Infineon TLE5014P16 User manual

User’s Manual 1 Rev. 1.0

www.infineon.com/sensors 2019-03-12

TLE5014

GMR-Based Angle Sensor

User’s Manual

About this document

Scope and purpose

This document covers the TLE5014 with the different interfaces SENT, SPC, PWM and SICI. It provides further

information what should be considered using this sensor in an application and how to program it.

Intended audience

This document is aimed at experienced hardware and software engineers using the TLE5014 iGMR angle

sensor.

This documents contains information for the following devices:

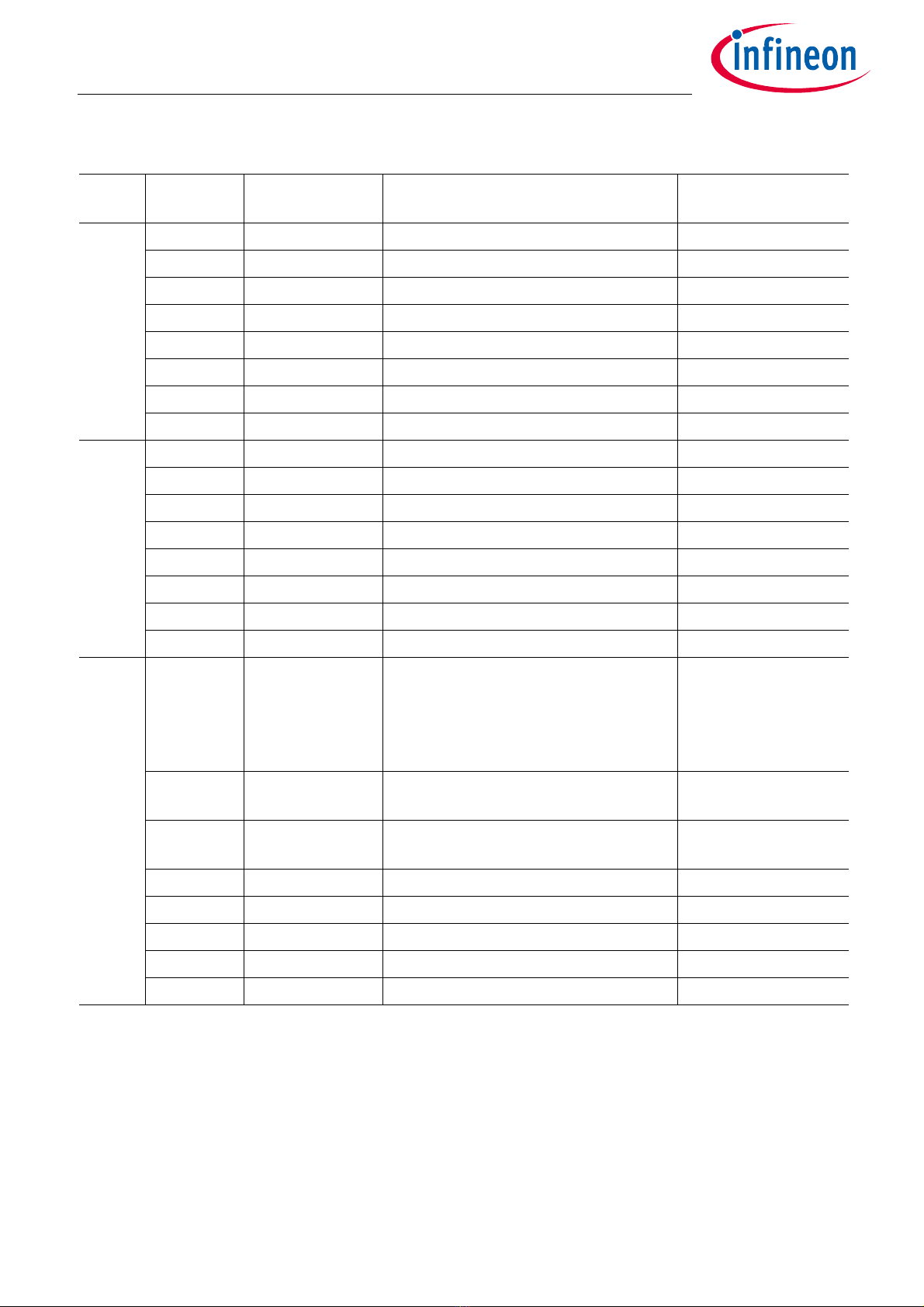

Table 1 Derivatives covered by this user manual

Product Type Marking Ordering Code Package Comment

TLE5014P16 014P SP001231814 PG-TDSO-16 PWM Interface, single die

TLE5014S16 014S SP001231818 PG-TDSO-16 SENT Interface, single die

TLE5014C16 014C SP001231806 PG-TDSO-16 SPC Interface, single die

TLE5014S16D 014SD SP001410046 PG-TDSO-16 SENT Interface, dual die

TLE5014C16D 014CD SP001410042 PG-TDSO-16 SPC Interface, dual die

TLE5014P16D 014PD SP001673472 PG-TDSO-16 PWM Interface, dual die

User’s Manual 2 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

1 Application Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Interfaces overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 PWM Interface Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 SPC Interface Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 SENT Interface Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 EEPROM Page Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 EEPROM Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Page 0x006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Page 0x009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Page 0x00A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4 Page 0x00B - 0x00E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.5 Page 0x00F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 Working Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.1 STAT Register 0x00: Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2 AVAL Register 0x02: Angle Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3 ASPD Register 0x03: Angle Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.4 RAW_X Register 0x06: X raw value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.5 RAW_Y Register 0x07: Y raw value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.6 TEMP Register 0x0A: Temperature raw value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.7 ANG_BASE register 0x14: Angle base and rotation direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6 SICI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 Basic Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 SICI Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2.1 Bit Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2.2 Communication Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.2.3 CRC generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2.4 SICI Application Example: Reading working register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.2.5 SICI Application Example: EEPROM read/write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3 SICI Programming in Bus Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7 EEPROM Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1 Writing and Reading of EEPROM Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2 Verification of EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.3 Locking of EEPROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8 Initial Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.1 Zero Angle Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.2 Look-up Table Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.3 Customer ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9 Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1 Angle Read Out Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.2 Angle Base Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.3 Look-up Table Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.4 Temperature calculation from Short Serial Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.5 Reading registers with SICI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table of Contents

User’s Manual 3 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

9.6 Reading EEPROM with SICI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.7 Writing EEPROM with SICI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

10 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

User’s Manual 4 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

Application Circuits

1 Application Circuits

The application circuits in this chapter show the various communication possibilities of the TLE5014.

