Inficon RSH-600 User manual

OPERATING MANUAL

RSH-600

Rotary Sensor Head

PN 153800-L

C

over

P

age

Trademarks

The trademarks of the products mentioned in this manual are held by the companies that

produce them.

Scotch-Brite®is a registered trademark of 3M.

Teflon®and Kapton®are registered trademarks of E. I. du Pont de Nemours and Company or its affiliates.

All other brand and product names are trademarks or registered trademarks of their respective companies.

Disclaimer

The information contained in this manual is believed to be accurate and reliable. However, INFICON assumes

no responsibility for its use and shall not be liable for any special, incidental, or consequential damages related

to the use of this product.

Due to our continuing program of product improvements, specifications are subject to change without notice.

Copyright

©2018 All rights reserved.

Reproduction or adaptation of any part of this document without permission is unlawful.

1–1

RSH-600 Operating Manual

Table Of Contents

Trademarks

Disclaimer

Copyright

Chapter 1

Introduction

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 How to Contact INFICON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Returning Your RSH-600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.5 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.6 Base Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.7 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.8 Replacement Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2

Installation

2.1 Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 Functional Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Crystal Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.4 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.5 Adjustable Flange Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.6 Copper Head Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.7 Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.8 Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.9 Crystal Position Feedback Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.10 Protection from Evaporant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Chapter 3

Troubleshooting and Maintenance

3.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Troubleshooting RSH-600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 Maintain the Temperature of the Crystal . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Use the Optimum Crystal Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.5 Crystal Concerns when Opening the Chamber . . . . . . . . . . . . . . . . . . . . . . 3-4

3.6 Crystal Holder Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.7 Crystal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Chapter 4

