MAINTENANCE

Periodically inspect the Engine Transverse Bar. Ensure

all parts move freely. To help prevent rust, wipe clean

and/or blow dry after each use. If rust appears, sand

affected area and cover with suitable utility paint. Store

the Engine Transverse Bar in a clean, dry area.

REPLACEMENT PARTS

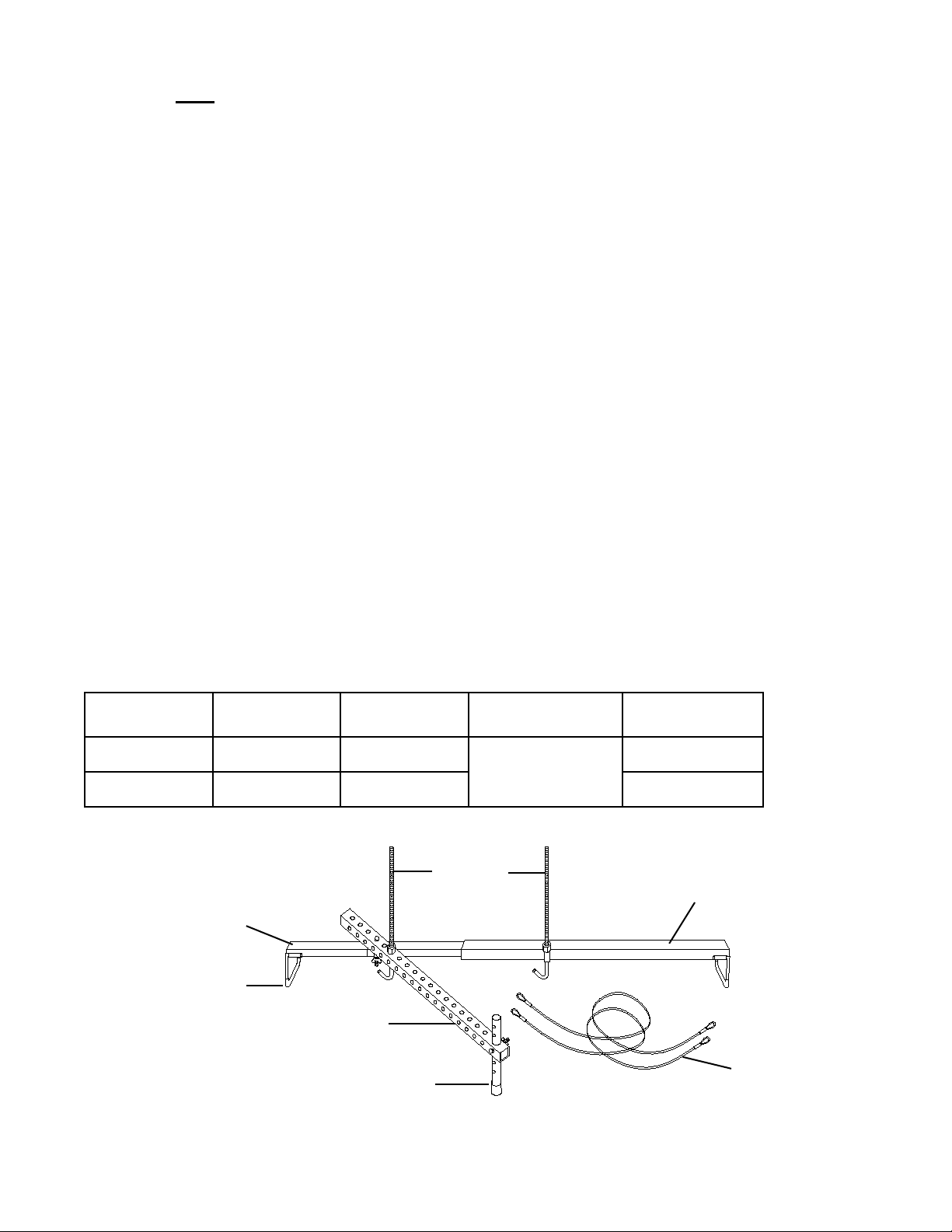

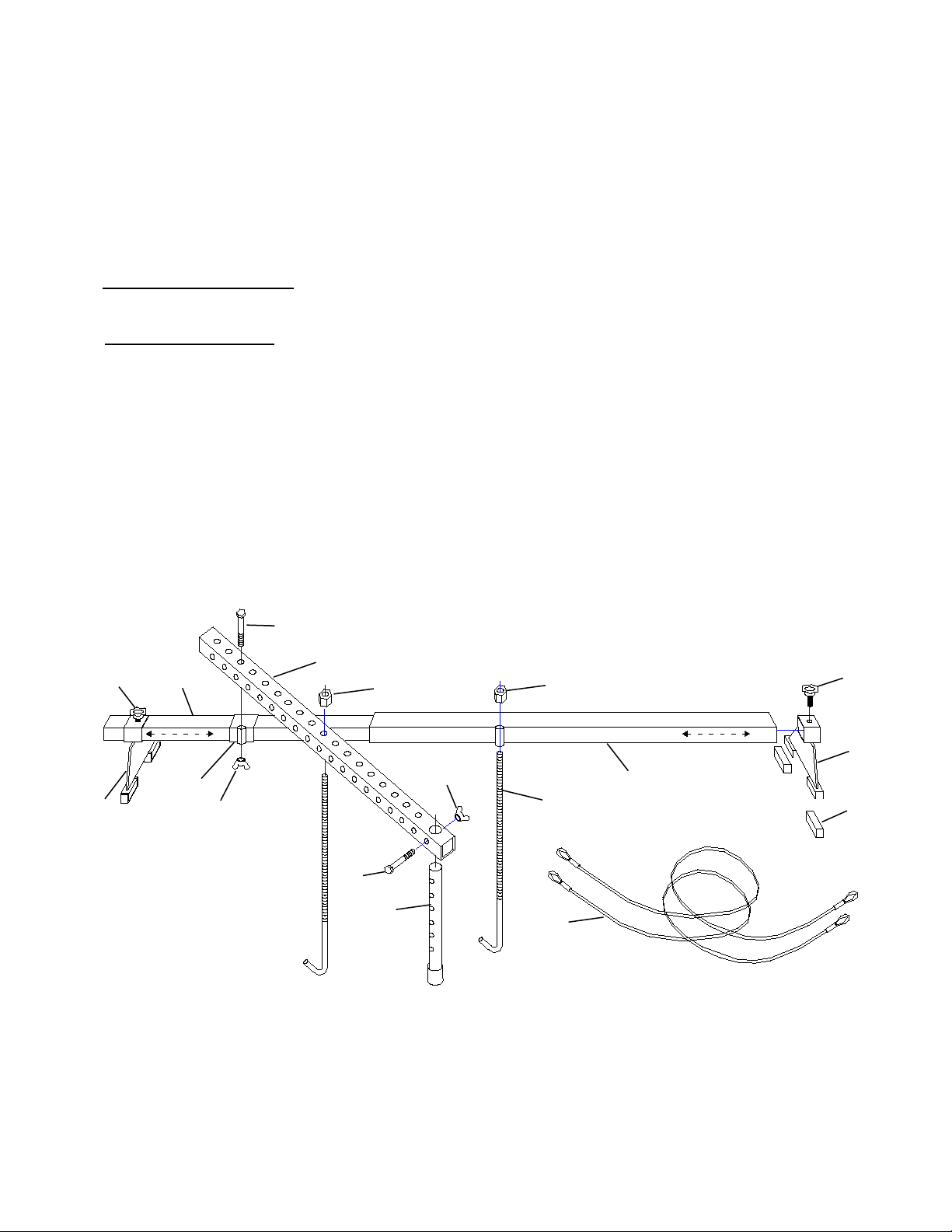

(Refer to Figure 2 & 3)

Not all components of the Engine Transverse Bar are

replacement items, but are illustrated as a convenient

reference of location and position in the assembly

sequence. When ordering parts, give part number

and description. Call or write for current pricing: SFA

Companies 10939 N. Pomona Ave. Kansas City, MO

Tel: (888)332-6419 Fax: (816)891-6599

Omega Website: http://www.omegalift.com

OPERATION

1. Determine the location of the two engine support bolts

on your vehicle. Then place the Engine transverse

bar directly over these two bolts.

2. Adjust the boom extension (#2) to ensure that both

legs (#13 & 14) are sitting inside the fender of the

engine compartment.

If the inside fender lips are more than 61" apart

apart, the Engine Transverse Bar must not be

used. Do not exceed the designated marking (61").

Over-extending could cause the Engine Support Bar

to collapse, resulting in personal injury or property

damage.

3. Adjust to ensure the support arm (#10) is in correct

position. The rubber tip of the adjustable leg (#6)

should be on a flat, reinforced surface capable of

supporting the weight of engine. Tighten both wing

nuts (#4 & 8) to secure the adjustable leg (#6) and

support arm (#10).

4. Lower the threaded hooks (#3) to appropriate position.

Ensure that the hooks are directly over the engine