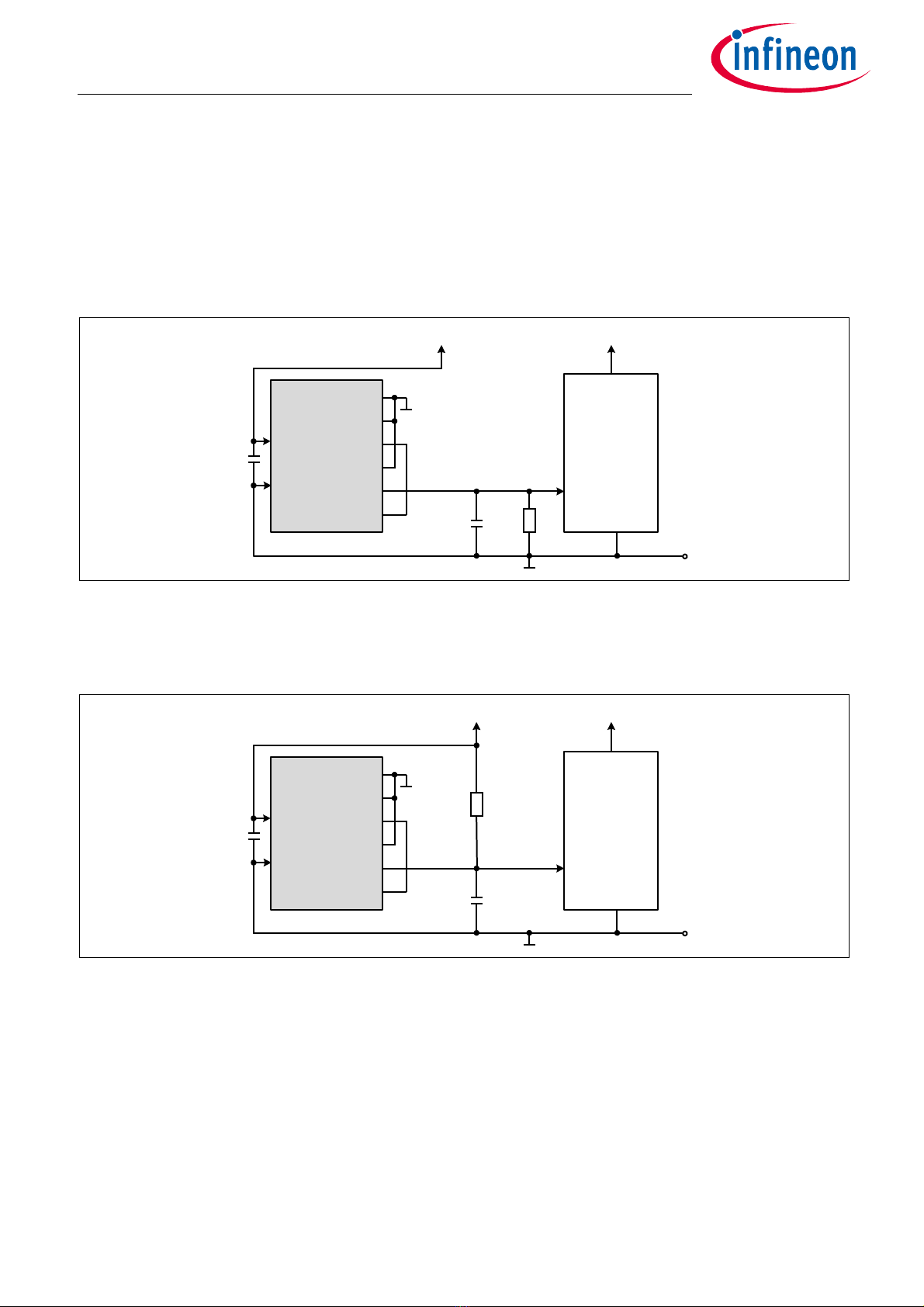

Figure 1 shows a basic application circuit of a TLE5014 with PWM interface. The pull-down resistor is required

to ensure that the sensor starts with a low level after power-on or reset (PWM starts with a rising edge). If the

sensor is configured in such a way, that the PWM starts with a falling edge, the pull-down has to be replaced

by a pull-up.

Figure 1 Application circuit for TLE5014 with PWM, sensor configured to start with a rising edge of

PWM

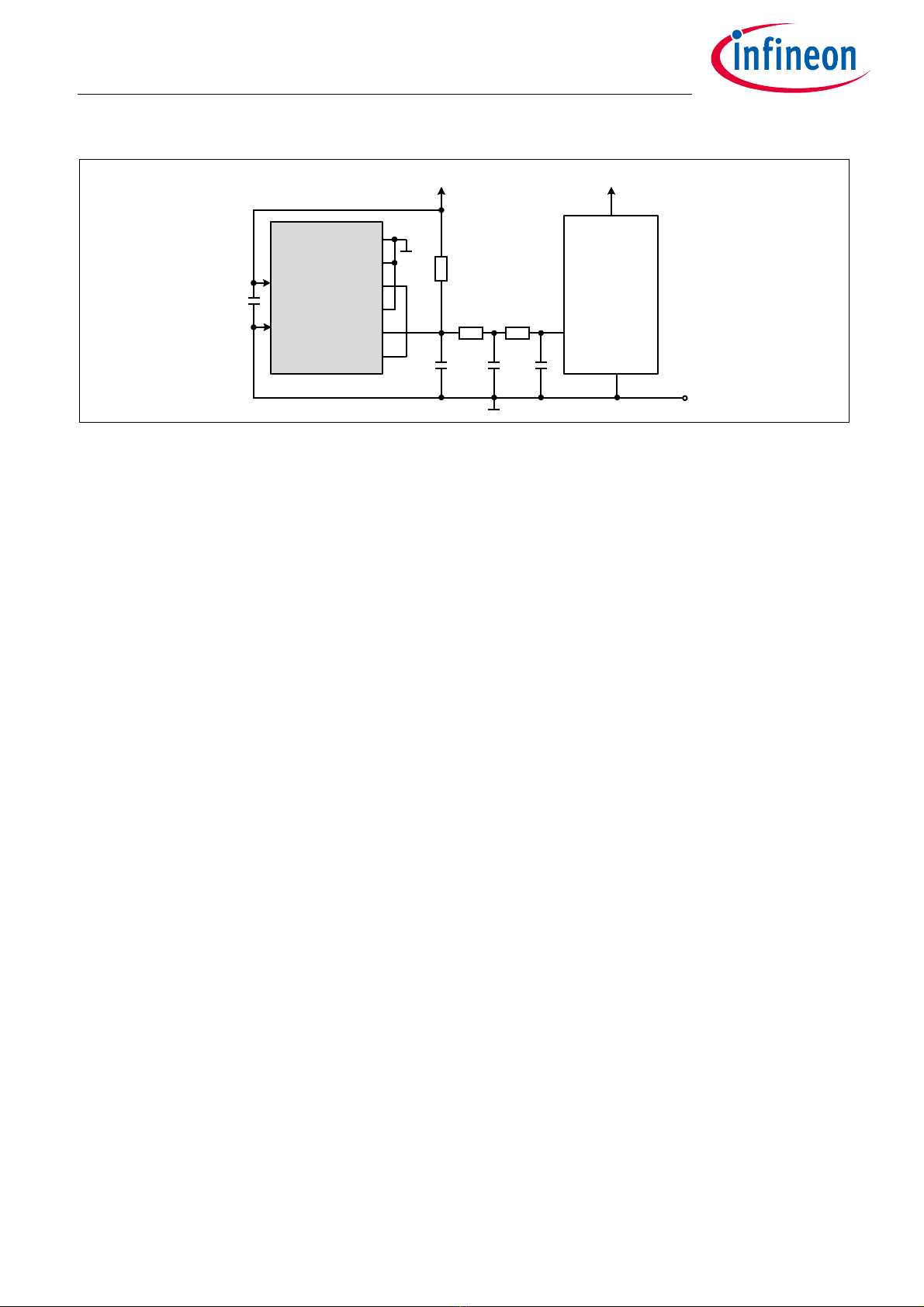

Figure 2 shows a basic application circuit of the TLE5014 with SPC mode.

Figure 2 Application circuit for TLE5014 with SPC, SPC address is configured to be “0” (IF1 and IF2

connected to GND)

The circuit shows the minimum external circuit which is needed to operate the SPC interface. The generation

of the trigger pulse (switch to pull the line low) is not shown. Depending on EMC requirements, additional

circuitry may be required. The value of Cwand Rpare specified in the datasheet.