Outline Drawings

1–1

RSH-600 Operating Manual

Chapter 1

Introduction

1.1 Introduction

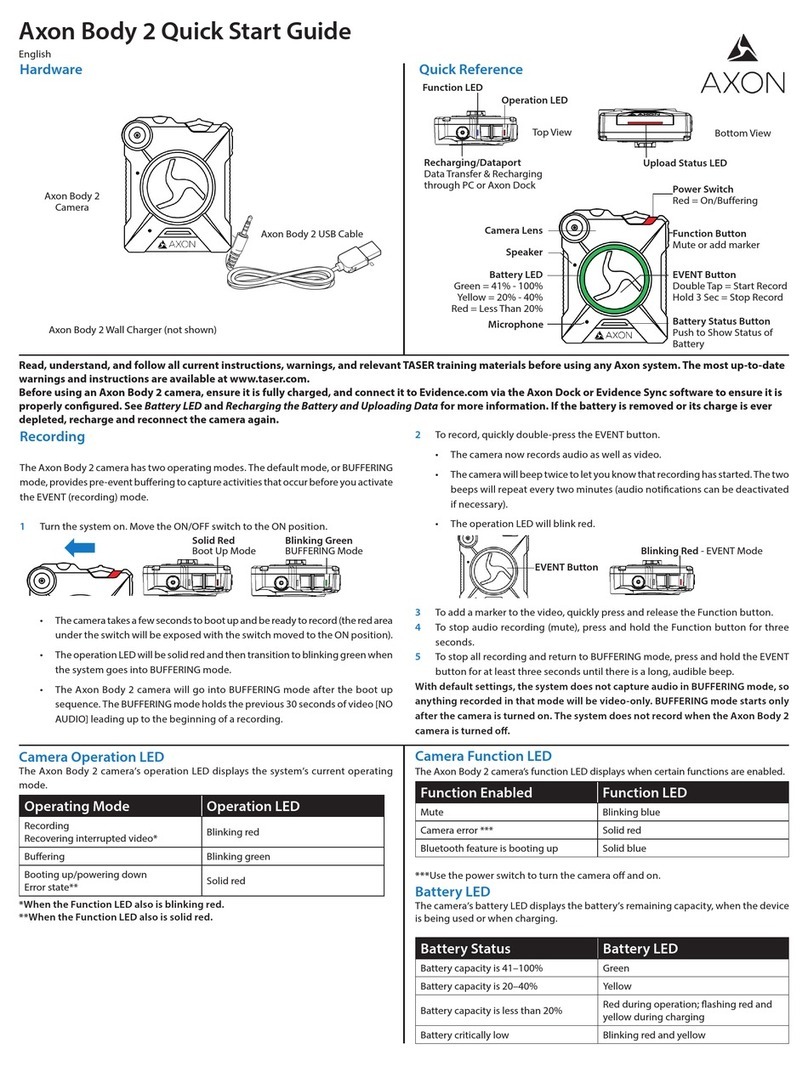

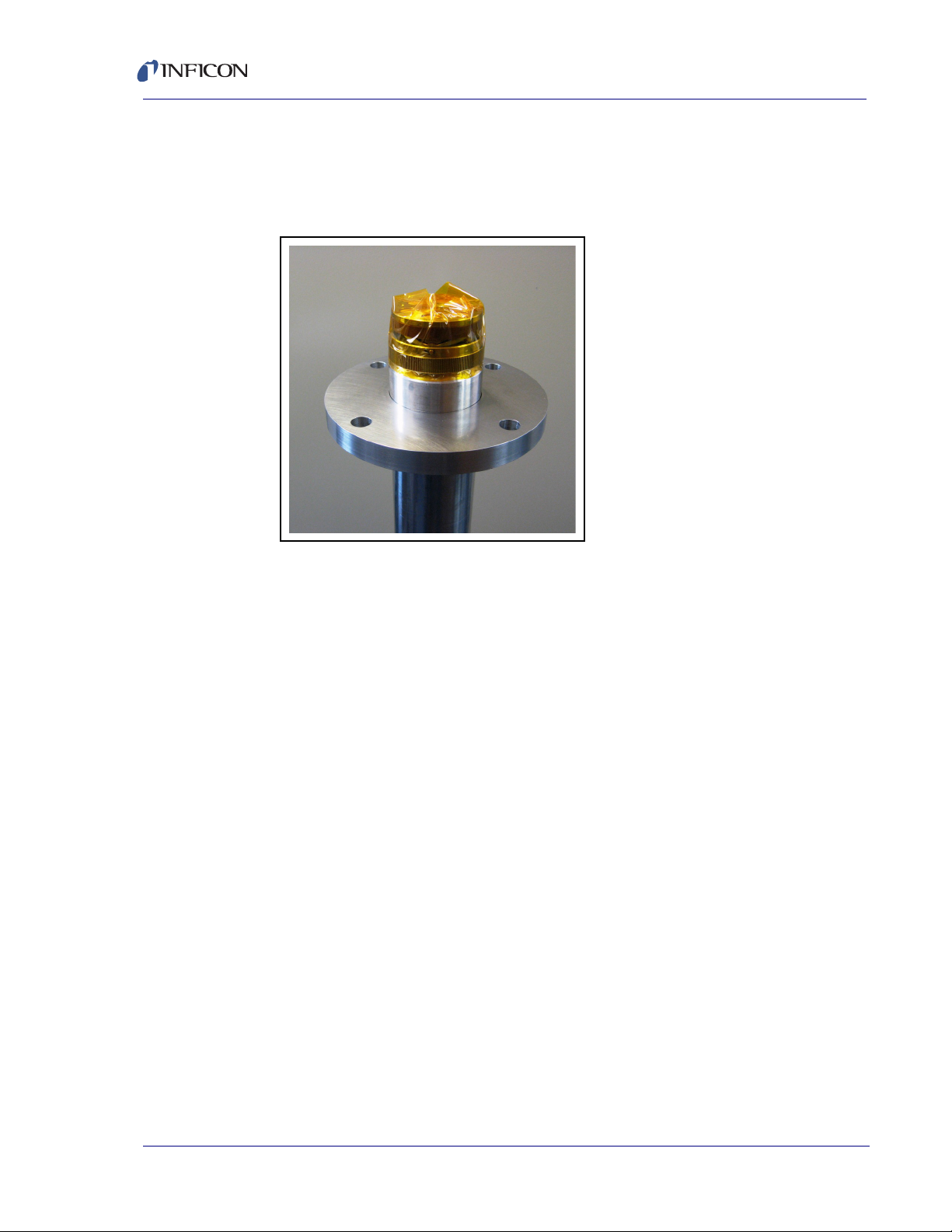

The RSH-600 rotary sensor is designed for the most demanding processes

employing very thick films and several different materials. See Figure 1-1.

Switching the crystal without venting the system makes it possible to run

automatically with continuous deposition. The fixed position of the crystal being

measured also makes it unnecessary to change the tooling factor.

RSH-600 can be used to deposit a different material on each of six crystals

providing greater measurement accuracy. Upon completion of deposition of one

material, the deposition controller may be programmed to switch crystals for the

next material. Switching crystals may also be actuated manually.

The RSH-600 sensor holds six crystals in a thermally shielded, water cooled

housing, insuring excellent crystal performance in temperature environments up to

300ºC. Crystals are housed in an easily removable Teflon®and stainless steel

crystal holder.

