INFLOOR 24535 User manual

for

24535 and 24538

(July 2008)

Infloor Sales & Service SW Adjustable Manual Pressing Tool

Operating Instructions

2

Index

1, Structure of Infloor Sales & Service SW adjustable manual pressing tools

................ P-3

2, Available jaws .................................................................................................................. P-4

3, Preparation before use .................................................................................................... P-4

Step 1, Choose correct pressing jaws........................................................................................... P-4

Step 2, Mount appropriate pressing jaws on to pressing tool..........................................................P-5

Step 3, Adjustment for pressing tool............................................................................................ P-6

4,Cautions and parameters for pressing tool adjustment................................................. P-7

5, Special operations at corners or narrow spaces............................................................. P-7

6, Pressing F5 (U-profile) fittings with the pressing tool................................................... P-9

7, Pressing tool wears and final rejection......................................................................... P-10

8, Preservation and maintenance....................................................................................... P-11

3

Operation Instruction for Infloor Sales & Service adjustable Manual Pressing Tools

Infloor Sales & Service provides adjustable manual tools 24535 and 24538. The 24535 is for

pressing fittings from 1/2” to 5/8”, and the 24538 is for pressing fittings from 1/2” to 1”.

Below is the introductions on how to use the Infloor Sales & Service SW adjustable manual

pressing tools 24538with lengthened handles.

The key operation instruction of pressing tool 24535 is similar to 24538 except two points:

The 24538 is for press fittings 1/2” to 1” , and doesn’t need longer handles to deal

with the 1/2” to 5/8“ press fittings but does need longer handles to deal with the 3/4” and 1”

2nd, the pressing jaws used on the pressing tool 24535 are smaller than the jaws on pressing

1, Structure of Infloor Sales & Service adjustable manual pressint tools

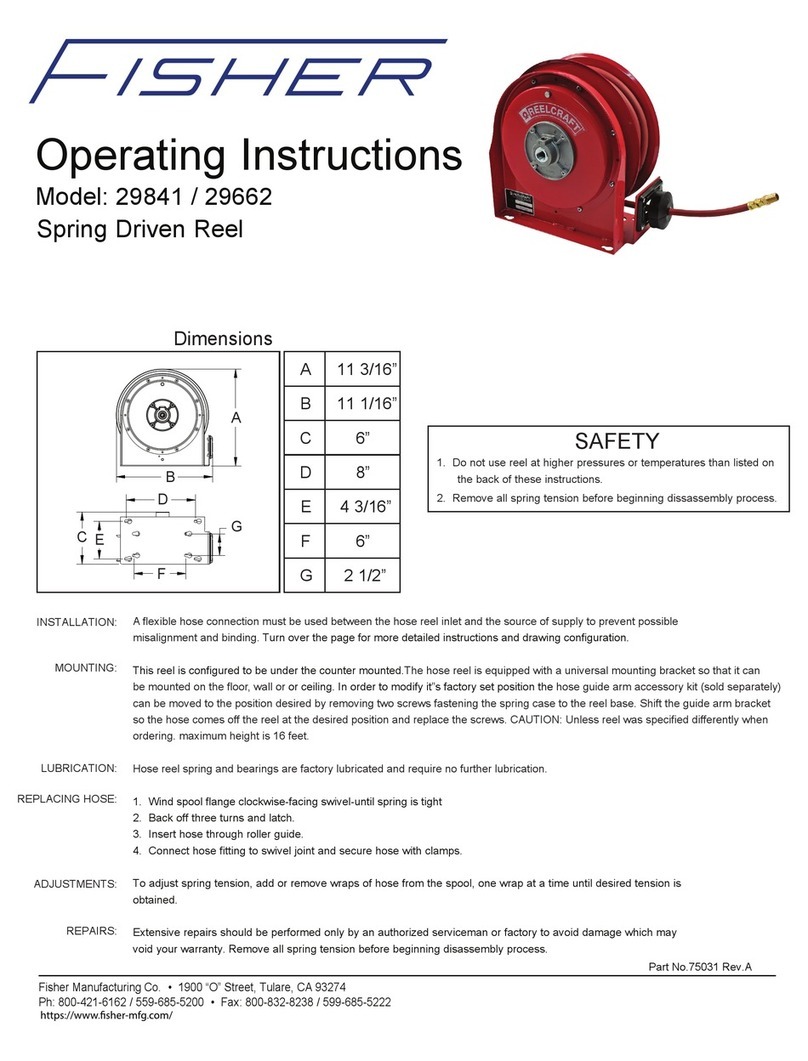

Below is the pressing tool picture illustrated with the name of each part/component for pressing

pressing tool head pressing tool handle

Main part names:

1:Screw(M6×25), 2: Pressing tool body, 3: Pin in pressing tool body, 4: Connection block, 5 :Pin 1

in handle, 6: Pin 2 in handle, 7: Screw(M8), 8: Right handle, 9:Left handle, 10: Contact point on

right handle, 11: Contact point on left handle, 12: Lengthened handle, 13: Locking screw(M6×12),

14: Adjusting screw, 15 Connection arm, 16:Butterfly-shape screw (M8).

tool 24538, therefore could not be interchangeably mounted on 24538.

tool 24538, which is simular to 24535 on structure.

