Infrico VBZ Ibiza User manual

VBZ Ibiza Cases

GELATO DISPLAY CASES

Service & Installation Manual

2

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

CONTENTS

1 GENERAL INFORMATION ..................................................................................................................... 3

2 SAFETY PRECAUTIONS ......................................................................................................................... 3

3 SERIAL DATA PLATE.............................................................................................................................. 3

4 RECEIVING AND INSPECTING THE EQUIPMENT .................................................................................. 4

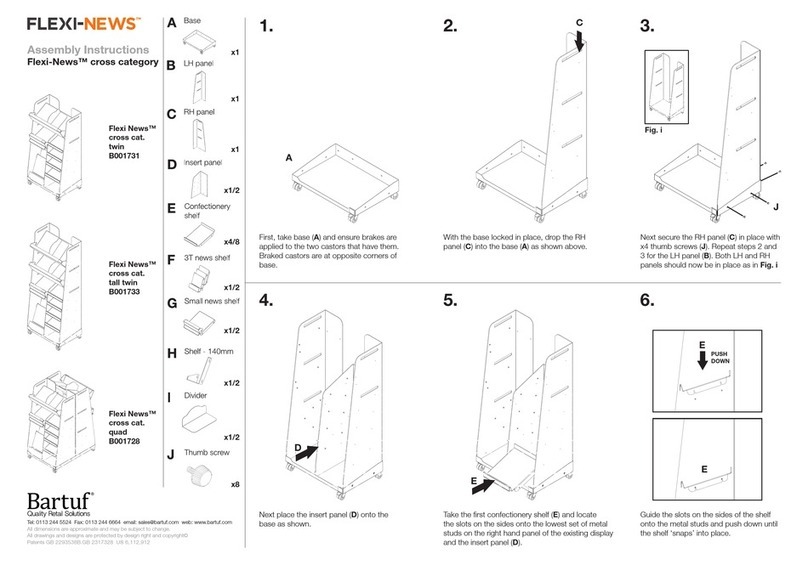

5 INSTALLATION ...................................................................................................................................... 4

5.1 Loc tion ....................................................................................................................................... 4

5.2 Uncr ting ..................................................................................................................................... 5

5.3 Ventil tion ................................................................................................................................... 5

5.4 Leveling ........................................................................................................................................ 5

5.5 Se ling C se to Floor .................................................................................................................... 6

5.6 Initi l cle ning procedure ............................................................................................................ 6

6 ELECTRICAL INSTRUCTIONS ................................................................................................................. 6

7 STARTUP PROCEDURE ......................................................................................................................... 7

8 OPERATION .......................................................................................................................................... 7

8.1 Temper ture control djustment ................................................................................................ 7

8.2 Defrost control ............................................................................................................................. 8

8.3 Lo ding product ......................................................................................................................... 10

9 MAINTENANCE, CARE AND CLEANING .............................................................................................. 10

9.1 Cle ning procedure .................................................................................................................... 10

9.2 P rts nd Service ........................................................................... Error! Marcador no definido.

10 SPECIFICATIONS ................................................................................................................................. 12

11 TROUBLE SHOOTING CHART .............................................................................................................. 12

12 WARRANTY ........................................................................................................................................ 14

12.1 Two ye r p rts & L bor w rr nty .............................................................................................. 15

12.2 W rr nty cover ge .................................................................................................................... 15

12.3 Addition l four ye r compressor p rt w rr nty ........................................................................ 15

12.4 W rr nty conditions for the supplied products ........................................................................ 16

12.5 Exclusions from nd conditions to w rr nty cover ge .............................................................. 17

12.6 Report for the client .................................................................................................................. 18

3

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

Congr tul tions on your purch se. This refriger tor h s been m nuf ctured under strict qu lity

controls nd meets the high st nd rds set by Infrico. Before shipping, e ch individu l c binet h s been

tested in order to ssure qu lity product. Furthermore, it h s been produced with recycl ble m teri ls

using n environment lly friendly process, m king n ctive contribution to the preserv tion of our

environment.

To get to know ll the benefits of your new equipment, ple se re d this instruction m nu l

c refully before inst lling.

WARNING! Use this unit only for its intended purpose as described in this manual.

When using electric l ppli nces, b sic s fety prec utions should be followed, including the

following:

•This refriger tor must be properly inst lled nd loc ted in ccord nce with this m nu l before it is

used.

•Do not llow children to climb, st nd or h ng on the shelves in the refriger tor. They could d m ge

the refriger tor nd seriously injure themselves.

•Do not touch the cold surf ces in freezer comp rtments when h nds re d mp or wet. Skin m y stick

to these extremely cold surf ces.

•Do not store or use fl mm ble products ne r the refriger tor.

