Industriarmatur SIPP Node 400 User manual

Industriarmatur Sweden AB ○ Kämpegatan 16 ○ SE-411 04 GÖTEBORG ○ hone +46 31 80 95 50 ○ info@industriarmatur.se ○

www.industriarmatur.se

SIPP Node 400 and 500

Safe Indication of Petroleum Products

Installation Instructions

English version

Installation instructions SIPP Node 400 and 500, Version 4, December, 2016

2

Table of contents

1

Preparations .......................................................................................................... 3

2

Tools ..................................................................................................................... 3

3

Consumables ......................................................................................................... 3

4

Installation ............................................................................................................ 4

Mounting on rim ............................................................................................... 4

Mounting verticalon rim / splinter ....................................................................... 4

SIPP Node 00 – wall mounting.......................................................................... 4

Mounting of unit ............................................................................................... 4

Electrical installation ...............................................................................................

6

Commissioning .......................................................................................................

7

Documentation .......................................................................................................

Installation instructions SIPP Node 400 and 500, Version 4, December, 2016

3

1Preparations

•Check and classify the pit status in the installation protocol. If the pit is in poor

condition, cancel the installation, comment on the installation protocol and notify the

customer. NEVER install and commission a unit where cleaning is necessary.

•Check the station: the position of the draining well, the gradient of the ground at the

outlet, and the soil absorbency (if no draining well is available).

•The SIPP Node unit must not be in the way of other equipment, the outlet must not

create ice patches when it’s cold, and pumped out water must not be able to run back

to the pit.

•When in doubt – chec station drawings.

•Make sure the unit will not interfere with other equipment such as a service hatch for

transformer, wires or similar.

•Determine whether it is best to mount the unit standing on the rim or sitting on the

wall/splinter using the wall mounting plate.

2Tools

•Concrete hammer drill with 10mm and mm drill

•Small spirit level with magnet

•Marker pen

•Hand sledge

•Rubber mallet

•Spanner 1 mm

•Spanner 17mm

•Philips screwdriver long bit

•Tubing cutter

•Knife

•Extension cable

Consumables

•Metal clips for 8mm and 12mm hose/cable

•Plug mm

•Stainless steel screw 4x22mm

•Rubberized ring clamps for 3 mm hose

•Cable ties, large and small

•Anchor bolt M10, 70mm

Installation instructions SIPP Node 400 and 500, Version 4, December, 2016

4

4Installation

Mounting on rim

•Unscrew the wall bracket and remove the installation pole from the unit.

•Place the installation pole on the rim, mark the holes and then drill a mm deep hole

using a 10mm concrete drill.

•Knock in an expansion bolt so that it bottoms and about 1 mm protrudes (let the nut

remain in place when the bolt is knocked in).

Mounting vertically on rim/splinter

•Hold the wall bracket at the selected installation height. Mark one of the upper holes

using a marker pen.

•Drill mm deep using the 10mm concrete drill and knock in the expander bolt.

•Install the wall bracket provisionally; use the spirit level to mark the remaining holes.

•Drill the three remaining holes; knock in the anchor bolts and install the wall bracket

permanently. Check it is level and adjust if necessary with a hammer.

•Fasten the installation pole to the wall bracket.

SIPP Node 500 – wall mounting

•Install the supplied wall brackets to the cabinet's four corners.

•Drill mm deep using 10mm concrete drill and knock in the expander bolt at the

chosen installation height.

•Install the cabinet on a provisional basis, check it is level with the spirit level and mark

the remaining holes.

•Drill the remaining holes, knock in the expander bolts and install the cabinet

permanently.

Mounting the unit

•SIPP Node 400 - Fasten the unit to the installation pole using a 17mm spanner. Check

that the suction hose has enough room, if not fit the unit higher up on the pole.

•SIPP Node 500 - Attach the mounting pole into the bracket, use a rubber mallet to

fasten the pole properly. Loosely screw the two buttons onto the back of the cabinet,

hang the cabinet on the mounting pole and then tighten the buttons firmly.

•Install the hose for dirty water (red) and the air hose (grey). The hoses should be as

short as possible and must be directed back into the pit but must not be directed back

down into the suction cage. Install using double metal clips side-by-side by drilling mm

holes and using plugs; use too many rather than too few.

NOTE!

The hoses must under no circumstances risk being submerged!

•Install the outlet hose (green) with metal clips by drilling mm holes and using plugs.

