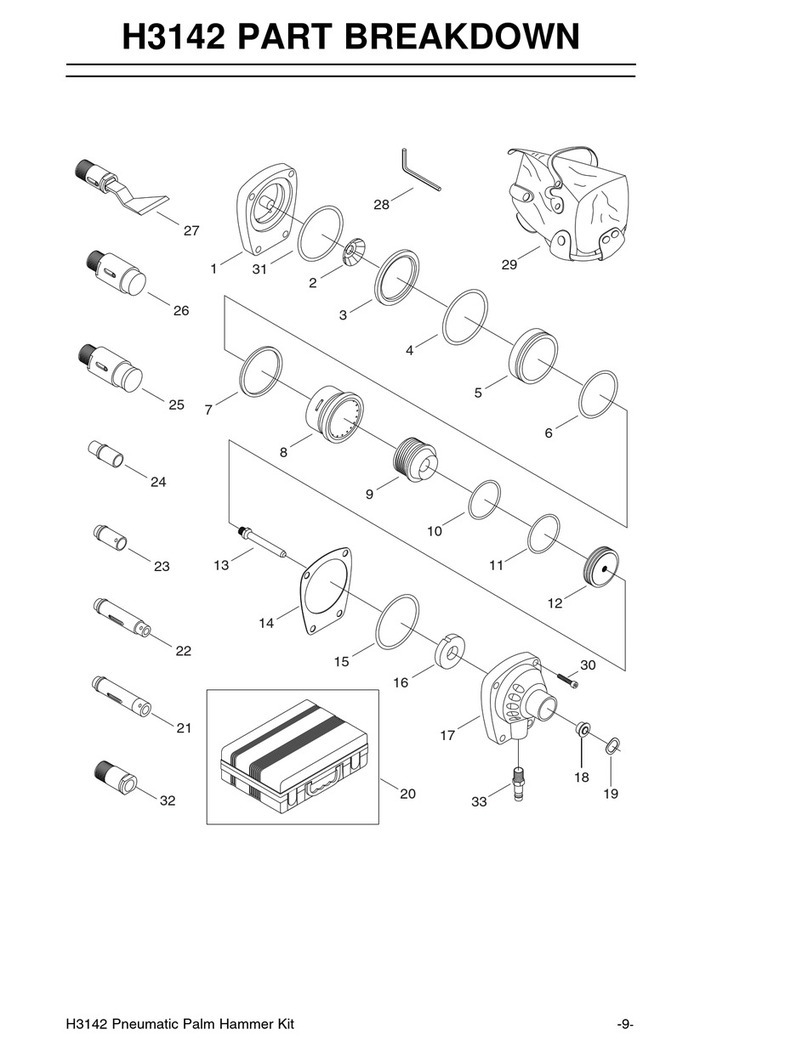

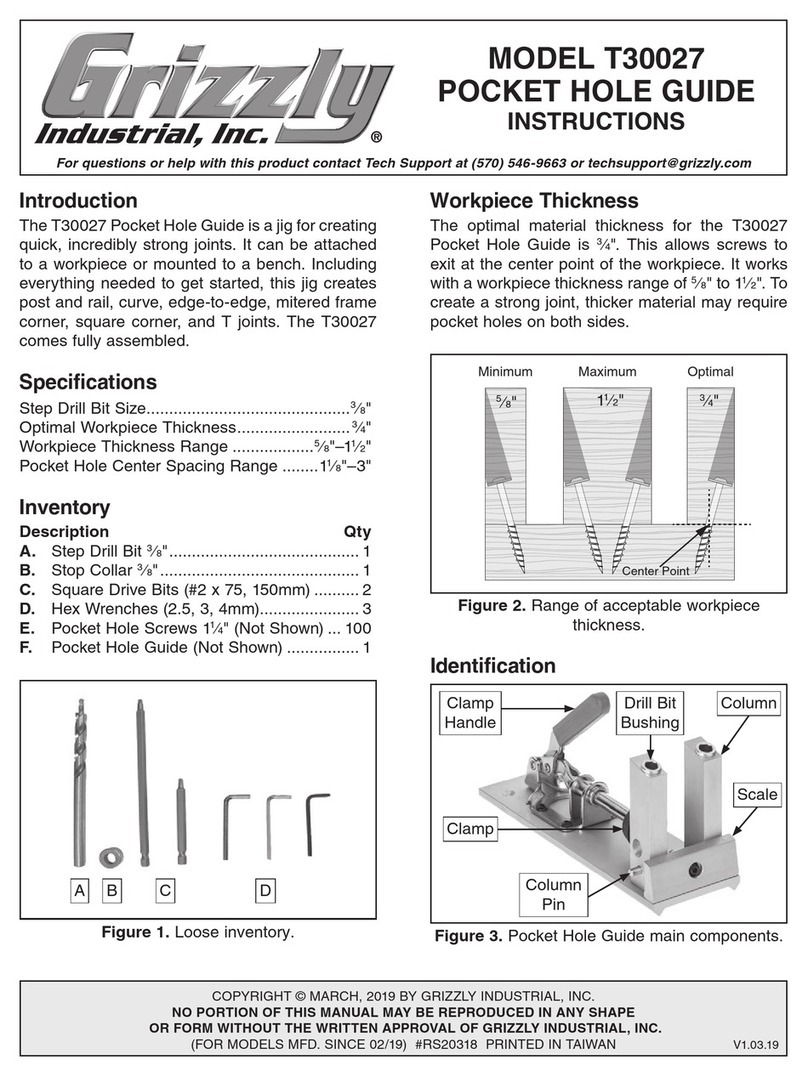

Introduction

Great for all sheet metal forming, the Model

G0497 Planishing Hammer includes an integrated

filter/regulator and lubricator, and can shape mild

steel up to 16 gauge.

Inventory

Planishing Hammer ........................................... 1

Mounting and Setup

1. With the help of an assistant, carefully uncrate

the planishing hammer.

2. Determine the most suitable location for your

planishing hammer based on the planned

usage of the machine. Larger workpieces will

require a larger space around the planishing

hammer.

3. Mount the planishing hammer to the floor

using fasteners appropriate for the floor

type.

4. Check the oil level in the lubricator. If the oil

level is low, refill with an SAE 10-weight non-

detergent, non-additive oil.

5. Install a male 1⁄4" NPT quick connector fitting

into the air inlet of the planishing hammer.