Crystal position is switched by applying a one second pulse to a 110/115 V (ac) or

24 V (dc) pneumatic valve. A 7-pin connector provides an indication of the number

of the active crystal. This may be used to interface with a thin film controller for

automatic crystal switching operation. Refer to the controller operating manual for

programming instructions.

Figure 1-1 RSH-600 and sensor head options

1–2

RSH-600 Operating Manual

1.2 Safety

When using this manual, please pay attention to the Notes, Cautions, and Warnings

found throughout. For the purposes of this manual they are defined as follows:

NOTE: Pertinent information that is useful in achieving maximum efficiency

when followed.

CAUTION

Failure to heed these messages could result in damage

to the instrument.

WARNING

Failure to heed these messages could result in

personal injury.

1.3 How to Contact INFICON

Worldwide customer support information is available under Support at

www.inficon.com where you can contact:

a Technical Support Engineer with questions regarding applications.

a Service Engineer with questions regarding troubleshooting, diagnosing or

repairing a defective sensor.

Sales and Customer Service, to find the INFICON Sales office nearest to you.

Repair Service, to find the INFICON Service Center nearest to you.

If you are experiencing a problem with RSH-600, please have the following

information readily available:

the serial number of RSH-600,

a description of your problem,

an explanation of any corrective action that you may have already attempted,

and the exact wording of any error messages that you may have received.

1–3

RSH-600 Operating Manual

1.4 Returning Your RSH-600

Do not return any component of your sensor to INFICON without first speaking with

a Customer Support Representative. You must obtain a Return Material

Authorization (RMA) number from the Customer Support Representative.

If you deliver a package to INFICON without an RMA number, your package will be

held and you will be contacted. This will result in delays in servicing your instrument.

Prior to being given an RMA number, you may be required to complete a

Declaration of Contamination (DOC) form if your sensor has been exposed to

process materials. DOC forms must be approved by INFICON before an RMA

number is issued. INFICON may require that the sensor be sent to a designated

decontamination facility, not to the factory.

1.5 Unpacking and Inspection

1If the RSH-600 sensor has not been removed from its shipping container, do

so now.

2Carefully examine the RSH-600 sensor for damage that may have occurred

during shipping. This is especially important if there is obvious rough handling

on the outside of the container. Immediately report any damage to the carrier

and to INFICON.

3Do not discard the packing materials until inventory is taken and a functional

verification test is performed. See section 2.2.

4Take an inventory of the order by referring to the order invoice and verifying that

the items listed in section 1.6 were received.

