INFIMED FENIX OT-01 User manual

User Manual

OPERATING TABLE FENIX

OT-01

Serial numer ……………………………..

Edition 3.0

June 2022

2

Manufacturer:

INFIMED Ltd.

Kabaty 1 Street

34-300 Żywiec

Poland

WWW.INFIMED.PL

Tel/fax +48 33 861 40 96

SRN: PL-MF-000015633

NIP 553 251 29 67

REGON 243274947

In accordance with the classification of medical devices according to Regulation (EU) 2017/745 of

the European Parliament and of the Council, the lamp has been classified as class I.

The manufacturer declares that the product complies with the essential requirements of

Regulation (EU) 2017/745 of the European Parliament and of the Council and the Act on medical

devices.

The compliance procedure was carried out in accordance with Annex VIII of the Regulation.

3

Table of contents:

1. Safety............................................................................................................................................... 5

1.1. General safety remarks ................................................................................................................ 5

1.2. General notes on the safe use of the product ............................................................................. 5

1.3. Technical parameters ................................................................................................................... 6

1.4. General requirements .................................................................................................................. 7

1.5. Product description ..................................................................................................................... 8

1.6. Description of the components of an example table.................................................................. 8

2. Transport and start-up ........................................................................................................................ 9

2.1. Transport ...................................................................................................................................... 9

2.2. Unpacking and initial start-up .................................................................................................... 10

3. Operation and performance............................................................................................................. 11

3.1. Raising and lowering of the tabletop ..................................................................................... 11

3.2. Angular change of the tabletop position................................................................................ 11

3.3. Tabletop function adjustment................................................................................................ 12

3.3.1. Changing the angle of the headrest .................................................................................... 12

3.3.2. Changing the angle of the back rest.................................................................................... 12

3.3.4. Footrest rotation adjustment.............................................................................................. 13

3.3.5. Kidney bridge angle adjustment (additional option) .......................................................... 13

3.3.6. Longitudinal adjustment of the tabletop (additional option) ............................................ 13

3.4. Assembly and disassembly of selected components ................................................................ 14

3.4.1. Assembly and disassembly of the headrest ....................................................................... 14

3.4.2. Assembly and disassembly of footrests ............................................................................. 14

3.4.3. Assembly and disassembly of mattresses .......................................................................... 15

3.5. Table mobility............................................................................................................................ 15

4. Static charge prevention ........................................................................................................... 15

5. Risk of collisions......................................................................................................................... 15

6. Performance evaluation............................................................................................................ 15

7. Defect and faults ....................................................................................................................... 16

8. Cleaning and disinfection .......................................................................................................... 16

9. Maintenance and repairs .......................................................................................................... 16

10. Condition checks and inspections ............................................................................................. 17

11. Troubleshooting potential faults and table diagnostics............................................................ 17

4

12. Liquidation of the product......................................................................................................... 17

13. Additional accessories .............................................................................................................. 18

14. Table labels.................................................................................................................................. 21

5

1. Safety

The product has been designed and manufactured to ensure its safe use and operation. A

prerequisite for the safe use of the table is to read, understand and follow the rules included in this

manual.

1.1. General safety remarks

- Do not use, operate or service the table in a manner inconsistent with this manual.

- The user has no right to make independent modifications or repairs to the product. The occurrence

of such a fact will void the warranty on the product. Repairs may be made by service personnel or

manufacturer's representative.

1.2. General notes on the safe use of the product

- Before using the table, make sure the footrests and headrest are properly secured and locked.

- Before performing functional movements, block the possibility of rolling the table

- After changing the angle position of the footrest and locking its position with the pressure handle,

make sure that it is properly interlocked.

- When performing Trendelenburg and anti-Trendelenburg positions, as well as lateral tilting of the

tabletop, it is essential to remember to properly secure (fasten) the patient to protect him from

uncontrolled sliding off the operating table top.

- When performing hydraulic anti-Trendelenburg/Trendelenburg positions, side tilting, segmenting

and tabletop sliding, be careful not to collide with the base or substrate.

- When performing Trendelenburg and anti-Trendelenburg positions, the footrests, backrest and

headrest should be in a level or pivoted position above horizontal.

- Do not implement longitudinal movement when the tabletop is in an angled position with respect

to the ground (e.g., Trendelenburg and anti-Trendelenburg positions and lateral tilting).

