Inficon BPG400 User manual

Operating Manual

tina03e1 (0206) 1

Bayard-Alpert Pirani Gauge

BPG400

BPG400-SD

BPG400-SP

2tina03e1 (0206) BPG400 v1.om

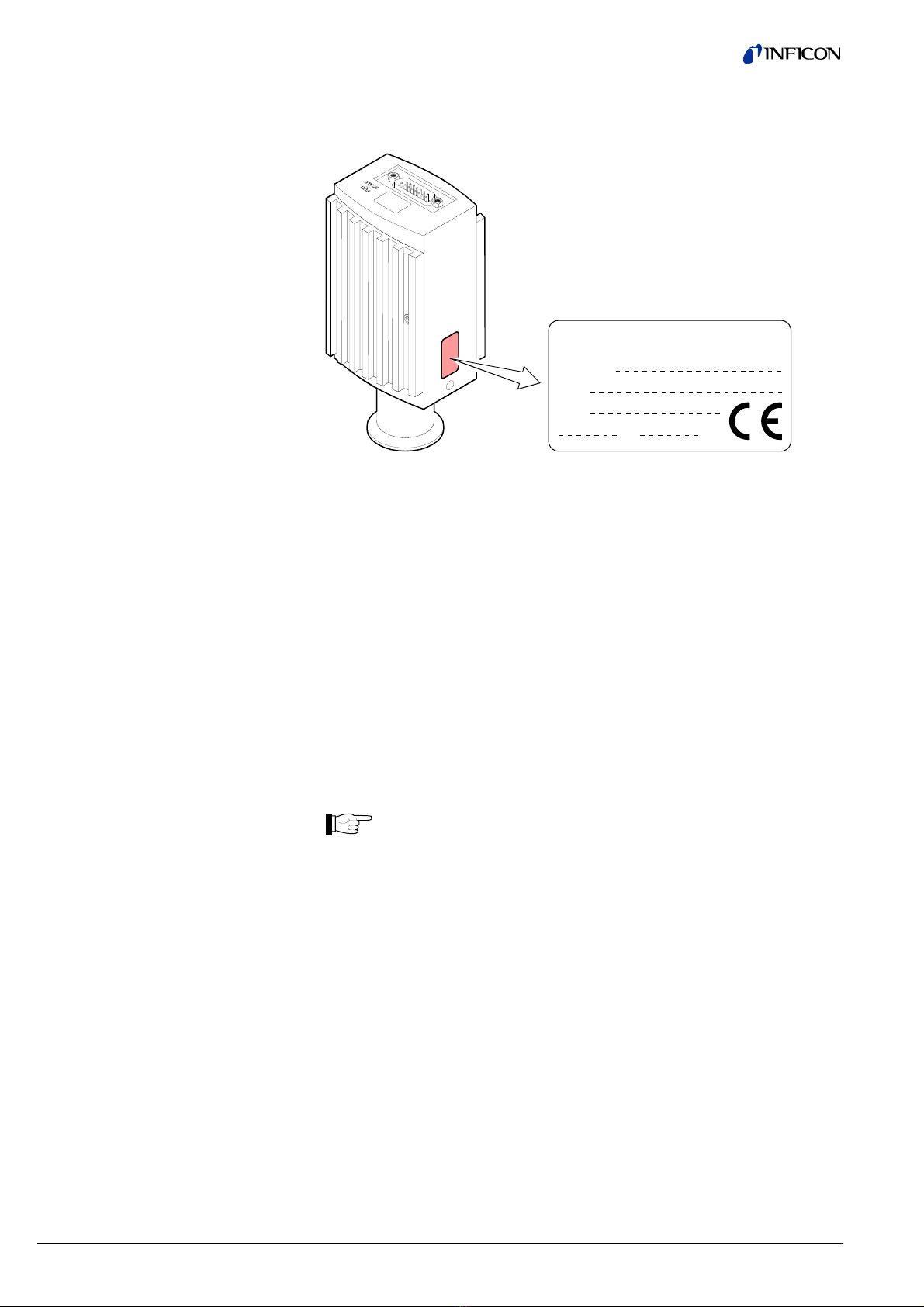

In all communications with INFICON, please specify the information on the product

nameplate. For convenient reference copy that information into the space provided

below.

Model:

PN:

SN:

V W

INFICON AG, LI-9496 Balzers

This document applies to products with the following part numbers:

BPG400 (without display)

353-500 (vacuum connection DN 25 ISO-KF)

353-502 (vacuum connection DN 40 CF-R)

BPG400 (with display)

353-501 (vacuum connection DN 25 ISO-KF)

353-503 (vacuum connection DN 40 CF-R)

BPG400-SD (with DeviceNet interface and switching functions)

353-507 (vacuum connection DN 25 ISO-KF)

353-508 (vacuum connection DN 40 CF-R)

BPG400-SP (with Profibus interface and switching functions)

353-505 (vacuum connection DN 25 ISO-KF)

353-506 (vacuum connection DN 40 CF-R)

The part number (PN) can be taken from the product nameplate.

If not indicated otherwise in the legends, the illustrations in this docu-

ment correspond to the KF vacuum connection. They apply to other

vacuum connections by analogy.

In illustrations that apply to all types of the BPG400 gauge family, the

gauge with part number 353-500 is shown.

All BPG400 versions are shipped with an instruction sheet (®&[8]). BPG400-SD

and BPG400-SP come with a supplementary instruction sheet describing the field-

bus interfaces and the switching functions (®&[9]).

We reserve the right to make technical changes without prior notice.

The BPG400 gauges have been designed for vacuum measurement of non-flam-

mable gases and gas mixtures in a pressure range of 5×10-10 … 1000 mbar.

The gauges can be operated in connection with the INFICON Vacuum Gauge

Controller VGC103 or VGC40x or with other control devices.

Product Identification

Validity

Intended Use

tina03e1 (0206) BPG400 v1.om 3

Over the whole measuring range, the gauge has a continuous characteristic curve

and its measuring signal is output as logarithm of the pressure.

The gauge functions with a Bayard-Alpert hot cathode ionization measurement

system (for p < 2.0×10-2 mbar) and a Pirani measurement system (for

p > 5.5×10-3 mbar). In the overlapping pressure range of 2.0×10-2 …

5.5×10-3 mbar, a mixed signal of the two measurement systems is output. The hot

cathode is switched on by the Pirani measurement system only below the switching

threshold of 2.4×10-2 mbar (to prevent filament burn-out). It is switched off when the

pressure exceeds 3.2×10-2 mbar.

DeviceNet™ Open DeviceNet Vendor Association, Inc.