1–4

RSH-600 Operating Manual

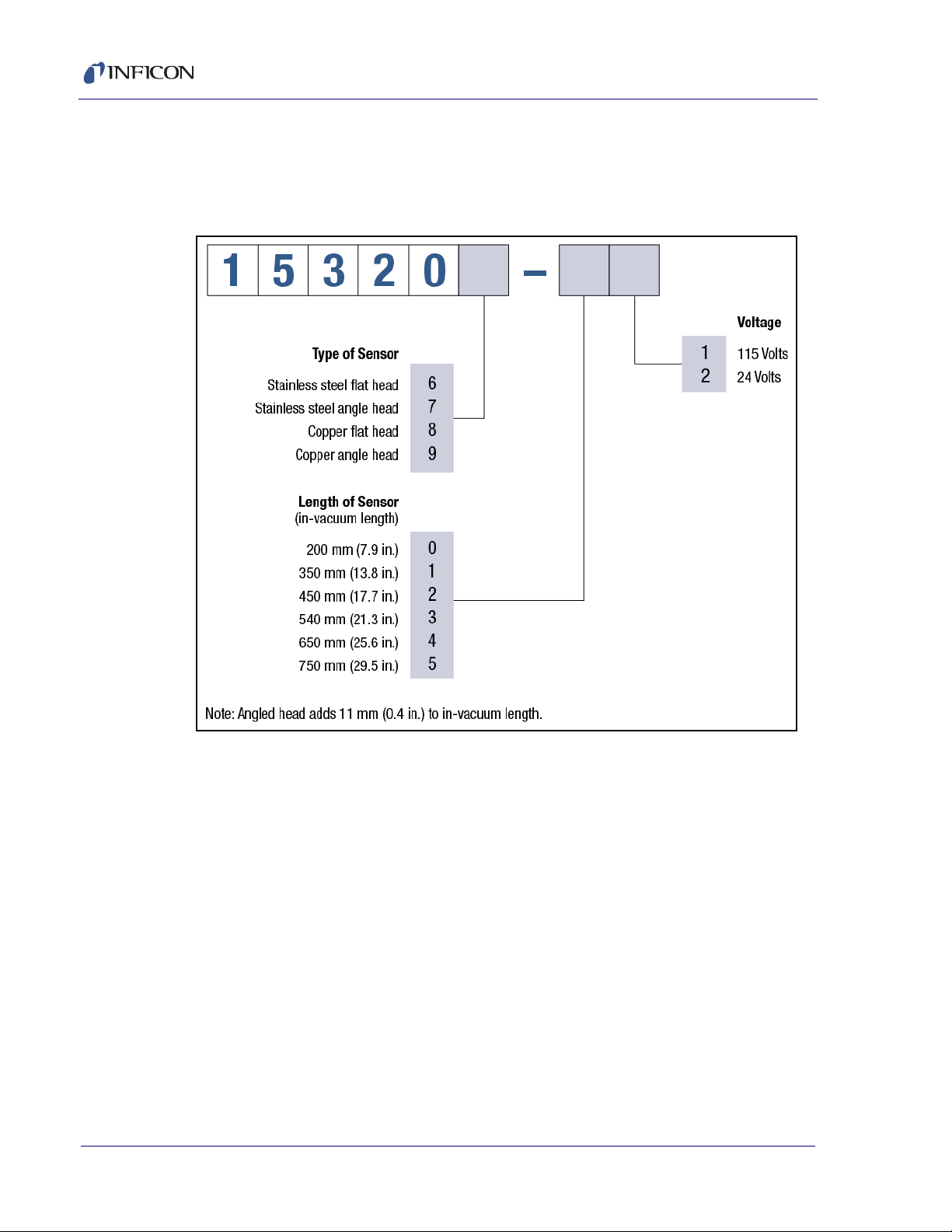

1.6 Base Configuration

RSH-600 Rotary Sensor Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15320X-XX

See Figure 1-2 below for possible configurations.

Figure 1-2 RSH-600 configurations

Crystals (2 boxes, 10 total) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103200-2

Technical Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153800 on 074-5000-G1 CD

1–5

RSH-600 Operating Manual

1.7 Specifications

Number of Crystals: 6

Crystal Size . . . . . . . . . . . . . . . . . . . 14 mm (0.550 in.) diameter

Installation Aperture: . . . . . . . . . . . . 5.08 cm (2.0 in.) diameter

Overall Length

RSH-600 w/flat head . . . . . . . . . 208 mm (8.19 in.) plus in-vacuum length

RSH-600 w/angled head . . . . . . 219 mm (8.62 in.) plus in-vacuum length

Adjustable in-vacuum Length . . . 200 mm (7.9 in.) (standard)

350 mm (13.8 in.)

450 mm (17.7 in.)

540 mm (21.3 in.)

650 mm (25.6 in.)

Power Requirement . . . . . . . . . . . . . 115 V (ac) @ 50 mA or 24 V (dc) @ 20 mA

Crystal Switching Method. . . . . . . . . Air Actuated @ 55 psi (4 kg/cm2) regulated

Cooling Method . . . . . . . . . . . . . . . . Water-cooled @ 5 L/m at 2 kg/cm2(28 psi)

Air and Water Connections. . . . . . . . (3) 6.35 mm (1/4 in.) quick connects

Operating Temperature. . . . . . . . . . . 300°C max with water cooling and Standard

Head Cover

400°C max with water cooling and Copper

Head Cover

Weight: (standard length) . . . . . . . . 200 mm (7.9 in.) RSH-600 - Flat - 3.8 kg

(8.5 lb.)

RSH-600 - Angled - 4.5 kg (9.9 lb.)

1–6

RSH-600 Operating Manual

1.8 Replacement Parts and Accessories

Flat Copper Head Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153731

Angled Copper Head Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153731-2

Flat Stainless Steel Head Cover (See Figure 1-3) . . . . . . . . . . . . . . . . . . . 153708

Angled Stainless Steel Head Cover (See Figure 1-4) . . . . . . . . . . . . . . . . 153713

Flat Crystal Retainer Assembly (See Figure 1-3). . . . . . . . . . . . . . . . . . . . 153204

Angled Crystal Retainer Assembly (See Figure 1-4) . . . . . . . . . . . . . . . . 153204-2

Flat Crystal Holder (See Figure 1-3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153710

Angled Crystal Holder (See Figure 1-4) . . . . . . . . . . . . . . . . . . . . . . . . . . . 153716

Flat Spring Retainer Assembly (See Figure 1-3) . . . . . . . . . . . . . . . . . . . . 153706

Angled Spring Retainer Assembly (See Figure 1-4) . . . . . . . . . . . . . . . . . 153714

Flat Spring Retainer Contact Kit (See Figure 1-3) . . . . . . . . . . . . . . . . . . . 153724