- When using the operating table in the vicinity of high-frequency medical instruments and

defibrillators, follow the recommendations in the operating instructions of these instruments.

Improper use can become the cause of dangerous accidents. There is a danger of serious burns to

the patient through contact with metal parts of the table or its equipment.

- When moving the table, avoid collisions.

- Do not disinfect the table in disinfection chambers and use high-pressure equipment for cleaning.

- Do not use bleaching agents, active chlorine or oxygen for cleaning and disinfection.

- For washing plastic parts, do not use any agents whose ingredients destroy their structure.

6

- Do not use agents containing alcohol to wash and disinfect mattresses.

- If the product will not be used for an extended period of time, it should be stored under the

following environmental conditions:

- temperature: 25⁰C (77⁰F) ± 10⁰C (18⁰F)

- humidity: 50% ± 25%

- The table is designed to be installed and operated only indoors with the following environmental

conditions:

- temperature: 25⁰C (77⁰F) ± 10⁰C (18⁰F)

- humidity: 50% ± 25%

- atmospheric pressure 700 do 1060 hPa

Failure to comply with the above requirements for cleaning and disinfection in the first place will

void the product warranty

1.3. Technical parameters

Total length of the table with 4 or 5 sections tabletop

2100 mm

Total length of the table with 6 sections tabletop

2300 mm

Total length of the table with back rest for shoulder arthroscopy

Around 2100 mm

Width of the tabletop

500 mm

Total width of the tabletop (side rails)

560 mm

Height adjustment (with mattress)

680 mm – 1030 mm

Lateral tilt adjustments

± 30°

Trendelenburg / anti-Trendelenburg adjustment

± 40°

Backrest adjustment

- 45° ; +85°

Footrest adjustment

- 90° ; +25°

Footrest abduction

max 180°

Headrest tilt angle

± 45°

Kidney bridge adjustment

~120 mm

Optional longitudinal slide

350 mm

7

Table mass

250 kg

Maximum working load

250 kg

Period of use

10 years

At the special request of the customer, it is possible to manufacture a product with changed

technical parameters, without reducing its safety.

1.4. General requirements

Using, operating and servicing the table inconsistently with the guidelines of the manual is

absolutely forbidden and may lead to danger and irreparable damages due to the user's fault, for

which the manufacturer is not responsible.

Any interference with the table elements inconsistent with the instructions, use of equipment

other than that offered by the manufacturer may be permitted only on the basis of a written

consent from the manufacturer.

The user must ensure that all persons operating, handling the product have read, understood and

followed this manual. In addition, he is obliged to ensure that the table is used only for its intended

purpose and in conditions suitable for this purpose. The user is obliged to guarantee all necessary

measures to ensure the safe and appropriate operation of the product, to prevent any risk to the

safety of his life and health, as well as that of patients and third parties.

Storage - if the product will not be used for a long period of time, it should be stored under the

following environmental conditions:

- temperature: 25⁰C (77⁰F) ± 10⁰C (18⁰F)

- humidity: 50% ± 25%

The table is designed to be installed and operated only in enclosed spaces with the following

environmental conditions:

- temperature: 25⁰C (77⁰F) ± 10⁰C (18⁰F)

- humidity: 50% ± 25%

- atmospheric pressure 700 do 1060 hPa

Permissible temperature change in 12 hours not more than 20°C.

During transport, storage and unpacking of the product, the temperature change must not be

greater than 10°C per hour. Do not unpack the product before it has reached the temperature of the

room intended for installation. In the event of significant temperature differences between the

transport temperature and the temperature of the room in which the product is to be operated, the

8

table must be left for a minimum of 12 hours to equalise the temperature level. After this period the

table can be put into operation.

In the case of transport of the table under specific conditions (low ambient temperature) the

methods of transportation, securing must be agreed with the manufacturer.

1.5. Product description

The operating table FENIX OT-01 is made of stainless, acid-resistant steel and is designed to support

the patient during all surgical and specialised procedures and operations.

The operating table FENIX OT-01 is equipped with a multi-segment table top mounted on a mobile

base with central wheel locking. Vertical movement of the table top, as well as its longitudinal and

lateral tilting, is provided by a mechanical-hydraulic drive. The functional movement of the tabletop

segments is assisted by gas springs and the optional longitudinal movement is carried out

mechanically. The table top can be of four, five or six sections and has the option of interchanging

the footrest sections with the headrest section. It is permeable to X-rays along its entire length and is

fitted with high-quality anti-static polyurethane or foam mattresses. An optional version of the

backrest table for shoulder arthroscopy with detachable side segments is available. A variety of

accessories can be fitted to the table to support the correct positioning of the patient depending on

the type of operation being performed.

