Table of contents

Current Sensor TLI4971 ................................................................................................................... 1

About this document....................................................................................................................... 1

Table of contents............................................................................................................................ 2

1Application and Programming circuit ....................................................................................... 3

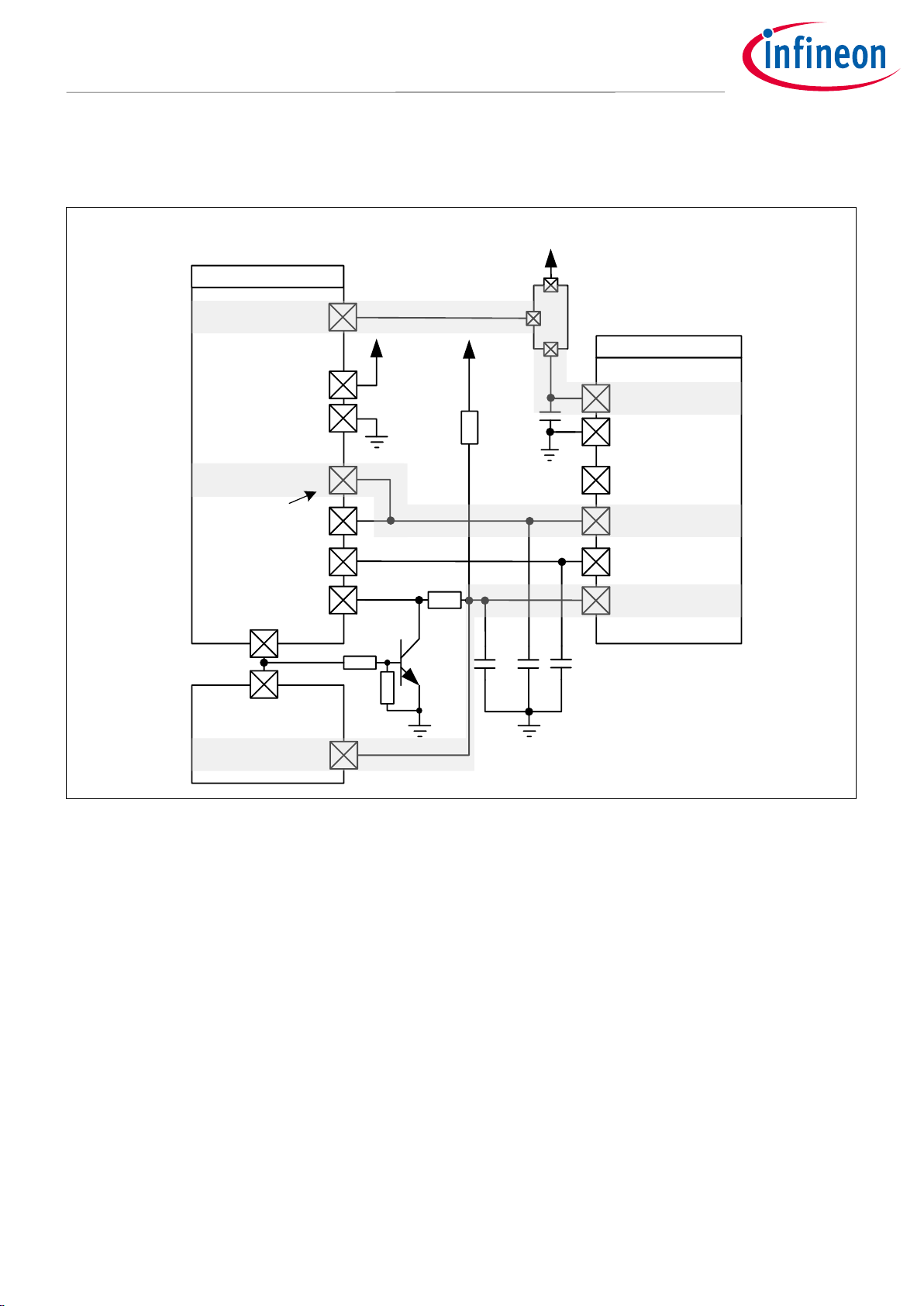

1.1 Circuit / Precondition..............................................................................................................................3