Functional Principle

Trademarks

4tina03e1 (0206) BPG400 v1.om

Contents

Product Identification 2

Validity 2

Intended Use 2

Functional Principle 3

Trademarks 3

1 Safety 6

1.1 Symbols Used 6

1.2 Personnel Qualifications 6

1.3 General Safety Instructions 7

1.4 Liability and Warranty 7

2 Technical Data 8

3 Installation 13

3.1 Vacuum Connection 13

3.1.1 Removing and Installing the Electronics Unit 15

3.1.2 Installing the Optional Extension 16

3.1.3 Using the Optional Baffle 17

3.1.3.1 Installing the Baffle 17

3.1.3.2 Replacing the Baffle 19

3.2 Electrical Connection 20

3.2.1 Use With INFICON VGC103 or VGC40x Vacuum Gauge Controller 20

3.2.2 Use With Other Controllers 21

3.2.2.1 Making an Individual Sensor Cable 21

3.2.2.2 Making a DeviceNet Interface Cable (BPG400-SD) 24

3.2.2.3 Making a Profibus Interface Cable (BPG400-SP) 25

3.2.3 Using the Optional Power Supply (With RS232C Line) 26

4 Operation 28

4.1 Measuring Principle, Measuring Behavior 28

4.2 Operational Principle of the Gauge 29

4.3 Putting the Gauge Into Operation 29

4.4 Degas 30

4.5 Display (BPG400) 30

4.6 RS232C Interface 32

4.6.1 Description of the Functions 32

4.6.1.1 Output String (Transmit) 32

4.6.1.2 Input String (Receive) 34

4.7 DeviceNet Interface (BPG400-SD) 35

4.7.1 Description of the Functions 35

4.7.2 Operating Parameters 35

4.7.2.1 Operating Software 35

4.7.2.2 Node Address Setting 35

4.7.2.3 Data Rate Setting 36

4.7.3 Status Lights 36

4.8 Profibus Interface (BPG400-SP) 37

4.8.1 Description of the Functions 37

4.8.2 Operating Parameters 37

4.8.2.1 Operating Software 37

4.8.2.2 Node Address Setting 37

4.9 Switching Functions (BPG400-SD, BPG400-SP) 38

4.9.1 Setting the Switching Functions 38

5 Deinstallation 40

tina03e1 (0206) BPG400 v1.om 5

6 Maintenance, Repair 42

6.1 Maintenance 42

6.1.1 Cleaning the Gauge 42

6.2 Adjusting the Gauge 42

6.2.1 Adjustment at Atmospheric Pressure 42

6.2.2 Zero Point Adjustment 43

6.3 What to Do in Case of Problems 44

6.4 Replacing the Sensor 46

7 Options 47

8 Spare Parts 47

9 Storage 47

10 Returning the Product 48

11 Disposal 48

Appendix 49

A: Relationship Output Signal – Pressure 49

B: Gas Type Dependence 50

C: Literature 52

Declaration of Contamination 53

For cross-references within this document, the symbol (®2XY) is used, for cross-

references to further documents and data sources, the symbol (®&[Z]).

6tina03e1 (0206) BPG400 v1.om

1 Safety

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and environmental damage.

Caution

Information on correct handling or use. Disregard can lead to malfunctions or

minor equipment damage.

Notice

Hint, recommendation

The result is O.K.

The result is not as expected

Optical inspection

Waiting time, reaction time

Skilled personnel

All work described in this document may only be carried out by persons who

have suitable technical training and the necessary experience or who have been

instructed by the end-user of the product.

1.1 Symbols Used

1.2 Personnel Qualifications

tina03e1 (0206) BPG400 v1.om 7

· Adhere to the applicable regulations and take the necessary precautions for the

process media used.

Consider possible reactions between the materials (®211) and the process

media.

Consider possible reactions of the process media due to the heat generated by

the product.

· Adhere to the applicable regulations and take the necessary precautions for all

work you are going to do and consider the safety instructions in this document.

· Before beginning to work, find out whether any vacuum components are con-

taminated. Adhere to the relevant regulations and take the necessary precau-

tions when handling contaminated parts.

Communicate the safety instructions to all other users.

INFICON assumes no liability and the warranty becomes null and void if the end-

user or third parties

· disregard the information in this document

· use the product in a non-conforming manner

· make any kind of interventions (modifications, alterations etc.) on the product

· use the product with accessories not listed in the corresponding product

documentation.

The end-user assumes the responsibility in conjunction with the process media

used.

1.3 General Safety

Instructions

1.4 Liability and Warranty

8tina03e1 (0206) BPG400 v1.om

2 Technical Data

Measuring range (air, N2, O2) 5×10-10 … 1000 mbar, continuous

Accuracy 15% of reading in the range of

10-8 … 10-2 mbar

(after 5 min stabilization)

Repeatability 5% of reading in the range of

10-8 … 10-2 mbar

(after 5 min stabilization)

Gas type dependence ®Appendix B

Switching on threshold

Switching off threshold

2.4×10-2 mbar

3.2×10-2 mbar

Emission current

p £7.2×10-6 mbar

7.2×10-6 mbar <p <3.2×10-2 mbar

5 mA

25 µA

Emission current switching

25 µA Þ5 mA

5 mA Þ25 µA

7.2×10-6 mbar

3.2×10-5 mbar

Degas emission current

(p <7.2×10-6 mbar)

»16 mA (Pdegas »4 W)

Control input signal 0 V/+24 VDC, active high

(control via RS232 ®232)

Duration max. 3 min, followed by automatic stop

In degas mode, BPG400 gauges keep supplying measurement values, however

their tolerances may be higher than during normal operation.

Output signal (measuring signal) 0 … +10 V

Measuring range 0.774 V Z5×10-10 mbar

… +10 V Z1000 mbar

Relationship voltage-pressure logarithmic, 0.75 V/decade

(®Appendix A)

Error signal <0.3 V/0.5 V (®244)

Minimum loaded impedance 10 kW

Display panel

Dimensions

Pressure units (pressure p)

LCD matrix, 32×16 pixels,

with background illumination

16.0 mm × 11.2 mm

mbar (default), Torr, Pa

(selecting the pressure unit ®232)

DANGER

The gauge must only be connected to power supplies, instruments or

control devices that conform to the requirements of a grounded extra-

low voltage (SELV-E according to EN 61010). The connection to the

gauge has to be fused (INFICON-controllers fulfill these requirements).

Measurement

Emission

Degas

Output signal

Display (BPG400)

Power supply

tina03e1 (0206) BPG400 v1.om 9

Operating voltage at the gauge +24 VDC (20 … 28 VDC) 1)

ripple max. 2 Vpp

Power consumption

Standard

Degas

Emission start (<200 ms)

£0.5 A

£0.8 A

£1.4 A

Power consumption

BPG400

BPG400-SD, BPG400-SP

£16 W

£18 W

Fuse necessary 1.25 AT

BPG400-SD requires an additional, separate power supply for the

DeviceNet interface (®224).

Supply voltage at the DeviceNet con-

nector, (Pin 2 and Pin 3) +24 VDC (+11 … 25 VDC)

Power consumption <2 W

The gauge is protected against reversed polarity of the supply voltage.

For reasons of compatibility, the expression "sensor cable" is used for all

BPG400 versions in this document, although the pressure reading of the

gauges with fieldbus interface (BPG400-SD and BPG400-SP) is

normally transmitted via DeviceNet or Profibus.