The outlet hose must not be longer than m; if the outlet hose needs to be longer,

Installation instructions SIPP Node 400 and 500, Version 4, December, 2016

5

extend using a 12mm transparent hose. Make sure that water cannot run back into the

pit and that the ground around the outlet can accept the water.

NOTE!

Make sure the all is right or runo and

that a siphon cannot orm in the hose. Consider possible burial o drainage

pipes or leading the outlet to a draining well.

•Lower the suction hose into the draining well and measure how much it needs to be

shortened by holding the hose up against the unit and checking against the fastening

point for the hose.

•Pull up the suction hose from the draining well and shorten the outer casing to the

required length. Be careful not to cut or damage the hose and the cable inside.

•Install by threading the primer pump cable followed by the suction hose and level sensor

hose through the installation point in the unit.

•Cut the suction hose with a hose cutter to the desired length and attach to the main

pump.

•Coil the primer pump cable around three fingers to the required length and fasten with

two cable ties. Then connect all hoses/cables on the left side of the unit using two cable

ties.

•Connect the main power cable to the main power switch.

•Photograph the installation (minimum from the front and tubing installation)

•Clear up all rubbish from the installation.

•The installation is now ready for commissioning.

•

5Electrical installation

•The customer is responsible for carrying out the electrical installation.

•SIPP Node 400 is a permanently installed unit to be supplied with 230VAC and protected

with 6A.

•SIPP Node 500 is a permanently installed unit to be supplied with 230VAC and protected

with 16A-T or 10A-D.

•The power cable is connected to the unit's main switch. Light on indicates voltage to the

swiitch. To turn on the power to the device turn the switch from 0 to 1.

•

6Commissioning

For commissioning, use the template Installation protocol for the SIPP Node.

•Check the placement and installation o the unit

•Con igure and complete documentation in the SIPP Warehouse

•Veri y and document all points in accordance with the installation protocol

deployment phase by means o the service inter ace.

•

7Documentation

Formaterat: Teckensnitt:Verdana, 10 pt, Fet

Formaterat: Liststycke, Justerat, Punktlista + Nivå: 1 +

Justerad vid: 0,63 c + Indrag vid: 1,27 c

Formaterat: Liststycke, Justerat, Höger: -0,1 c , Avstånd

Efter: 1 Rad, Punktlista + Nivå: 1 + Justerad vid: 0,63 c +

Indrag vid: 1,27 c

Formaterat: Liststycke, Höger: 0 c , Avstånd Efter: 0 pt,

Punktlista + Nivå: 1 + Justerad vid: 0,63 c + Indrag vid:

1,27 c , Mönster: Inget (Vit), Tabbstopp: 1,62 c , Till

vänster + 3,23 c , Till vänster + 4,85 c , Till vänster +

6,46 c , Till vänster + 8,08 c , Till vänster + 9,69 c , Till

vänster + 11,31 c , Till vänster + 12,92 c , Till vänster +

14,54 c , Till vänster + 16,16 c , Till vänster + 17,77 c ,

Till vänster + 19,39 c , Till vänster + 21 c , Till vänster +

22,62 c , Till vänster + 24,23 c , Till vänster + 25,85 c ,

Till vänster

Installation instructions SIPP Node 400 and 500, Version 4, December, 2016

6

The documentation, including installation protocol and photographs, should be filed.

Information about the installation should be shared with the customer. The installation protocol

should be signed and sent to the customer for approval.