1) The 24535 doesn’t need longer handles and is only for press fitting sizes 1/2” to 5/8”.

press fittings.

4

2, Available jaws

The pressing jaws used on the pressing tool 24535 are smaller than the jaws on pressing tool 24538,

corresponding jaws for them and read the notes carefully.

Table of available pressing jaws

All the jaws below are U-profile for pressing

Infloor Sales & Service F5 fitting.

Notes:

Specification number is engraved on one side of each jaw. The number stands for the pipe

outer diameter by mm. Please make sure the lettered sides of the two opposite jaws are

positioned on the same side.

The jaws engraved with specification number alone, stand for U-profile jaws (for pressing

F5 fittings).

3, Preparation before use

Step 1, Choose correct pressing jaws

Appropriate pressing jaw should be selected per the pipe size.

Picture Jaw specifications Suitable tool

23456

24535

1/2" Press Tool Module

24537

5/8" Press Tool Module

24540

24538

1/2” L Press Tool Module

24541

5/8” L Press Tool Module

24542

3/4” L Press Tool Module

24543

1” L Press Tool Module

therefore could not be interchangeably mounted on 24538, please refer to the following table for the

5

Step2, Mount appropriate pressing jaws on to pressing tool

A, You need to open the pressing tool handles and then take off two screws (Part No.1,M6×25), see

following picture.

B, Position the two opposite jaws in the pressing tool head, make sure the two jaws are evenly well

positioned and the specification number on the two jaws are on the same side, then fix the jaws with

the screws (Part No.1,M6

x

25).

Note:please don't over tighten the jaws, little looseness is allowed

C, Please pay attention to the jaw positioning, make sure the center of pressing hole formed by these

two opposite jaws is by the jaws openning direction rather than the handles opening direction.

D, Trial-Pressing-Force evaluation

Try to close the pressing tool without fitting and lengthened handles mounted, the appropriate Trial-

6

Pressing-Force to fully close the pressing tool jaws should be about 33 LBS. If not, then the pressing

tool need adjustment before use, please refer to next step for adjustment.

Step3, Adjustment for pressing tool

A, Open the pressing tool and release the "locking screw" (Part No. 13) counter-clockwise for about 3

rounds.

B, If the Trial-Pressing-Force is too small, you should turn the "adjusting screw”

(Part No. 14) clockwise for about 1/4 round. If the Trial-Pressing-Force is too big, then you should

should turn the "adjusting screw" counter-clockwise.You should repeat this process until the Trial

-Pressing -Force is about 33 LBS.

Note:The adjusting screw (Part No. 14) should not be touched again when the Trial-Pressing-

Force reaches about 33 LBS, the pressing tool adjustment should be immediately

locked by locking screw (Part No. 13) at the next step to finish the adjustment.

7

C, Close the pressing tool and tighten up the "locking screw" (Part No. 13) clockwise,then open the

pressing tool,the adjustment is finished.

D, For pressing fittings 3/4" and 1 ” , the lengthened handles (Part No.12) should be mounted

after adjustment.

Lengthened handles are not necessary when pressing fittings no bigger than 5/8”. Lengthened

handles are only necessary for pressing fittings 3/4" and 1" .

4,Cautions and parameters for pressing tool adjustment

(1) Adjustment should be made on the following occasions:

New pressing tool is to be used.

Pressing tool jaws can not be fully closed when pressing fittings.

Change pressing jaws,

User finds that Operation Force changes a lot in pressing fittings than before.

Closed pressing tool can be openned freely without using any force.

Pressing effect is bad.

(2) In case of new tools,due to the burrs in tool production, Operation Force change after 60 times

of pressing is possible but is normal,the tool can still be used after proper adjustment.

(3) After adjustment, Operation Forces for pressing fittings could refer to following table.

Note:The forces listed above are for pressing fitting 1 / 2 ” without lengthend

handles, and for pressing fittings 3/4" and 1" mounted with lengthened handles.

5, Special operations at corners or narrow spaces

Specification 16 1/2” 25 3/4” 32 1”

Operation

Force (pounds) 44 LBS 88 LBS 99 LBS

Infloor Sales & Service adjustable manual pressing tools provide special design for occasions

where there isn’t enough space to open the handle or lengthened handles such as corners or narrow

spaces. In this case, you can operate as below steps:

8

A, Close the pressing tool, release and take off the butterfly-shape screw (Part No. 16 ),

B, Open the pressing tool, then take off the pin(Part No. 6) fixed with the butterfly-shape screw.

C, Now you can adjust the angle from pressing tool head to pressing tool handles, to make sure the

jaws are rightly positioned over the sleeved-fittings and you can open the pressing tool enough

to press fittings.

9

D, Mount back the pin and the butterfly-shape screw onto the pressing tool. Put the pressing tool on

right position and close the handles to finish the pressing procedure.

E, Release and remove the butterfly-shape screw and the pin from the pressing tool, if necessary take

off the lengthened handles,then open the jaws and move the pressing jaws away from the pressed

fitting without opening the handles or lengthened handles.