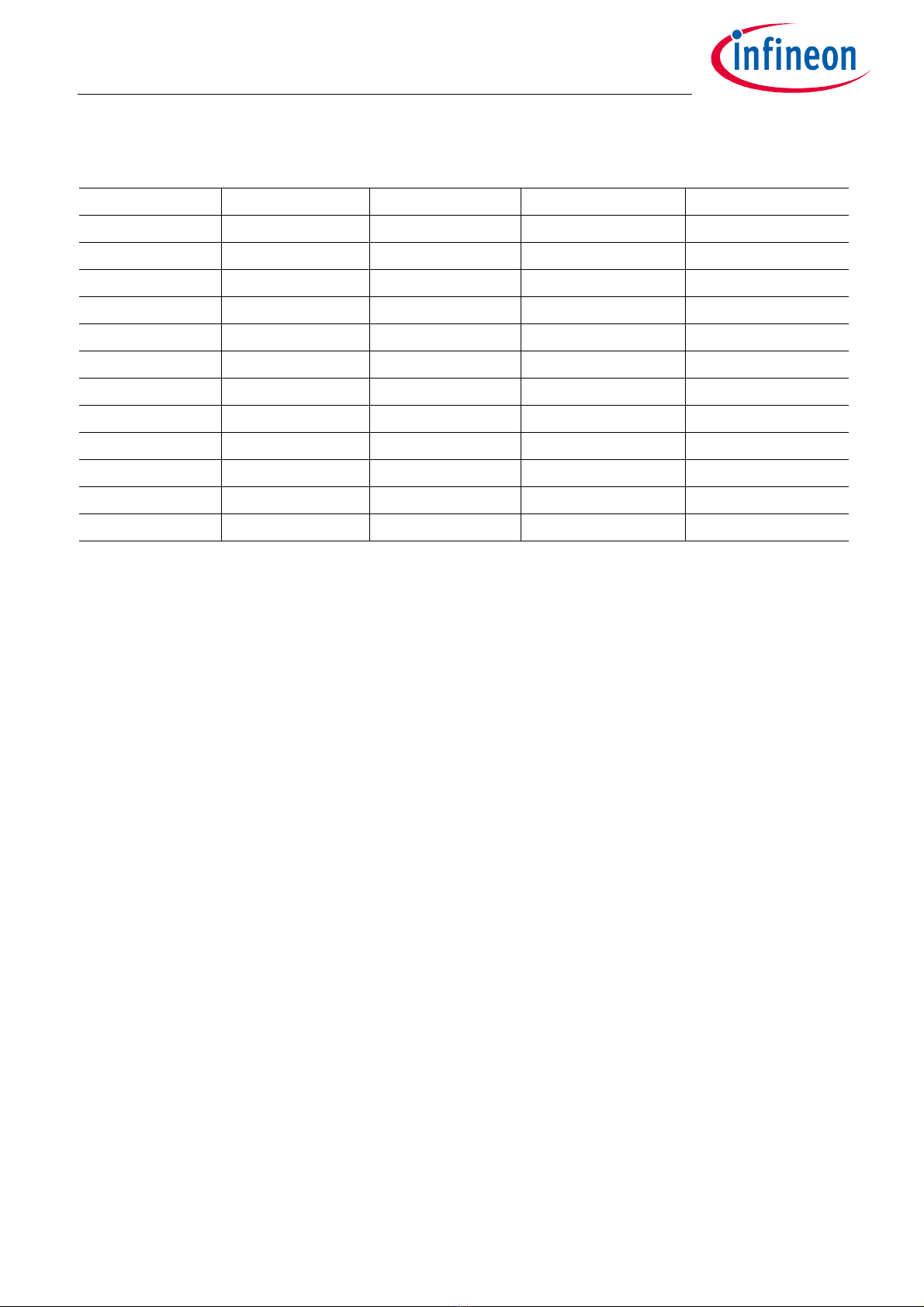

The TLE5014 can also be used with a SENT interface (Figure 3). The circuit shown is according to the SAE

J2716-2010 SENT specification.

TLE501 4

GND

µController

Master

10 0nF

VDD

VDD

GND

IF1

IF2

IF3

IFA

IFB

IFC

VµC

Rp

PWM

Cw

TLE501 4

GND

µController

Master

10 0nF

VDD

VDD

GND

IF1

IF2

IF3

IFA

IFB

IFC

VµC

Rp

SP C

Cw

User’s Manual 5 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

Application Circuits

Figure 3 Application circuit for TLE5014 with SENT

TLE501 4

GND

µController

Master

10 0nF

V

DD

V

DD

GND

IF1

IF2

IF3

IFA

IFB

IFC

V

µC

10 k

56 0 10k

68 p 2.2n 10 0p

User’s Manual 6 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

Interfaces overview

2 Interfaces overview

Depending on the application, the TLE5014 is available with different interfaces:

• PWM (Pulse Width Modulation)

• SPC (Short PWM Code)

• SENT (Single Edge Nibble Transmission)

• SICI (Single-wire Interface for Calibration and Inspection; for programming purpose only)

PWM

The PWM is an unidirectional interface. Only one line is needed in which the angle value is transmitted. The

angle value corresponds to the duty cycle of the signal data. A reserved duty cycle range is implemented which

is used for indication of internal detected device errors. The data duty cycle range and the error duty cycle

range can be programmed via EEPROM setting.

SPC

The SPC is an interface based on the SENT protocol. The ECU (master µC) sends a trigger pulse which triggers

the TLE5014 to transmit the 12-bit angle value. If desired, the temperature can also be transmitted on a slow

channel (short serial message). The SPC also sends a CRC nibble and an end-pulse to terminate the

communication. One line is needed for the transmission and the pins IF1, IF2 and IFC are used to set the slave

number. Up to four slaves can be connected to one ECU; the ECU trigger pulse length will trigger the respective

sensor.

SENT

SENT is a standardized interface described in SAE J2716-2010.

SICI

A PWM based, bidirectional interface which is used for programming purpose only.

Further details on the SENT, SPC and PWM interface can be found in the data sheet of TLE5014.

2.1 PWM Interface Configuration

The following configuration of the PWM interface is possible. Further details are in the EEPROM register

description in Chapter 4.

Table 2 PWM Interface configuration

Parameter EEPROM

Register

Description

PWM data duty cycle range

minimum value

0x0060 This value determines the low value of the duty cycle for

angle transmission. It corresponds to an angle value of 0°

PWM data duty cycle range

maximum value

0x0062 This value determines the high value of the duty cycle for

angle transmission. It corresponds to an angle value of

359.91°

PWM diagnostic duty cycle low 0x0064 This value determines the duty cycle which indicates a

sensor failure detected by the internal safety mechanism

User’s Manual 7 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

Interfaces overview

Care has to be taken when programming the low and high diagnostic duty cycle that there is no overlap with

the programmed data duty cycle range. In such a case, diagnostic information (e.g. sensor failure) could not

be distinguished from a valid transmitted angle value. It is recommended to add a safety margin between the

diagnostic and the data duty cycle range.

2.2 SPC Interface Configuration

The following table shows the different options for SPC interface configuration. The details for the EEPROM

setting are shown in Chapter 4.3

PWM diagnostic duty cycle high 0x0066 This value determines the duty cycle which indicates a

sensor reset or a sensor start-up error (BIST error)

PWM predevider for PWM period 0x0068 This value is used for PWM frequency adjustment according

to Equation (4.1)

PWM period 0x006A This value is used for PWM frequency adjustment according

to Equation (4.1)

PWM starting edge 0x00A2 This value determines the starting edge of the PWM protocol.