Electrical connector

BPG400

BPG400-SD, BPG400-SP

D-Sub,15 pins, male

®222

®223

Cable for BPG400

Analog values only

Without degas function

Analog values

With degas function

Analog values

With degas function

And RS232C interface

Cable for BPG400-SD, BPG400-SP

4 conductors plus shielding

5 conductors plus shielding

7 conductors plus shielding

depending on the functions used,

max. 15 conductors plus shielding

Max. cable length (supply voltage 24 V1))

Analog and fieldbus operation

RS232C operation

£35 m, conductor cross-section 0.25 mm²

£50 m, conductor cross-section 0.34 mm²

£100 m, conductor cross-section 1.0 mm²

£30 m

Gauge identification 42 kWresistor between Pin 10 (sensor

cable) and GND

Switching functions

BPG400

BPG400-SD, BPG400-SP

Adjustment range

none

2 (Setpoints A and B)

1×10-9 mbar … 100 mbar

Setpoints adjustable via potentiometers

(Setpoints A and B), one floating, nor-

mally open relay contact per setpoint

(®223, 38)

Relay contact rating

Voltage

Current

£60 V

£0.5 ADC

1) Measured at sensor cable connector (consider the voltage drop as function of

the sensor cable length).

Sensor cable

10 tina03e1 (0206) BPG400 v1.om

Data rate

Data format

Connections (sensor cable connector)

TxD (Transmit Data)

RxD (Receive Data)

GND

9600 baud

binary

8 data bits

one stop bit

no parity bit

no handshake

Pin 13

Pin 14

Pin 5

(Function and communication protocol of the RS232C interface ®232)

Fieldbus name DeviceNet

Standard applied ®&[6]

Communication protocol, data format ®&[1], [4]

Interface, physical CAN bus

Data rate (adjustable via "RATE"

switch)

125 kbaud

250 kbaud

500 kbaud

"P" (125 kbaud, 250 kbaud, 500 kbaud

programmable via DeviceNet

(®&[1])

Node address (MAC ID)

(Adjustable via "ADDRESS", "MSD",

"LSD" switches)

0 … 63dec

"P" (0 … 63 programmable via

DeviceNet, ®&[1])

DeviceNet connector Micro-Style, 5 pins, male

Cable Shielded, special DeviceNet cable,

5 conductors (®224 and &[4])

Cable length, system wiring According to DeviceNet specifications

(®&[6], [4])

Fieldbus name Profibus

Standard applied ®&[7]

Communication protocol data format ®&[10], [7]

Interface, physical RS485

Data rate £12 Mbaud (®&[10])

Node address

(Adjustable via hexadecimal

"ADDRESS", "MSD", "LSD" switches)

00 … 3Fhex (0 … 127dec)

Profibus connection D-Sub, 9 pins, female

Cable Shielded, special Profibus cable

(®225 and &[5])

Cable length, system wiring According to Profibus specifications

(®&[7], [5])

RS232C interface

DeviceNet interface

(BPG400-SD)

Profibus interface

(BPG400-SP)

tina03e1 (0206) BPG400 v1.om 11

Materials exposed to vacuum

Housing, supports, screens

Feedthroughs

Insulator

Cathode

Cathode holder

Pirani element

stainless steel

NiFe, nickel plated

glass

iridium, yttrium oxide (Y2O3)

molybdenum

tungsten, copper

Internal volume

353-500, 353-501

353-505, 353-507

353-502, 353-503

353-506, 353-508

£24 cm3

£24 cm3

£34 cm3

£34 cm3

Pressure max. 2 bar (absolute)

Admissible temperatures

Storage

Operation

Bakeout

-20 … 70 °C

0 … 50 °C

+150 °C (without electronics unit or with

bakeout extension ®216)

Relative humidity

(year's mean / during 60 days) £65 / 85% (no condensation)

Use indoors only

altitude up to 2000 m NN

Type of protection IP 30

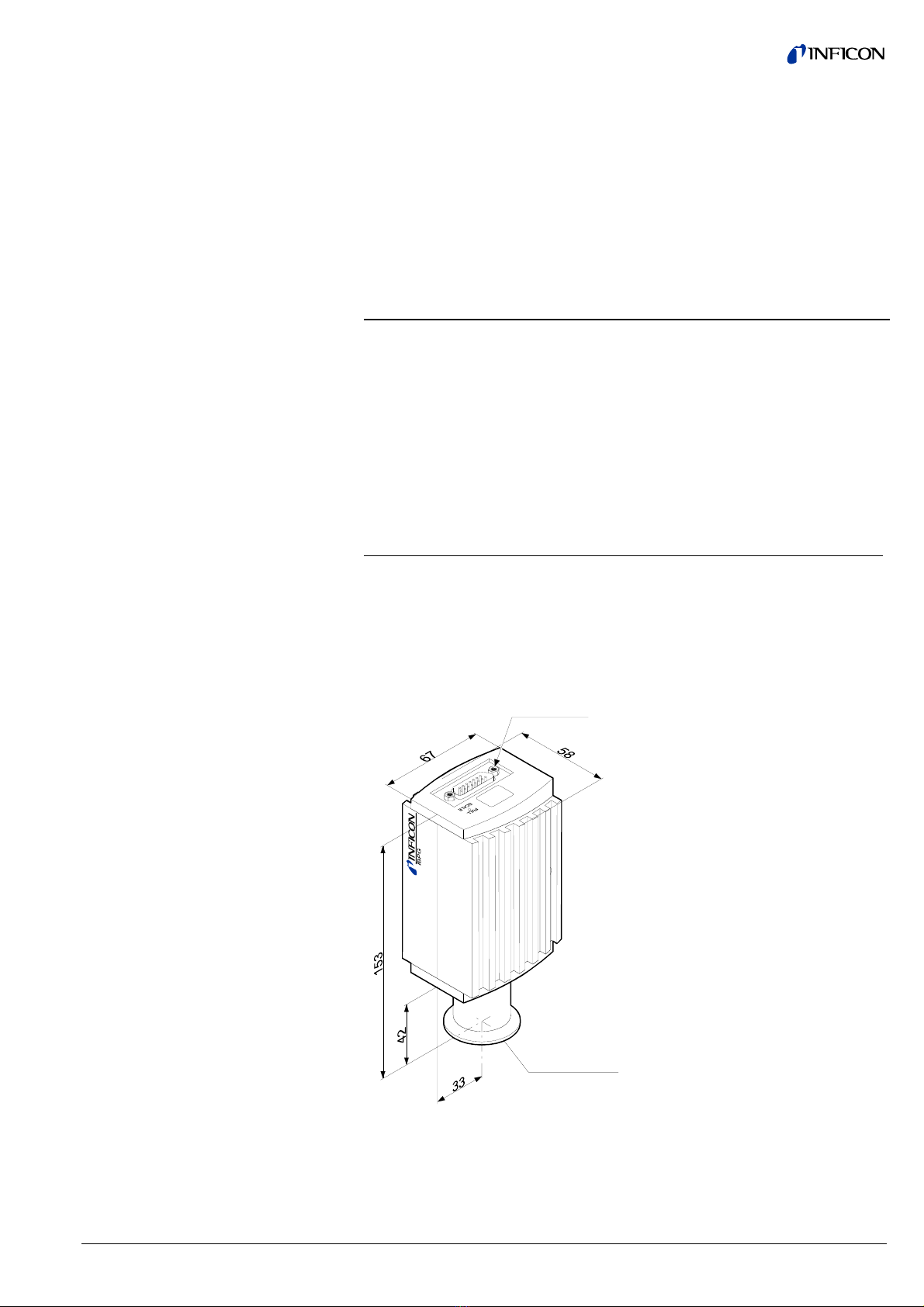

Part numbers

353-500

353-501

353-505

(353-507) 1)