1.6. Description of the components of an example table

Nr

Description

Nr

Description

1

Headrest section

5

Base with central brake

1a

Headrest tilt adjustment

5a

Column rubber cover

1b

Headrest attachment to backrest

5b

Column cover

1c

Side rail

5c

Table travel lock lever

2

Backrest section

2a

Backrest tilt adjustment

5e

Mech-hyd function selector

2b

Lock release lever

5f

Anti-static wheels

2c

Backrest handles

5g

Swivel wheel

2d

Side rail

5h

Potential equalisation connector

2e

Detachable side segments

5i

Foot pump drive levers

3

Seat segment

9

3a

Side rail

4

Footrest segment

4a

Footrest angle adjustment lever

4b

Side rail

8

Optional kidney bridge

4c

Adjustment for side recline

8a

Kidney bridge adjustment

4d

Footrest attachment to seat

8b

Lever attachment socket

2. Transport and start-up

2.1. Transport

For the time of transport of the table by means of transport the table must be placed in the transport

position. The transport position means minimal lowering of the top, lowering of the backrest

segments, the headrest and the footrests below horizontal. During transport the product must be

protected against moisture and dust and immobilised. The table must not be moved by grasping the

table top. For carrying, use the straps, which must be pulled under the base of the table. During

transport, storage and unpacking of the product, the temperature change must not be greater than

5

8b

5a

5b

4

1a

8

2

2c

5i

3

1

5f

5g

5h

5e

5c

1b

2d

2b

1c

2a

8a

3a

4b

4a

4c

4d

10

8-10°C per hour. Products must not be stacked in layers if not clearly marked on the transport

packaging.

2.2. Unpacking and initial start-up

The table is supplied by the manufacturer in a box with a total weight of approximately 250 kg.

The table must not be unpacked outside the building.

The table should be prepared for use in the following order:

a) Ensure that the transport packaging has stood long enough in the room where the table is to

be used

b) Open the transport packaging

c) Remove all materials securing the table during transport

d) Remove and set aside all supplied accessories

e) Set footrests, backrest, headrest in "zero" position - horizontal to the ground

f) With the help of additional persons remove the table from the transport pallet. Do not lift

the table by grasping the tabletop components. Use the straps placed under the base.

g) Carefully read the User manual

h) Carry out the first start of the table according to the guidelines contained in the next section

of this manual.

If the product will not be used for a long period of time, it should be stored under the following

environmental conditions: temperature: 25⁰C (77⁰F) ± 10⁰C (18⁰F), humidity: 50% ± 25%.

The product is designed to be installed and operated only indoors with the following

environmental conditions: temperature: 25⁰C (77⁰F) ± 10⁰C (18⁰F), humidity: 50% ± 25%,

atmospheric pressure: 700 to 1060 hPa.

2.3. Instalation and first start-up

After having carried out all the necessary operations for unloading the table, position the product at

the desired place of work, meeting the requirements set out in this manual.

Set the table into its working place, then press the locking lever of the passage

The table must be connected to the equipotential installation by a cable via potential equalizing

clamp or by antistatic floor.

11

3. Operation and performance

3.1. Raising and lowering of the tabletop

The height of the tabletop is variable within the range specified in the product parameters. To set the

worktop to the desired height, select the appropriate function of the drive selector "5i" and then

press the appropriate foot pump lever "5c" (one lowers and the other raises the tabletop) until the

desired position is reached. When the end positions are reached, the tabletop will stop.

Do not lower the tabletop if the footrests or backrest are significantly lowered in relation to the

tabletop.

When lowering the height of the tabletop, take care that there is no collision between the

elements of the tabletop and the table base or the ground.

Special attention should be paid to the movements carried out, due to the possibility of damaging

the table in the event of two movements being put together, e.g. lateral tilting with Trendelenburg

or mechanical collisions of the table elements.

3.2. Angular change of the tabletop position

The change of the angular position of the tabletop is realised within the range indicated in the

technical parameters of the table. In order to set the tabletop in the desired angular inclination with

respect to the ground, select the appropriate function of the drive selector "5i" and then press the

5c

5c

5i

12

appropriate lever of the foot pump "5c" (one tilts the tabletop into the Trendelenburg or right

position and the other into the Antitrendelenburg or left position) until the desired position is

reached. When the end positions are reached, the tabletop will stop.