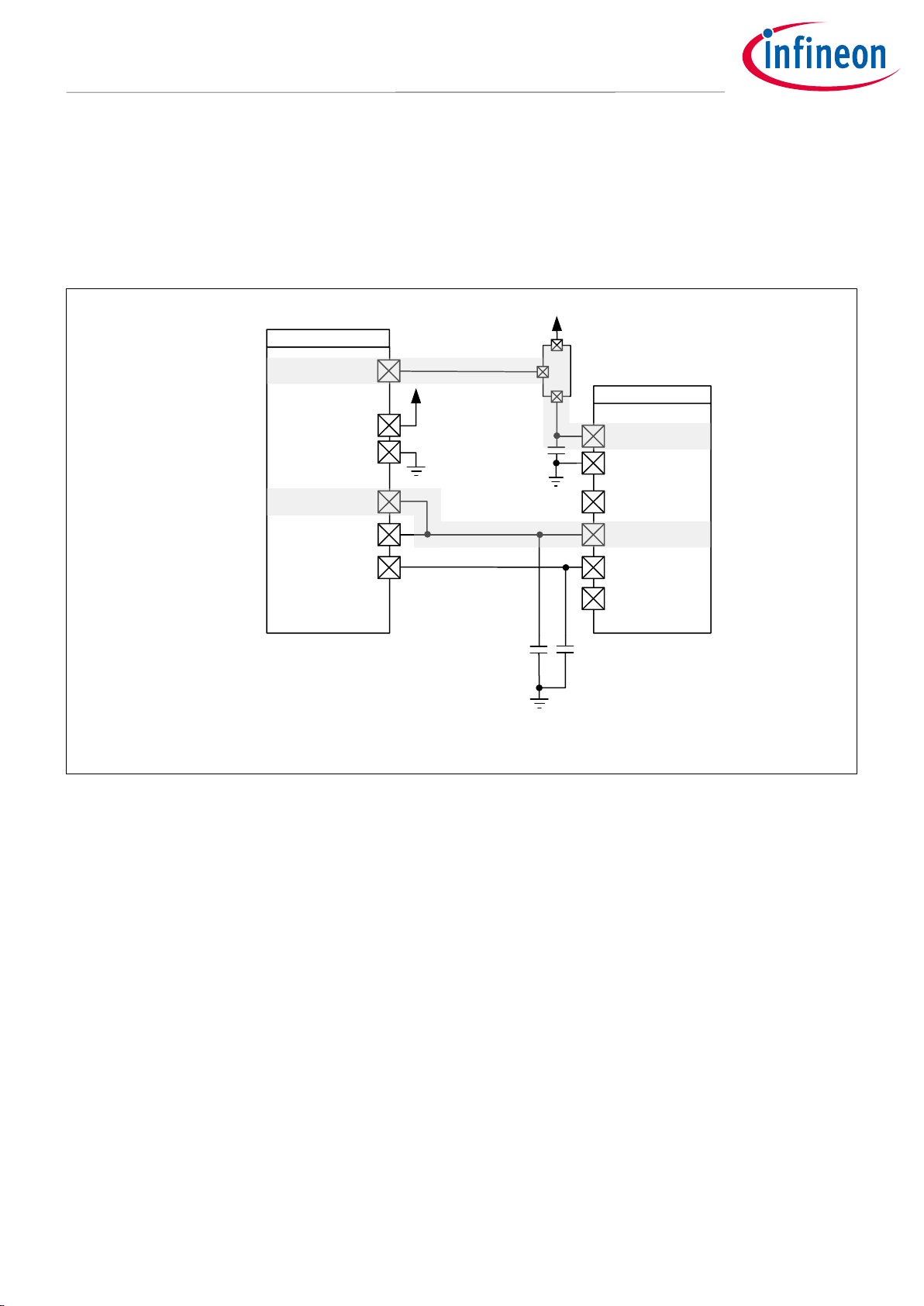

1.2 In-circuit programming...........................................................................................................................4

2Serial Inspection and Configuration Interface (SICI)................................................................... 6

2.1 Hardware Implementation .....................................................................................................................6

2.2 Entering Communication Mode..............................................................................................................6

2.3 Communication timing...........................................................................................................................7