•Unplug the refriger tor before cle ning nd m king rep irs.

NOTE: We strongly recommend that any servicing be performed by a qualified technician.

The seri l d t pl te is perm nently ffixed l bel which h s import nt electric l nd

refriger tion d t bout your product, s well s the model nd seri l number. This l bel is loc ted in

the interior comp rtment on ll st nd rd models.

Serial Number

1

GENERAL INFORMATION

2

SAFETY PRECAUTIONS

3

SERIAL DATA PLATE

4

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

•All Infrico products re f ctory tested for perform nce nd re free from defects when shipped.

•When your equipment rrives, you should c refully inspect the unit for d m ge during delivery.

•If d m ge is detected, you should s ve ll the cr ting m teri l nd m ke note on the c rrier's bill of

l ding describing the d m ge. A freight cl im should be filled immedi tely.

•If d m ge is subsequently noted during or immedi tely fter inst ll tion, cont ct our customer c re

service.

NOTE: Infrico is not responsible for damage incurred during shipment.

This unit is intended for indoor use only.

Be sure the loc tion chosen for your unit must be ble to provide good ir circul tion for most

efficient refriger tion.

Avoid loc tions ne r he t sources such s stoves, ovens, fryers, nd lso direct sunlight where

temper tures c n re ch extreme v lues. Besides, do not select loc tion in n re where

temper tures m y drop below 55ºF or incre se more th n 80ºF nd 55% Rh.

Front l tempered gl ss hinged in str ight

gl ss series. Tilt forw rd gl ss system.

You should llow enough cle r nce between the unit nd the front l opening gl ss in order to

m ke use of the st y open fe ture of doors t 120º. This front opening gl ss f cilit tes n e sy ccess

nd cle ning.

4

RECEIVING AND INSPECTING THE EQUIPMENT

5

INSTALLATION

5.1

Location

5

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

Furthermore, the floor t the fin l loc tion must be strong enough to support the tot l weight

of the c binet plus the m ximum product lo d. Also, it must be level nd free of vibr tion. Reinforce the

floor if necess ry.

These Infrico units re shipped from the f ctory on wooden p llet nd p ck ged in wooden

cont iner. The wooden is tt ched to the wooden b se with the use of l rge st ples. These should be

first removed to void scr tching the unit when lifting off the cr te.

All p ck ging m teri ls used re environment lly friendly nd m y be recycled or reused.

Actively contribute to the protection of the environment by insisting on p ck ging recovery nd remov l

methods th t re environment lly friendly.

NOTE: Infrico does not recommend laying the unit down on its front, side or back. However,

you must be certain to allow the unit to remain in an upright position afterwards for at least 24 hours

before plugging it in so that the compressor oil and refrigerant may settle.

To ssure m ximum oper ting efficiency, the equipment should be loc ted where continuous

ir supply c n circul te underne th nd behind the c binet.

Restricting the ir supply will gener te n excessive he t lo d on the condensing unit nd

dversely ffect its oper ting efficiency. Do not t ny time obstruct the grill re in the front of the

c binet in ny w y.

NOTE: Any restriction of the proper air flow, total or partial, will avoid the warranty on the

unit.

It is extremely import nt th t the c binet is perfectly level for proper oper tion so th t the

dr in p n will dr in properly, the doors will line up with the fr mes nd the unit will not be subject to

undue str in.

In VBZ, we inst ll feet djust ble from f ctory. You c n djust these feet s you wish.

5.2

Uncrating

5.3

Ventilation

5.4

Leveling

6

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

To m int in NSF S nit tion listing c ses must h ve se led to the floor.

Use NSF se l nt such s silicone or equiv lent cove mouldings or tiles re ccept ble.

Do not block ny louvered holes.

Before st rting-up nd pl cing ny food inside the c binet, firstly remove

the protective film nd then cle n the complete unit thoroughly. If ny

dhesive rem ins, elimin te it with lcohol. W shing with mild so p

nd w rm w ter solution is recommended for cle ning ll the st inless

steel surf ces of your c binet. This should be followed by cle ning with

b king sod solution. Rinse thoroughly with cle r w ter nd dry with

cle n, soft cloth.

NOTE: Never use abrasive or harsh cleaners, concentrated detergents, solvents or chemicals

when cleaning the unit.

The supply volt ge should be checked before connection to ssure th t proper volt ge for the

c binet wiring is v il ble. To determine correct unit volt ge, ple se refer to the seri l d t pl te

loc ted on n inner w ll of the unit. Verify th t this inform tion ex ctly m tches the electric l

ch r cteristics t the inst ll tion loc tion.

NOTE: Infrico requires that a sole use circuit be dedicated for the unit. Failure to do so voids

warranty.