When carrying out the Trendelenburg and reverse-Trendelenburg positions as well as lateral tilting

of the tabletop, one should always remember to secure the patient to prevent him/her from

uncontrolled sliding off the operating table.

When performing the Trendelenburg and reverse-Trendelenburg positions, the headrest, backrest

and footrests should be in a leveled or tilted position above the horizontal.

Particular attention should be paid to the movements performed, due to the possibility of

damaging the table in the event of two movements being put together, e.g. lateral tilting with

Trendelenburg, or mechanical collisions of table elements.

3.3. Tabletop function adjustment

3.3.1. Changing the angle of the headrest

The adjustment of the angle position of the headrest is carried out within the range specified in the

technical parameters of the table. In order to change the angle of the headrest, stand behind the

headrest, grasp the lever while resting your thumb on the headrest frame, then pull the lever

towards you, the headrest will be tilted above horizontal. To lower the headrest, repeat the above

steps, but keep the lever in place after you have released it and also use your muscles to lower the

headrest by pushing it down. If the lever is released early, the position of the headrest is locked in

the current position.

3.3.2. Changing the angle of the back rest

Adjustment of the backrest angle is carried out within the range specified in the table's technical

parameters. In order to change the backrest angle, stand behind the backrest, grasp the handles

with both hands, and then, simultaneously pressing the buttons (placed on the sides of the handles)

with your thumbs, change the backrest position by raising or lowering it. When the buttons are

released, the backrest movement is blocked. Changing the position of the backrest segment is

achieved using gas springs. However, these are only a supporting element and muscle power must be

used when adjusting the angle.

The optional back rest for shoulder arthroscopy additionally includes two (lateral) detachable

segments for shoulder surgery. The assembly and disassembly of the detachable segments is carried

out by means of pressure knobs and locking pins. To fit the lateral segment, ensure that the pressure

knobs are screwed in firmly enough, the locking pin is raised, then lift the segment (standing behind

the back rest) and slide it into the attachment socket in the frame. Once the segment is fully seated,

tighten the clamping knobs and release the locking pins. Disassembly takes place in reverse order.

3.3.3. Changing the angle of the footrests

13

Angle adjustment of the footrests is carried out within the range specified in the technical

parameters of the table. The change of the angle should be carried out separately for each footrest.

To do this, stand in front of the footrest, grasp the footrest with one hand and the lever underneath

with the other. Then pull the levers towards you and raise or lower the footrest. Please note that

when the lever is released, the footrest will automatically lift upwards (only without load). When the

lever is released, the position of the footrest will be locked.

Note that with a minimum lowering of the table, a collision between the footrest and the base

may occur. To avoid this, the lower extreme position of the footrests should only be set in the

raised table top position.

When performing the anti-Trendelenburg position, the footrests may collide with the base

3.3.4. Footrest rotation adjustment

The desired angle of the footrests is achieved by releasing (lifting) the handle, then turning the

footrests to the desired angle and locking the handle again.

Ensure that the handle is properly tightened.

3.3.5. Kidney bridge angle adjustment (additional option)

Adjustment of the angular position of the kidney bridge is carried out within the range specified in

the technical parameters of the table. To change the angle of inclination of the kidney bridge, stand

behind the headrest, fix the lever in the socket and turn, the bridge will be inclined above horizontal.

To lower the kidney bridge, repeat the above steps but turn the lever in the opposite direction.

3.3.6. Longitudinal adjustment of the tabletop (additional option)

Before adjusting the longitudinal position of the tabletop, make sure that the footrests and backrest

are above the level of the tabletop. If they are below level, it is essential that they are leveled or

raised above level.

Do not carry out longitudinal translation when the tabletop is in an angled position in relation to

the ground (e.g. Trendelenburg and anti-Trendelenburg positions and lateral tilting).

Do not exchange the position of the tabletop components (headrest and footrests) if the table is

equipped with longitudinal movement of the tabletop.

Once the above settings have been made in order to realise the longitudinal movement of the table

top, stand behind the backrest, grasp the handles with two hands, press simultaneously the shorter

inner handles located on both arms and move the top. The longitudinal position can be realised in

seven positions. When both handles are released at the same time, the movement will be locked.

