Inficon Easy Rate ERD E1 Series User manual

1 of 13

Easy Rate™ Sensor

INSTRUCTION SHEET

PN 074-677-P1A

Introduction

This instruction sheet describes the proper installation, operation, maintenance, and

repair of the Easy Rate single and dual sensors.

This product has a warranty of one year from the date of purchase. This warranty covers

defects of materials or workmanship under normal proper use and service. Refer to the

INFICON website for warranty details. The batch number of the sensor can be found on

the packaging label. It is important to document this number for any necessary warranty

claims.

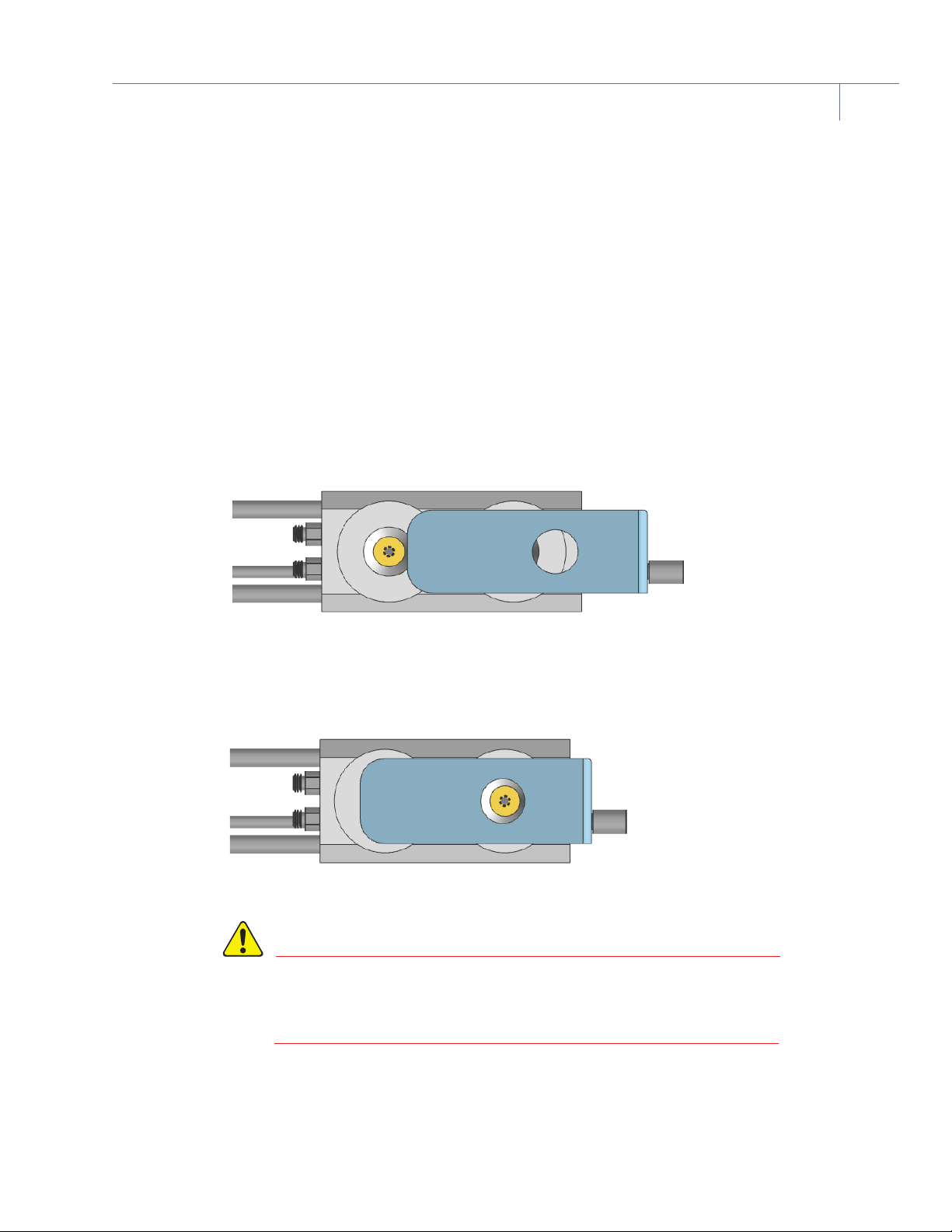

Figure 1 Easy Rate Sensors

2 of 13

Easy Rate Sensor

PN 074-677-P1A

Installation

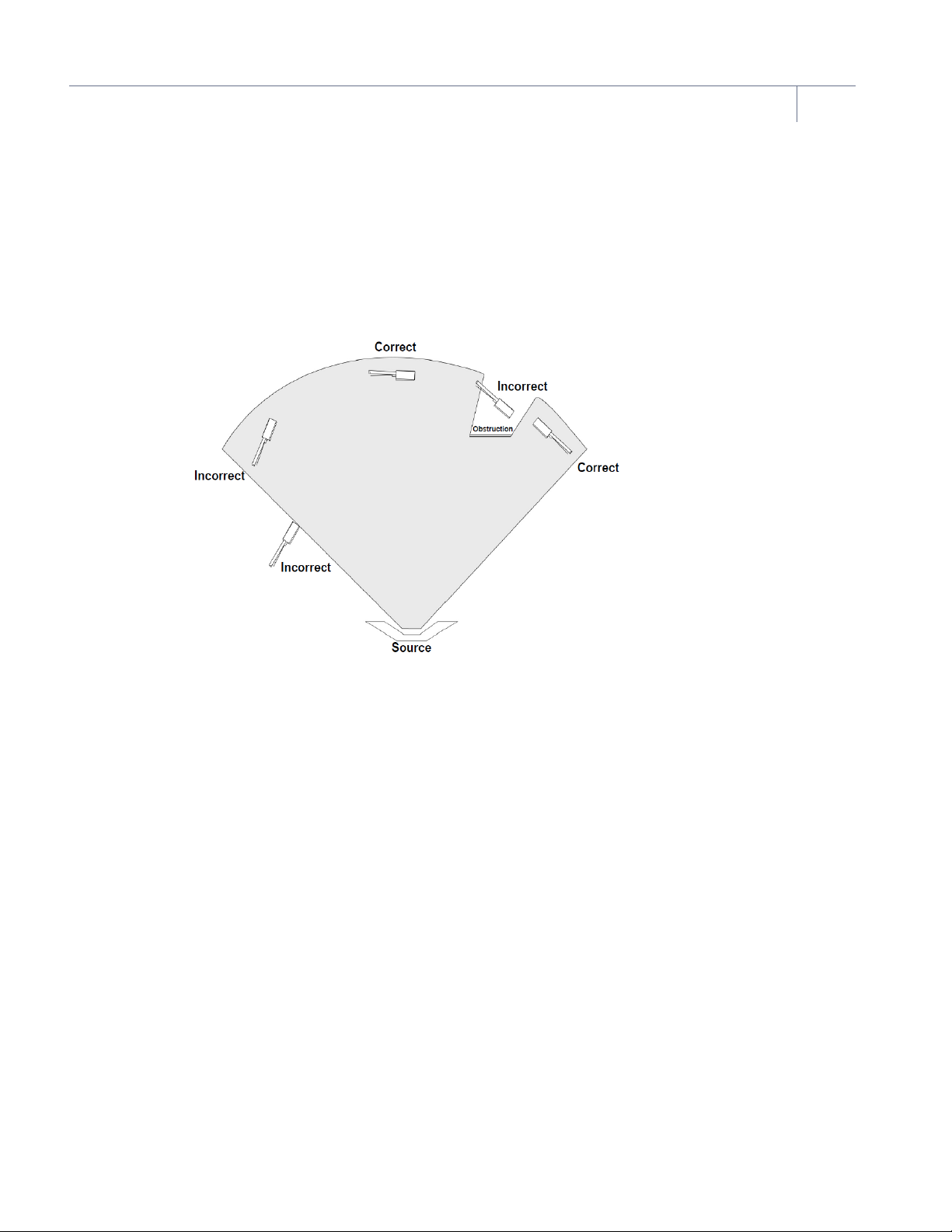

Install the sensor as far as possible from the evaporation source (a minimum of 25.4 cm