NOTE: The unit is designed to operate with a voltage fluctuation of 5% of the voltage indicated

on the cabinet serial data plate. Burnout of the compressor due to exceeding the high or low

voltage limits will automatically void the factory warranty.

Units re provided with U.L. pproved power cord nd plug which is f ctory inst lled. Infrico

uses for VBZ c ses NEMA 5-15P plugs. If you do not h ve the right outlet h ve certified electrici n

inst ll the correct power source:

5.5

Sealing Case to Floor

5.6

Initial cleaning procedure

6

ELECTRICAL INSTRUCTIONS

115 / 60 / 1 NEMA 5-15P

7

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

WARNING: Any alterations to this cord and plug could cause an electrical hazard and will void

the factory warranty. Furthermore, never use an adapter plug.

WARNING: Infrico will not warranty any units that are connected to an extension cord.

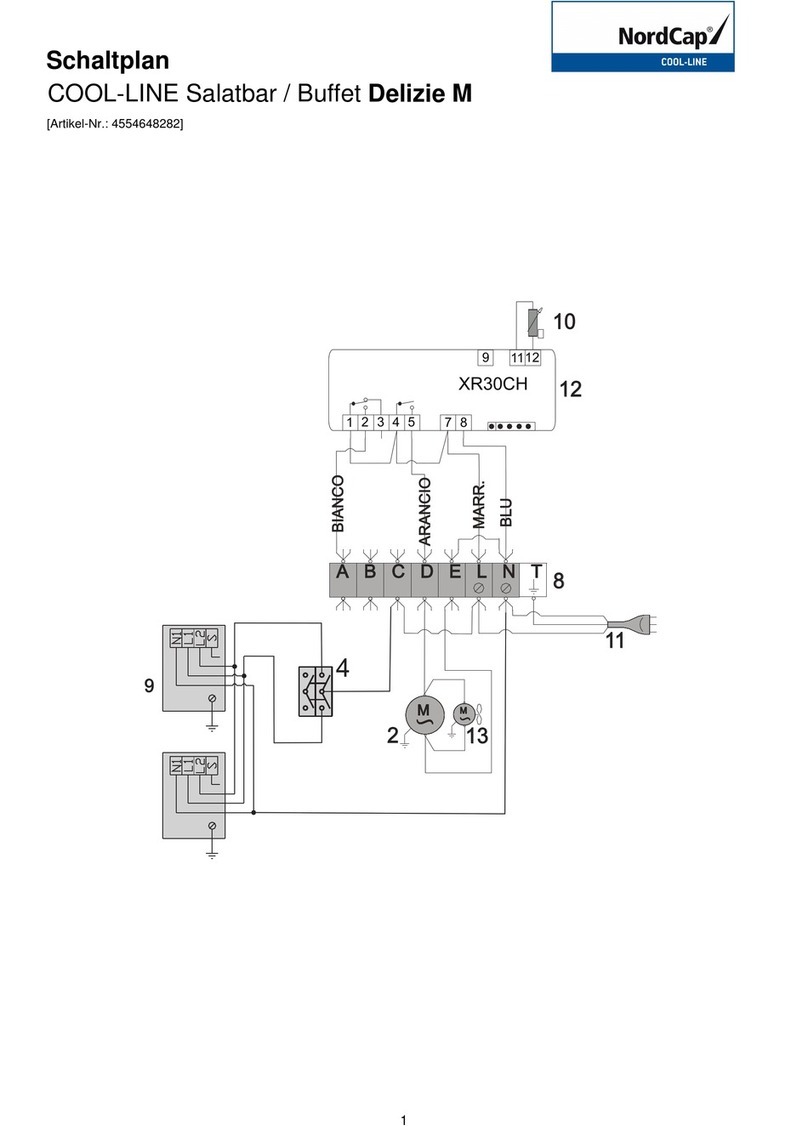

The wiring di gr m of the purch sed model will be provided tt ched to this m nu l s well s other

useful documents.

After the c binet h s been inst lled, levelled, cle ned nd electric lly connected in ccord nce

with this m nu l, it is re dy to oper te. Simply plug the unit in to begin oper tion.

The system should run smoothly nd quietly in ccord nce with gener lly ccepted commerci l

st nd rds. If ny unusu l noises re he rd, turn the unit off immedi tely nd check for ny obstructions

of the f ns.

All c binets must be given enough time to re ch norm l oper ting temper ture before pl cing

ny food inside c binet or p ns (if equipped). Continuous opening nd closing of the doors will h mper

the unit's bility to m int in optimum refriger tion perform nce.

NOTE: Before loading product, we recommend to run the unit empty during 24 hours.

During pull-down of open top models, p ns should be in pl ce nd top lid should be kept

closed.

NOTE: If the refrigerator is disconnected or shut off, wait five minutes before starting again.