4-40UNC 2B

DN 25 ISO-KF

353-500

353-501

Vacuum

Ambiance

Dimensions

12 tina03e1 (0206) BPG400 v1.om

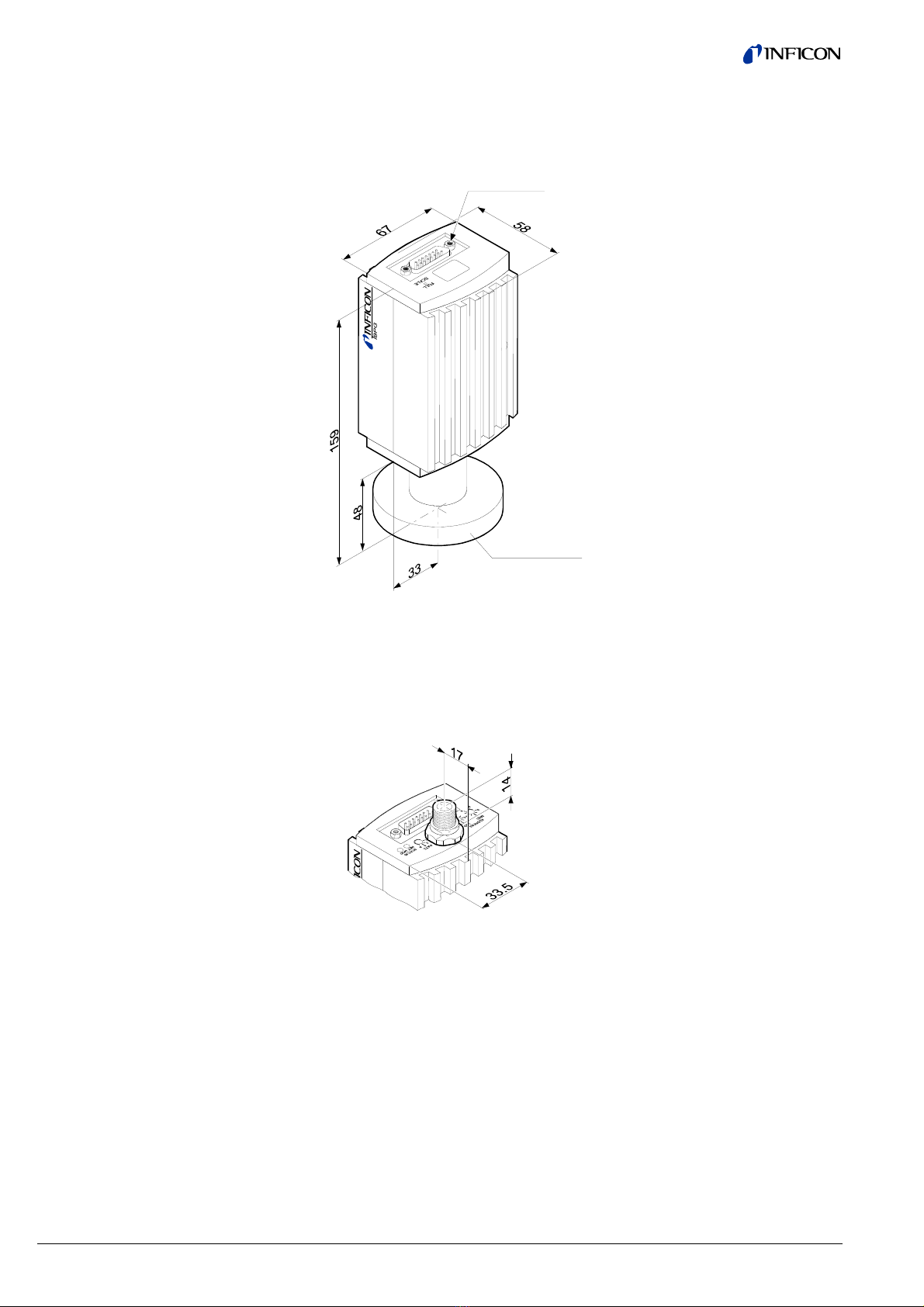

Part numbers

353-502

353-503

353-506

(353-508) 1)

4-40UNC 2B

DN 40 ISO-KF

353-502

353-503

1) Gauges with DeviceNet connector are 14 mm longer.

The other dimensions of housing and vacuum connection are identical.

Part numbers

353-507

353-508

Weight

353-500, 353-501

353-502, 353-503

353-505, 353-507

353-506, 353-508

285 g

550 g

430 g

695 g

tina03e1 (0206) BPG400 v1.om 13

3 Installation

DANGER

Caution: overpressure in the vacuum system >1 bar

Injury caused by released parts and harm caused by escaping process

gases can result if clamps are opened while the vacuum system is

pressurized.

Do not open any clamps while the vacuum system is pressurized. Use

the type of clamps which are suited to overpressure.

DANGER

Caution: overpressure in the vacuum system >2.5 bar

KF flange connections with elastomer seals (e.g. O-rings) cannot

withstand such pressures. Process media can thus leak and possibly

damage your health.

Use O-rings provided with an outer centering ring.

DANGER

The gauge must be electrically connected to the grounded vacuum

chamber. This connection must conform to the requirements of a

protective connection according to EN 61010:

· CF connections fulfill this requirement

· For gauges with a KF vacuum connection, use a conductive me-

tallic clamping ring.

Caution

Caution: vacuum component

Dirt and damages impair the function of the vacuum component.

When handling vacuum components, take appropriate measures to

ensure cleanliness and prevent damages.

The gauge may be mounted in any orientation. To keep condensates

and particles from getting into the measuring chamber, preferably

choose a horizontal to upright position. See dimensional drawing for

space requirements (®211).

· The gauge is supplied with a built-in grid. For potentially contaminating appli-

cations and to protect the electrodes against light and fast particles, installation

(®217) of the optional baffle is recommended (®247).

· For the vacuum connection sealing, use of a metal seal (®247) is recom-

mended, since elastomer seals (e.g. FPM) can impair the measurement accu-

racy already in the 10-6 mbar range by outgassing.

· The sensor can be baked at up to 150 °C. At temperatures exceeding 50 °C,

the electronics unit has to be removed (®215) or an extension (Option

®247) has to be installed (®216).

3.1 Vacuum Connection

14 tina03e1 (0206) BPG400 v1.om

Remove the protective lid.