(10 in.)) while still being in a position to accumulate thickness at a rate proportional to

accumulation on the substrate. Figure 2 shows proper and improper methods of

installing sensors.

Figure 2 Proper and improper methods of installing sensors

NOTE: For best process reproducibility, rigidly support the sensor by the #4-40 screw

mounting holes on the back of the sensor so it cannot move during maintenance

and crystal replacement.

To guard against spattering, use a source shutter to shield the sensor during initial soak

periods. If the crystal is hit with even a minute particle of molten material, it may be

damaged and stop oscillating. Even in cases when it does not completely stop

oscillating, it may immediately become unstable or, shortly after deposition begins,

instability may occur.

Plan the installation to ensure there are no obstructions blocking a direct path between

the sensor and the source. Install sensors in such a manner that the crystal face is aimed

directly at the source to be monitored. Verify that the angle of the sensor location (with

reference to the source) is well within the evaporant stream. If the sensor is not

perpendicular to the source, the coating on the crystal will be tapered and shortened

crystal life can result.

3 of 13

Easy Rate Sensor

PN 074-677-P1A

NOTE: In many cases, installing multiple sensors to monitor one source can improve

thickness accuracy for the product, using a feature known as multiple sensor

averaging. The installation requirements for multiple sensors are the same as for

a single sensor installation, and the locations chosen should be as defined in

Figure 2. Consult the Quartz Crystal Microbalance (QCM) thickness

measurement instrument operating manual for more information regarding the

availability of this feature.

Steps for installation:

1Assemble the sensor mounting bracket (provided by customer) on the process

system.

2Temporarily position and attach the sensor head as outlined in the general guidelines

in Figure 2.

3Temporarily install the feedthrough.

4Form (bend), measure, and mark the sensor tubes as required to achieve the desired

result.

CAUTION

Do not form the sensor tubes with a bend radius of less than

1.3 cm (0.5 in.).

CAUTION

Do not use the sensor body as a leverage point when bending

the tubes; doing so stresses the weld joints on the tubes and

may result in their failure.

CAUTION

Do not start a bend within 1.3 cm (0.5 in.) of a weld joint.

5Build the sensor/feedthrough assembly.

6Remove the sensor and the feedthrough.

7Cut the water cooling tubes and the air tube to the proper length. Verify that they are

clear of metal particles by forcing compressed air through the tubing.

8Connect the water cooling tubes and the air tube directly to the feedthrough, or use

vacuum rated couplings.

4 of 13

Easy Rate Sensor

PN 074-677-P1A

Vacuum rated connectors are recommended for use between the sensor and the

feedthrough to speed maintenance. If brazing adapters are to be used, attach them

to the sensor water-cooling tubes and to the air tube prior to connection to the

feedthrough. Make connections as follows:

CAUTION

To prevent damage to the feedthrough or sensor during

brazing, ensure that at least 2.45 cm (1 in.) of water tube

remains between the sensor head and the flame.

8a Clean the water tubes, the air tube, and adapter surfaces with solvent, if necessary.

8b Apply brazing flux to surfaces being joined.

8c Braze the connections using a flame temperature appropriate for the brazing

material being used.

CAUTION

Excessive application of brazing material, or excessive heat

due to brazing, may result in blockage of the water tubes or the

air tube.

8d Verify that each joint is not blocked by blowing compressed air through the cooling

tubes and the air tube.

8e Thoroughly clean the braze joint and helium leak test before installing the sensor and

feedthrough into the process chamber.

