CONTENTS

NP-eVENT-6_11-2010.doc 1 GB

CONTENTS

1. GENERAL INFORMATION............................................................................................2

INDICATIONS FOR USE ..........................................................................................2

OPERATOR'S RESPONSIBILITY FOR PATIENT SAFETY.....................................2

MARKING..................................................................................................................2

WARNINGS...............................................................................................................2

General safety warnings ..................................................................................3

Safety warnings regarding the protection agaist electric current......................3

ALERT NOTICES AND SYMBOLS...........................................................................4

USAGE ON PURPOSE.............................................................................................5

STORAGE AND TRANSPORT CONDITIONS..........................................................5

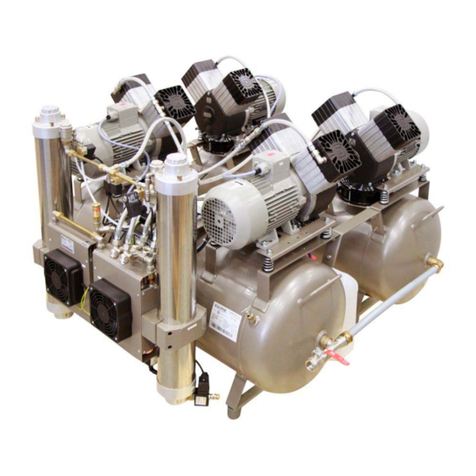

2. DEVICE DESCRIPTION.................................................................................................6

3. TECHNICAL DATA........................................................................................................8

4. OPERATION..................................................................................................................9

INSTALLATION AND FIRST PUTTING INTO OPERATION.....................................9

Unfixing of the air pump...................................................................................9

Compressed air connection ...........................................................................10

Electric connection.........................................................................................10

First putting into operation..............................................................................11

Additive accessory.........................................................................................11

PERSONNEL..........................................................................................................12

Switch on compressor....................................................................................12

Running on compressor.................................................................................12

Cleaning of air intake filter..............................................................................13

Cooling failure alarm......................................................................................13

Cleaning the compressor...............................................................................13

5. MAINTENANCE...........................................................................................................14

INFORMATION ON REPAIR SERVICE..................................................................14

INTERVALS OF MAINTENANCE ...........................................................................14

Check of safety valve.....................................................................................15

Replacement of filters of air pump..................................................................15

Replacement of filter in blow filter ..................................................................16

Replacement of filter in pressure regulator ....................................................16

Checking of capacity......................................................................................17

Fixing of compressor before shipping............................................................17

CUT-OFF.................................................................................................................17

DISPOSAL OF THE APPLIANCE...........................................................................17

6. TROUBLESHOOTING.................................................................................................18

7. SPARE PARTS............................................................................................................19

8. ELECTRIC AND PNEUMATIC DIAGRAMS................................................................20

WIRING DIAGRAM.................................................................................................20

PNEUMATIC DIAGRAM..........................................................................................21

9. PARTS LIST ..............................................................................................................64

10.WARRANTY ..............................................................................................................67