The protective lid will be

needed for mainte-

nance.

Make the flange connection.

When installing the gauge, make sure that the area around the con-

nector is accessible for the tools required for adjustment while the gauge

is mounted (®238, 42).

When installing the gauge, allow for installing/deinstalling the connectors

and accommodation of cable loops.

If you are using a gauge with display, make sure easy reading of the

display is possible.

The gauge is now installed.

Procedure

tina03e1 (0206) BPG400 v1.om 15

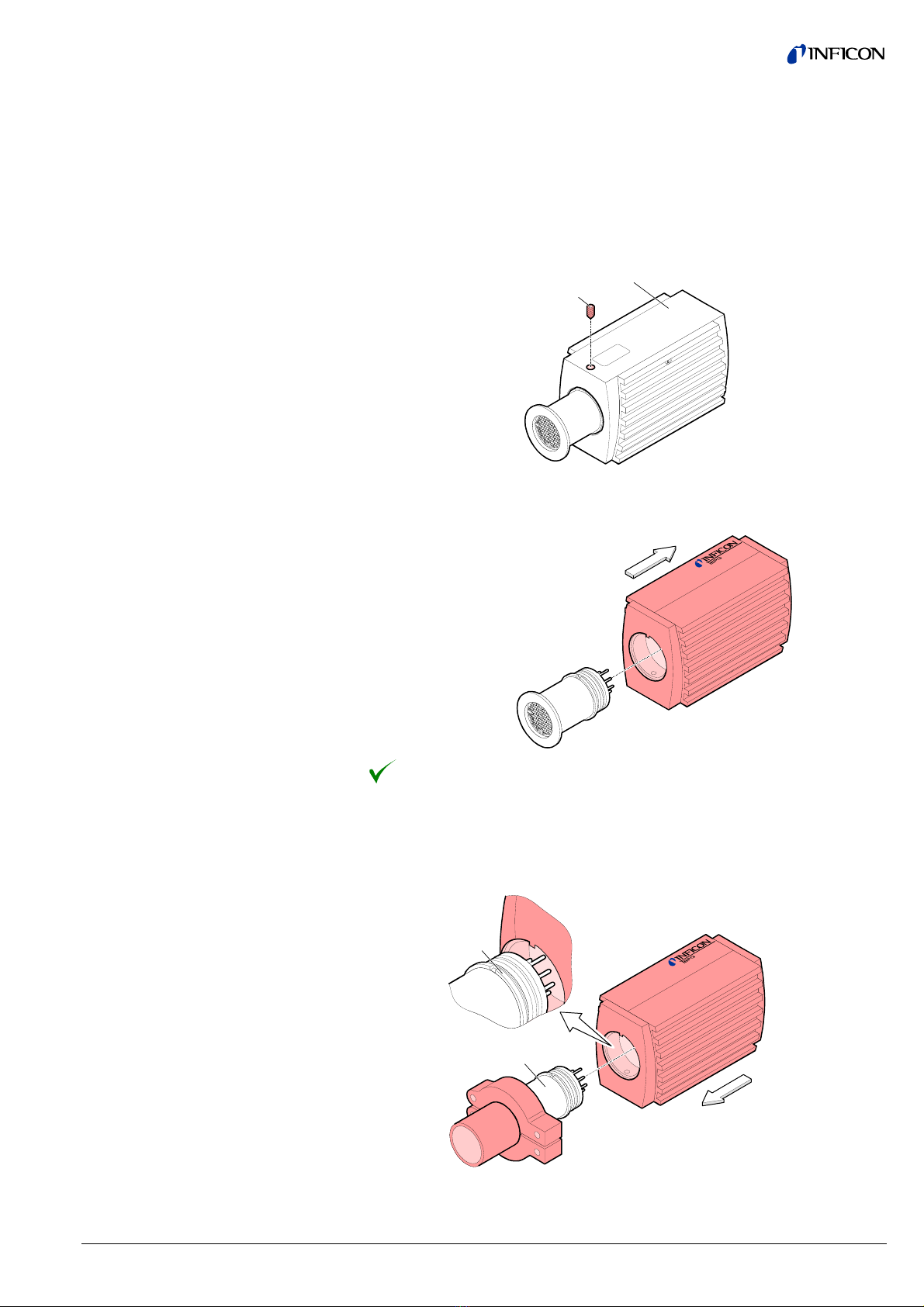

· Allen key, size 2.5 mm

Unscrew the hexagon socket set screw (1) on the side of the electronics

unit (2).

2

1

Remove the electronics unit without twisting it.

Removal of the electronics unit is completed.

Place the electronics unit on the sensor (3) (be careful to correctly align the

pins and notch (4)).

4

3

3.1.1 Removing and Installing

the Electronics Unit

Required tools / material

Removing the electronics unit

Installing the electronics unit

16 tina03e1 (0206) BPG400 v1.om

Slide the electronics unit in to the mechanical stop and lock it with the

hexagon socket set screw (1).

The electronics unit is now installed.