9With all water tube connections and the air tube connection installed, install the

sensor and feedthrough assembly into the process system and secure all retaining

hardware.

10 Shield the in-vacuum cable from heat radiating from the evaporant source or the

substrate heater. If the process allows, wrap aluminum foil around the cable, the

water tubes and the air tube.

11 Connect the external water tubes from the feedthrough to the water supply system

and flow controller. Use detachable coupling (Swagelok®or equivalent) for external

water tube connections. Apply water pressure and verify the water connections.

12 Because of geometric factors, variations in surface temperature, and differences in

electrical potential, the crystal and substrates often do not receive the same amount

of material. Tooling factor calibration is required to make sure that the thickness

indication on the instrument accurately represents the thickness on the substrates.

Refer to the instrument operating manual for tooling factor calibration procedures.

5 of 13

Easy Rate Sensor

PN 074-677-P1A

Actuator Function Check

Temporarily connect an air supply to the actuator air tube and test operation for 10 to 15

cycles. Operating range is:

70–80 psi (gauge)

85–95 psi (absolute)

5.8–6.5 bar (absolute)

584–653 kPa (absolute)

When actuated, shutter movement should be smooth, rapid, and complete, and should

extend as shown. The crystal aperture must be completely exposed. It is acceptable if

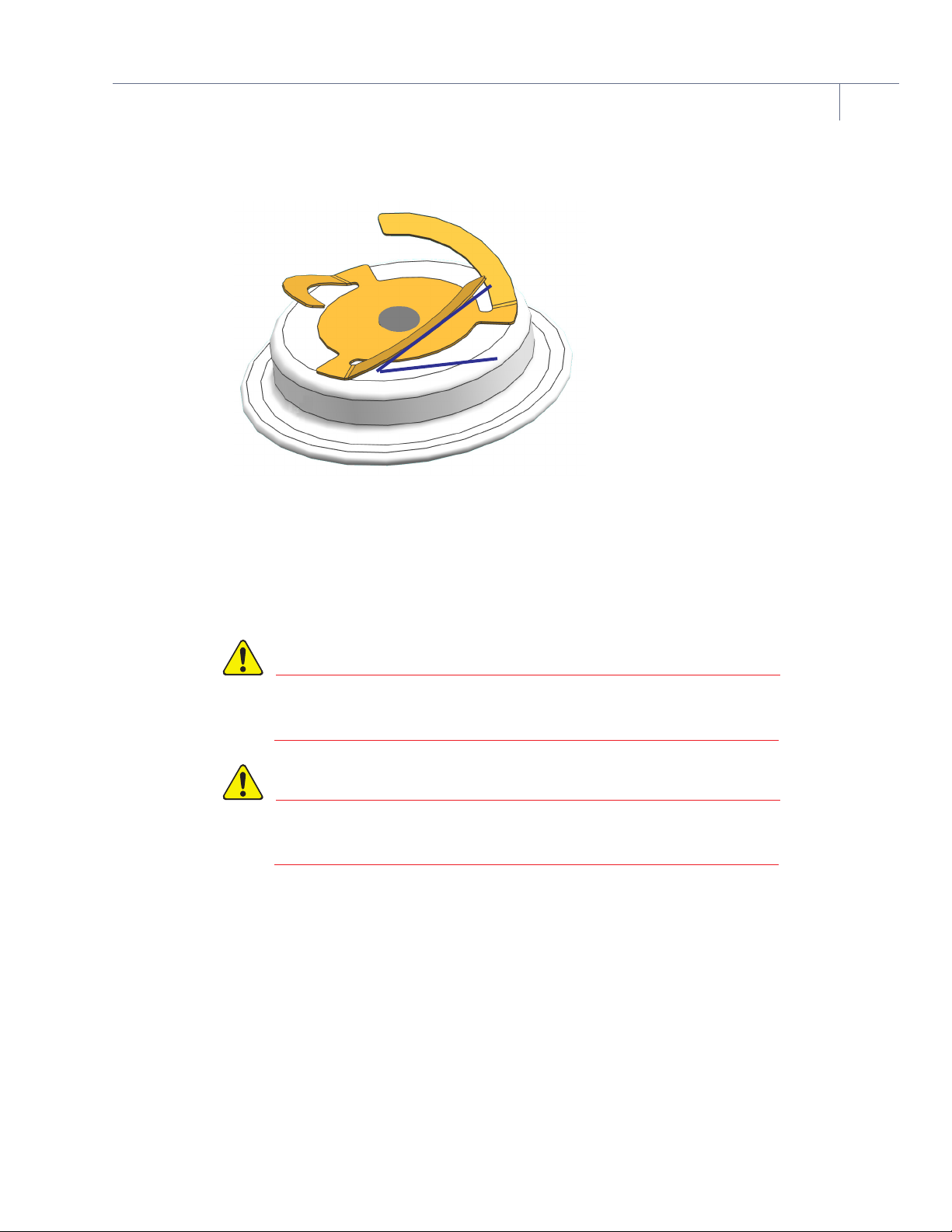

the crystal holder is only partially exposed. (See Figure 3.)

Figure 3 Acceptable shutter end extension

When deactivated, the shutter should completely cover the crystal opening.

Repositioning of the shutter or actuator may be required to achieve optimum on/off

positioning. If operation is found to be impaired, contact INFICON. (See Figure 4.)

Figure 4 Shutter completely covering the crystal opening

NOTE: A solenoid valve (PN 750-420-G1) is required with any new shutter installation.

WARNING

Do not exceed 100 psi (gauge), 115 psi (absolute), 7.9 bar

(absolute), or 791 kPa (absolute). Connection to excessive

pressure may result in personal injury or equipment damage.

6 of 13