Spring Contact (See Figure 1-3 and Figure 1-4) . . . . . . . . . . . . . . . . . . . . 153726

Flat Retainer Screw (See Figure 1-3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153709

Angled Retainer Screw (See Figure 1-4) . . . . . . . . . . . . . . . . . . . . . . . . . . 153715

Angled Retainer Spacer (See Figure 1-4) . . . . . . . . . . . . . . . . . . . . . . . . . 153717

M3x6 Screw for Flat Crystal Retainer Assembly (See Figure 1-3). . . . . . . 144-101

M3x12 Screw for Angled Crystal Retainer Assembly (See Figure 1-4) . . . 144-224

Solenoid Valve Assembly, 24 V (See Figure 4-1). . . . . . . . . . . . . . . . . . . . 153707

Crystal Position Male Connector (See Figure 4-1). . . . . . . . . . . . . . . . . . . 889128

Adjustable Flange (See Figure 4-1 and Figure 4-2). . . . . . . . . . . . . . . . . . 153202

O-ring for Adjustable Flange (See Figure 4-1) . . . . . . . . . . . . . . . . . . . . . . 803188

1–7

RSH-600 Operating Manual

Figure 1-3 Rotary sensor head - flat

Stainless Steel Cover

Crystal Holder

P/N 153708

P/N 153710

Spring Contact

Retainer Screw

Spring Retainer

Spring Retainer

P/N 153726

P/N 153709

Copper Cover (not shown)

P/N 153731

Contact Kit (set of 6)

P/N 153724

Assembly

P/N 153706

Crystal Retainer

Assembly

P/N 153204

1–8

RSH-600 Operating Manual

Figure 1-4 Rotary sensor head - angled

Stainless Steel Cover

Copper Cover (not shown)

Crystal Holder

P/N 153716

P/N 153713

P/N 153731-2

Spring Retainer

Assembly

P/N 153714

Crystal Retainer

Assembly

P/N 153204-2

Retainer Screw

P/N 153715

M3x12 Screw

P/N 144-224

Spring Contact

P/N 153726

Retainer Spacer

P/N 153717

2–1

RSH-600 Operating Manual

Chapter 2

Installation

CAUTION

During installation, special care must be taken to protect

the barrel surface from being damaged. Scratches or

gouges may prevent RSH-600 from forming a good

vacuum seal to the O-ring.

Successful operation of any crystal sensor depends on proper placement,

compatibility of its construction with its operating environment and connection to

proper utilities.

CAUTION

RSH-600 must be clean and grease free when installed in

the vacuum chamber. The sensor must be handled while

wearing clean nylon gloves. If parts do become

contaminated, clean them thoroughly using a suitable

solvent to avoid outgassing and excessive peeling of

deposition material from the sensor surfaces.