2.3.1 Single low/high PWM transmission ...................................................................................................7

2.4 Interface Timing Definition.....................................................................................................................9

2.5 Definition of Voltage Levels ....................................................................................................................9

3Interface description .............................................................................................................10

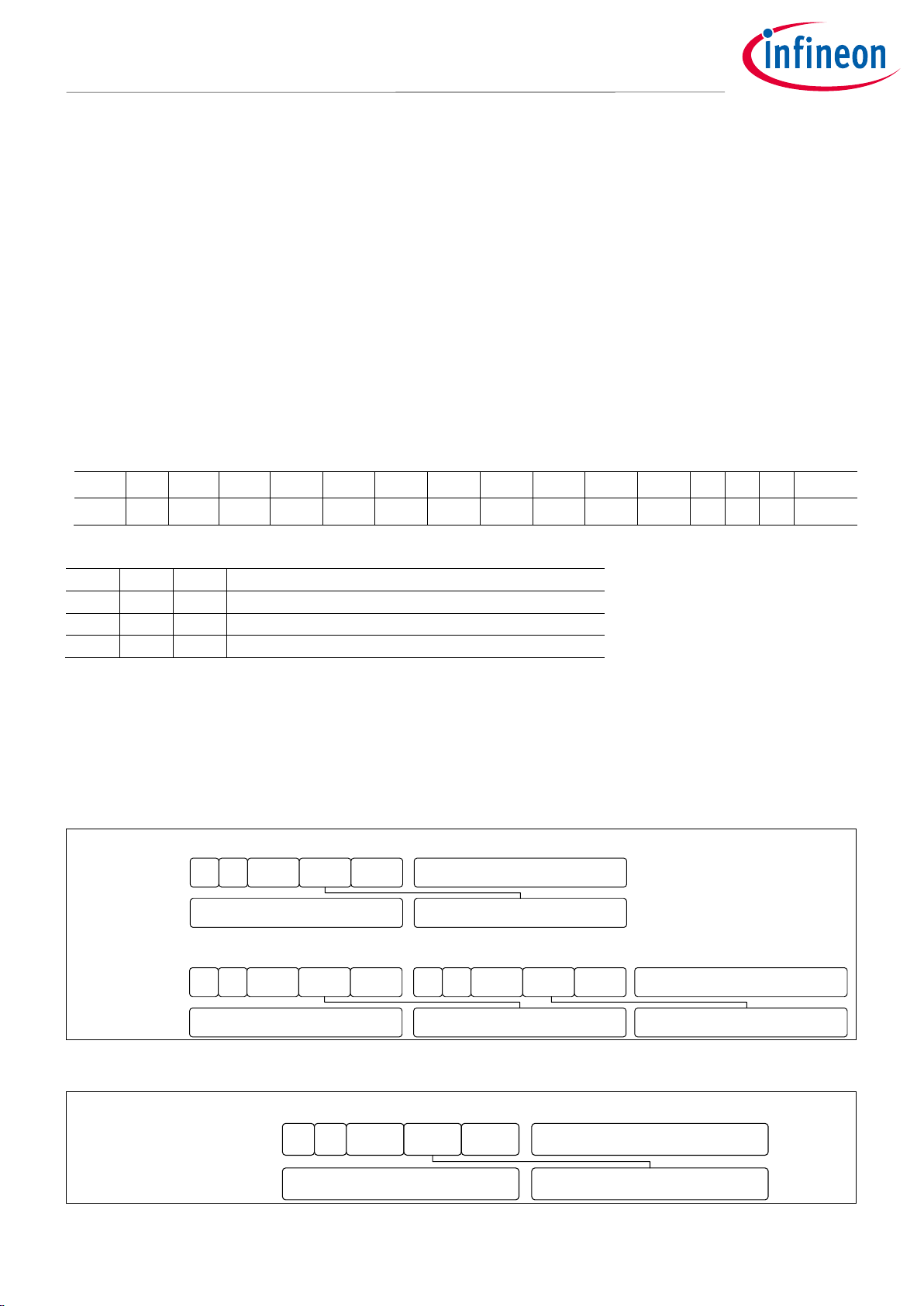

3.1 Command Structure..............................................................................................................................10