support bolts or brackets; therefore the engine does

not swing when vehicle is disassembled.

5. Attach the looped ends of the two 1/8" braided

steel cables (#12) to the engine support bolts on

the engine and loop middle of braided cables over

hooks. If the engine being supported is equipped with

engine lift brackets, hook the hooks (#3) directly into

engine lift brackets for extra protection.

Note: Use only fasteners rated Grade 5 or higher as

engine support bolts.

6. Tighten the barrel hex. nuts (#7) on both hooks

until cables are snug or hex. nuts are tight against

support bar.

7. Double check that engine is properly supported

before disassemble the vehicle.

Item Part No. Description Qty

1 - Boom 1

2 - Boom Extension 1

3 * Threaded Hook 2

4 * Wing Nut, M12 1

5 * Hex. Bolt M12x120 1

6 44700-6 Adjustable Leg 1

7 * Barrel Hex. Nut 2

8 * Wing Nut, M8 1

9 * Hex. Bolt M8x65 1

10 - Support Arm 1

11 - Transfer Adapter 1

12 44700-12 Braided Steel Cable, 1/8" 2

13 - Leg, Boom 1

14 - Leg, Boom Extension 1

(*) 44700-15 Hardware Kit -

16 - Knob Screw 1

17 - Rubber Block (44100) -

- 44700-M0 Manual -

- 44700-L0 Label for 44700 -

- 44100-L0 Label for 44100 -

Parts List

(*) Hardware Kit includes item# 3, 4, 5, 7, 8 & 9

5

!

• Study, understand, and follow all instructions

provided before use.

• Do not exceed rated capacity.

• Do not exceed maximum width.

• Never crawl under the suspended load for any

reason.

• Ensure that the engine is supported securely

before repairing.

• Do not use this device for any purpose other than

that for which it is intended.

• No alterations shall be made to this product.

• Failure to heed these markings may result in

personal injury and/or property damage.

! WARNING