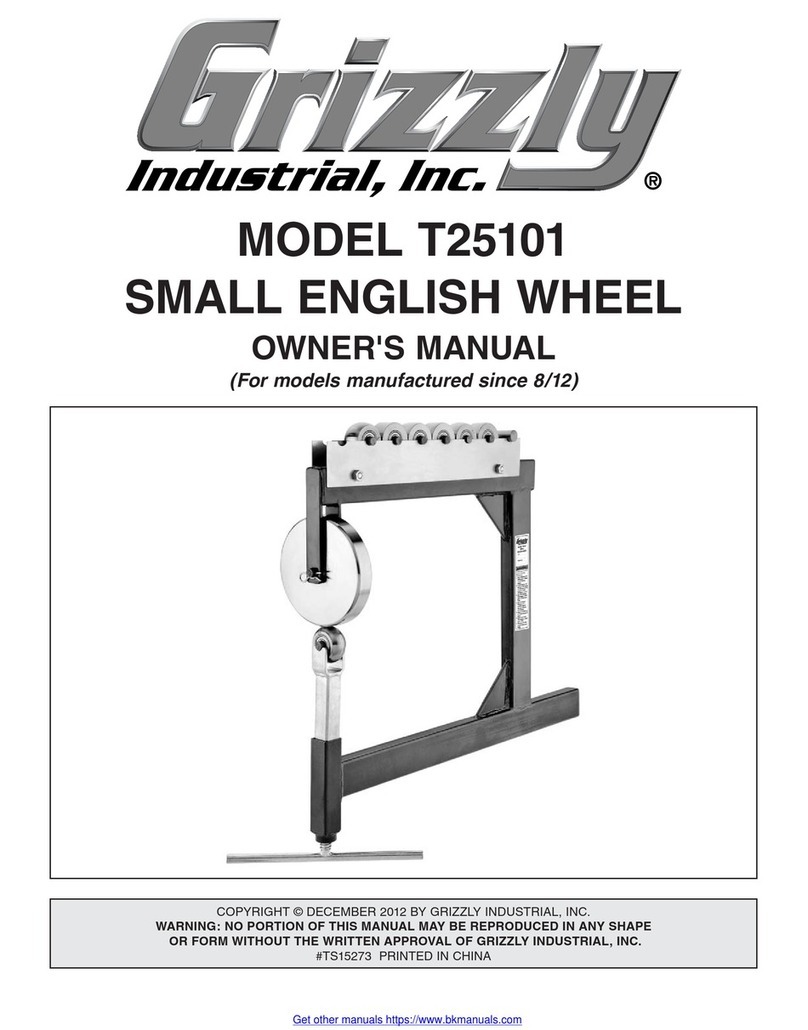

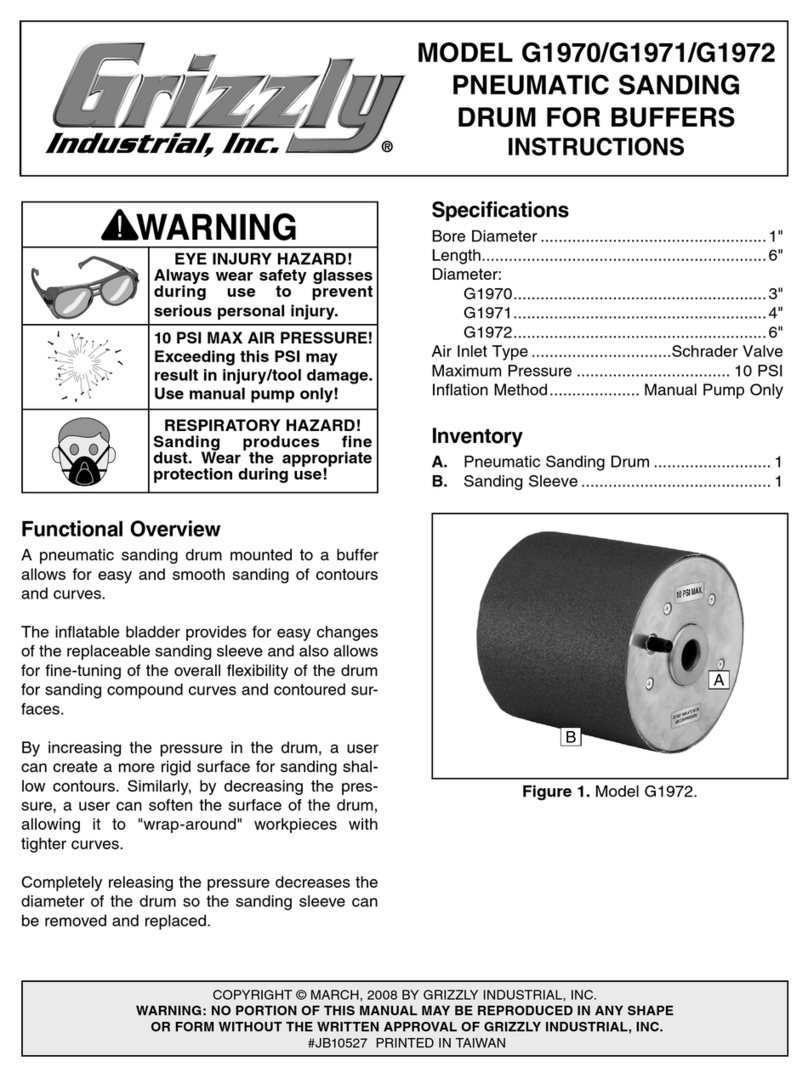

Figure 1. Model G0497 Planishing Hammer.