2–2

RSH-600 Operating Manual

2.1 Configurations

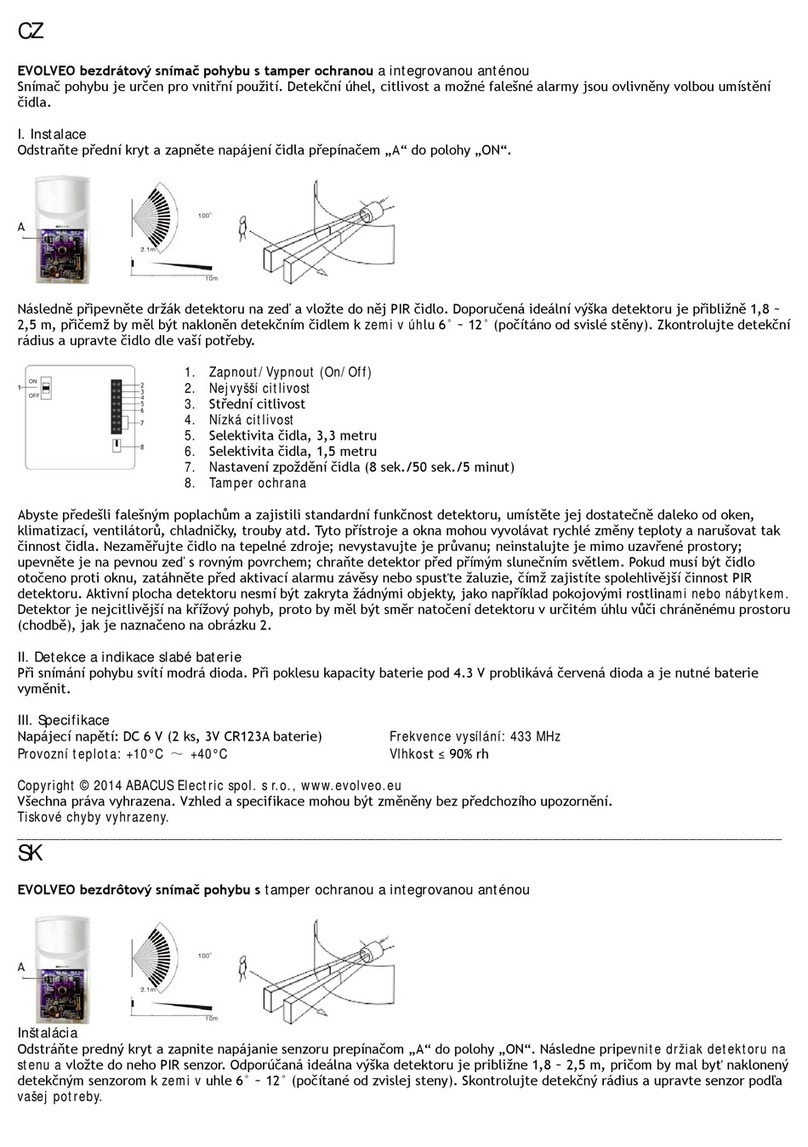

RSH-600 can be configured with a flat head or a 45° angled head. This allows for

mounting in various locations within the vacuum chamber. Standard head covers are

made of stainless steel. Copper head covers are available for applications where

temperature is a concern (see

Figure 2-1

). All versions of RSH-600 are fixed to their

specified lengths, but may be adapted to be adjustable in length using the optional

adjustable mounting flange (see

section 1.8

for optional accessory information).

Figure 2-1 RSH-600 sensor head cover cooling efficiency

2–3

RSH-600 Operating Manual

2.2 Functional Verification

RSH-600 is equipped to operate on a 115 V (ac), 60 Hz line or a 24 V (dc) supply,

depending on the model number. The required voltage on the body of the

pneumatic valve mounted on the side of RSH-600 can be verified. RSH-600 may

be bench checked using the following procedure:

1Connect air pressure (55 psi) via 6.35 mm (1/4 in.) plastic tubing to the air inlet

fitting at the base of the solenoid valve marked "P."

2Connect RSH-600 as shown in Figure 2-2 or use any convenient method of

applying and removing the control voltage. RSH-600 will advance when the

voltage is applied and latch into position when it is removed. The electrical

pulse duration should be at least one second.

Figure 2-2 Electrical connection

Control

Voltage

115 V (ac)

or

24 V (dc)

J1 RSH

Switch

2–4

RSH-600 Operating Manual

2.3 Crystal Sensor Installation

Install the sensor as far as possible from the evaporation source (a minimum of

30.5 cm (12 in.)) while still being in a position to accumulate thickness at a rate

proportional to accumulation on the substrate. Figure 2-3 shows proper and

improper methods of installing sensors.

Figure 2-3 Sensor installation guidelines

To guard against spattering, use a source shutter to shield the sensor during the

initial soak periods. If the crystal is hit with even a minute particle of molten material

it may be damaged and stop oscillating. Even in cases when it does not completely

stop oscillating, it may immediately become unstable, or shortly after deposition

begins instability may occur.

Plan the installation to ensure that there are no obstructions blocking a direct path

between the sensor and the source. Install sensors in such a manner that the

center axis of the crystal is aimed directly at the source to be monitored. Verify that

the angle of the sensor location (with reference to the source) is well within the

evaporant stream.

2–5

RSH-600 Operating Manual

2.4 Mounting

The RSH-600 smooth sealing surface mounts to an O-ring sealed nipple (not

included). The optional adjustable flange allows the in-vacuum length to be

adjustable up to the RSH-600 original length. A flat head cover is typically used for

centered top mount applications while the angled heads may be used for either

off-center top mount or side mount applications. The customer must supply

specifications regarding mounting holes, exterior diameter of flange, and the

system mating flange.

NOTE: The head cover must be removed from RSH-600 prior to installation.

To remove the standard stainless steel head cover: loosen the retainer ring

nut. Push the head cover inward while turning it counterclockwise until it

stops (1/16 of a turn). Pull the head cover outward.

To remove the optional copper head cover: loosen the Allen head screws

that clamp the head to RSH-600 then gently pull the head off of the

RSH-600 barrel.

The vacuum system must be equipped with a 5.08 cm (2.0 in.) diameter aperture

port. This port must have an O-ring to provide vacuum seal to the fixed flange on

RSH-600. If the head cover has been removed, simply slide RSH-600 through the

5.08 cm (2.0 in.) port. Secure RSH-600 to the port using four 1/4-24 bolts minimum.