Easy Rate Sensor

PN 074-677-P1A

Actuator Installation

If installing an actuator on an existing standard single or dual sensor, the actuator front

face should align as shown with the sensor body. (See Figure 5.) Installation of the

sensor shutter on existing equipment requires either a Single Shutter Assembly (PN

784-209-G1) or a Dual Shutter Assembly (PN 784-210-G1).

Figure 5 Actuator front face alignment

1If replacing an actuator assembly, remove the failed assembly.

2Place the actuator clamp onto the actuator using the grooves on the actuator to

center the clamp.

3Rotate the shutter module until the holes through the actuator assembly of the

shutter module coincide with the #4-40 tapped holes in the rear side of the standard

crystal sensor assembly.

4Secure the shutter module to the standard crystal sensor assembly utilizing the

#4-40 hardware provided with the shutter assembly.

5Position the shutter directly over the center of the crystal opening. Tighten the shutter

cap screw. Make certain the shutter, when activated, does not block deposition of the

evaporant stream onto any portion of the crystal.

In-Vacuum Cable

In-vacuum microdot cable connectors should be hand tightened only. To remove the

in-vacuum cable, hold the sensor body microdot connector in place using the flat sides

of the connector, prior to attempting to loosen the in-vacuum cable.

WARNING

If the microdot connector is not held or clamped in place, prior

to removing the microdot cable, the sensor may be damaged.

7 of 13

Easy Rate Sensor

PN 074-677-P1A

The standard cable length from the sensor to the feedthrough is:

25.4 cm (10 in.) for In-vacuum cable PN 783-500-023, which is used in the following

Easy Rate Sensor configurations: ERS-X1XE1XX and ERD-X1E1XX

76.2 cm (30 in.) for In-vacuum cable PN 783-500-024, which is used in the following

Easy Rate Sensor configurations: ERS-X2XE1XX and ERD-X2E1XX

NOTE: Refer to the Easy Rate Sensor data sheet (located at inficon.com) for

information on part number configuration. The cable length from the crystal to

the oscillator should not exceed 91.44 cm (36 in.) unless a ModeLock instrument

is used. Refer to the instrument operating manual for cable length limitations.