To st rtup of the equipment nd lso to the control of the temper ture, the m chine th t you

h ve purch sed is equipped by digit l controller.

7

STARTUP PROCEDURE

8

OPERATION

8.1

Temperature control adjustment

8

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

The temper ture is set t the f ctory but loc l conditions m y need slight djustment.

: This turns the condensing unit nd lights off. There is still power to the controller.

: for displ ying or modifying the set point. When displ ying the m ximum nd minimum

temper ture, these c n be deleted by keeping the button pressed for 3 second.

This displ ys the m ximum stored temper ture; in progr mming mode nd “Function

Menu” mode it is used to look through the p r meter codes or incre se the v lue of the v ri ble in use.

This displ ys the minimum stored temper ture; in progr mming mode nd

“Function Menu” mode it is used to look through the p r meter codes or decre se the v lue of the

v ri ble in use.

: This turns the light on nd off.

Note: while in the OFF st tus, the light button is ctive.

VBZ ice-cre m c ses re designed nd f ctory set to m int in n ver ge c binet temper ture

of 2/6ºF.

Import nt: Recommend to switch off the ice-cre m c ses t night (during non-working hours).

This equipment is designed to conserve ice cre ms during the exhibition nd s le hours, thereby we

prevent ny potenti l block ge or products le ks s well s consuming n excess of energy.

The defrost timer is present for defrost period by temper ture.

Ice Cre m c ses, VBZ, h ve hot g s defrost system which works by routing superhe ted

compressor disch rge g s directly to the ev por tor, voiding ny ccumul tion of frost.

8.2

Defrost control

9

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

After every cycle, the w ter gener ted is routed to p n on the re r of the unit nd is

ev por ted by the he t given off by the compressor except to VBZ where this p n must be removed

m nu lly.

The defrost timer is loc ted on the condensing unit, in the b ck of the c binet.

Starting a Manual Defrost Cycle

If m nu l defrost is required, you m y push the DEF key for more th n 2 seconds nd m nu l

defrost will st rt.

Adjusting Interval between Defrost Cycles (IdF)

The defrost cycles re performed periodic lly t n interv l of: Ice Cre m c ses (VBZ) = 5h. This

interv l st rts being counted from the end of the previous count. The dur tion of the defrost therefore

does not ffect then the interv l between defrost cycles. The p r meter th t controls the interv l

between defrosts cycles is:

IdF: Determines the time interval between the beginning of two defrost cycles.

To djust this p r meter, you m y follow the next instruction:

1. Enter the Progr mming mode by pressing the SET + DOWN keys for 3s (the “°C” or “°F” LED

st rts blinking).

2. Select the required p r meter: IdF. Press the SET key to displ y its v lue

3. Use UP or DOWN to ch nge its v lue.

4. Press SET to store the new v lue.

To exit: Press SET + UP or w it 15s without pressing key.

NOTE: the set v lue is stored even when the procedure is exited by w iting the time-out to expire.

Important: To ensure regul r defrosts, the interv l between defrost cycles must be gre ter th n the

m ximum defrost dur tion, plus the dripping time nd post-dripping time.

Adjusting the Maximum Defrost Duration (MdF)

This p r meter determines the m ximum defrost dur tion on the ev por tor in minutes if

defrost by temper ture is selected. If timed defrost h s been selected, this represents the ctu l

dur tion of the defrost selected. You m y follow the l st instruction, but the p r meter th t h s to be

ch nged in this c se is "MdF". The def ult v lue is: Ice Cre m c ses (VBZ) = 15 minutes.

DEF key

DOWN key

UP

key

1

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

These models defrost with every cycle of the compressor. The w ter gener ted is routed to

p n on the re r of the unit nd is ev por ted by the he t given off by the compressor.

Important: If the thermost t is set too cold, the compressor will be running continuously nd the

ev por tor will become blocked by ice.

•Before introducing food into the c binet, it is dvis ble to le ve it empty while in oper tion until it

re ches the working temper ture. Once this h s been re ched, you c n proceed to lo d the

equipment.

•When introducing food, enough sp ce must be left between the goods to en ble ir circul tion.

•Never llow the goods to prevent doors from closing.

•Do not exceed the m ximum weight per shelf of 55 lb.

•Do not obstruct the f n with the lo d nd ssure th t this never exceeds the m ximum lo d level

determined. The lo d must therefore lw ys be situ ted underne th the f n.

•Never put hot food in the c binet.

•Do not le ve food inside the unit when it is going to rem in shut down either from power out ge or

f ult in the equipment.

•If the c binet is going to rem in shut down for prolonged periods, try to le ve it unplugged, empty,

cle n nd with door j r.

•Food or drinks m y be well wr pped or enclosed in irtight cont iners to void odours inside the unit.