14

It is absolutely necessary to ensure that the locking mechanism works and that the worktop cannot

be moved despite the release of the handles.

3.4. Assembly and disassembly of selected components

3.4.1. Assembly and disassembly of the headrest

The headrest is mounted to the backrest segment. Special headrest mounting clips are used for this

purpose. There is a yoke in the backrest, on which a pin located in the upper part of the joint of the

headrest is fixed. Locking is carried out by means of pressure knobs that raise the locking tongue in

the aforementioned joint.

To attach the headrest, make sure the pressure knobs are unscrewed firmly enough, then take the

headrest with both hands and, standing behind the back rest, seat the hinge pins evenly on the

yokes. Pay particular attention to pressing the headrest evenly. Otherwise it may be difficult to fit.

Once the joints are fully seated on the yokes, tighten the pressure knobs. Removal of the headrest is

carried out in the reverse order.

It is not permissible to swap places between the headrest and the footrest segment in the case of a

table fitted with a longitudinal sliding top.

3.4.2. Assembly and disassembly of footrests

Footrests are mounted to the seat segment. Special footrest mounting clamps are used for this

purpose. There is a yoke in the seat, on which a pin located in the upper part of the footrest joint is

fixed. Locking is carried out by means of pressure knobs that raise the locking tongue in the

aforementioned joint.

To attach the footrest, make sure the pressure knob is sufficiently tightened, then take the footrest

with both hands and, standing in front of the seat, place the joint pin evenly on the yoke. Once the

joint is fully seated on the yoke, tighten the pressure knob. Footrest removal is carried out in the

reverse order.

Analogous assembly and disassembly takes place for the second footrest.

15

Ensure that the footrests are properly secured before use.

3.4.3. Assembly and disassembly of mattresses

The mattresses are disassembled without the use of tools. Both in the case of Velcro and pin

fastening, their removal consists of applying the appropriate muscle force and detaching the

mattress from the base of the respective segment. Assembly consists of placing the mattress in the

correct position and pressing it to the ground.

3.5. Table mobility

The table base is equipped with a set of wheels that allow the table to be moved in all directions. In

order to block the movement, the base has been fitted with a travel lock system. The best way to roll

the table is to put the table top in the following position: footrests set approx. 45° down from the

horizontal, backrest and headrest approx. 30° up from the horizontal. In this position, release the

movement lock (lift up the release lever at the base) and drive the table with sufficient force. In

order to lock the passage of the table again, push the lever at the base as far down as possible. This

will extend the special feet on which the table rests immovably.

4. Static charge prevention

The design of the table has safe pathways for potential flux exit through the use of antistatic wheels

and feet and suitable mattresses with antistatic properties. The operating table must be used on an

antistatic floor. The table must be connected to the potential neutralisation system via a cable via

the potential equalisation terminal. The equipotential bonding cable is included in the standard table

equipment!

5. Risk of collisions

The table allows to be positioned in such a way that in certain extreme positions, and especially

when using accessories fixed to the side rails, mechanical collisions can occur. Care must be taken to

avoid such situations in order not to damage the table or the accessories.

Operate the table consciously with care and full responsibility.

6. Performance evaluation

Before each first start-up and use of the table on any given day, the correctness of its operation

must be assessed.

How to assess the state of correct operation:

a) Move the table to the required position and block its passage (extend the locking feet - see

3.5. for the way of extension). Then, by applying some force, try to move the table, top in any

direction. In this situation there should be no movement in any direction.

16

b) Check the operation of the mechanisms controlled by the pneumatic springs and the

corresponding retarders. Once the position has been properly adjusted (see sections

Operation and functioning), it should not be possible to change the position of the individual

table segments without pressing the appropriate retarders and applying sufficient force.

c) Check that there is no play in the mechanical connections impeding the correct use of the

table.

If during the test carried out in this way no inaccuracies or damages are detected and no disturbing

noises are heard by the user, the table can be used. Otherwise refer to the troubleshooting point.

In the event that the table is not fully operational, i.e. the parameter values obtained differ from

those specified in the instructions, it must not be used. This fact must be reported to the

manufacturer or his representative. The use of an inoperative table may lead to damage, which is

chargeable to the user and for which the manufacturer is not responsible.