It can be rising or falling. In case a rising edge is selected, the

PWM protocol will start with a HIGH level. In case a falling

edge is selected, it will start with a LOW

Table 3 SPC Interface configuration

Parameter EEPROM

Register

Description

SPC low time 0x00A2 This value can be 5 UT or 3UT.With5UT,theSPCnibbleis

compliant to the SENT specification

Temperature information in SPC

protocol

0x00A2 The SPC frame can contain two additional nibbles for

transmitting the temperature information

Rolling counter 0x00A2 A 4-bit rolling counter (rolling counter nibble) can be

activated which counts the transmitted frames. This is

necessary for functional safety applications to increase the

diagnostic coverage

Rolling counter in CRC 0x00A2 The rolling counter information can be coded in the CRC of

the SPC frame instead of being transmitted as extra nibble.

In this case the rolling counter information has 2 bit only.

This feature reduces overall frame length of the SPC protocol

SPC trigger 0x00A2 Two options are available for the total trigger length. It can

be constant with a length of 90 UT or variable. The variable

trigger length is tlow +12 UT and depends on the trigger low

time tlow. Both settings can be used in a bus configuration as

the address of the sensor is defined by the low time tlow only.

The advantage of the variable trigger length is that the total

frame length can be reduced

Table 2 PWM Interface configuration (cont’d)

Parameter EEPROM

Register

Description

User’s Manual 8 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

Interfaces overview

SPC address setting in bus mode

The address of the sensor, so that it responds to a corresponding SPC trigger pulse, has to be set in the

EEPROM. All parts delivered from Infineon have the default address of ID = 0 in the EEPROM. Please refer to

description of EEPROM register 0x00A4 in Description EEPROM Address 0x00A4 CRC_CFG for correct setting.

The address of the sensor written to the EEPROM must be identical to the address of the sensor defined via

hard-wiring of the pins IF1, IF2 and IFC. Table 4 shows how the sensor address has to be set using the pins IF1,

IF2, IFC.

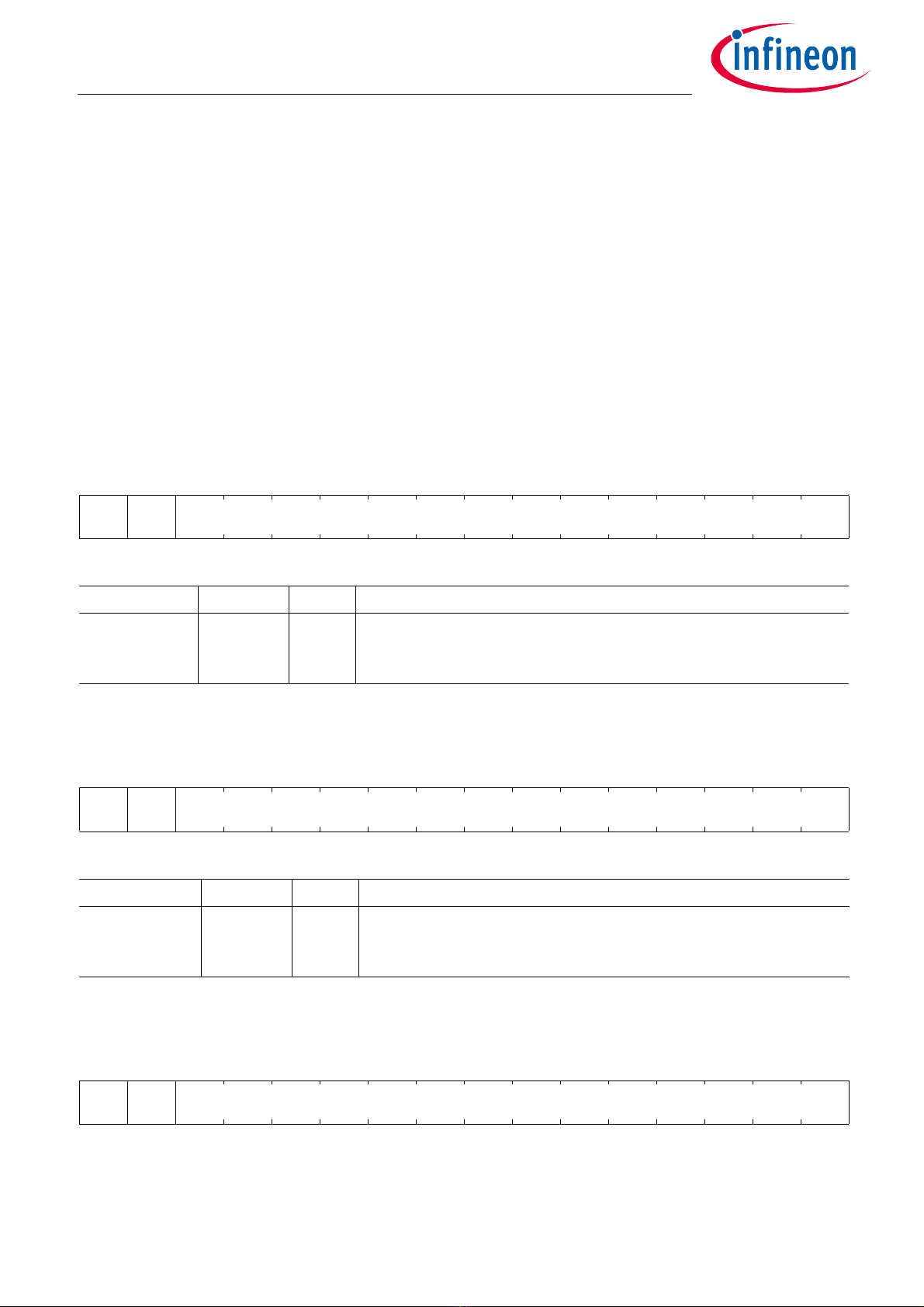

Figure 4 shows a SPC frame with constant trigger length of 90UT, a status nibble, 3 data nibbles, a rolling

counter nibble and a CRC nibble. The low time of the trigger nibble determines the address of the sensor.

Figure 4 SPC frame with constant trigger length and rolling counter enabled as additional nibble

SPC short serial message 0x00A2 A short serial message (slow message) can be activated,

which transmits one bit of a 16 bit information in each SPC

frame and thus needs 16 SPC frames for the whole data

transmission.This transmitted information is the

programmed angle base and rotation direction, the chip

temperature and 32 bit of the customer ID.

SPC unit time (UT) 0x00A2 The SPC unit time (UT) can be selected in the range of 1.0 µs

to 3.0 us.

Table 4 SPC Address Configuration

Address IF1 IF2

0GNDGND

1IFCGND

2GNDIFC

3IFCIFC

Table 3 SPC Interface configuration (cont’d)

Parameter EEPROM

Register

Description

Synchronisation

Frame

Trigger Nibble

µC Activity

Sensor Activity

90 UT 56 UT 12 … 27 UT 12 … 27 UT 12 … 27 UT 12 … 27 UT 12 … 27 UT 12 UT

Status Nibble Data Nibble 1 Data Nibble 3Data Nibble 2 CRC End

pulse

12 … 27 UT

Rolling counter

User’s Manual 9 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

Interfaces overview

SPC status nibble

The 4-bit status nibble of the SPC protocol has different content depending on SPC protocol configuration:

• No short serial message:

• Short serial message (SSM) enabled:

In this configuration, the sensor ID is coded in the CRC and not available in the status nibble. There is also the

option, that the rolling counter is not a dedicated nibble but the information is also coded in the CRC.