•Remove gel to products every night nd store them inside regul r freezer, to llow proper defrost

cycle nd cle ning on the equipment.

Cleaning the cabinet

To cle n the c binet, the following instruction should be followed:

•Disconnect the unit from the power supply nd remove ll food product from inside.

•Open ll doors nd llow the c binet to re ch room temper ture. Remove ll ccessories nd cle n

them with b king sod or mild so p nd w rm w ter solution. Dry ll the ccessories completely

with soft cle n cloth.

•Once the c binet h s re ch room temper ture, w sh the entire c binet inside nd out with b king

sod or mild so p nd w rm w ter solution. Rinse thoroughly with cle r w ter nd dry with soft

8.3

Loading product

9

MAINTENANCE, CARE AND CLEANING

9.1

Cleaning procedure

11

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

cle n cloth. F ilure to dry ll surf ce completely m y c use w ter st ins. There re lso st inless steel

cle ners v il ble which c n restore nd preserve the finish of the steels protective l yer.

•Return ll ccessories to their initi l positions nd plug the unit in.

•E rly signs of st inless steel bre kdown c n consist of sm ll pits nd cr cks. If this h s begun, st r to

pply st inless steel cle ners in order to restore the p ssivity of the steel.

•M ny product foods h ve n cidic content which c n tt ck st inless steel, such s must rd,

m yonn ise, lemon juice, tom toes nd other veget bles.

NOTE: Never use steel pads, wire brushes or scrapers to clean the cabinet.

NOTE: Cleaning solutions need to be alkaline based or non-chloride cleaners. Any cleaner

containing chlorides will damage the protective film of the stainless steel.

Cleaning the condenser coil

The condenser coil, which is loc ted directly behind the re r p nel grill, must be checked

periodic lly. The frequency of cle ning depends on the oper ting environment. Air must be ble to

freely circul te through the condenser, so the surf ce of the condenser must be kept free of dirt nd

gre se for proper system oper tion. Dirty condensers result in compressor f ilure nd product loss. If

the condenser coil is dirty or blocked, follow this instruction:

•Disconnect the power supply

•Remove the lower grill on the re r of the c binet

•In some models, it will be necess ry to remove screws nchoring condensing unit to

fr me r ils nd c refully slide out.

•If the condenser h s housing cover, its screws must be removed.

•C refully cle n dirt from the condenser using v cuum cle ner of soft brush; never use wire brush.

•He vier dust build up m y require compressed ir to blow through the condenser coil.

•Repl ce the condenser cover, slide condensing unit b ck into position nd tighten ll screws.

•Fin lly, repl ce the lower re r p nel nd reconnect electric l power supply.

WARNING: Never use water for this cleaning procedure as water can damage the electrical

components located near or at the condenser coil.

Doors/Hinges Maintenance

Over time nd with he vy use doors the hinges m y become loose. If it is noticed th t the door

is beginning to s g, it m y become necess ry to tighten the screws th t mount the hinge br ckets to the

fr me of the unit.

12

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

Drain Maintenance

E ch unit h s dr in loc ted inside the unit which removes the condens tion from the

ev por tor coil nd ev por tes it t n extern l condens te p n. If you notice excessive w ter

ccumul tion on the inside of the unit be sure the dr in tube is connected from the ev por tor housing

to the condens te ev por tor dr in p n.

If w ter is collected underne th the unit you m y w nt to check the condens te ev por tor

dr in tube to be sure it is still loc ted inside the dr in p n.

Be sure ll dr in lines re free of obstructions; typic lly, food product is found blocking dr in

lines c using w ter to b ck up nd overflow the dr in p ns.

M ny oper ting problems re derived from c uses th t c n be e sily elimin ted without the

need to cont ct the Technic l Dep rtment. The following p ge shows t ble with types of problems

th t m y come up, their c use, nd how to resolve them.

PROBLEM POSSIBLE SOLUTION

Compressor will not st rt-no

hum.

1.- Disconnect switch open.

2.- Blown fuse.

3.- Defective wiring.

4.- Overlo d protector tripped.

5.- Open control cont cts (control m y be defective, or unit loc tion

m y be too cold).

6.- Defective overlo d protector.

7.- Low ch rge of freon-check for le ks.

Compressor will not st rt-no

hums but cycles on overlo d.

1.- Low volt ge.

2.- Unit wired incorrectly.

3.- St rting c p citor defective.

4.- St rting c p citor se l.

5.- Compressor motor defective.

6.- High he d pressure.

7.- Be ring of pistons tight-low oil ch rge.

10

TROUBLE SHOOTING CHART

13

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

PROBLEM POSSIBLE SOLUTION

Compressors st rt, but st rting

rem ins in circuit.

1.- Low volt ge.

2.- Unit wired incorrectly.