Operation

The information below describes normal use of the sensor.

Crystal Handling

Any contamination of the crystal or scratches on the surface will reduce crystal life and

cause rate noise. Contamination and scratches also interfere with adhesion of the

deposited material on the crystal.

To avoid crystal contamination:

insert the crystal directly from its package into the crystal holder

never handle the crystal with bare or gloved fingers

never drop or place the crystal onto a work area

Crystal Replacement

When transporting the crystal from the package to the crystal holder, use Teflon™

tweezers or a vacuum pencil. Touch the crystal only at the perimeter, never in the center

region.

1Wearing clean nylon gloves, grip the crystal holder and pull it straight out of the

sensor body. For dual and single shuttered sensors, remove the shutter using the

thumb screw prior to this step.

2If a crystal is already installed, invert the crystal holder and push on the crystal from

the deposited electrode face of the crystal until the crystal is free from the spring

contact.

NOTE: Crystal will potentially break using this method. If the crystal needs to be

preserved for analytical reasons, gently pressing in two of the spring tab

contacts holding the crystal in place should allow for the crystal to be freed

without damaging it.

8 of 13

Easy Rate Sensor

PN 074-677-P1A

3Grasp the edge of the new crystal with a clean pair of Teflon™tweezers. Orient the

crystal so the patterned electrode is facing up. Gently insert the edge of the crystal

into the crystal holder pushing aside the spring contacts until the crystal is seated

evenly and securely in the crystal holder.

NOTE: If using a vacuum pencil, the suction surface touching the crystal must be

kept clean. When not in use, store the vacuum pencil so that its tip does not

touch other surfaces. Regularly clean or replace the suction tip.

4Reinstall the holder in the sensor body; push the holder straight in making certain that

it is completely seated in the sensor body.

Maintenance

Establishing a regular maintenance cycle based on the needs of the process is essential

to the long term successful operation of the sensor. Sensor maintenance also impacts

reproducibility of results. The following are the components that should be inspected

during maintenance.

Crystal Holder

The crystal holder makes electrical and thermal connection to the crystal at the crystal

perimeter. Coating material will eventually start to build up on the crystal holder contact

surface and will reduce the electrical and thermal conductance. This leads to reduced

crystal life and increased rate noise. Material buildup on the holder must be removed

regularly to maintain a constant size of the aperture run-to-run.