Therefore, four different versions of the CRC calculation exist:

• No short serial message (SSM) and rolling counter as nibble

Input data for the CRC calculation are:

STATUS & DATA1 & DATA2 & DATA3 & ROLLING_CNT

• Short serial message (SSM) enabled and rolling counter as nibble

the CRC calculation has to include a special 4-bit “ID-nibble” and is performed with the following input

data:

STATUS & DATA1 & DATA2 & DATA3 & ROLLING_CNT & ID_NIBBLE

ID_NIBBLE = (0 0 ID(MSB) ID(LSB))

• Short serial message (SSM) is disabled and rolling counter is included in CRC (no rolling counter as nibble)

The CRC calculation has to include a special 4-bit “RC-nibble” and is performed with the following input

data:

STATUS & DATA1 & DATA2 & DATA3 & RC_NIBBLE

RC_NIBBLE = (RC(MSB) RC(LSB) 0 0)

• Short serial message (SSM) is enabled and rolling counter is included in CRC (no rolling counter as nibble)

The CRC calculation has to include a special 4-bit “RC_ID-nibble” and is performed with the following input

data:

STATUS & DATA1 & DATA2 & DATA3 & RC_ID_NIBBLE

RC_ID_NIBBLE = (RC(MSB) RC(LSB) ID(MSB) ID(LSB))

Table 5 SPC Status Nibble

Bit Description

0 (LSB) Sensor ID (LSB)

1SensorID(MSB)

2 Internal sensor failure

3 (MSB) Sensor reset or start-up (BIST) failure

Table 6 SPC Status Nibble

Bit Description

0 (LSB) Data bit of SSM

1 Start bit of SSM

2 Internal sensor failure

3 (MSB) Sensor reset or start-up (BIST) failure

User’s Manual 10 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

Interfaces overview

Synchronization of the Rolling Counter

The first transmitted SPC frame has a rolling counter value of 0. The next frame transmits a rolling counter

value which is incremented by 1. In case the rolling counter is coded in the CRC, it is a 2-bit value. In this

configuration, a synchronization of the counter value (sensor value and counter value in the micro controller)

is required. The following two options are possible:

• Calculate the CRC with the received sensor data and a RC_NIBBLE of RC_NIBBLE = 0000B. Repeat this until

the calculated CRC matches with the transmitted CRC. This frame has the rolling counter value of 0. The

next transmitted frame has the incremented counter value of 1 and so on. As the rolling counter has 2 bit

in case it is coded in the CRC, latest the fourth transmitted frame needs to have a matched CRC. If this is

not the case an error occurred.

• For the first transmitted frame, calculate the four possible CRCs with the RC_NIBBLE values 0000Bto 0011B.

The CRC which is matching the transmitted CRC has the correct rolling counter value. Use this value as

starting value which is incremented with the next received frame.

CRC calculation for SPC protocol

The checksum nibble is a 4-bit CRC of the data nibbles including the status nibble. The CRC is calculated using

a polynomial x4+x3+x2+1 with a seed value of 0101B. The remainder after the last data nibble is transmitted as

CRC. The CRC calculation method is based on “recommended” implementation in the SENT standard 2010.

For this “recommended” implementation, the CRC is calculated based on the input data which is then

augmented with four extra zero bits and an additional CRC calculation step.

Code example:

//Table CRC, Poly=0xD

uint8_t cr4Table[16] = {0, 13, 7, 10, 14, 3, 9, 4, 1, 12, 6, 11, 15, 2, 8, 5};

//Example:

//Status Nibble = 0x6

//Data Nibble = 0x7, 0x4, 0x8, 0x7, 0x4, 0x8

uint8_t nibble[7] = {6, 7, 4, 8, 7, 4, 8};

uint8_t nb_nibble = 0x7;

Table 7 Examples for ID Nibble, RC_Nibble and ID_RC_Nibble calculation

ID RC ID_Nibble RC_Nibble RC_ID_Nibble

00B–0000B––

01B– 0001B––

10B– 0010B––

11B– 0011B––

–00

B–0000

B–

–01

B–0100

B–

–10

B–1000–

–11

B–1100

B–

00B00B– – 0000B

01B01B– – 0101B

10B10B– – 1010B

11B11B– – 1111B

User’s Manual 11 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

Interfaces overview

//Seed value = 0x5

uint8_t crc = 0x5;

for(uint8_t i=0;i<nb_nibble;i++){

crc = nibble[i] ^ cr4Table[crc];

}

//Final XOR

crc = 0x0 ^ cr4Table[crc];

2.3 SENT Interface Configuration

The following table shows the different options for SENT interface configuration.

SENT Status Nibble

The 4-bit status nibble of the SENT protocol contains the following information:

Table 8 SENT Interface configuration

Parameter EEPROM

Register

Description

SENT low time 0x00A2 This value can be 5 UT or 3 UT. With 5 UT, the nibble is

compliant to the SENT specification

SENT protocol type 0x00A2 Two different SENT implementations can be configured:

Standard SENT: Status nibble, 3 x 4-bit data nibbles, CRC

nibble

Single Secure SENT: Status nibble, 3 x 4-bit data nibbles, 2x4-

bit rolling counter; Inverted data nibble, CRC nibble

Sent short serial message 0x00A2 A short serial message (slow message) can be activated

which transmits one bit of additional information in each

SPC frame. This transmitted information is the programmed

angle base and rotation direction, the chip temperature and

32 bit of the customer ID

SENT error indication 0x00A2 In case of an internal chip error, the error can be indicated

only in the status nibble by setting an error bit or in the status

nibble and also in the SENT data range. In this case an error

code of “4091” is sent. For this option, the data range has not

the full 12-bit resolution but only 1 … 4088 LSB

Sent unit time (UT) 0x00A2 The SENT unit time (UT) can be selected in the range of 1.5 µs

to 3.0 us

Table 9 SENT Status Nibble

Bit Description

0 (LSB) error indication or start-up (BIST) error or sensor reset

1 reserved

2 short serial message bit (data bit)

3 (MSB) short serial message bit (start indication)

User’s Manual 12 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

Interfaces overview

CRC calculation for SENT protocol

The checksum nibble is a 4-bit CRC of the data nibbles and does not include the status nibble (different to SPC

CRC implementation). The CRC is calculated using a polynomial x4+x3+x2+1 with a seed value of 0101B. The

remainder after the last data nibble is transmitted as CRC. The CRC calculation method is based on

“recommended” implementation in the SENT standard 2010. For this “recommended” implementation, the

CRC is calculated based on the input data (without STATUS nibble) which is then augmented with four extra

zero bits and an additional CRC calculation step.