3.- St rting c p citor se l.

4.- Running c p citor defective.

5.- St rting rel y defective.

6.- High he d pressure.

7.- Be rings of pistons tight-low oil ch rge.

Compressor st rts nd runs,

but cycles on overlo d

1.- Low volt ge.

2.- Running c p citor defective.

3.- Overlo d protector defective.

4.- High he d pressure.

5.- F n motor, pump, etc… , wire to wrong of overlo d protector.

Compressor tries to st rt when

thermost t closes but cuts out

on overlo d, st rt fter sever l

ttempts.

1.- Low volt ge.

2.- St rt c p citor defective.

3.- Overlo d protector defective.

4.- High he d pressure.

5.- F n motor, pump, etc… , wire to wrong of overlo d protector.

Compressor st rts but

immedi tely cuts out on

overlo d

1.- St rting rel y cont cts points welded together.

2.- St rting c p citor defective.

3.- Compressor short cycles.

St rting rel y burns out.

1.- Low volt ge.

2.- High volt ge.

3.- Compressors short cycles.

4.- Incorrect running c p citor.

5.- Incorrect rel y.

Running c p citors burn out. 1.- Line volt ge too high.

He d pressure to low

1.- Insufficient refriger nt ch rge.

2.- Le k in the system.

3.- Cold loc tion.

He d pressure to high

1.- Unit overch rged.

2.- Air or other non-condens ble g ses in system.

3.- Clogged condenser ( ir-cooled)

4.- Defective condenser f n motor.

5.- Unit loc tion too hot.

6.- Restriction in exp nsion v lve, str iner or drier.

7.- Disch rge v lve p rti lly closed.

8.- Restriction in disch rge line.

14

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

PROBLEM

POSSIBLE SOLUTION

Compressor short cycles

1.- Control differenti l set too close.

2.- Refriger nt underch rge, check pressure control.

3.- Refriger nt overch rge.

4.- Disch rge v lve le king.

5.- Cutting out on high pressure control, if used.

6.- Cutting out on overlo d protector bec use if tight be rings struck

piston, high he d pressure or restricted ir cooled condenser.

Running cycles too long, or

unit oper tes continuously

1.- Insufficient refriger nt ch rge.

2.- Dirty or restricted condenser.

3.- Unit loc tion too hot.

4.- Control cont cts stuck.

5.- Air or other non-condens ble g ses in system.

6.- Exp nsion v lve plugged or defective.

7.- Fixture doors left open too long.

8.- Insufficient, defective or w ter logged insul tion.

9.- Ev por ted oil logged.

Noisy unit

1.- Compressor oil ch rge low.

2.- F n c ble on condenser or ev por tor bent c using vibr tions.

3.- Be ring on ev por tor or condenser motors lose or worn.

4.- Tube r ttles.

5.- Lose p rts on condensing unit.

6.- C se is not level.

De r user:

You must receive the w rr nty certific te duly filled out within m ximum period of 20 d ys

from the purch se d te so th t the equipment you h ve just purch sed m y benefit from the w rr nty

specified in this document. Otherwise, this w rr nty m nuf ctures d te.

It is very import nt th t you re d the tt ched document tion c refully so th t you h ve full

knowledge of the use nd c re pplic ble to your equipment. This being the c se, we re sure th t you

will be completely s tisfied with its oper tion.

11

WARRANTY

15

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

Infrico USA, Corp. (“Infrico”) w rr nts to the origin l customer th t the Infrico br nd equipment

sold hereunder, except for p rts nd ccessories which c rry the w rr nty of supplier (the

“Equipment”) will be free from defects in m teri l nd f ctory workm nship under norm l conditions of

use nd m inten nce for period of (2) two ye rs from the D te of Inst ll tion (W rr nty

Commencement D te), but in no event to exceed (27) months from the D te of Shipment. W rr nty is

Not Tr nsfer ble.

If there is defect in m teri l or f ctory workm nship covered by this W rr nty reported to

Infrico during the period the pplic ble W rr nty is in force nd effect, Infrico will rep ir or repl ce, t

Infrico’s option, th t p rt of the Equipment th t h s become defective. Infrico will cover l bor cost

within (2) ye rs from the W rr nty Commencement d te or (27) months from shipment d te, whichever

occurs first. Infrico sh ll be r ll l bor costs in connection with the inst ll tion of these repl cement

p rts, provided th t, the inst ll tion is conducted by Infrico or its uthorized represent tive. Ch rges for

w rr nty tr vel time not to exceed (2) hours or up to (100) miles tot l. Any ch rges exceeding those

st ted herein must h ve prior uthoriz tion by Infrico.