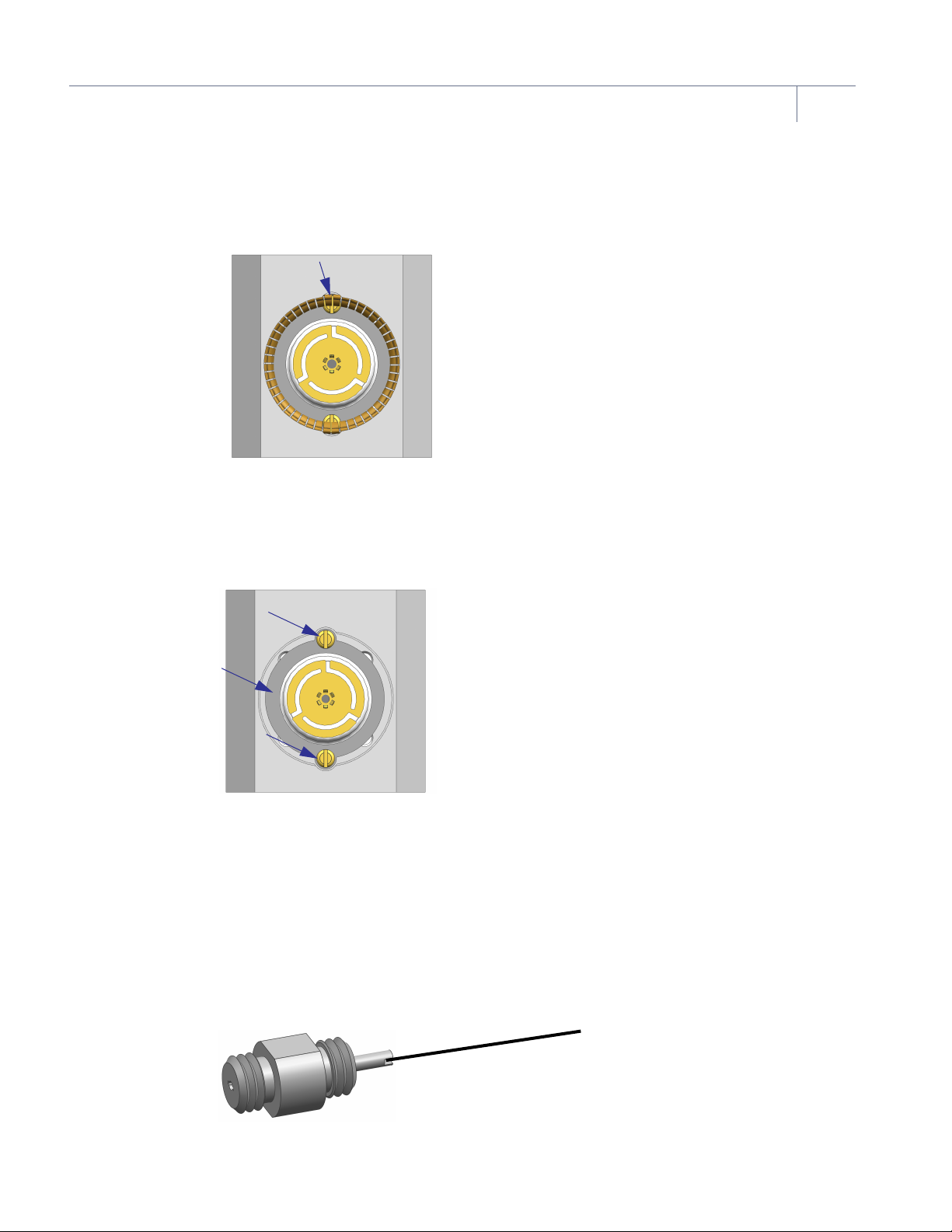

Crystal Leaf Spring

All Easy Rate Sensors have contact leafs that make the electrical connection from the

sensor to the rear electrode on the crystal. These contact leaves must be inspected

regularly. While rarely necessary, the spring contacts may need adjustment. Bend them

to a 45º angle as shown in Figure 6.

9 of 13

Easy Rate Sensor

PN 074-677-P1A

Figure 6 Contact leaf adjustment

Repair

Repairs to this sensor can be done in the field by an electrical technician at the risk and

responsibility of the sensor owner.

NOTE: Beyond the warranty period, this sensor is not serviced by INFICON.

WARNING

INFICON is not responsible for any damage or loss of property

that may occur during a sensor repair.

WARNING

Do not attempt to repair a sensor under warranty. Doing so will

void the warranty.

Electrical Test

If an issue with the sensor is suspected, first check the sensor assembly for continuity

and isolation. Measure continuity with a digital multimeter (DMM) capable of measuring

50 MΩ. Figure 7 shows the standard sensors. The same test can be applied to the right

angle sensor.

Continuity: <1 ΩFrom the microdot connector center pin to leaf spring center

Isolation: >50 MΩFrom the microdot connector center pin to the sensor body

10 of 13

Easy Rate Sensor

PN 074-677-P1A

Figure 7 Single and Dual Sensor Continuity and Isolation

Electrical Connection Repair

If the continuity test fails, the electrical connection will need to be replaced. For a dual

sensor, the steps below will need to be repeated for each crystal cavity. Images in these

instructions may be for one sensor, but the concept of the instruction is applicable to all

versions.