Code example:

//Table CRC, Poly=0xD

uint8_t cr4Table[16] = {0, 13, 7, 10, 14, 3, 9, 4, 1, 12, 6, 11, 15, 2, 8, 5};

//Example:

//Data Nibble = 0x7, 0x4, 0x8, 0x7, 0x4, 0x8

uint8_t nibble[6] = {7, 4, 8, 7, 4, 8};

uint8_t nb_nibble = 0x6;

//Seed value = 0x5

uint8_t crc = 0x5;

for(uint8_t i=0;i<nb_nibble;i++){

crc = nibble[i] ^ cr4Table[crc];

}

//Final XOR

crc = 0x0 ^ cr4Table[crc];

User’s Manual 13 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

EEPROM Page Map

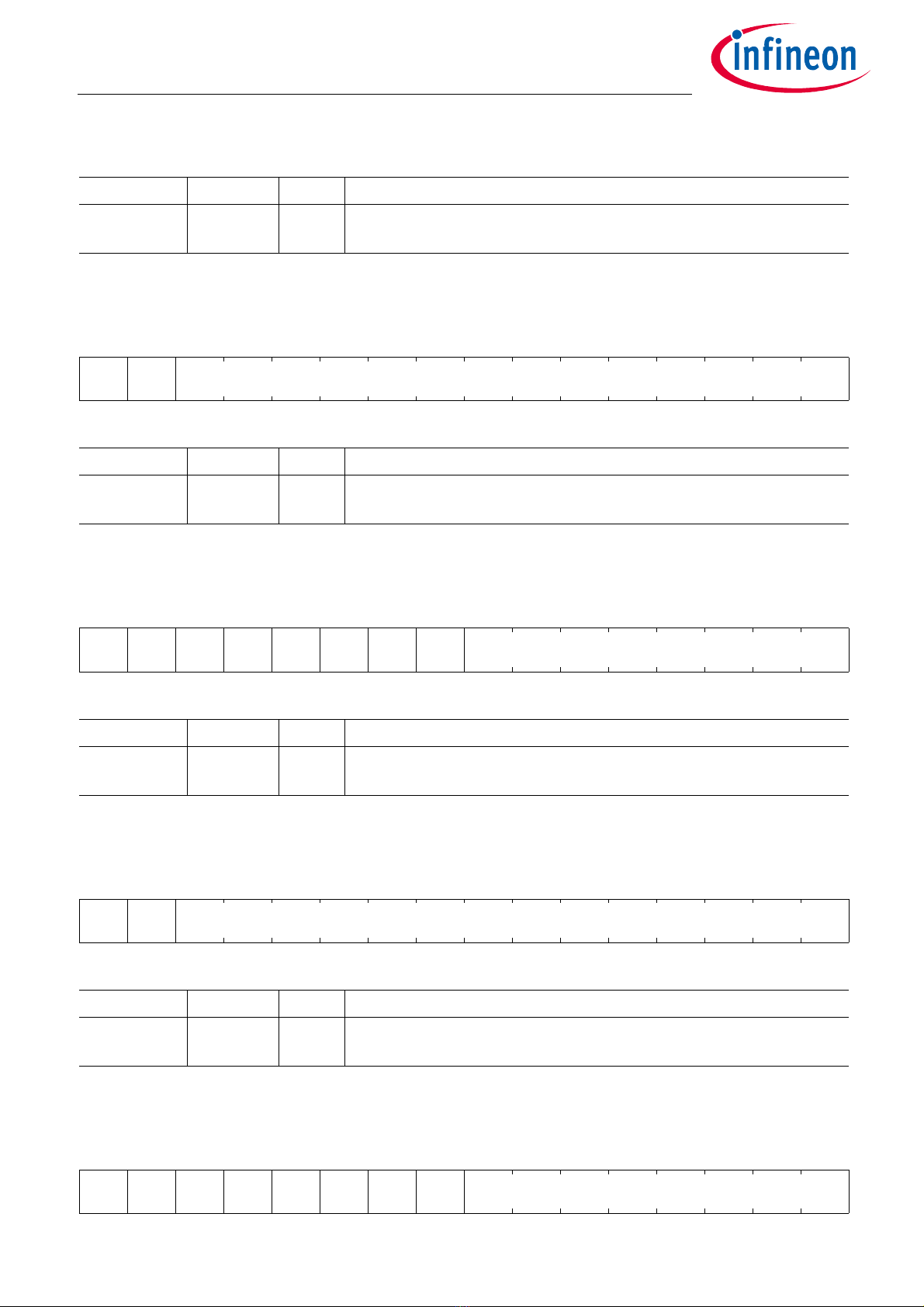

3 EEPROM Page Map

The TLE5014 has an EEPROM as non-volatile memory where sensor configuration data can be stored. The

memory is organized in pages, each page contains 8 registers, each register has 16 bit. Some pages and

registers can be accessed by the user and the content can be modified thus changing chip configuration. Care

has to be taken when modifying content of the EEPROM as the device behavior can be changed and no or

wrong output data can be generated. There is no automatic restore functionality where the pre-programmed

status can be recovered.

The EEPROM content is secured by a CRC. In case any content of the EEPROM is changed, the CRC has to be

recalculated and written to the corresponding register, otherwise an error is indicated. The CRC has always be

calculated out of several pages and registers, which are indicated in the description of the corresponding CRC

(Table 10). The algorithm for the CRC calculation is described in Chapter 6.2.3.