Reinstall the head cover. See Figure 2-4.

Figure 2-4 Typical mounting configuration

J2

J1

15.24 cm (6 in.) Coaxial Cable

Oscillator

3 m (10 ft.) Coaxial Oscillator

Water In

Optional Flange

Water Out

Air Solenoid Valve

Cable to QCM

2–6

RSH-600 Operating Manual

2.5 Adjustable Flange Installation

1Apply a small amount of vacuum compatible grease to the entire surface of the

O-ring that is included with the adjustable flange and then install the O-ring into

the O-ring groove in the adjustable flange.

2Loosen the hex socket head screw on the adjustable flange.

3Remove the cover from the RSH-600 sensor.

4If the crystal holder contains any crystals, remove the holder and remove and

discard the crystals. Reinstall the crystal holder.

5Cut a piece of Kapton® tape (or equivalent), 3.8 cm (1.5 in.) to 5.08 cm (2 in.)

wide, to a length of approximately 16 cm (6.3 in.).

6Position the Kapton tape with the bottom edge of the tape on the beveled

surface just below the knurled ring. Not starting at any of the three bayonet

pins, wrap the tape around the circumference of the sensor. Fold the excess

tape over the top of the crystal holder. See Figure 2-5.

Figure 2-5 Wrap Kapton tape

2–7

RSH-600 Operating Manual

7Stand the RSH-600 sensor upright on a firm surface. Place the adjustable

flange, with smooth side up, over the top of the sensor barrel. With the flange

seating surface perpendicular to the sensor barrel, forcefully push the flange

downward, sliding the flange onto the sensor barrel. See Figure 2-6.

Figure 2-6 Slide flange onto sensor barrel

8Slide the adjustable flange to the desired position on the sensor barrel and then

secure the flange to the barrel by tightening the hex socket head screw on the

flange.

9Remove the Kapton tape. Use a lint-free cloth dampened with reagent grade

isopropyl alcohol to clean the surfaces that were in contact with the tape.

2–8

RSH-600 Operating Manual

2.6 Copper Head Installation

The optional copper head must be installed after RSH-600 has been mounted on

the vacuum system. The copper head has two main pieces, the clamping ring and

the head cover.

1Loosen the Allen head screw on the clamping ring and on the clamp portion of

the head cover.

2Attach the clamping ring to the head cover.

3Remove the crystal retainer to expose two gold springs. One spring makes

contact with the backside of the retainer. The other spring makes contact with

one of the individual crystal contacts.

4Align the hole in the head cover so that the crystal, that this spring contacts, is

exposed. Note the position of this spring and replace the crystal retainer.

5Carefully slide the cover over the barrel of RSH-600 until it touches the crystal

retainer, then rotate the cover so that the crystal, in contact with the spring, is

centered in the hole in the cover.

6Tighten the Allen screws on the clamping ring.

The clamping ring should be left attached to the head during crystal changing. Only

the head cover should be removed so the alignment process will not have to be

repeated unless the head is removed from the chamber.

If no flange was ordered and dimensions are needed for a custom adjustable

flange, INFICON can provide essential dimensions and O-rings.

2.7 Cooling System

The direction of the water flow is not important. Use 6.35 mm (1/4 in.) plastic tubing

to connect one port to a water supply. The water flow rate should be 5 L/m (1.3 g/m)

at 2 kg/cm2(28 psi). Water temperature should be less than 30°C. Connect the

other port to a drain or water recycle system.

2.8 Air Supply

Use 6.35 mm (1/4 in.) plastic tubing to connect the air inlet port to an air supply.

Make sure the plastic tube is rated higher than 55 psi. The air pressure should be

regulated to 4 kg/cm2(55 psi).