3.2 Read / Write Command.........................................................................................................................10

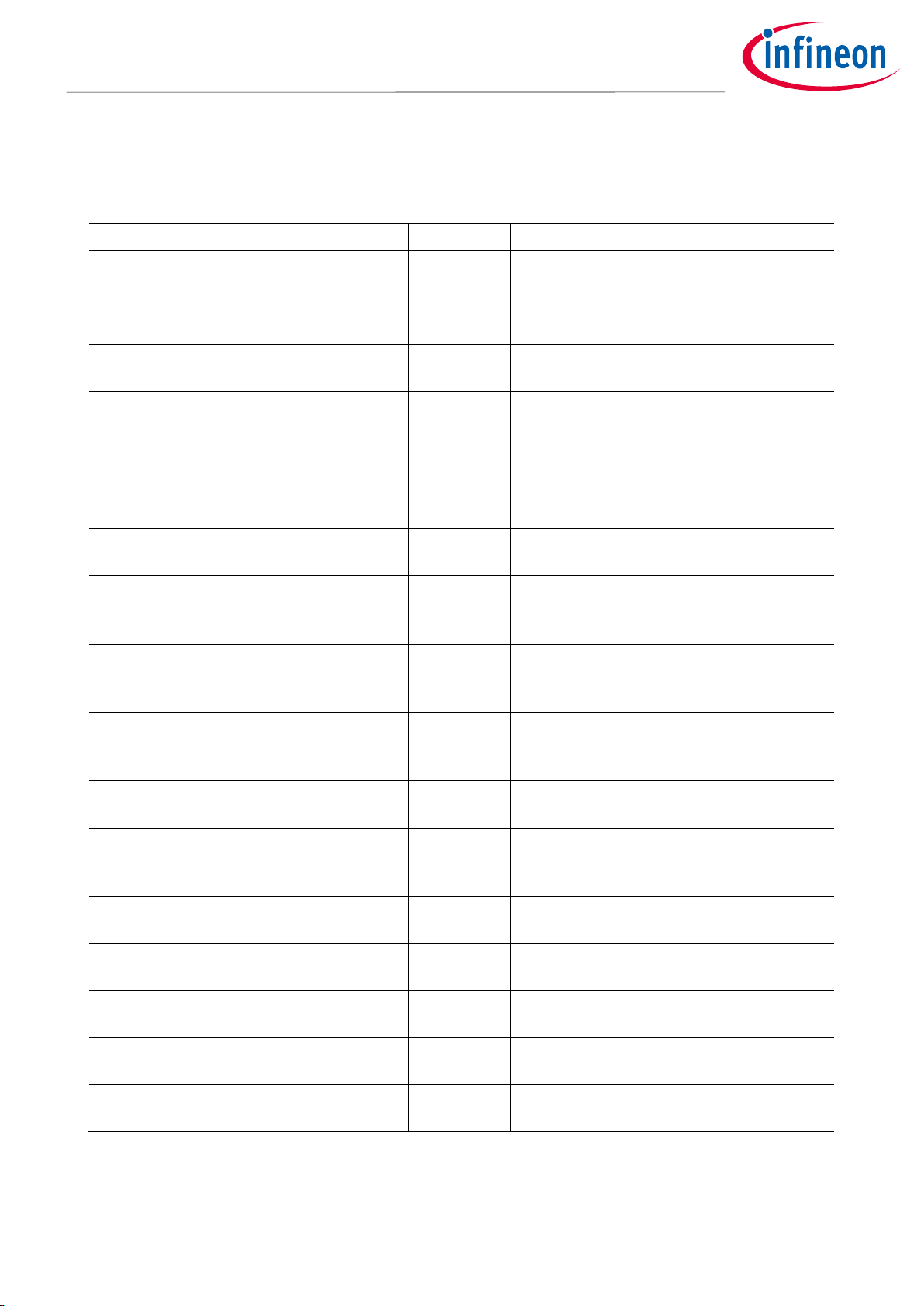

3.3 Interface Commands.............................................................................................................................11

3.4 Write and programming sequence.......................................................................................................12

3.5 Temporary register................................................................................................................................12

3.6 Read Example (temperature register read out) ...................................................................................13

