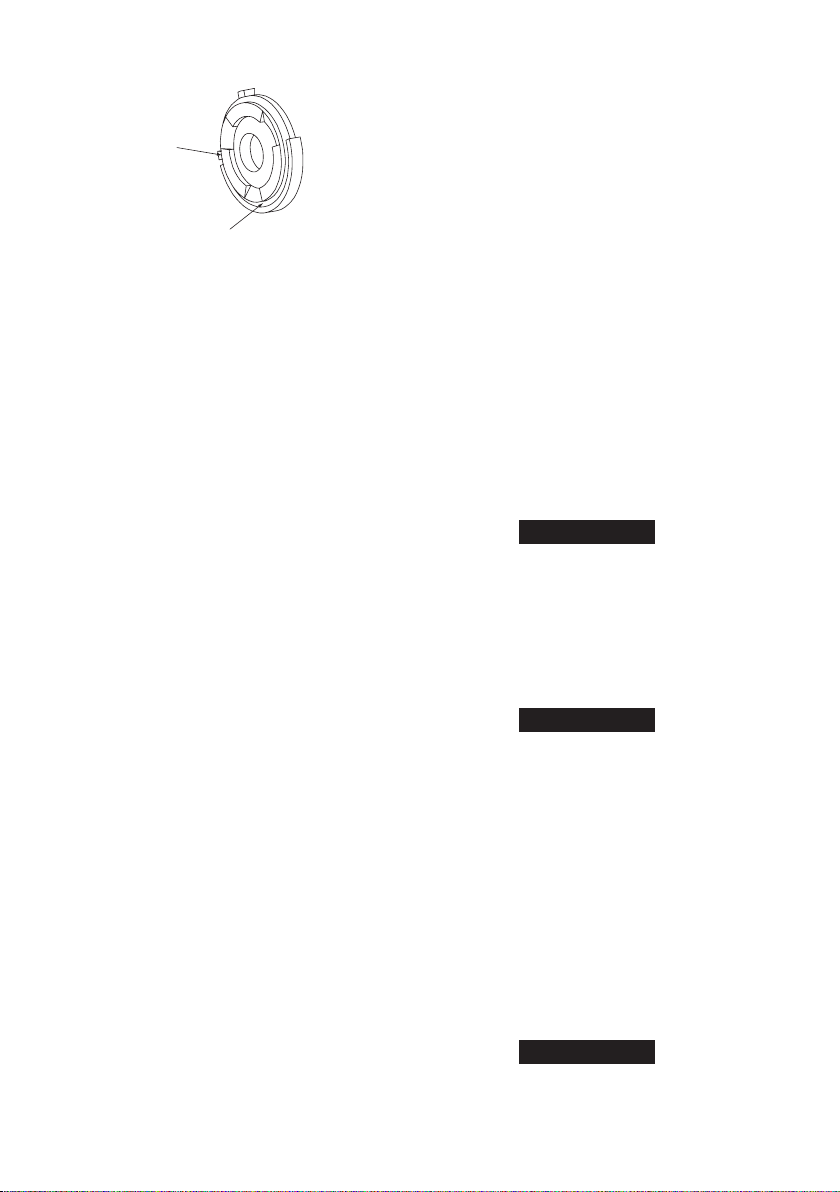

Glue points for 61H-A11 End Plate Assembly

Apply Adhesives

at the indicated

places

(Dwg. TPD1083)

3. Place the Front End Plate Seal (26) on the end plate hub and

lightly press the Seal against the adhesive at the four contact

points to bond the Seal to the End Plate.

4. Install the End Plate Assembly, Seal end trailing, over the shaft of

the Rotor.

5. Using nger pressure, press the Seal Cup Assembly (28), felt end

trailing, onto the Rotor Spacer (27) until the felt seal cup is ush

with one end of the Spacer. Impregnate the felt with

Ingersoll Rand No. 50 Oil.

6.

Install the Spacer, Seal Cup trailing, over the shaft of the Rotor.

Make certain the Spacer enters the central opening of the Front End

Plate and the Seal Cup Assembly enters the recess in the End Plate.

7. Install the Front Rotor Bearing, red stained end trailing, over the

shaft of the Rotor.

8.

If the Bearing Nut Retainers (32) were removed from the Bearing

Nut Assembly (31), use snap ring pliers to install the Retainers on

the Nuts.

9.

Thread the Nut onto the shaft of the Rotor, Retainer end leading,

and tighten the Nut between 14 and 19 ft-lb (19 to 26 Nm) torque.

10. Remove the Rotor from the vise and after turning it end for end,

clamp the copper-covered vise jaws on the ats of the Bearing

Nut with the unassembled rotor shaft upward.

11. Wipe each Vane (24) with a light lm of oil and place a Vane in

each slot in the Rotor.

12. One end of the Cylinder Assembly (21) has three ports while the

other end has one. With the end having three ports toward the

Front End Plate, install the Cylinder Assembly over the Rotor.

Make certain the Cylinder Dowel Pin (22) at that end enters the

small notch in the End Plate.

13. Install the Rear Rotor Bearing Washer (20) into the counterbore of

the Rear End Plate Assembly (18).