2–9

RSH-600 Operating Manual

2.9 Crystal Position Feedback Connections

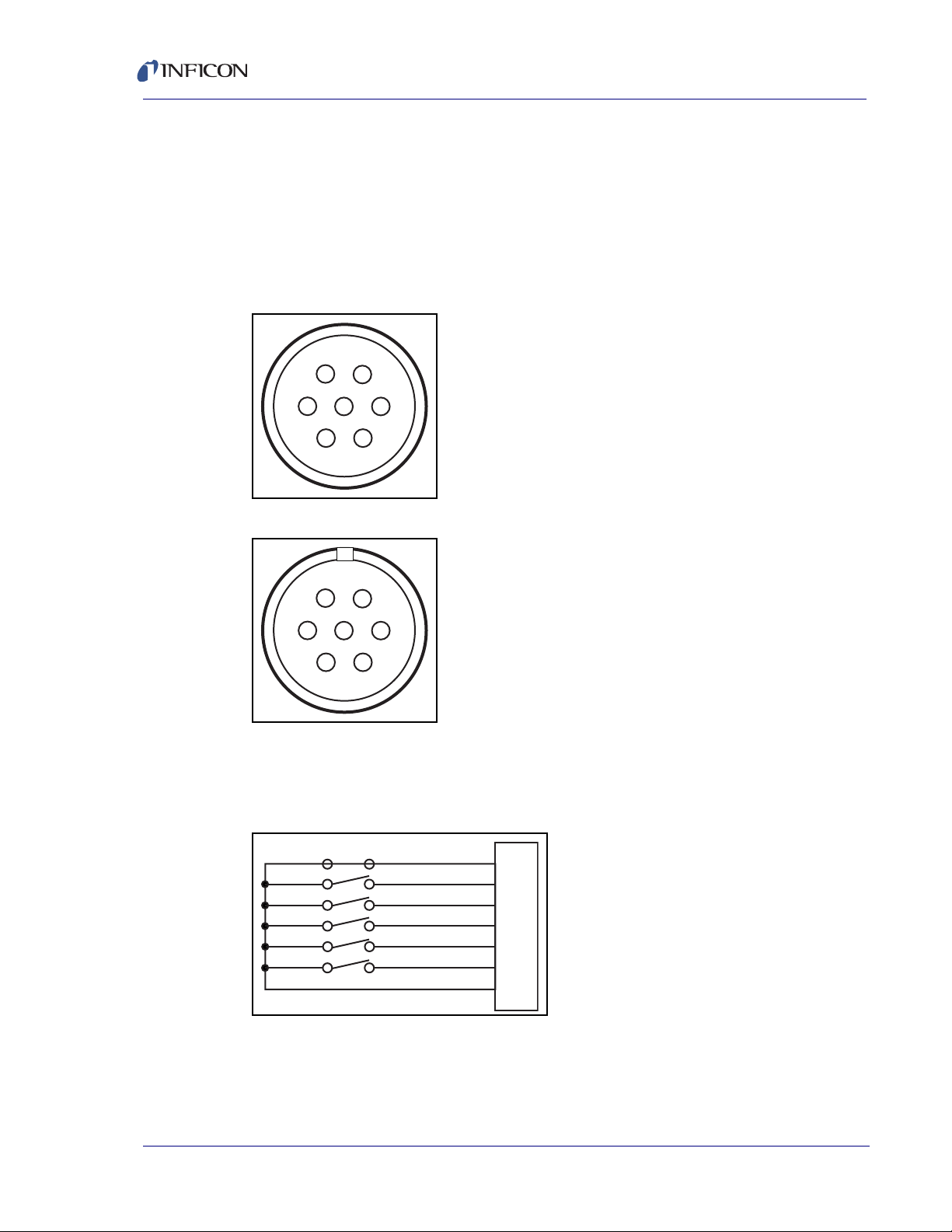

The crystal position connector has seven pins. Pin numbers 1 through 6

correspond to the six crystals and pin number 7 is the common pin. A short

between pin 7 and one of the pins 1 through 6 indicates the active crystal. For

example, if pin 7 is shorted to pin 1, then crystal 1 is the active crystal.

Use this connector to interface with the controller for automatic crystal selection.

Refer to the controller operating manual for programming instruction.

Figure 2-7 Crystal position connector

Figure 2-8 Mating connector (male) - crystal position connector

RSH-600 provides a switch closure through connector J2 that can be used to

indicate which crystal is active at a given time. Switch closure will be affected by

crystal positions.

Figure 2-9 Crystal position feedback diagram (crystal 1 is the active crystal)

2.10 Protection from Evaporant

Place aluminum foil over the RSH-600 head cover and barrel to protect them from

evaporants during a vacuum operation.

1

2

34

5

6

7

6

5

43

2

1

7

Common

Crystal 1

Crystal 2

Crystal 3

Crystal 4

Crystal 5

Crystal 6

1

2

3

4

5

6

7

Table of contents

Other Inficon Accessories manuals

Popular Accessories manuals by other brands

Lifetime

Lifetime FREESTANDINGPOWER LIFT 71730 Owner's manual with assembly instructions

Vaisala

Vaisala HMP60 series user guide

Black & Decker

Black & Decker BDXPA0042 instruction manual

Vuly

Vuly THUNDER Assembly manual

Tascam

Tascam US-122 owner's manual

Honeywell

Honeywell Farenhyt Series Installation and maintenance instructions