4EEPROM ...............................................................................................................................14

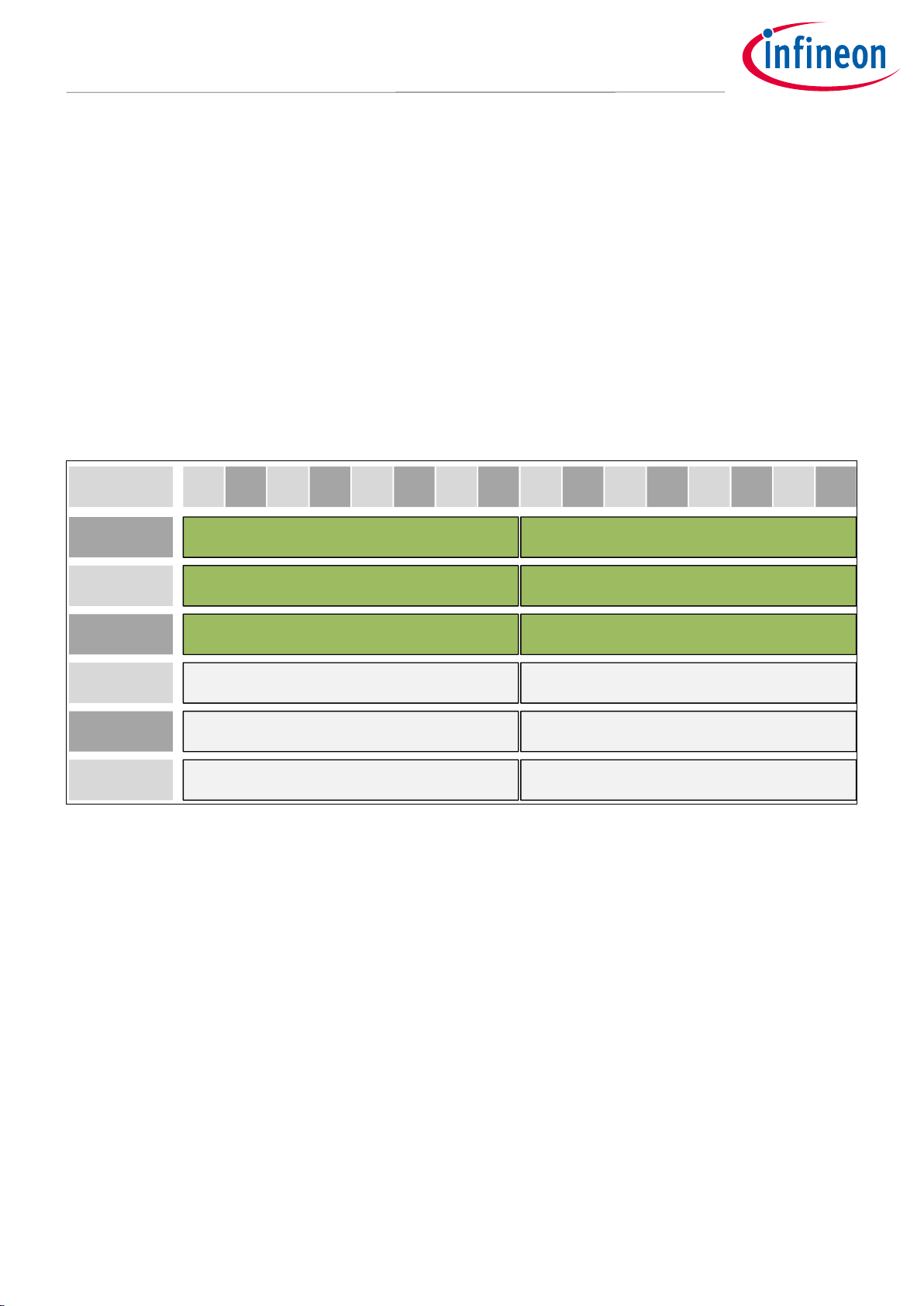

4.1 EEPROM Content...................................................................................................................................15