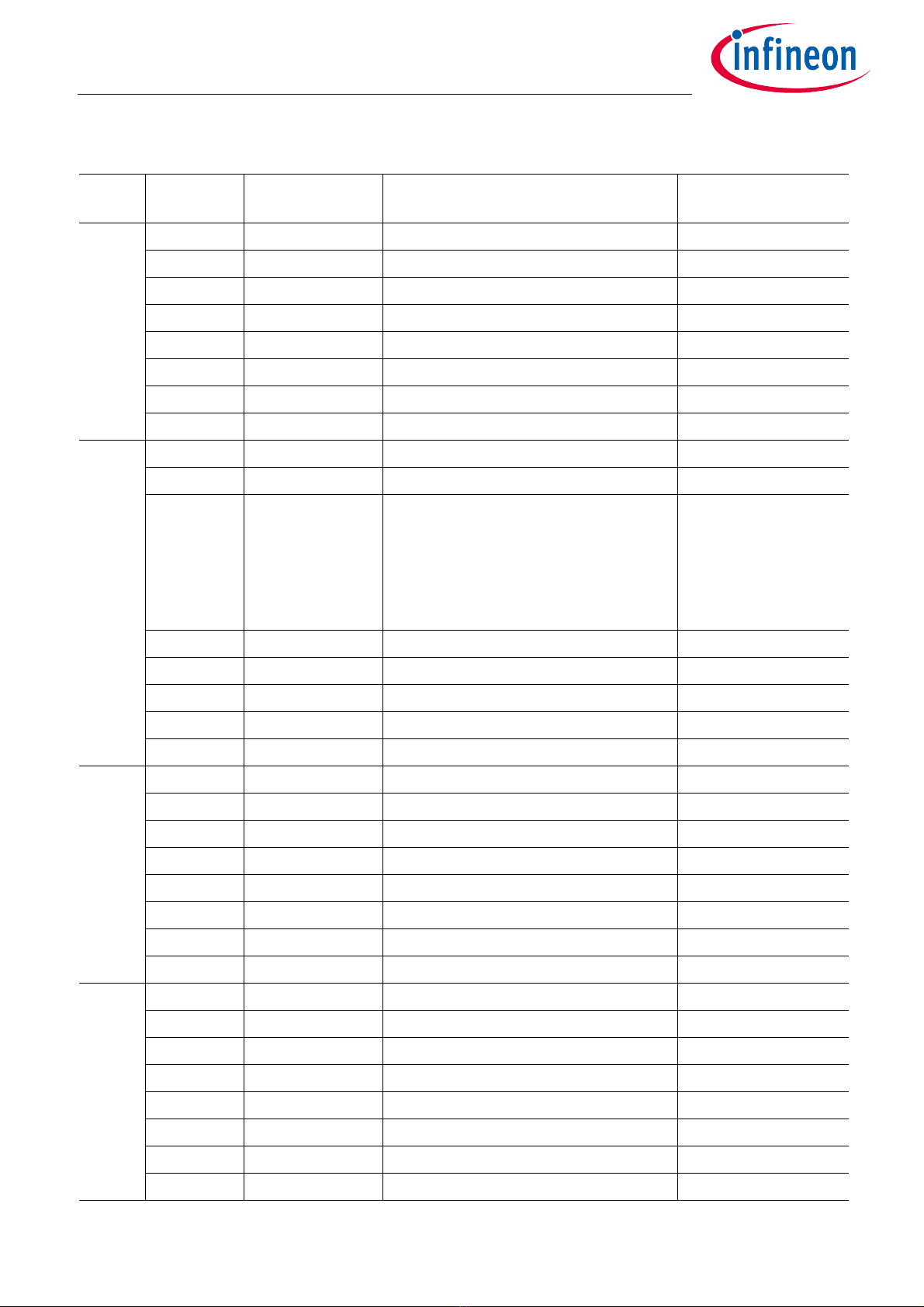

The following Table 10 shows the pages and EEPROM registers of each page and their function. A detailed

description of the EEPROM registers and the possible settings can be found in Chapter 4.

The startup value of each configuration register of the TLE5014 is stored in a corresponding EEPROM register,

which can be modified by the user. Table 10 lists the allocation of the user-configurable EEPROM pages.

Care shall be taken when the EEPROM configuration is changed, as not all possible configurations are released

by Infineon. This means, that they can be used for testing purpose but not necessarily for production. All

released configurations can be found in the TLE5014 datasheet.

Table 10 EEPROM page map

Page EEPROM

Register

Name Description Default value of Reg.

0x006 0x0060 OUT_LIM_MIN PWM data duty cycle range minimum

value

0x0062 OUT_LIM_MAX PWM data duty cycle range maximum

value

0x0064 OUT_STAT_L PWM diagnostic duty cycle low

0x0066 OUT_STAT_H PWM diagnostic duty cycle high

0x0068 TMR_PREDIV PWM predevider for PWM period

0x006A TMR_PERIOD PWM period

0x006C – Reserved

0x006E CRC_EEP CRC has to be calculated with following

values: page 0x002 & 0x003 & 0x004 &

0x005 & register 0x0060 & 0x0062 &

0x0064 & 0x0066 & 0x0068 & 0x006A &

0x006C & first byte of 0x006E (bit [15:8] &

0xFF00)

User’s Manual 14 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

EEPROM Page Map

0x009 0x0090 – Reserved

0x0092 – Reserved

0x0094 – Reserved

0x0096 ACSTAT Activation of internal safety mechanism

0x0098 MOD1 3 V/5 V, pad configuration, LUT options

0x009A MOD2 Lock function for register PWI_MD_USR

0x009C IF123_CFG Pin configuration of pin IF1, IF2, IF3

0x009E IFABC_CFG Pin configuration of pin IFA, IFB, IFC

0x00A 0x00A0 ANG_BASE Angle base & rotation direction

0x00A2 PWI_MD_USR Interface configuration

0x00A4 CRC_CFG Configuration CRC and SPC address;

CRC has to be calculated with following

values: registers 0x0096 & 0x0098 &

0x009A & 0x009C & 0x009E & 0x00A0 &

0x00A2 & first byte of 0x00A4 (bit [15:8] &

0xFF00)

0x00A6 – Reserved

0x00A8 – Reserved

0x00AA – Reserved

0x0AC – Reserved

0x00AE – Reserved

0x00B 0x00B0 LUT_0 Look-up table value for 0°

0x00B2 LUT_1 Look-up table value for 11.25°

0x00B4 LUT_2 Look-up table value for 22.50°

0x00B6 LUT_3 Look-up table value for 33.75°

0x00B8 LUT_4 Look-up table value for 45.00°

0x00BA LUT_5 Look-up table value for 56.25°

0x00BC LUT_6 Look-up table value for 67.50°

0x00BE LUT_7 Look-up table value for 78.75°

0x00C 0x00C0 LUT_8 Look-up table value for 90.00°

0x00C2 LUT_9 Look-up table value for 101.25°

0x00C4 LUT_10 Look-up table value for 112.50°

0x00C6 LUT_11 Look-up table value for 123.75°

0x00C8 LUT_12 Look-up table value for 135.00°

0x00CA LUT_13 Look-up table value for 146.25°

0x00CC LUT_14 Look-up table value for 157.50°

0x00CE LUT_15 Look-up table value for 168.75°

Table 10 EEPROM page map (cont’d)

Page EEPROM

Register

Name Description Default value of Reg.

User’s Manual 15 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

EEPROM Page Map

0x00D 0x00D0 LUT_16 Look-up table value for 180.00°

0x00D2 LUT_17 Look-up table value for 191.25°

0x00D4 LUT_18 Look-up table value for 202.50°

0x00D6 LUT_19 Look-up table value for 213.75°

0x00D8 LUT_20 Look-up table value for 225.00°

0x00DA LUT_21 Look-up table value for 236.25°

0x00DC LUT_22 Look-up table value for 247.50°

0x00DE LUT_23 Look-up table value for 258.75°

0x00E 0x00E0 LUT_24 Look-up table value for 270.00°

0x00E2 LUT_25 Look-up table value for 281.25°

0x00E4 LUT_26 Look-up table value for 292.50°

0x00E6 LUT_27 Look-up table value for 303.75°

0x00E8 LUT_28 Look-up table value for 315.00°

0x00EA LUT_29 Look-up table value for 326.25°

0x00EC LUT_30 Look-up table value for 337.50°

0x00EE LUT_31 Look-up table value for 348.75°

0x00F 0x00F0 [7:0] CRC_LUT 8-bit CRC for Look-up table; CRC has to

be calculated with following values:

page 0x00B & 0x00C & 0x00D & 0x00E &

first byte of register 0x00F0 (bits [15:8] &

0xFF00)

0x00F2 CUST_ID_0 16-bit of customer ID, will be

transmitted via short serial message

0x00F4 CUST_ID_1 16-bit of customer ID, will be

transmitted via short serial message

0x00F6 CUST_ID_2 16-bit of customer ID

0x00F8 CUST_ID_3 16-bit of customer ID

0x00FA CUST_ID_4 16-bit of customer ID

0x00FC CUST_ID_5 16-bit of customer ID

0x00FE CUST_ID_6 16-bit of customer ID

Table 10 EEPROM page map (cont’d)

Page EEPROM

Register

Name Description Default value of Reg.