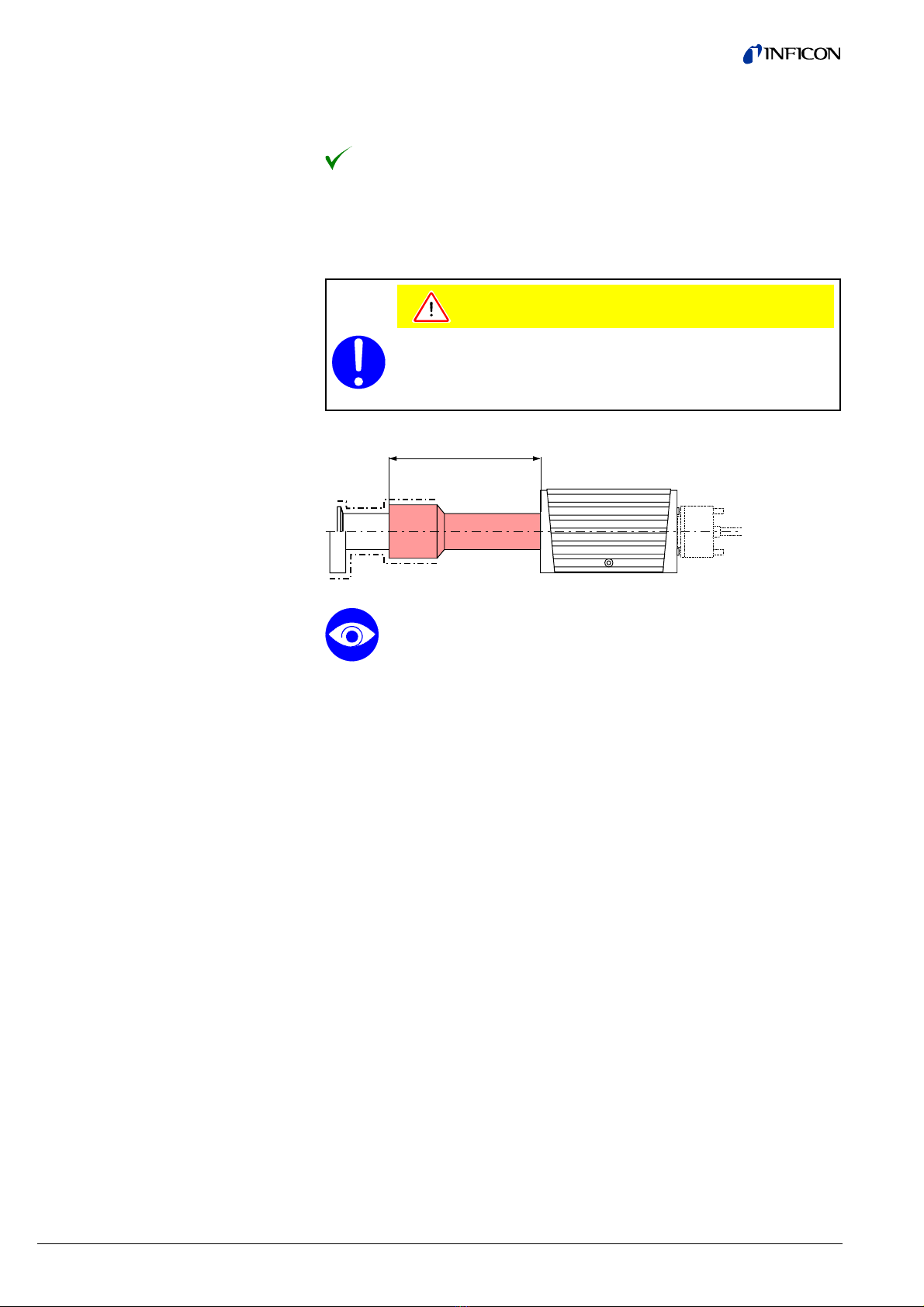

With the optional extension (®247) the sensor can also be baked during opera-

tion at temperatures up to 150 °C (only at p<10-2 mbar because at high tempera-

tures, the accuracy of the Pirani sensor decreases).

Caution

Caution: rising heat

The electronics unit of gauges that are installed vertically, above the

source of heat can be damaged through rising heat even with an

installed extension.

123

Bakeout area

When installing the extension, make sure that the area around the con-

nector is accessible for the tools required for adjustment while the gauge

is mounted (®238, 42).

When installing the gauge, allow for installing/deinstalling the connectors

and accommodation of cable loops.

If you are using a gauge with display, ensure easy reading of the display.

· Extension (®247)

· Allen key, size 2.5 mm

· Allen key, size 1.5 mm

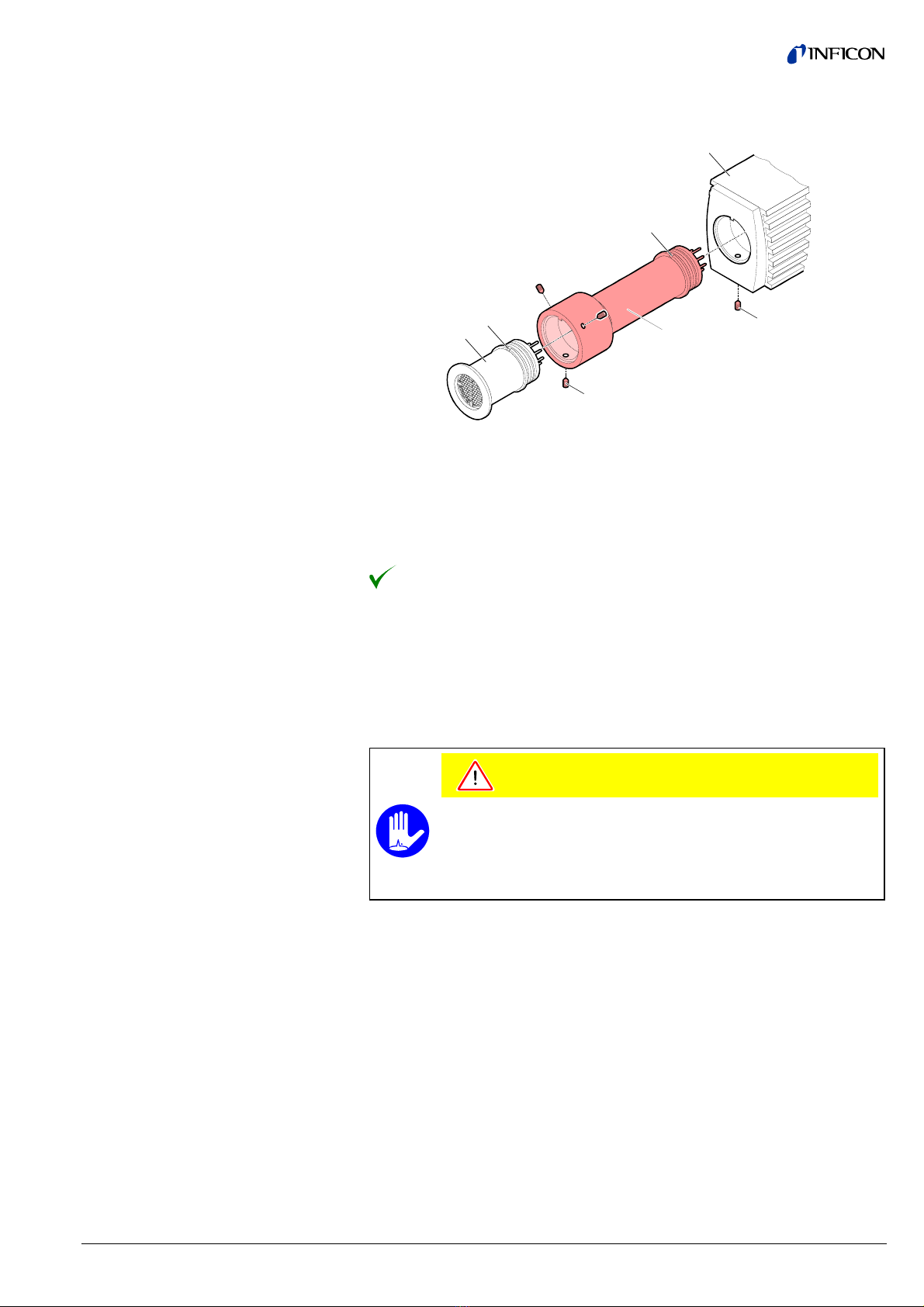

Remove the electronics unit (2) (®215).

Slide the sensor (3) into the extension (6) to the mechanical stop (be careful

to correctly position the pins and notch (4)).

3.1.2 Installing the Optional

Extension

Bakeout area

Required tools / material

Procedure

tina03e1 (0206) BPG400 v1.om 17

Secure the sensor with the hex socket set screws (7) using an Allen key,

size 1.5 mm.

6

7

3

4

4a

2

1

Slide the electronics unit (2) in to the mechanical stop (be careful to cor-

rectly align the pins and notch (4a)).

Secure the electronics unit (2) with the hex socket set screw (1) using an

Allen key, size 2.5 mm.