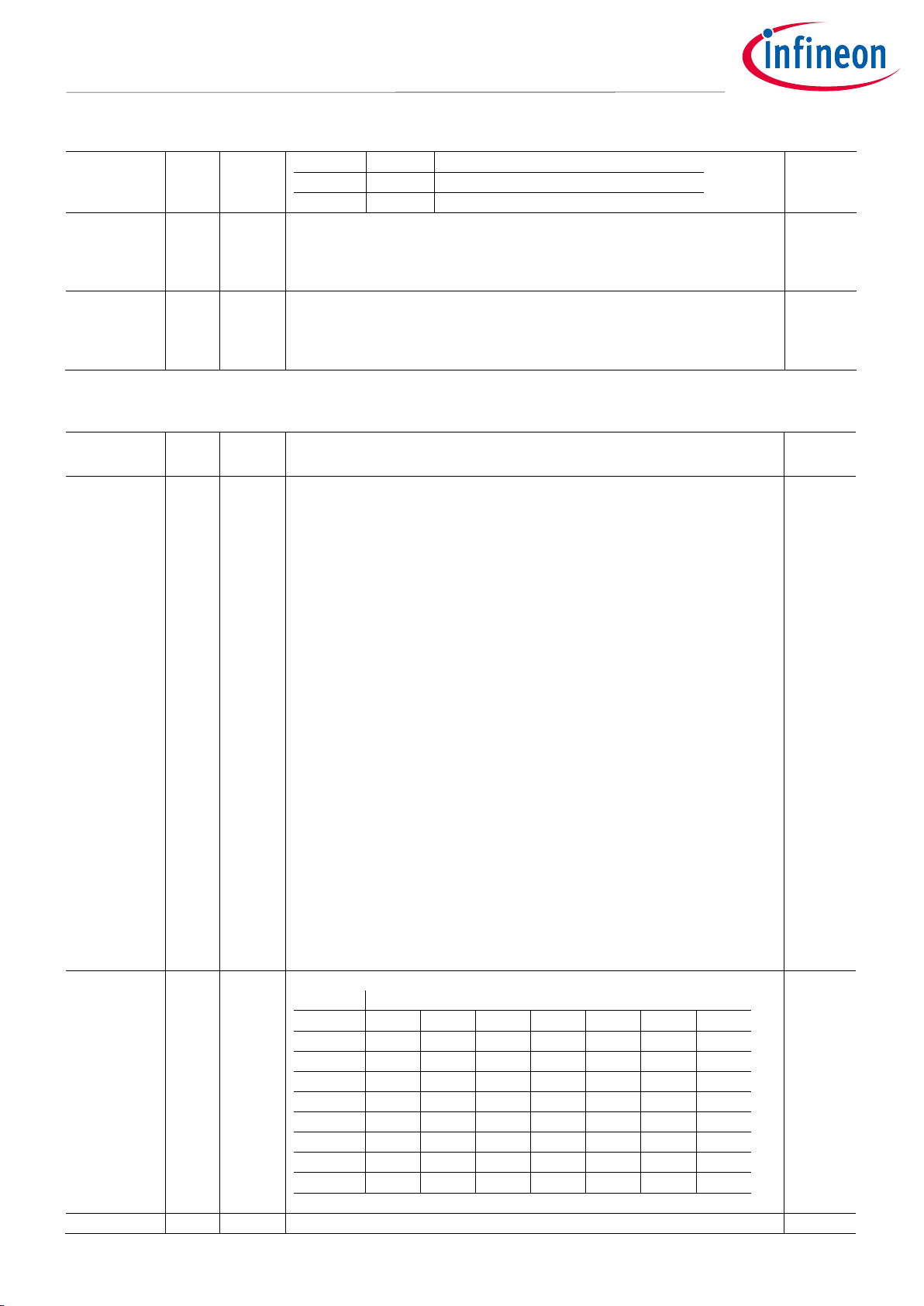

4.2 Programming Example .........................................................................................................................17

4.3 Margin Test ............................................................................................................................................19

4.4 Cyclic Redundancy Check .....................................................................................................................21

4.5 Code example CRC calculation.............................................................................................................23