User’s Manual 16 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

EEPROM Page Map

Figure 5 TLE5014 EEPROM bitmap

Page 0x006 1514131211109876543210

0x0060 - -

0x0062 - -

0x0064 - -

0x0066 - -

0x0068 - - ------

0x006A - -

0x006C - - -------------

0x006E - - ------

Page 0x009

0x0090 - - --------------

0x0092 - - --------------

0x0094 - - --------------

0x0096

0x0098

0x009A

0x009C ------

0x009E ------

Page 0x00A

0x00A0 ANG_DIR -

0x00A2

0x00A4 -----AS_NR

0x00A6 - - --------------

0x00A8 - - --------------

0x00AA - - --------------

0x00AC - - --------------

0x00AE - - --------------

Page 0x00B

0x00B0

0x00B2

0x00B4

0x00B6

0x00B8

0x00BA

0x00BC

0x00BE

Page 0x00C

0x00C0

0x00C2

0x00C4

0x00C6

0x00C8

0x00CA

0x00CC

0x00CE

Page 0x00D

0x00D0

0x00D2

0x00D4

0x00D6

0x00D8

0x00DA

0x00DC

0x00DE

Page 0x00E

0x00E0

0x00E2

0x00E4

0x00E6

0x00E8

0x00EA

0x00EC

0x00EE

Page 0x00F

0x00F0 --------

0x00F2

0x00F4

0x00F6

0x00F8

0x00FA

0x00FC

0x00FE

CUST_ID_2

CUST_ID_3

CUST_ID_4

CUST_ID_5

CUST_ID_6

CUST_ID_0

CUST_ID_1

LUT_22

LUT_23

LUT_24

LUT_25

LUT_26

LUT_27

CRC_LUT

LUT_28

LUT_29

LUT_30

LUT_31

LUT_21

LUT_10

LUT_11

LUT_12

LUT_13

LUT_14

LUT_15

LUT_16

LUT_17

LUT_18

LUT_19

LUT_20

LUT_8

LUT_9

LUT_3

LUT_4

LUT_5

LUT_6

LUT_7

TMR_PERIOD

CRC_EEP

LUT_0

LUT_1

LUT_2

ANG_BASE

ACSTAT

MOD1

MOD2

IF123_CFG

IFABC_CFG

PWI_MOD

S_NR_EEP CRC_CFG

OUT_LIM_MIN

OUT_LIM_MAX

OUT_STAT_L

OUT_STAT_H

TMR_PREDIV

User’s Manual 17 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

EEPROM Register Description

4 EEPROM Register Description

This chapter describes the EEPROM registers which can be accessed via SICI in the EEPROM programming

mode. Further registers needed for EEPROM programming are described in Chapter 7.1.

Care shall be taken that there is no unintended modification of bits. When modifying registers, reserved bits

have to be read and written back with the same value.

4.1 Page 0x006

The page 0x06 is used for the configuration of the PWM protocol. It is only relevant in case PWM is selected as

interface in the register PWI_MD_USR (0x00A2). The following tables EEPROM Register Address 0x0060

OUT_LIM_MIN to EEPROM Register Address 0x006E CRC_EEP show the details.

EEPROM Register Address 0x0060 OUT_LIM_MIN

1514131211109876543210

OUT_LIM_MIN

Field Bits Type Description

OUT_LIM_MIN 13:0

Minimum value of data duty cycle range; 0% … 100% mapped to

0 … 16383

EEPROM Register Address 0x0062 OUT_LIM_MAX

1514131211109876543210

OUT_LIM_MAX

Field Bits Type Description

OUT_LIM_MAX 13:0

Maximum value of data duty cycle range; 0% … 100% mapped to

0 … 16383

EEPROM Register Address 0x0064 OUT_STAT_L

1514131211109876543210

OUT_STAT_L

User’s Manual 18 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

EEPROM Register Description

Field Bits Type Description

OUT_STAT_L 13:0

Low value of diagnostic duty cycle; 0% … 100% mapped to 0 … 16383

EEPROM Register Address 0x0066 OUT_STAT_H

1514131211109876543210

OUT_STAT_H

Field Bits Type Description

OUT_STAT_H 13:0

High value of diagnostic duty cycle; 0% … 100% mapped to 0 … 16383

EEPROM Register Address 0x0068 TMR_PREDIV

1514131211109876543210

TMR_PREDIV

Field Bits Type Description

TMR_PREDIV 7:0

For calculation of PWM frequency according to Equation (4.1)

EEPROM Register Address 0x006A TMR_PERIOD

1514131211109876543210

TMR_PERIOD

Field Bits Type Description

TMR_PERIOD 13:0

For calculation of PWM frequency according to Equation (4.1)

EEPROM Register Address 0x006E CRC_EEP

1514131211109876543210

CRC_EEP

User’s Manual 19 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

EEPROM Register Description

The PWM frequency of the PWM output can be programmed with the two parameters TMR_PREDIV and

TMR_PERIOD according to the following Equation (4.1):

(4.1)

Example:

For TMR_PREDIV = 12, TMR_Period = 15384, the PWM frequency calculates to f= 200 Hz.

4.2 Page 0x009

Care has be taken that there is no unintended modification of bits. When modifying registers, reserved bits

have to be read and written back with the same value.

Field Bits Type Description

CRC_EEP 7:0

CRC has to be calculated with following values: page 0x002 & 0x003 &

0x004 & 0x005 & register 0x0060 & 0x0062 & 0x0064 & 0x0066 & 0x0068

& 0x006A & 0x006C & first byte of 0x006E (bit [15:8])

Description EEPROM Register Address 0x0098 MOD1

1514131211109876543210

RST_3

_5

CLK_S

EL

FIR_M

DLUT_MD IFMD_ABC IFMD_

123

Field Bits Type Description

RST_3_5 13

0:BReset comparator set to < 3.0 V

1:BReset comparator set to < 4.2 V

CLK_SEL 12

For test purpose only

FIR_MD 11

Internal update rate of angle calculation:

0:B25.6 µs

1:B51.2 µs

LUT_MD 9:8

Look-up table (LUT) configuration:

00:BLUT disabled

01:BLUT range = 360° (angle steps = 11.25°)

10:BLUT range = 180° (angle steps = 5.625°)

11:BLUT range = 90° (angle steps = 2.813°)

fHz[] 40000000

1 TMR_PREDIV+()TMR_PERIOD()

----------------------------------------------------------------------------------------------

=

User’s Manual 20 Rev. 1.0

2019-03-12

TLE5014

GMR-Based Angle Sensor

EEPROM Register Description

IFMD_ABC 5:4

For test purpose only

IFMD_123 0

For test purpose only

Description EEPROM Register Address 0x009A MOD2

1514131211109876543210

MOD2

Field Bits Type Description

MOD2 15:0

Lock register for 0x00A2. The bits in this registers are connected with a

logical AND function with the corresponding bit in 0x00A2. This means

that a “0” in a bit of register 0x009A prohibits to set a “1” in the

corresponding bit of 0x00A2. Note: The bit will show as “1” in 0x00A2

but has no effect

Description EEPROM Register Address 0x009C IF123_CFG

1514131211109876543210

PAD_

OV_O

FF

PAD_S

PIKE

IF3_O

D

IF3_C

FG

IF2_O

D

IF2_C

FG

IF1_O

D

IF1_C

FG

Field Bits Type Description

PAD_OV_OFF 15

Enable/disable overvoltage functionality. Output deactivated in case

of overvoltage on VDD:

0:BOvervoltage functionality enabled

1:BOvervoltage functionality disabled

PAD_SPIKE 14

Activate spike filter for input stage:

0:BSpike filter disabled

1:BSpike filter enabled

IF3_OD 11

IF3 open drain enable:

0:BDisable (Push-Pull)

1:BEnable (Open Drain)

Field Bits Type Description

This manual suits for next models

5

Table of contents

Other Infineon Accessories manuals

Infineon

Infineon TLE493D-A2B6 User manual

Infineon

Infineon TLI4970-D050T4 CurrentSense Shield2Go User manual

Infineon

Infineon SP37 Instruction and safety manual

Infineon

Infineon TLE5501 Series User manual

Infineon

Infineon TLI4970 Mounting instructions

Infineon

Infineon XENSIV BGT60TR13C User manual

Infineon

Infineon TLE4997 User manual

Infineon

Infineon TLI493D-A2B6 User manual

Infineon

Infineon XENSIV TLI4971 Operating instructions