In ddition to the w rr nty set bove. Infrico w rr nts the hermetic lly nd semi-hermetic lly

se led compressor (p rt only) for n ddition l four (4) ye rs b sed on the inst ll tion d te. This

w rr nty is for defects both in workm nship nd m teri l under the norm l nd proper use nd

m inten nce service. The four (4) ye rs extended w rr nty only pplies to hermetic lly nd semi-

hermetic lly se led p rts of the compressor nd does not pply to ny other p rt or component,

including, but no limited to c binet, temper ture control, refriger nt, motor st rting equipment, f n

ssembly, or ny other electric l or mech nic l component.

P rts W rr nty Cover ge: Infrico w rr nts ll new c se p rts produced or uthorized by Infrico

to be free from defects in m teri l nd workm nship for period of (90) d ys from the W rr nty

Commencement D te. If ny defect in m teri l nd workm nship is found to exist within the w rr nty

period, Infrico will repl ce the defective p rt without ch rge. Defective p rts become the property of

Infrico.

Infrico will h ve no responsibility to honour cl ims received fter the d te the pplic ble

W rr nty expires. Notwithst nding the foregoing, ny cl im with reference to the Equipment or ny

p rts therefore for ny c use sh ll be deemed w ived unless submitted by the User to Infrico within (30)

11.1

Two year parts & Labor warranty

11.2

Warranty coverage

11.3

Additional four year compressor part warranty

16

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

d ys fter the d te the User discovered, or should h ve discovered, the cl im. In connection with ll

cl ims under this W rr nty, Infrico will h ve the right, t its own expense, to h ve its represent tives

inspect the Equipment t the User’s premises nd to request ll of User’s records pert ining to the

Equipment to determine whether defect exists, whether the conditions set forth in this W rr nty h ve

been s tisfied, nd whether or not the pplic ble W rr nty is in effect.

1. The m nuf cturer gu r ntees the product nd undert kes to rectify, t no ch rge, ny defects

observed due to f ults or defects in the m teri ls or production.

2. All products th t h ve been modified nd/or components subject to n tur l we r nd te r, s well s

defects resulting from non-compli nce with the instructions for use, inst ll tion, or oper tion, or from

uses not in keeping with the intended use of the product, from bnorm l environment l f ctors, from

unusu l oper ting conditions, from overlo d, from in dequ te cle ning or m inten nce, or from those

defects resulting from rep irs or h ndling c rried out by un uthorised Services, or those c used by the

use of ccessories or sp re p rts not design ted by the m nuf cturer, re excluded from the gu r ntee.

3. Users must dhere to the indic tions described in the instructions m nu l when st rting up or storing

the pp r tus.

4. If the pp r tus is not functioning correctly, users must m ke the checks indic ted in the m nu l nd,

if the problem persists, cont ct their distributor. This certific te must be presented if it is necess ry for

the technic l dep rtment to intervene.

5. This gu r ntee exclusively pert ins to the repl cement of the f ulty m teri l, nd under no

circumst nces m y n exch nge for nother pp r tus or n incre se in the gu r ntee period be

dem nded. The repl ced m teri l th t is under gu r ntee will rem in on site for ex min tion, with the

purch ser be ring the costs of inst ll tion or repl cement.

6. The return of ny pp r tus due to m nuf cturing defects or f ults MUST BE PREVIOUSLY

AUTHORISED. Otherwise, there will be no ch rge under ny circumst nces for ny costs nd risks th t

m y be derived from this process. Any pp r tus th t h s been uthorised for return by the

m nuf cturer must be submitted with p ck ging the s me s or simil r to th t which w s used for the

product when it w s received.

7. Nobody is uthorised to m ke ny other concessions or ccept on beh lf of the m nuf cturer ny

commitment th t does not comply with this gu r ntee.

8. If this gu r ntee certific te is lost or misl id, you must h ve express knowledge of it.

9. Any tr velling, food, nd workforce expenses of the technic l dep rtment c rrying out the rep irs,

including during the gu r ntee period of the pp r tus, re not covered.

10. The time t ken to rep ir the pp r tus sh ll not constitute motive for the purch ser to seek

compens tion of ny kind or extend the gu r ntee period.

11.4

Warranty conditions for the supplied products

17

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

11. This gu r ntee sh ll be inv lid ted in the c se of f ults produced s result of force m jeure

(we ther nd geologic l phenomen , fires, etc.) or those derived from improper or non-compli nt

inst ll tion of the pp r tus (connection volt ge, power supply fluctu tions, electric l connection not

conforming to instructions, etc.) or from m nipul tion of the n mepl te or of the d t included in this

certific te.

This W rr nty does not cover p rts or ccessories, which ( ) c rry the w rr nty of supplier or

(b) re, bused.

11.5

Exclusions from and conditions to warranty coverage

18

Revisión

: 0

5

Ref.:

MANU_

VBZ

16/02/2017

Ple se, complete the following report.

