6

SECTION 3: Installation

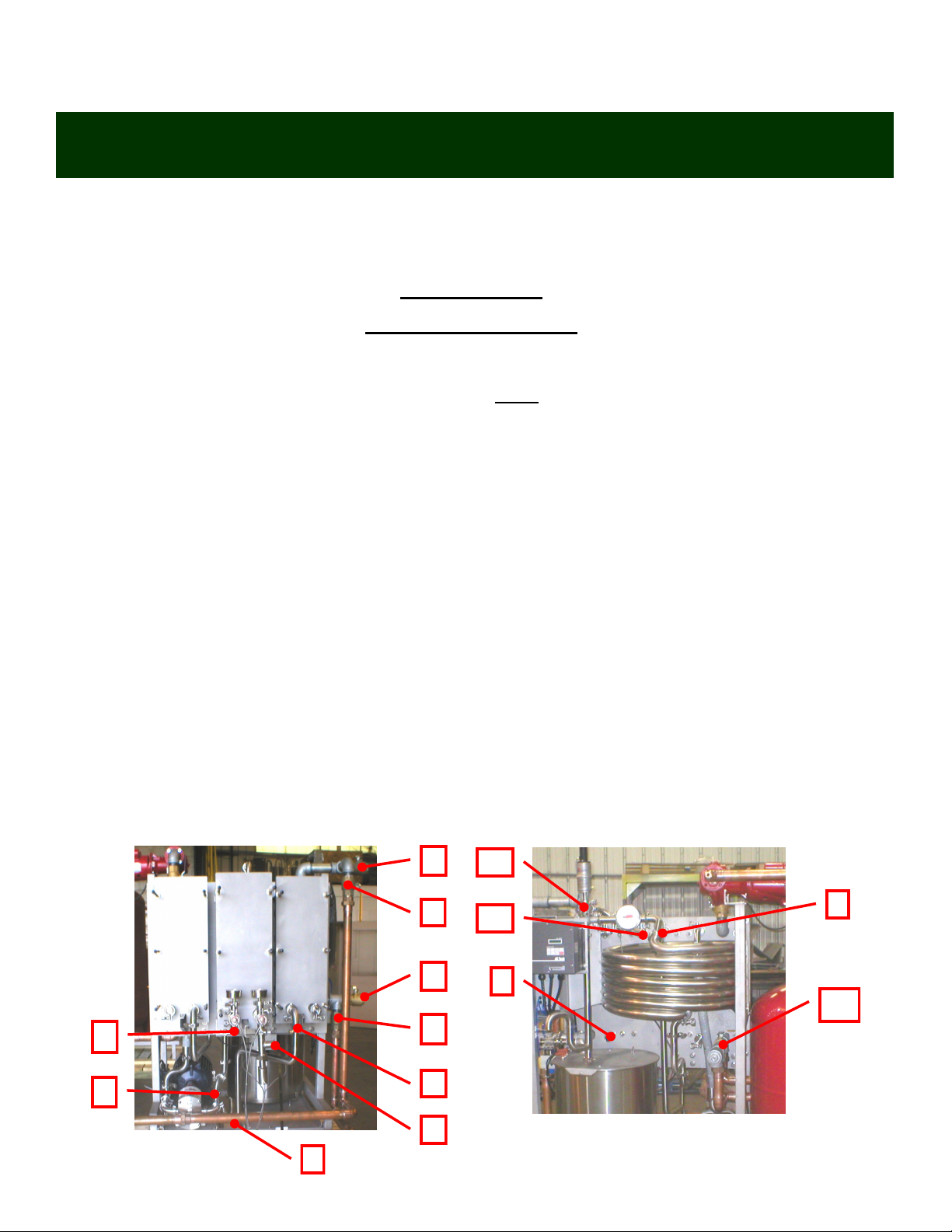

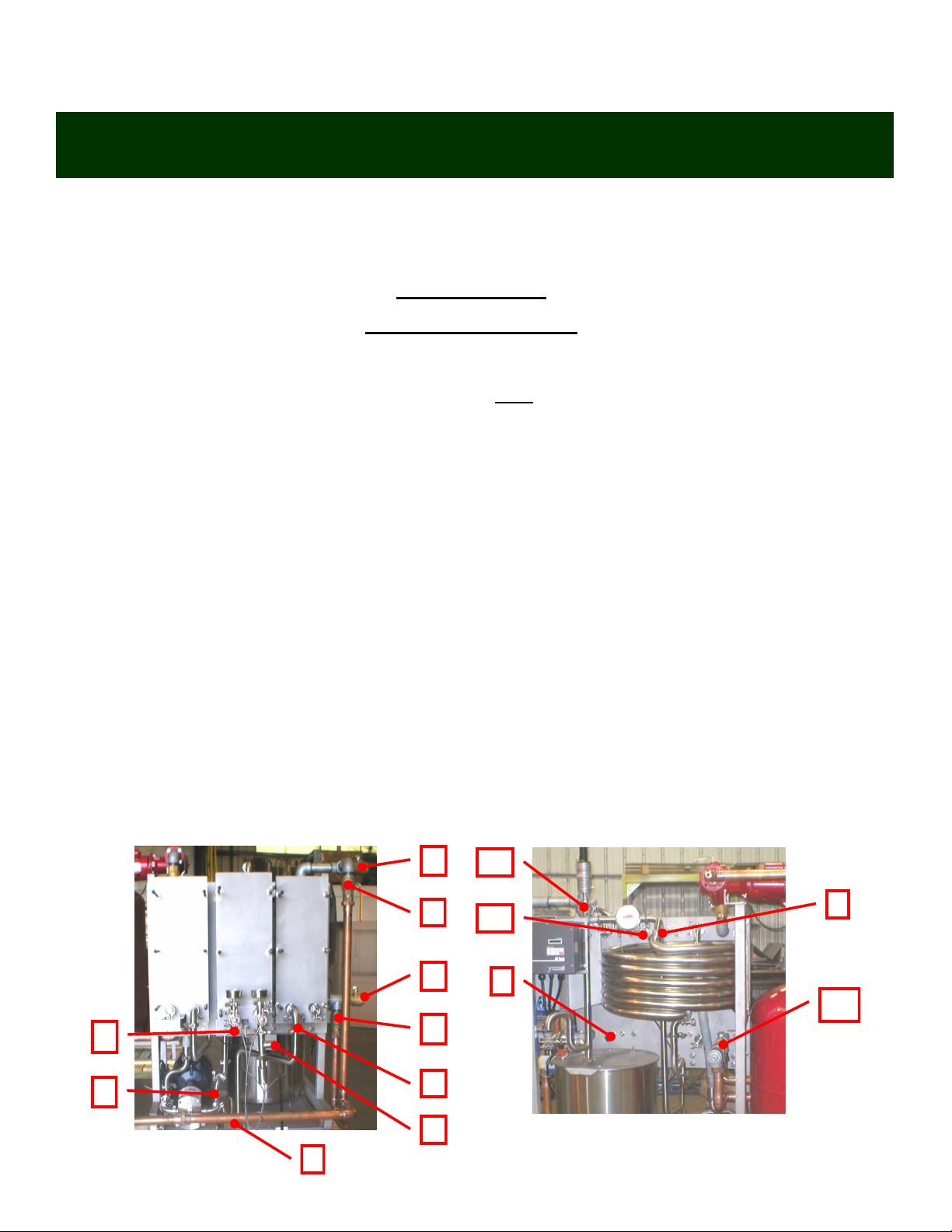

Pasteurized product outlet (standard): install a flexible hose from the

pasteurized product outlet on the back of the unit that can reach the following:

pasteurized product tank, raw product tank, and to a suitable drain. This hose

should be rated to withstand temperatures up to 190°F (87.8°C) and be chemical

resistant. At start up hose will be placed in the pasteurized product tank. When

flushing the system the hose should be directed to a drain. During cleaning, this

hose should be connected to a spray ball in the raw product tank.

Pasteurized product outlet (with cooling section): the pasteurized product

outlet is located on the front of the machine just above the balance tank. Flexible

hose or stainless tube must be run straight up from product outlet at least 2

inches (5 cm) above the plate packs to ensure that all piping fills completely.

From that point, use flexible hose as mentioned in the previous paragraph.

Pasteurized product outlet (hot-fill): the divert valve will be the product outlet

for a machine designed to hot fill product.

Filling Boiler System: to fill boiler system first make sure that all pipe fittings

are tight and the valves on the pasteurizer heating section are open. You may

decide to install a valve on the welded coupler next to the reducing valve on

the top of the 40 gallon (151.4 L) storage tank to help air removal for filling.

Open the air bleeder on top of the air scoop. Open cold water supply valve and

lift rapid fill lever, reducing valve to an upright position. Continue filling the

entire system until all air is removed and the system pressure is correct. Adjust

pressure if necessary. Place rapid fill lever back into horizontal position for

normal automatic operation and close water supply valve to prevent cold water

from entering an overheated boiler.

3-1. Installation

IMPORTANT WARNING: All electrical connections

should be made by a licensed professional in accordance

with state and local codes.