The extension is now installed.

In severely contaminating processes and to protect measurement electrodes opti-

cally against light and fast particles, replacement of the built-in grid by the optional

baffle (®247) is recommended.

The optional baffle will be installed at the sensor opening of the deinstalled gauge

(Deinstallation ®240).

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare hands increases the

desorption rate.

Always wear clean, lint-free gloves and use clean tools when working

in this area.

· Baffle (®247)

· Pointed tweezers

· Pin (e.g. pencil)

3.1.3 Using the Optional Baffle

3.1.3.1 Installing the Baffle

Required tools / material

18 tina03e1 (0206) BPG400 v1.om

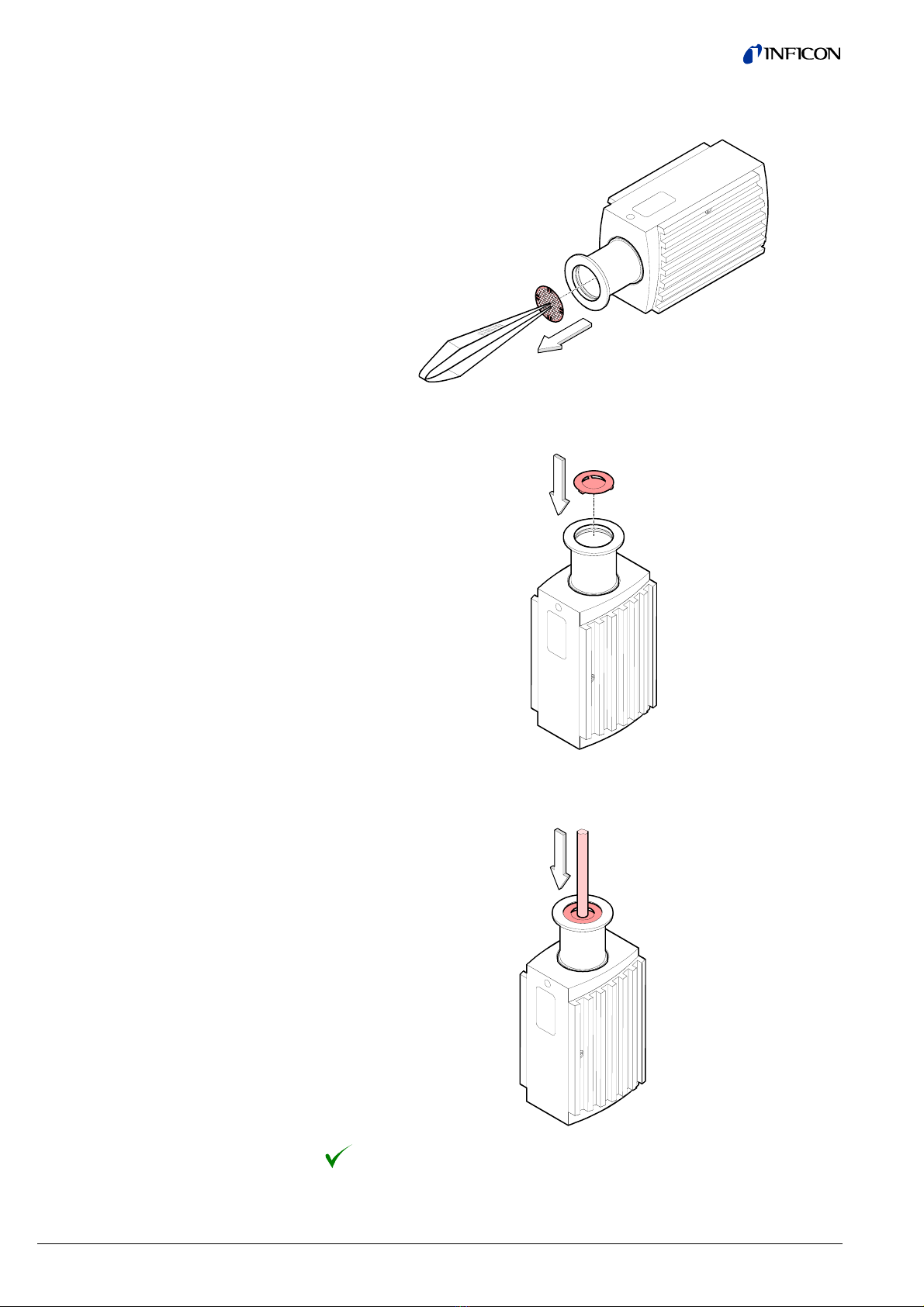

Carefully remove the grid with tweezers.

Carefully place the baffle onto the sensor opening.

Using a pin, press the baffle down in the center until it catches.

The baffle is now installed (Installation of the gauge ®213).