User: ___________________________________________________________

Address:_____________________________________ Tel:________________

Town / City St te:__________________________________________________

Distributor:_______________________________________________________

Purch se d te:____________________________________________________

Model:_________________________ Seri l No:_________________________

Compressor No: __________________________

Vendor Sign ture Purch ser Sign ture

R

E

T

U

R

N

T

O

T

H

E

M

A

N

U

F

A

C

T

U

R

E

R

User: ___________________________________________________________

Address:_____________________________________ Tel:________________

Town / City St te:__________________________________________________

Distributor:_______________________________________________________

Purch se d te:____________________________________________________

Model:_________________________ Seri l No:_________________________

Compressor No: __________________________

Vendor Sign ture Purch ser Sign ture

F

O

R

T

H

E

C

L

I

E

N

T

11.6

Report for the client

Infrico SL.

CR CO-762 Los Piedros-L s N v s s/n

14900 Lucen (Córdob ) Esp ñ

00 34 957 59 51 16 office

00 34 957 59 51 06 f x

sistenci tecnic @infrico.com

www.infrico.com

Table of contents

Popular Display Case manuals by other brands

DOCRILUC

DOCRILUC BMR-150 User and maintenance manual

Omcan

Omcan RS-CN-0120-4 instruction manual

Diamond

Diamond IN/VTAF15 Installation, operating and maintenance manual

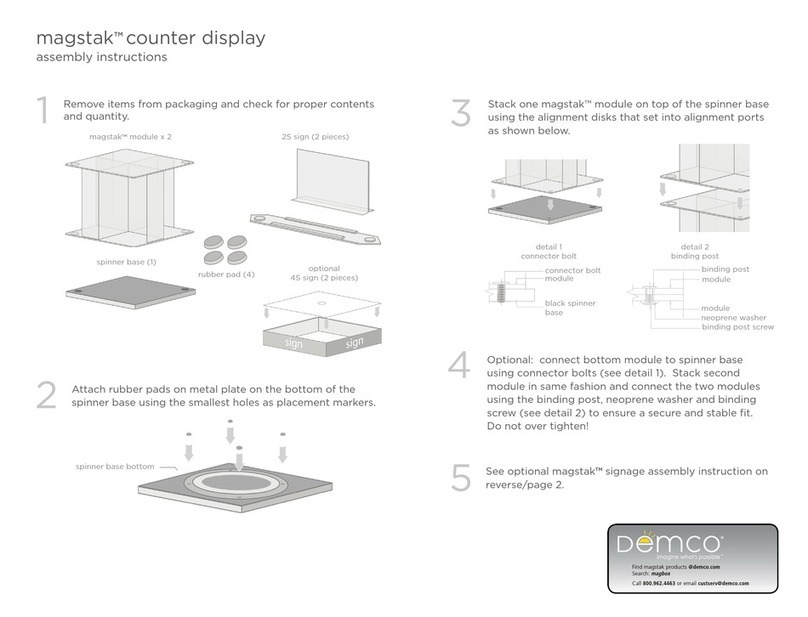

Demco

Demco magstak Assembly instructions

Fri-Jado

Fri-Jado 36-2-C SS user manual

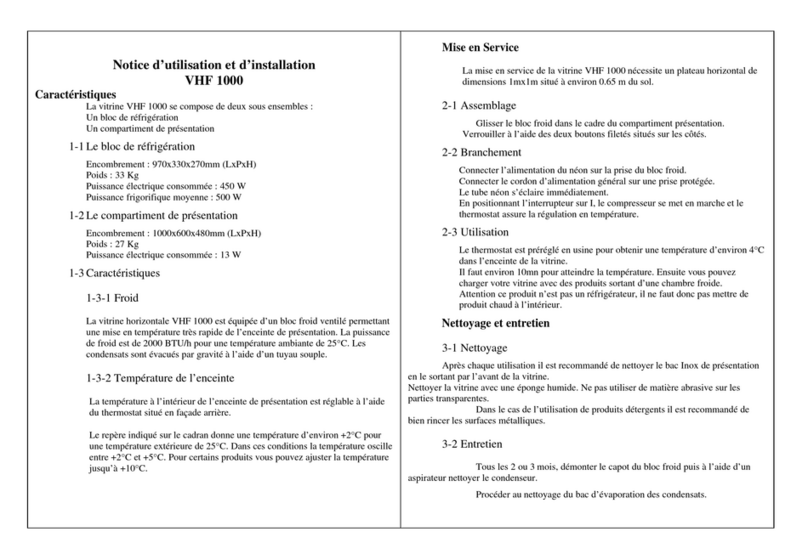

Roller Grill

Roller Grill VHF 1000 Use and installation manual