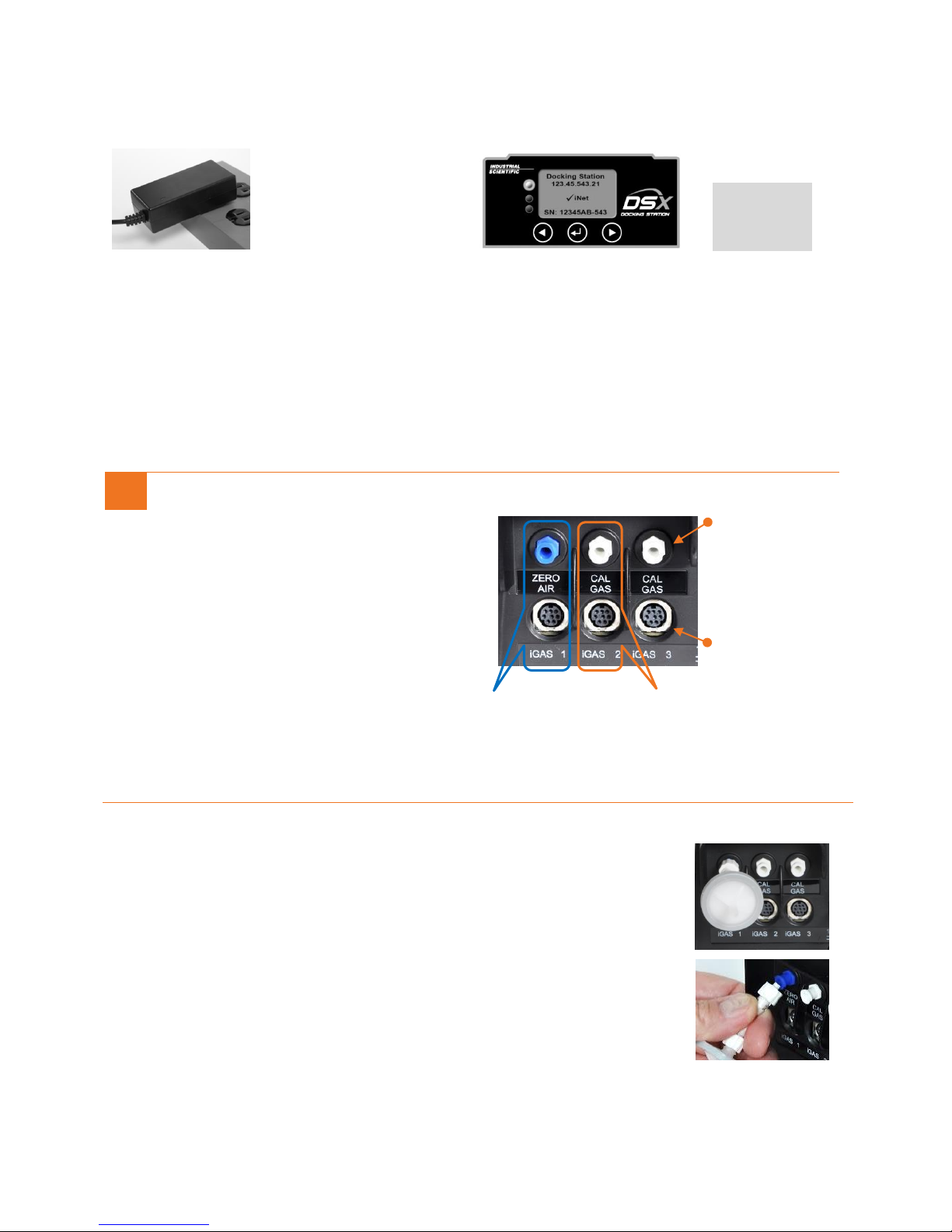

iGas port sets

Each docking station features three (shown here) or

six port sets.

A port set comprises two items that are vertically

aligned, a numbered cable port (labeled iGAS X,

where X=1, 2, 3, 4, 5, or 6) and a corresponding

intake port for tubing.

Use the port set iGAS 1 for air only. Its intake port

is labeled ZERO AIR and is blue in color.

Use the port sets iGAS 2 through iGAS 6 for

calibration gas. Each set’s intake port is labeled

CAL GAS and is white in color.

intake port

for tubing

cable port

Fresh air port set

Calibration gas port set

Close-up of port sets 1, 2, and 3

8

Fresh-air fitting

The fresh-air fitting is installed at the factory and is connected to the blue intake

port labeled ZERO AIR (shown here). The corresponding iGAS 1 cable port is

not used with the fresh-air fitting.