Procedure

tina03e1 (0206) BPG400 v1.om 19

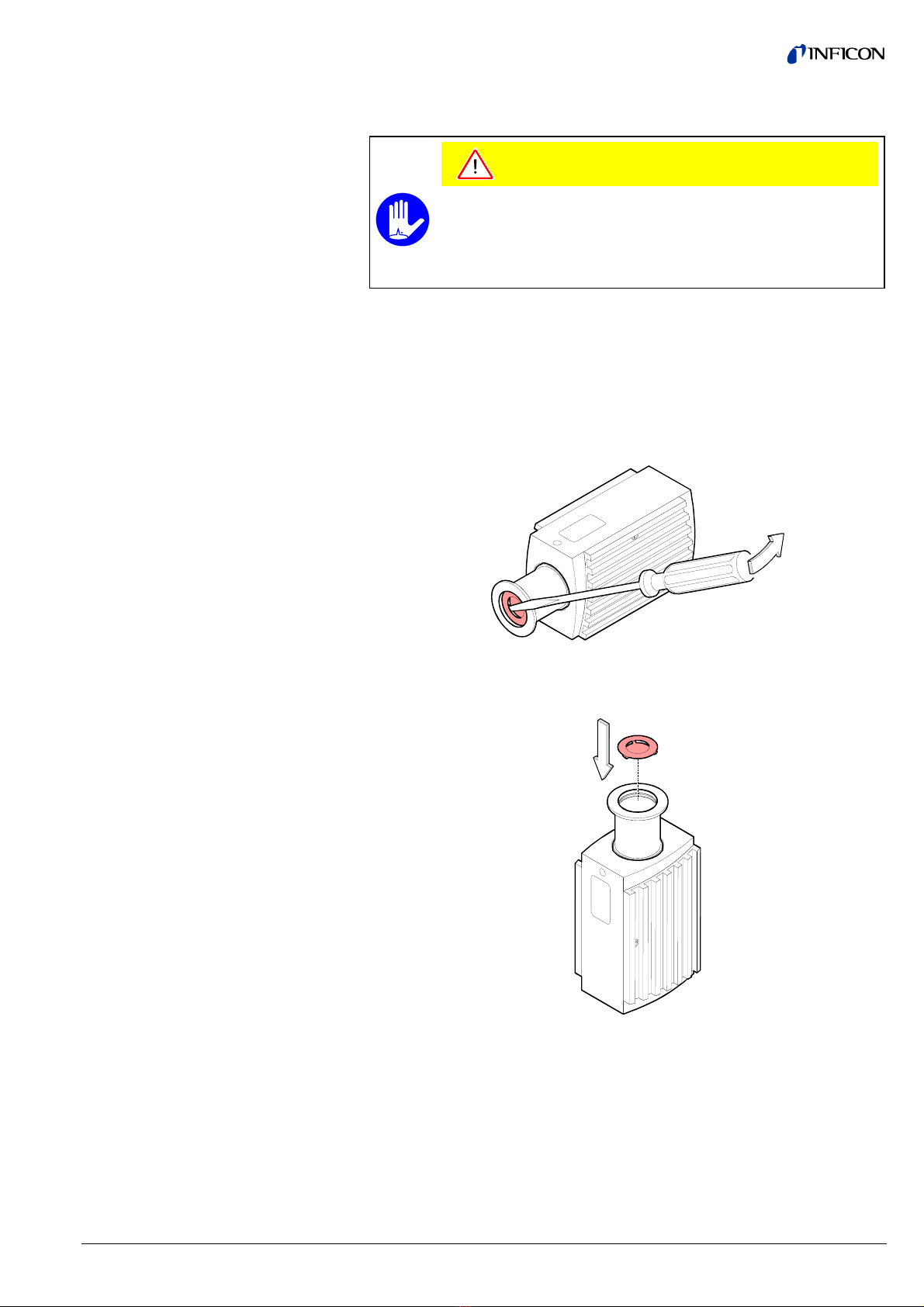

In case of severe contamination the baffle can be easily replaced. For this purpose,

the gauge first has to be deinstalled (Deinstallation of the gauge ®240).

Caution

Caution: dirt sensitive area

Touching the product or parts thereof with bare hands increases the

desorption rate.

Always wear clean, lint-free gloves and use clean tools when working

in this area.

· New baffle (®247)

· Screwdriver No 1

· Pin (e.g. pencil)

Carefully remove the baffle with the screwdriver.

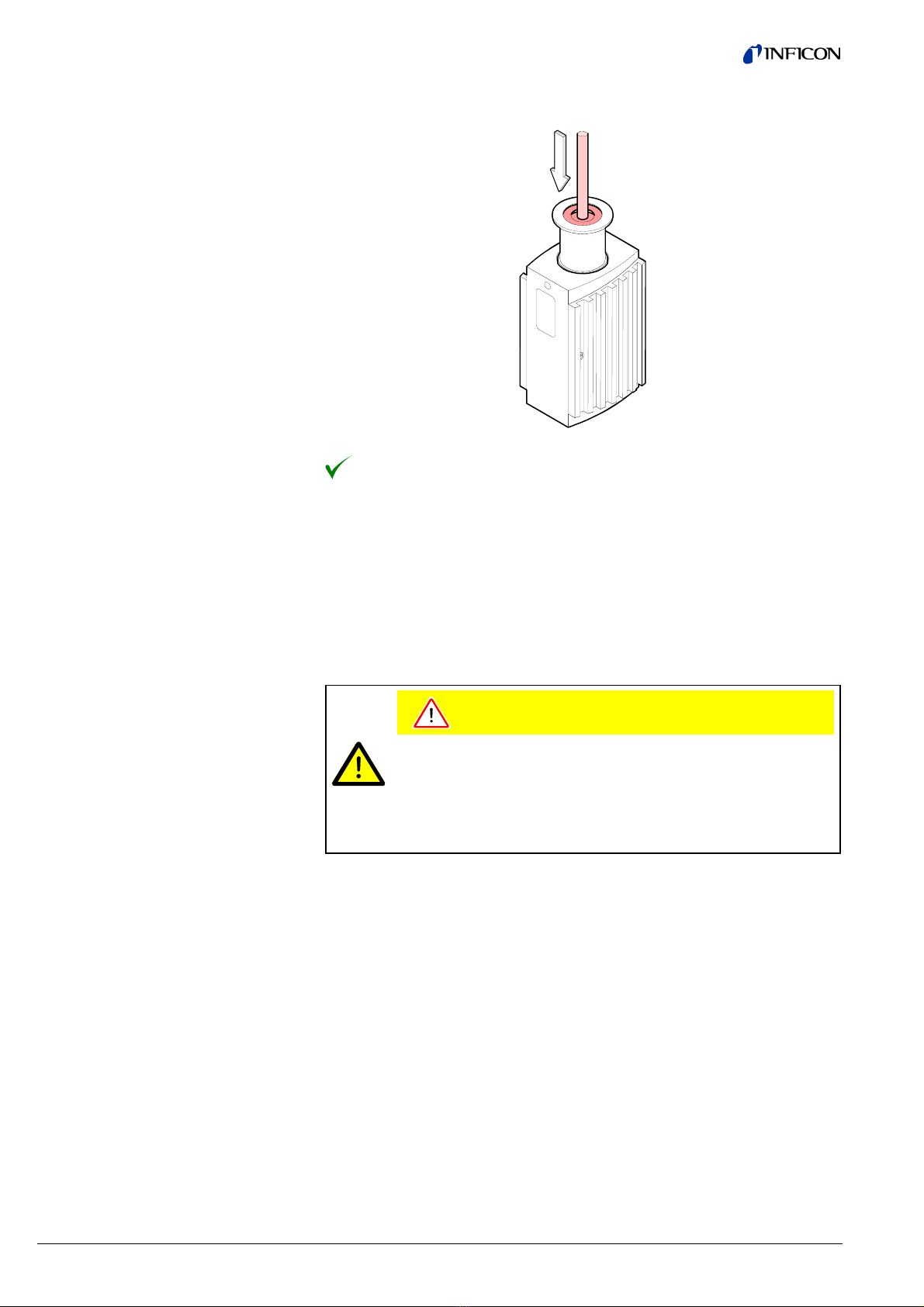

Place new baffle carefully onto the sensor opening.

3.1.3.2 Replacing the Baffle

Required tools / material

Procedure

20 tina03e1 (0206) BPG400 v1.om

Using a pin, press the baffle down in the center until it catches.

The new baffle is now installed (Installation of the gauge ®213).

If the gauge is used with an INFICON VGC103 or VGC40x controller, a corre-

sponding sensor cable is required (®247). The sensor cable permits supplying

the gauge with power, transmitting measurement values and gauge statuses, and

making parameter settings.

Caution

Caution: data transmission errors

If the gauge is operated with the INFICON VGC103 or VGC40x

Vacuum Gauge Controller (RS232C) and a fieldbus interface at the

same time, data transmission errors may occur.

The gauge must not be operated with an INFICON VGC103 or

VGC40x controller and DeviceNet or Profibus at the same time.

· Sensor cable for INFICON controllers (®247)

3.2 Electrical Connection

3.2.1 Use With INFICON

VGC103 or VGC40x

Vacuum Gauge

Controller

Required material

Other manuals for BPG400

1

This manual suits for next models

2

Table of contents

Other Inficon Accessories manuals