Cod. 710.0185.40.00 Rev1B –11.2018 © Copyright 2018 Ingersoll Rand - All rights reserved 1 - 9

- EN -

Introduction

This manual is an integral part of the product you bought, and must remain with the product even if this will be resold.

It is highly recommended that the qualified*personnel for installation maintenance and/or control will fully comply with the contents of

this manual and the prevention and safety rules in force in the country where the system will be used. In this way, not only the usage of

the product will be rational, but also the service will result cost effective.

In case your product will present any kind of problem, please contact your local authorized Ingersoll Rand distributor.

Please note that, when necessary, the use of original spare parts will ensure efficiency and long duration to your product.

Due to the continuous technological evolution, Ingersoll Rand reserves the right to modify the specifications contained in this manual

without giving previous notice.

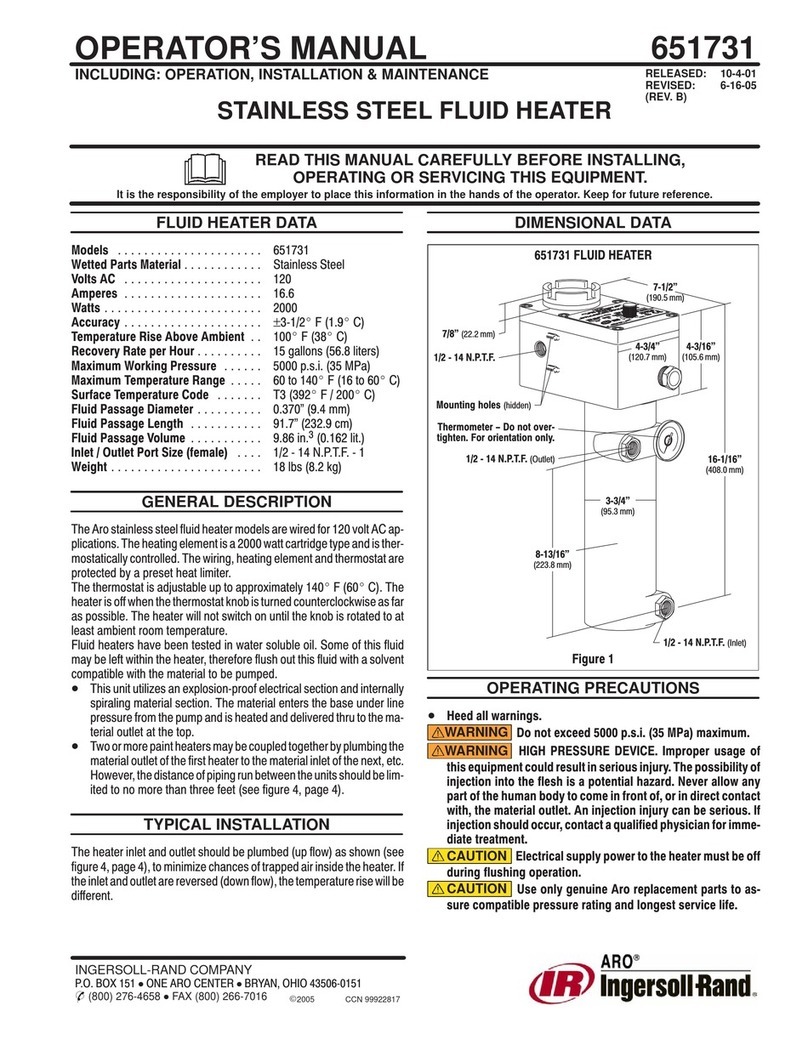

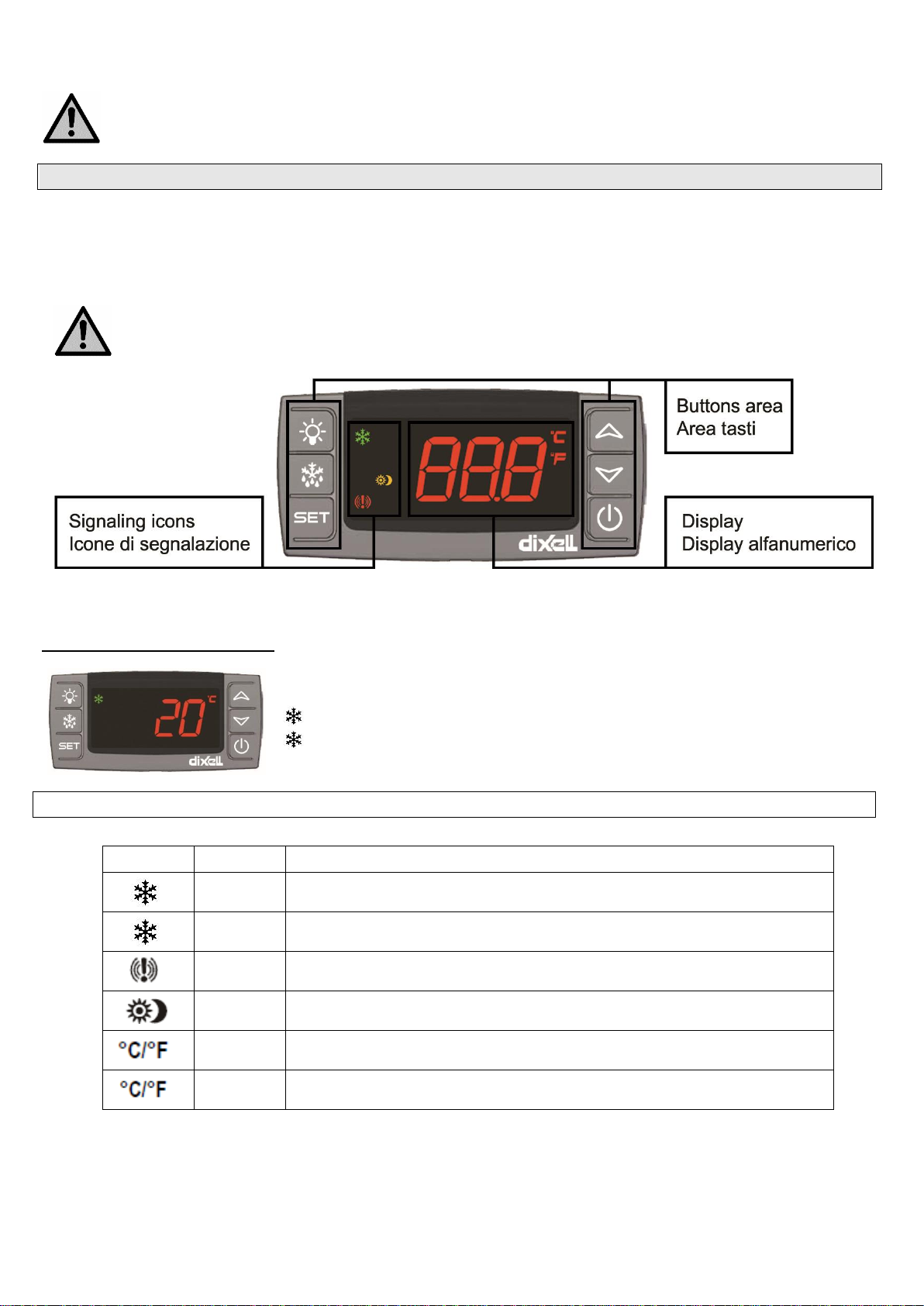

Symbols and labels used in the manual and on the product

Read the Operators manual before attempt to start

up the product and to perform any service operation

on the heater.

Pay particular attention to components or systems

under pressure.

Installation, maintenance, and/or control operations

preceded by these symbols must be performed

exclusively by qualified personnel*.

Pay particular attention to the indications preceded

by these symbols.

Don’t lift from this point.

Attention: Before performing any

maintenance operation on this product,

do not forget to disconnect the electric

supply, to completely discharge air

pressure, and to refer to the Operators

manual.

Pay particular attention to the risk of electric shock.

Pay particular attention to hot surfaces.

* Qualified personnel must be trained and certified in accordance with local laws and regulations.

Warranty

The Company warrants that the equipment manufactured by it and delivered hereunder will be free of defects in material and

workmanship for a period of twelve months from the date of placing the Equipment in operation or eighteen months from the date of