If your application uses a fresh-air fitting, go to step 9.

If your application does not use a fresh-air fitting and requires a zero-grade-air cylinder, remove

the fresh-air fitting: turn its white swivel connector counterclockwise.

Cal station

123.456.321.654

SN: 101231B-123

Setup

14

9-14

iGas cylinder connections

The docking station is compatible only with iGas cylinders that

are equipped with demand-flow regulators. Each compatible

cylinder is connected to the docking station using an iGas card-

reader-and-tubing assembly (assembly; shown at right).

Whether it contains calibration gas or zero-grade air, each

cylinder is connected to its port set in the same manner.

Connections for a calibration gas cylinder are shown and

described below using the port set, iGAS 2−CAL GAS.

If you are connecting a zero-grade-air cylinder, follow the

instructions below, but use the port set iGAS 1−ZERO AIR.

Depending on site needs, each calibration-gas port set can be

connected for use or left disconnected when not needed. The air

port set should always have either the fresh-air fitting or a zero-

grade-air cylinder connection.

Note: The docking station will recognize any incompatible cylinders on connection and

will indicate the error on the display screen. A Standalone Mode unit will recognize the

compatible cylinders contained in its memory, which can be updated by contacting

Industrial Scientific.

tubing and cable (connect to docking station)

card reader (connects to cylinder’s card)

iGas card-reading-and-tubing assembly

9. Attach the appropriate

demand-flow regulator to the

cylinder. Turn the cylinder

clockwise to tighten.

10. Slide the iGas card,

which is attached to the

cylinder, into the assembly’s

card reader.

11. Attach the open end of

the assembly’s tubing to the

regulator nipple.

12. If the regulator is

equipped with a pressure

switch (recommended for

DSXi units and required for

iNet Accounts), plug its tab

into the slot on the side of the

card-reader.

13. Attach the tubing's white

swivel connector to the CAL

GAS port located directly

above the iGAS 2 cable port.

Turn clockwise to tighten.

14. Plug the cable connector

(arrow faces up) into the

iGAS 2 cable port.

Note: The docking station will not recognize when any assembly’s tubing and cable are misconnected to two different port sets; bump test and

calibrations will fail.

Repeat steps 9-14 to connect additional calibration gas cylinders using the port sets iGAS 3, 4, 5, or 6.

Setup Instruction

15

15

Settings for Standalone Mode units ONLY

15.1 Find the unit’s IP address on

its display screen

(123.456.321.654 shown here).

Open a web browser and enter

https:// followed by the unit’s IP

address and press enter.

15.2 In the security dialog box, for both

user name and password enter DSX (case

sensitive). Click on OK.

15.3 At the security warning window,

choose the option that allows you to

continue. Note: it may say “not

recommended”.

The DSX Configurator will open.

15.4 Click on the configurator’s

Cal Station tab.

Set the date and time (24-hour

format). Click on Set Clock.

Set the on-dock task (bump test,

calibration, or none).

Enable the Download Data log

feature with a checkmark

(recommended). This enables the

automatic download of a docked

instrument’s data to a connected

USB data storage device. To

disable this feature (not

recommended), click on the box

to remove the checkmark.

Click on Save.

Cal station

123.456.321.654

SN: 101231B-123

Setup

16

15.5 Click on the configurator’s

Information tab.

From the Language drop-down

menu, choose the desired

language for the docking station

display.

The Audible alarm feature is

enabled with a checkmark and

causes the docking station to

alarm when an instrument is

docked. To disable this feature,

click on the box to remove the

checkmark and turn off the on-

dock alarm.

When the Menu Locked option is

enabled with a checkmark, the

docking station cannot be used

for on-demand tasks.

Click on Save & Reboot.