MODEL G0497

PLANISHING HAMMER

INSTRUCTION SHEET

This machine presents

serious injury hazards

to untrained users.

Read through this entire

instruction sheet to

become familiar with

the controls and opera-

tions before starting the

machine!

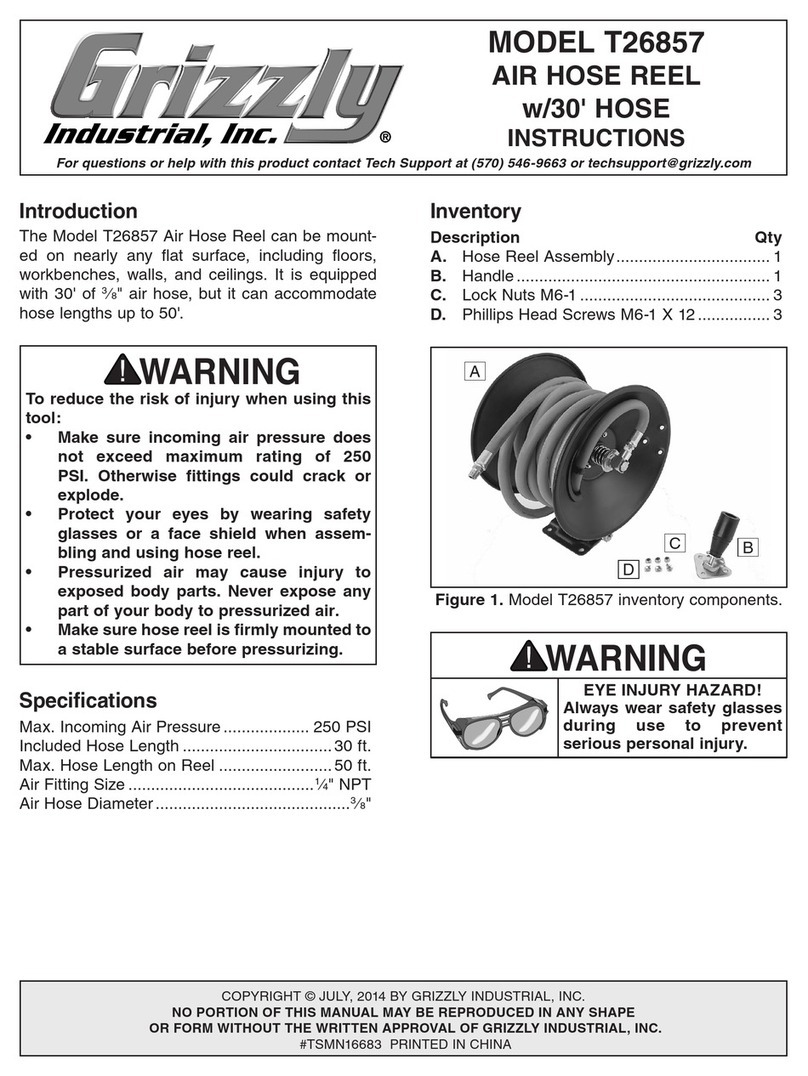

The Model G0497 has a maximum operating

pressure of 120 psi. exceeding this maxi-

mum can lead to high pressure parts failure,

which may cause serious personal injury!

INJURY HAZARD!

Disconnect tool from air and

power to prevent accidental

operation during service!

EYE/EAR INJURY HAZARD!

Wear safety glasses and

hearing protection during

use of this tool!

CRUSHING HAZARD!

Keep hands clear of hammer

mechanism at all times!

Machine Data

Control Power ...........110V, Single-Phase, 60 Hz

Blows per Minute ......................................... 4600

Air Pressure ....................................... 90-120 PSI

Air Consumption ..................................... 12 CFM

Throat ............................................................. 24"

Weight ......................................................168 lbs