Other manuals for SIPP Node 400

2

This manual suits for next models

1

Table of contents

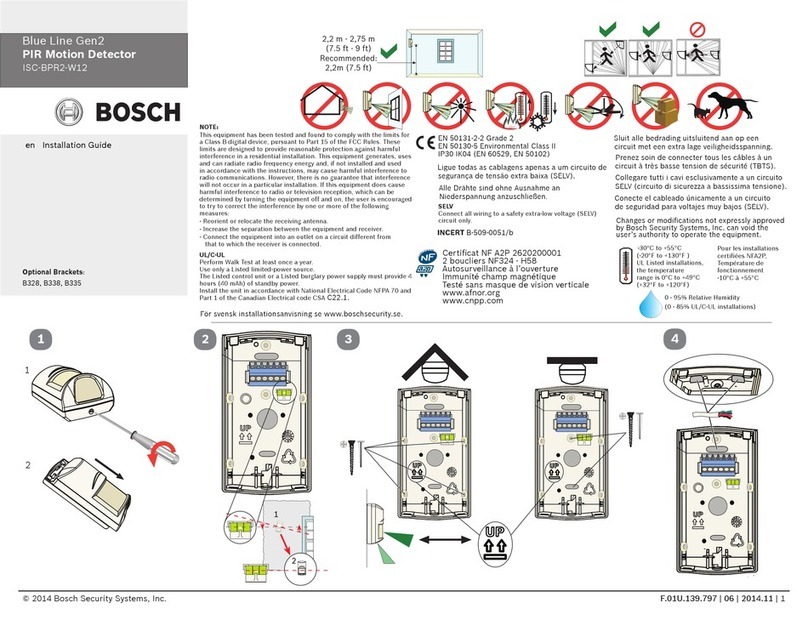

Popular Security Sensor manuals by other brands

Diablo Controls

Diablo Controls DSP-15 user manual

MSA

MSA Ultima OPIR-5 Programming guide

SAGEMCOM

SAGEMCOM Siconia LoRa ATGHMP915 V2 user manual

Inficon

Inficon XL3000flex Translation of the original operating instructions

Data Harvest

Data Harvest 1190 manual

Sensitron

Sensitron SMART3H-FM LITE instruction manual

Micropack

Micropack FS301 quick start guide

EDWARDS SYSTEMS TECHNOLOGY

EDWARDS SYSTEMS TECHNOLOGY IRC-3 Maintenance and troubleshooting manual

Bticino

Bticino HA4619 Instructions for use

McShine

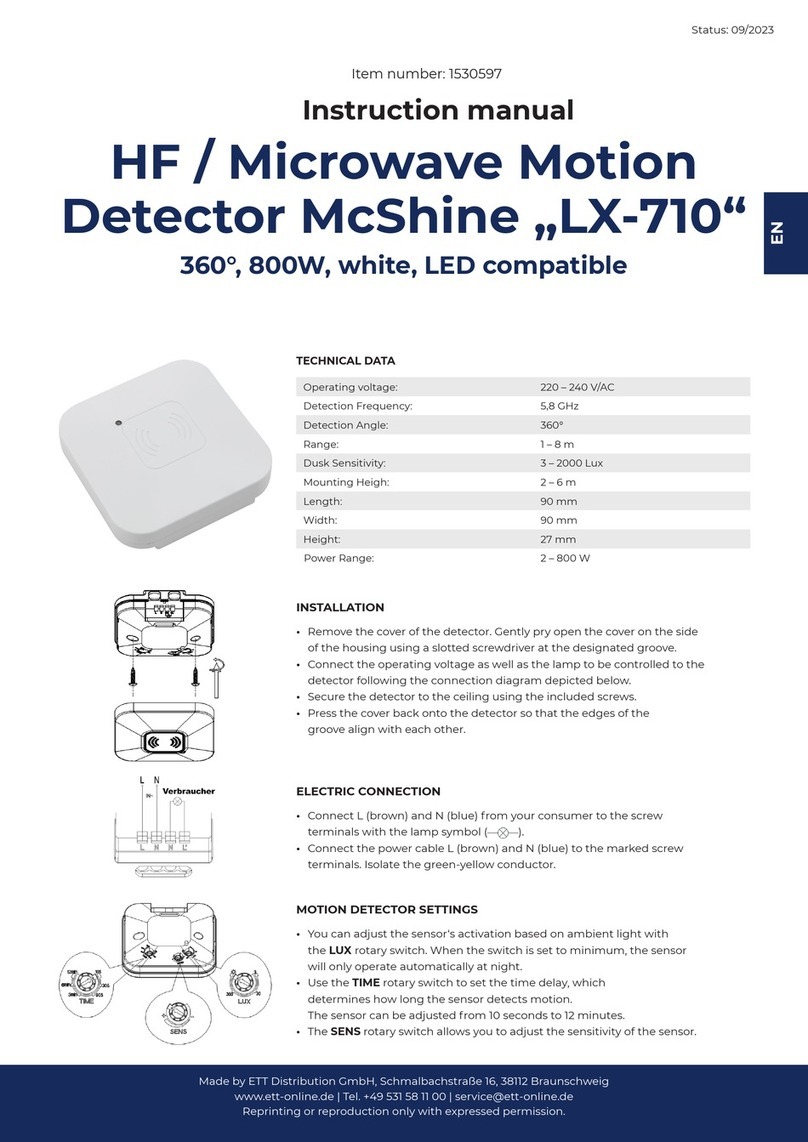

McShine LX-710 instruction manual

Dors

Dors 200 user manual

Agilent Technologies

Agilent Technologies InfinityLab LC Series user manual