14. Insert the Controller Assembly (17), bearing end leading, into the

rear end plate counterbore against the Bearing Washer. Make

certain the Wiper Plate Alignment Pin (19) enters the slot in the

brass wiper plate of the Controller Assembly.

15. With the Rear End Plate Assembly leading, thread the Controller

Assembly onto the shaft of the Rotor. Using the Controller

Wrench (57), tighten the Controller Assembly between 8 and 10

ft–lb (10.5 and 13.5 Nm) torque.

Assembly of the Tool

1. Drop the two Motor Clamp Washers (30), concave side trailing,

into the large end of the Arbor Housing (33).

2. Remove the assembled motor from the vise and insert it,

Controller Assembly trailing, into the Arbor Housing. Make certain

the Bearing Nut Assembly (31) at the front of the motor engages

the Arbor Coupling (39).

3. Thread the Throttle Handle Assembly (1) into the assembled

Arbor Housing and tighten the joint between 74 and 100 ft-lb

(100 and 135 Nm) torque.

4. Install the two Rear End Plate Retaining Screws (12) ush with the

handle surface or one thread below ush. If the Screws protrude

above the handle surface, the Rear End Plate Assembly (18) is not

properly engaged and is out of position.

5. Install the Rear Exhaust Deector Seal (35) in the internal groove

at the large end of the Exhaust Deector (34).

6. Install the Front Deector Seal (36) on the hub of the Arbor

Housing adjacent to the wrench ats.

7. Slide the Exhaust Deector onto the Arbor Housing and, using

a thin blade screwdriver, spiral the Deector Retaining Ring (37)

into the groove ahead of the Deector.

8. Using nger pressure, press the Seal Cup Assembly (38), felt end

trailing, onto the small end of the Bearing Nut Assembly (31) until

the felt seal cup is ush with the end of the Nut. Impregnate the

felt with Ingersoll Rand No. 50 Oil.

9. Push the Rear Arbor Bearing (40) onto the threaded hub farthest

from the wrench ats on the Arbor Assembly (41).

10.

Thread the assembled Bearing Nut Assembly/Seal Cup Assembly

onto the Arbor with the Seal Cup toward the Bearing. Tighten the

Nut between 14 and 19 ft-lb (19 and 26 Nm) torque.

11. Position the Seal Cup Assembly (42), felt end trailing, onto the

Arbor near the wrench ats. Use the Wheel End Bearing (43) to

push the Seal Cup Assembly onto the Arbor until the Bearing

seats. Remove the Bearing and impregnate the felt with

Ingersoll Rand No. 50 Oil.

12. For Models 61H120H63, 61H120H64 and 61H150H63,

proceed as follows:

Apply 1 cc of Ingersoll Rand No. 68 Grease to the inside

surfaces of the Arbor Coupling (39) and install the Coupling

on the Bearing Nut at the motor end of the Arbor.

Insert the assembled Arbor, Coupling end rst, into the Arbor

Housing, making certain the Coupling engages the Bearing

Nut on the Rotor.

Install the Wheel End Bearing (43) and Bearing Clamp

Washer (44), concave end leading, onto the Arbor.

If the Dust Washer (45) was removed from the inside of the

Wheel Guard (47), install a new Washer and impregnate it with

Ingersoll Rand No. 50 Oil.

The Wheel Guard has left–hand threads.

e. While placing the Wheel Guard to the desired position, thread

the Guard onto the Arbor Housing and tighten it between 40

and 50 ft-lb (54 and 68 Nm) torque.

f. Insert the Inner Wheel Flange Key (49) into the slot on the

Arbor.

g. Align the internal slot in the Inner Wheel Flange (48) with the

Key and install the Inner Wheel Flange on the Arbor through

the Wheel Guard.

h. Using snap ring pliers, install the Inner Wheel Flange

Retainer (50) on the Arbor against the Flange.

To seat the Retainer and bias the motor, make a spacer from

tubing that will t over the Arbor and is approximately the

size of the Retainer. After sliding the spacer onto the Arbor,

thread the Wheel Flange Nut (52) onto the Arbor until the

Retainer is snug against the Inner Wheel Flange. Remove the

Nut and spacer.

i. If the Oil Chamber Plug (3) was removed and the oil drained,

ll the oil chamber with Ingersoll Rand No. 50 Oil and tighten

the Plug between 3.5 and 6 ft-lb (5 and 8 Nm) torque.

j. Install a grinding wheel, the Outer Wheel Flange (51) and the

Wheel Flange Nut (52).

13. For Models 61H120G4, 61H120L6, 61H150G4 and 61H150L6,

proceed as follows:

a. If the Dust Washer (45) was removed from the inside of

the Wheel End Bearing Cap (46), install a new Washer and

impregnate it with Ingersoll Rand No. 50 Oil.

b. Install the Wheel End Bearing (43) on the Arbor and position

the Bearing Clamp Washer (44) on the Arbor with the concave

end against the Bearing.

c. Position the Wheel End Bearing Cap over the Arbor against the

Washer.

While tightening the Cone Wheel Adapter (53) or Collet

Body (54), maintain the alignment of the Bearing, Washer

and Cap to facilitate Arbor insertion into the Housing.

a.

b.

c.

d.