shipment from the factory, whichever shall first occur. The Purchaser shall be obligated to promptly report any failure to conform to this

warranty, in writing to the Company in said period, whereupon the Company shall, at its option, correct such nonconformity, by suitable

repair to such equipment or, furnish a replacement part F.O.B. point of shipment, provided the Purchaser has stored, installed, maintained

and operated such Equipment in accordance with good industry practices and has complied with specific recommendations of the

Company. Accessories or equipment furnished by the Company, but manufactured by others, shall carry whatever warranty the

manufacturers have conveyed to the Company and which can be passed on to the Purchaser. The Company shall not be liable for any

repairs, replacements, or adjustments to the Equipment or any costs of labor performed by the Purchaser or others without Company's

prior written approval.

The effects of corrosion, erosion and normal wear and tear are specifically excluded. Performance warranties are limited to those

specifically stated within the Company's proposal. Unless responsibility for meeting such performance warranties are limited to specified

tests, the Company's obligation shall be to correct in the manner and for the period of time provided above.

THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER, EXPRESSED OR

IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE HERBY DISCLAIMED.

Correction by the Company of nonconformities whether patent or latent, in the manner and for the period of time provided above, shall

constitute fulfillment of all liabilities of the Company for such nonconformities whether based on contract, warranty negligence, indemnity,

strict liability or otherwise with respect to or arising out of such Equipment.

The Purchaser shall not operate Equipment which is considered to be defective, without first notifying the Company in writing of its

intention to do so. Any such use of Equipment will be at Purchaser's sole risk and liability.

Note that this is Ingersoll Rand standard warranty. Any warranty in force at the time of purchase of the equipment or negotiated as

part of the purchase order may take precedence over this warranty.