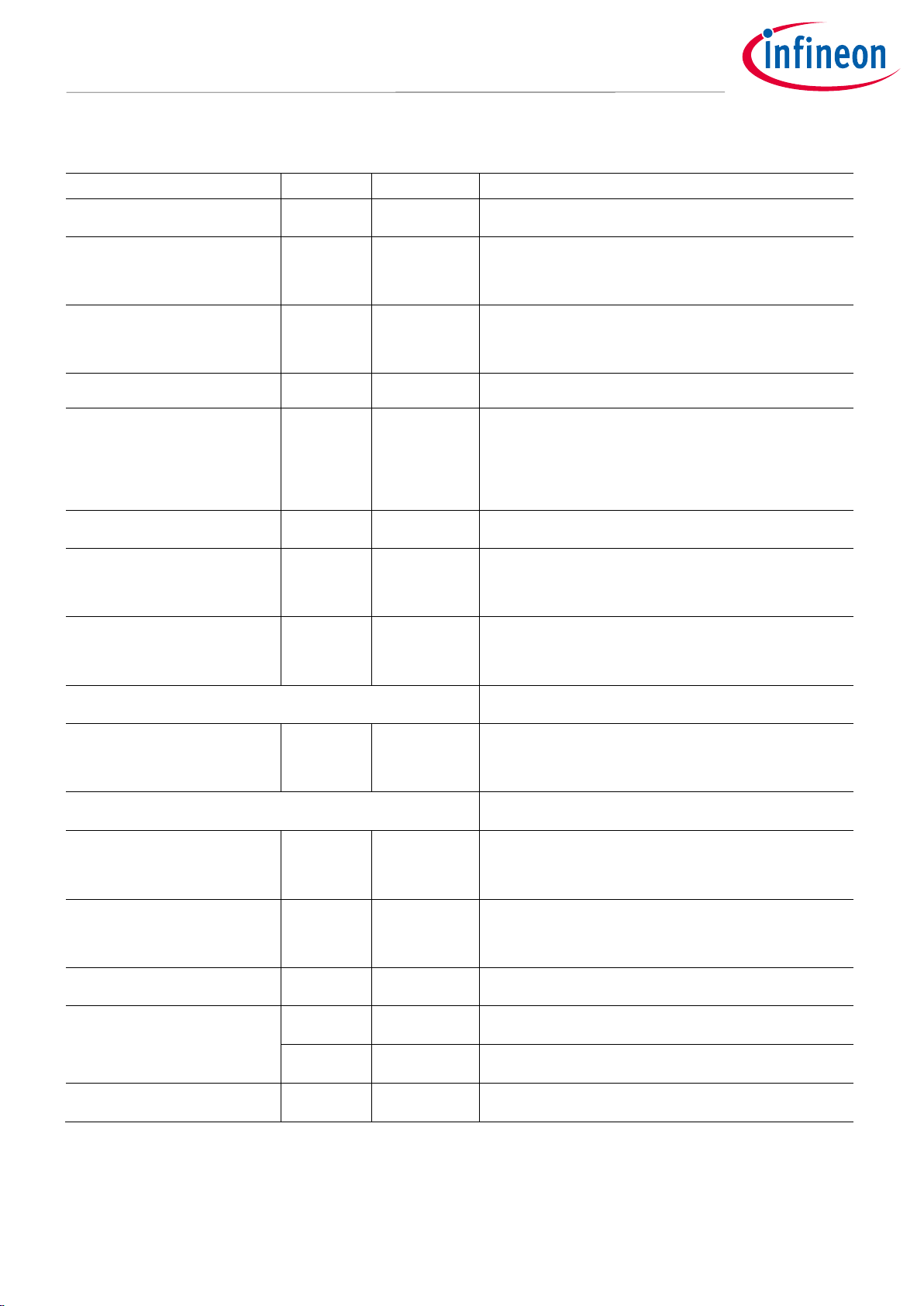

5Operation Mode ....................................................................................................................24

5.1 Single-Ended Mode ...............................................................................................................................24

5.2 Fully-differential Mode..........................................................................................................................24

5.3 Semi-differential Mode..........................................................................................................................25

6How to connect the sensor in a 5V domain................................................................................26

6.1 Single-Ended Mode ...............................................................................................................................26

6.2 Semi and or Fully-differential Mode .....................................................................................................26

7Diagnosis Mode.....................................................................................................................27

8Glossary...............................................................................................................................29