G, Mount back the pin and the butterfly-shape screw onto the pressing tool. The pressing at corner or

narrow space is then completed.

6, Pressing F5 (U-profile) fittings with the pressing tool

A, When pressing F5 series fittings, place the jaw's end align with the press sleeve’s end which is by

the plastic ring, close the pressing tool completely.

10

C, Close the pressing tool to press the fittings,the contact points on right and left handles(Part No. 10

and 11) must contact.

7, Pressing tool wears and final rejection

Over a long time use, the pressing tool components/parts might wear out badly, the Trial-Pressing-

Force may not be able to reach about 33LBS or pressing jaws may not be able to be closed completely

in pressing fittings even after adjustment. In this case, the pressing tool should be discarded.

Contact

Contact

11

Infloor Sales & Service 24535 and 24538 pressing tools were tested 5000 times with positive results. In

this testing process, necessary adjustments were made on the pressing tool, but without any replacement of

pressing tool parts/components.

8, Preservation and maintenance

A, When the tool is not in use, it should be kept in either of the following ways:

Open the pressing tool with jaws mounted in the pressing tool head, keep well the threads on the

lenthened handles.

Take off the jaws, close the pressing tool, keep well the threads on the lenthened handles.

B, The pressing tool should be maintained periodically by cleaning and adding lubrication oil to pins

or screws at the following specified locations at least once every month.

Thread protection

Thread protection

Thread protection

Pins

Pins

Pins

12

C, Jaws should be kept clean.

D, Lengthened handles should be kept well,make sure the threads on handles are kept clean and well

without damage,and anti-corrosion agent should be sprayed onto the threads periodically.

E. In use or tool adjustment,the screws or pins taken off from the pressing tool should be well

preserved.

We wish we have been of good service to you,if you have any questions on using our pressing tools,

This manual suits for next models

1

Table of contents

Popular Tools manuals by other brands

Scheppach

Scheppach GS650 Translation of original operating manual

TOOLCRAFT

TOOLCRAFT 2559121 operating instructions

Bosch

Bosch GLL 2-20 Professional Original instructions

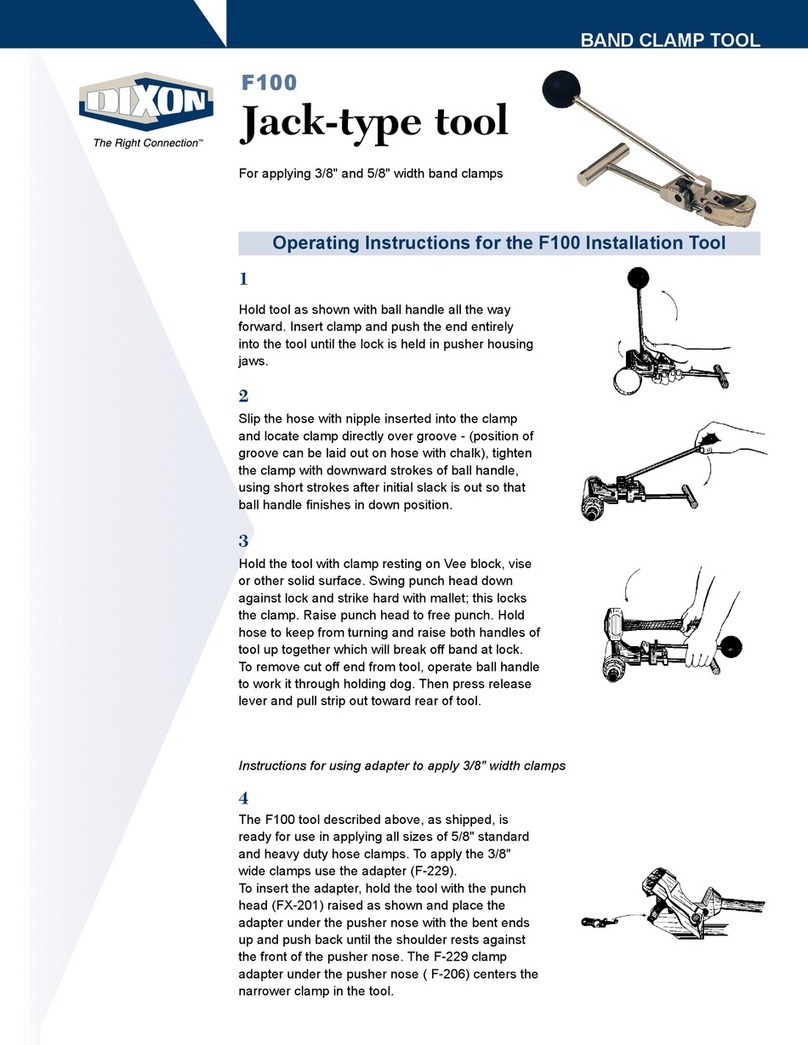

Dixon

Dixon F100 operating instructions

Hard Head

Hard Head 023864 operating instructions

Signode

Signode Josef Kihlberg JK20V779L operating instructions