New items required:

Crystal Retainer Assembly Easy Rate Sensor . . . . . . . . . . PN 784-205-G1

Coax Connector Female Flat Sides . . . . . . . . . . . . . . . . . . PN 784-323-P1

Reusable items:

0-80 Retainer Plate Easy Rate Sensor . . . . . . . . . . . . . . . PN 784-322-P1

Screw 0-80 x 0.125 in. LG Slot Pan HD SS GP . . . . . . . . . PN 080-011-P3

Holder Finger Spring Easy Rate Sensor . . . . . . . . . . . . . . PN 784-405-P1

Crystal Holder Assembly Easy Rate Sensor . . . . . . . . . . . PN 784-204-G1

Items not provided by INFICON:

22 AWG, Buss Wire, Solid, Tin Coated Copper

Tubing, Teflon™, Clear, 0.066 inch OD

Kester 48 Core LF Solder

Continuity (<1 Ω)

Isolation (>50 MΩ)

Continuity (<1 Ω)

Isolation (>50 MΩ)

11 of 13

Easy Rate Sensor

PN 074-677-P1A

Tools: Soldering iron, adjustable wrench, Teflon™tweezers, torque screwdriver or

wrench

1Grasp the microdot connector by the flat sides using an adjustable wrench and

loosen it. (See Figure 8.)

Figure 8 Microdot connector

NOTE: If the wire inside is still intact, the connection will break as the connector

comes loose. This is normal and expected.

2Pull the crystal holder out of the sensor body. (See Figure 9.)

Figure 9 Remove crystal holder

12 of 13

Easy Rate Sensor

PN 074-677-P1A

3Using Teflon™tweezers, gently pry the crystal holder spring out of the sensor body.

(See Figure 10.)

Figure 10 Crystal holder spring

NOTE: Move the spring circularly until the gap between the two ends is found and

pry it out from there.

4Loosen the two 0-80 screws and remove the 0-80 retainer plate. (See Figure 11.)

Figure 11 Loosen screws and retainer plate

5Pull the ceramic retainer assembly from the sensor body and inspect the cavity in the

sensor and components for debris or any possible contamination. If observed, clean

the sensor body and components.

6

Solder the wire onto the microdot connector. Prior to soldering, the wire end may need to

be crimped to fit the microdot slot.

For standard sensors, the wire should be soldered in parallel to the connector as

shown in Figure 12.

Figure 12 Standard sensor wire positioning

www.inficon.com [email protected]

Due to our continuing program of product improvements, specifications are subject to change without notice.

All trademarks are the property of their respective owners.

®

13 of 13

PN 074-677-P1A ©2018 INFICON

Easy Rate Sensor

For the standard single sensor, the wire can be soldered onto the microdot connector

prior to installation into the sensor. For the standard dual sensor, run the new

insulation into the sensor up to each crystal holder cavity followed by the connecting

wire, then solder the wire to the new microdot connector.

For right angle single and dual sensors, the wire should be soldered in perpendicular

to the connector as shown in Figure 13. This will help reduce the height of the solder

joint. To insert the connector into the sensor head, the wire will need to be

straightened.

Figure 13 Right angle single and dual sensor wire positioning

7Add the wire insulation over the wire. The insulation does not need to cover the

connector pin or solder joint. Trim any excess insulation, leaving some wire exposed.

8Thread the now wired connector onto the sensor body. Torque the connector to

1.7 N•m (240 oz•in).

9Install the ceramic retainer assembly into the cavity pushing the wire through the hole

in the center of the retainer.

10 Install the 0-80 plate and 0-80 screws to secure the ceramic retainer assembly.

11 Create a solder joint, joining the wire to the retainer, that is no taller than 0.11 cm

(0.045 in.). Trim any excess wire.

12 Perform continuity test once more.

13 Install the holder spring and crystal holder assembly to complete the repair.

This manual suits for next models

1

Table of contents

Other Inficon Accessories manuals