7. Defect and faults

Defects and faults detected in the product by operating personnel must be reported immediately to

the person in charge of technical maintenance at the facility. This person, having carefully recognised

the possible defect and its cause, is obliged to contact the service department or the manufacturer

for consultation and possible instructions for further action. A product that cannot be used safely

(mechanical damage) must not be used until it has been repaired.

8. Cleaning and disinfection

For cleaning and disinfection, use cleaning agents that do not contain active oxygen or chlorine. After

disinfection, rinse with distilled water to eliminate streaks. Use a dry soft sterile cloth for thorough

drying.

The product must not be disinfected in disinfection chambers.

A water jet must not be used to wash the table.

No agents whose ingredients damage the structure of the plastic must be used to wash plastic

items.

Disinfectants containing alcohol must not be used to wash and disinfect mattresses.

A list of disinfectants can be found in Annex 1 to the instructions.

Failure to comply with the above requirements will void the product warranty.

9. Maintenance and repairs

17

Any repairs to the product shall be carried out by the relevant service centre or the manufacturer's

direct representative. The user is not entitled to make any modifications or repairs to the product

himself without special training and authorisation. After the customer has obtained the

manufacturer's written consent for a possible repair to be carried out by the customer's technical

personnel, the manufacturer will make available all the necessary information needed to carry out

the repair.

All repairs, inspections and maintenance should be recorded in the Repair and Maintenance Service

Card included in the product manual (Annex 2).

10. Condition checks and inspections

In order to ensure that the product remains in good technical condition during its period of use, the

user is obliged to submit it to periodic technical inspections. Inspections are carried out by an

authorised service centre or by the manufacturer's direct representative. The inspection is carried

out at the user's expense.

11. Troubleshooting potential faults and table diagnostics

a) the table cannot be rolled

- check that the foot lock is not activated

- check for collision of the base with an element protruding from the ground

b) table does not stand stably

- check that there are no elements under the footer that destabilize the table

- check the adjustment of the feet

If in doubt, contact the manufacturer for the necessary assistance and clarification.

12. Liquidation of the product

The user, deciding to stop using the product, is obliged to disinfect it (a product that is not

disinfected in accordance with current environmental regulations is hazardous waste).