15.6 After the docking station reboots, you may disconnect it from the computer for Standalone Mode operation.

16

Records and data for Standalone Mode units ONLY

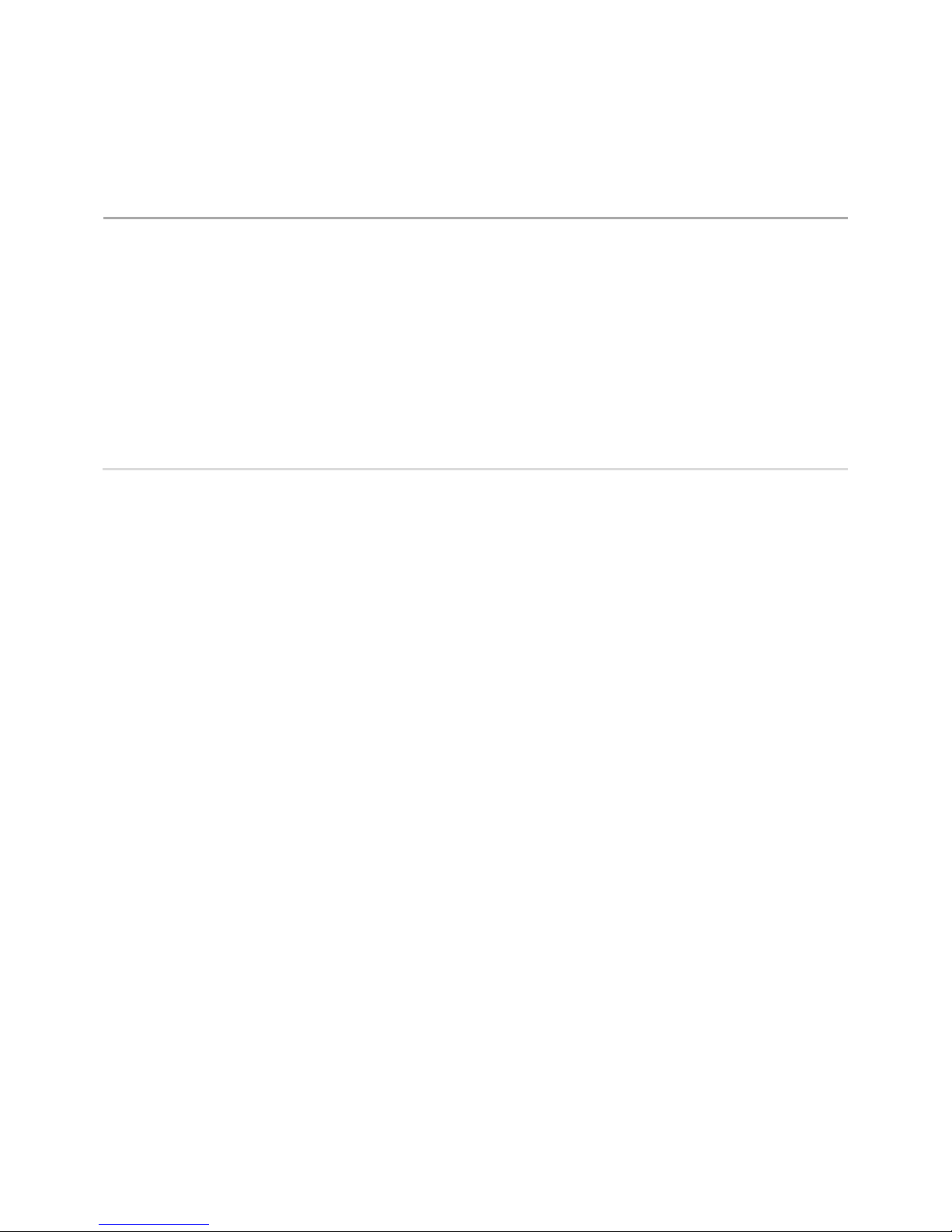

For Standalone Mode units, Industrial Scientific recommends that

a USB data storage device be connected to the docking station’s

USB port (type A). As shown here, the USB port is located on the

back of the unit next to the LAN port.

When connected, the following are automatically downloaded to

the device when an instrument is docked: instrument data logs

and records for docking station-performed bump tests and

calibrations. It is important to connect a USB device because no

records or data are ever saved to the docking station itself.

As noted earlier, records and data are saved to the USB device in

CSV file format, which can be opened with (or imported to) a

spreadsheet.

USB port

(type A)

Notes:

After a data log is downloaded to the USB device, the docking station will clear it from the instrument.

A compatible printer can be connected in place of the USB data storage device; however, only calibration and bump test records–not instrument

data logs–will be sent to the printer.

Either the USB device or printer can be connected at any one time, but not both at the same time.

Other manuals for DSX

2

This manual suits for next models

1

Table of contents

Other Industrial Scientific Docking Station manuals