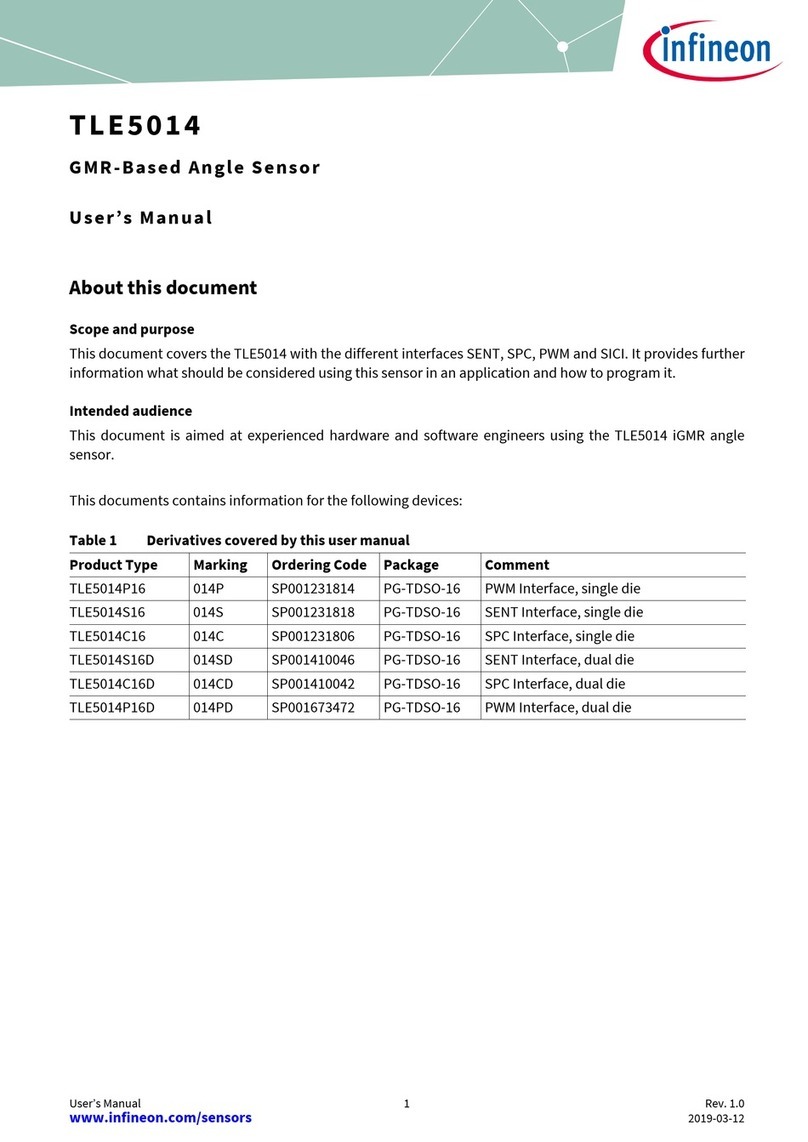

Trademarks of Infineon Technologies AG

All referenced product or service names and trademarks are the property of their respective owners.

Edition 2019-04-29

Published by

Infineon Technologies AG

81726 Munich, Germany

© 2019 Infineon Technologies AG.

All Rights Reserved.

Do you have a question about any

aspect of this document?

Document reference

IMPORTANT NOTICE

The information contained in this application note is

given as a hint for the implementation of the product

only and shall in no event be regarded as a description

or warranty of a certain functionality, condition or

quality of the product. Before implementation of the

product, the recipient of this application note must

verify any function and other technical information

given herein in the real application. Infineon

Technologies hereby disclaims any and all warranties

and liabilities of any kind (including without limitation

warranties of non-infringement of intellectual

property rights of any third party) with respect to any

and all information given in this application note.

The data contained in this document is exclusively

intended for technically trained staff. It is the

responsibility of customer’s technical departments to

evaluate the suitability of the product for the intended

application and the completeness of the product

information given in this document with respect to

such application.

For further information on technology, delivery terms

and conditions and prices, please contact the nearest

Infineon Technologies Office (www.infineon.com).

WARNINGS

Due to technical requirements products may contain

dangerous substances. For information on the types

in question please contact your nearest Infineon

Technologies office.

Except as otherwise explicitly approved by Infineon

Technologies in a written document signed by

authorized representatives of Infineon Technologies,

Infineon Technologies’ products may not be used in

any applications where a failure of the product or any

consequences of the use thereof can reasonably be

expected to result in personal injury.