18

13. Additional accessories

- One position clamp

EB-01

- Multi position clamp

EB-02

- Knee support

EB-03

- Angle arm support

EB-04

- Arm support

EB-05

- thigh holder

EB-06

- Side-shoulder support

EB-07

- Side support

EB-08

- Anesthetic frame

EB-09

- Anesthetic frame with adjustable width

EB-10

- Infusion holder

EB-11

- Hand/shank holder

EB-12

- Support for meniscus operation

EB-13

- Arm support, height adjustable

EB-14

- Arm support on a ball joint

EB-15

- Leg strap

ES-01

- Thigh strap

ES-02

- Abdominal strap

ES-03

- Hand/wrist strap

ES-04

- Gynecological bowl

ES-05

- Urological bowl

ES-06

- Holder for additional equipment, mobile

ES-07

- Holder for arm operations

ES-08

- Holder for tubes

ES-09

- Tray for additional accessories

ES-10

19

- X-ray tray

ES-11

- Chest support

ES-12

- Attachment for knee operations

ES-13

- Pubic support

ES-14

- Leg support, not-divided

ES-15

- Proctological attachment

ES-16

- Side rail extension

ES-17

- Tabletop extension

ES-18

- Strap for anesthetic frame

ES-19

- X-Ray translucent plate /mounted instead of leg rests/

ES-20

- Foot supports

ES-21

- Side support to the table top

ES-22

- Lithotomic stirrups

ES-23

- X-ray translucent plate

ES-30

- Orthopedic attachment with two extension devices and support roll

EO-01

- Bar support

EO-02

- Leg support

EO-03

- Support for plastering

EO-04

- Heel holder

EO-05

- Foot support

EO-06

- Clamp for orthopedic attachment supports

EO-07

- Knee operation attachment for orthopedic attachment (without extension

device) EO-08

- Hip support for side position

EO-09

- Support for orthopedic attachment arms

EO-10

- Knee support for side positions

EO-11

20

- Trolley for installation of orthopedic attachment

EO-12

- Mobile stand for additional equipment of orthopedic attachment

EO-13

- Leather shoes for orthopedic attachment

EO-14

- Small leather shoe

EO-15

- Attachment for hand operating

EO-20

- Support roller for hand surgery

EO-21

- Attachment for shoulder operations

EO-30

- Specialistic head rest with adjustable track

EN-01

- Specialistic head rest, horseshoe

EN-02

- Orthopedic head rest

EN-03

- Thoracic surgery head rest

EN-04

- Support for the doctor's hands

EN-05

- Specialized horseshoe headrest

EN-06

- Helmet type headrest

EN-07

- Adapter for specialistic head rests

EA-01

- DORO specialist mounting adapter for table backrest

EA-02

- Large stainless steel clamp for the carbon tabletop

ER-01

- Small stainless steel clamp for a carbon tabletop

ER-02

- Large clamp transparent for X-ray radiation for a carbon tabletop

ER-03

- Small clamp translucent to X-ray radiation for a carbon tabletop

ER-04

- Eccentric handle

ER-05

- Table top transparent for X-ray radiation

ER-06

Table of contents

Other INFIMED Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Maquet

Maquet CS100i Operator's guide

BRASSELER USA

BRASSELER USA Carbide burs Instructions for use

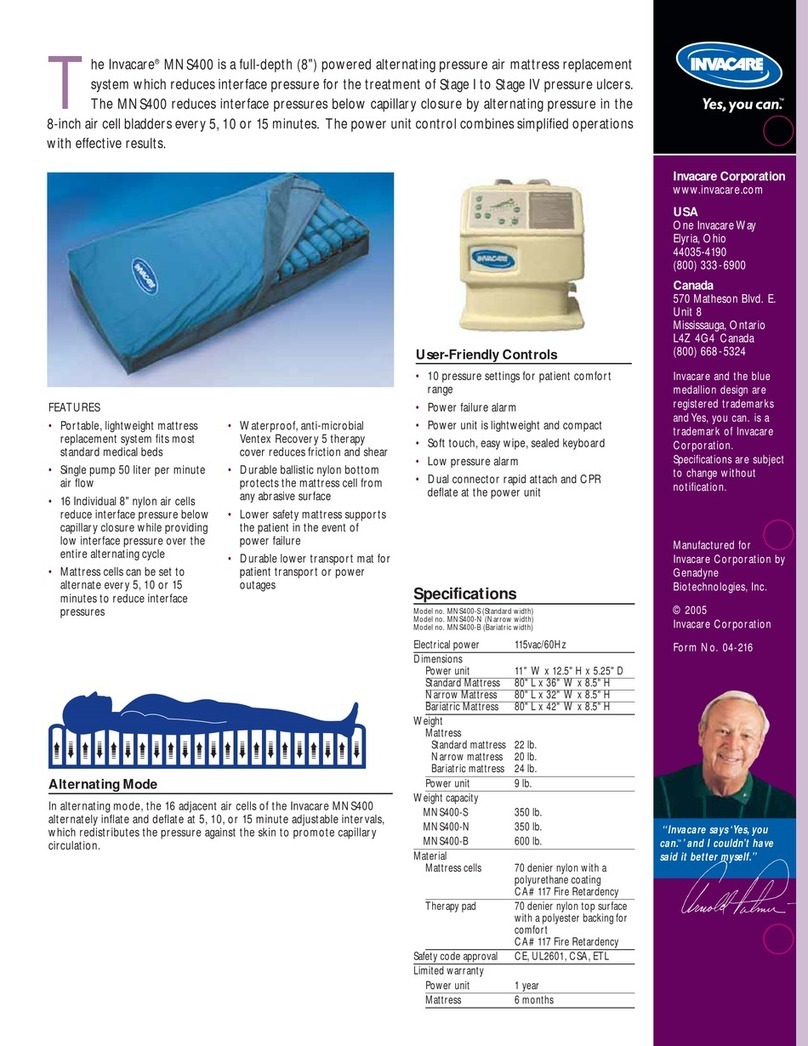

Invacare

Invacare Alternating Pressure Air Mattress MNS400-B Specification sheet

Otto Bock

Otto Bock 4R63 Instructions for use

Nox Medical

Nox Medical A1 manual

BMB MEDICAL

BMB MEDICAL TIM VELVET SWANN user manual

Sirona

Sirona Galaxis operating manual

DJO Global

DJO Global Vectra Genisys user manual

Shenzhen Creative Industry Co.

Shenzhen Creative Industry Co. Oxy-One Plus user manual

Click Medical

Click Medical RevoLock quick start guide

Cristofoli

Cristofoli Mini-incubator manual

Sissel

Sissel Cold Therapy Compression operating manual