3.1. TAPE DRILLING TEMPLATE (PAGE 15 OR PAGE 16) ON DOOR USING MOUNTING C AND DEVICE REF. C

FROM STEP 2 (PAGE 2).

3.2. PREPARE HOLES:

3.2.1. PREPARE OTHER HOLES PER TABLE BELOW.

3.2.2. TAP HOLES AS REQUIRED.

3.2.3. REMOVE TEMPLATE.

LL

VERTICAL C

L

C DEVICE REF.

L

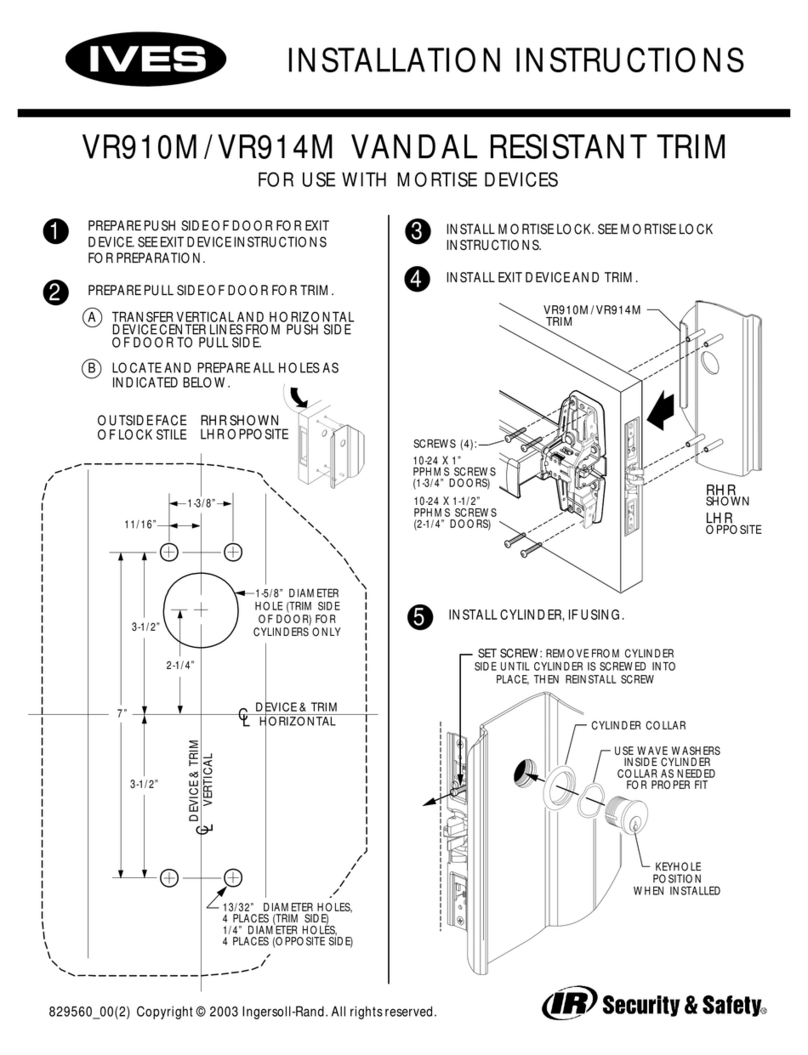

3.3. IF USING OUTSIDE TRIM, PREPARE DOOR USING SEPARATE TRIM DIRECTION SHEET. FOR SEX BOLT

INSTALLATIONS, DRILL 3/8” DIAMETER HOLES ON TRIM SIDE OF DOOR ONLY (SEE FIGURE BELOW).

3.4. DETERMINE DEVICE LENGTH:

DEVICE CAN BE TOUCHBAR DEVICE

CUT DOWN? SIZE LENGTH

SHORT DEVICE NO 20-1/2” 32-1/2”

LONG DEVICE YES 26-1/2” 44-1/2”

YES 20-1/2” 44-1/2”

DEVICE

TOUCHBAR

LENGTH

DEVICE LENGTH

LHR

SHOWN

SHORT TOUCHBAR

W/LONG CHANNEL

3DOOR AND HARDWARE PREPARATION

C DEVICE REF.

L

C VERTICAL

L

3/8” DIA. HOLE

4 PLACES

C DEVICE REF.

L

C VERTICAL

L

1/4” DIA. HOLE

4 PLACES

TRIM SIDE OF DOOR DEVICE SIDE OF DOOR

LHR

SHOWN

DEVICE FUNCTION PREPARE HOLES ON TEMPLATE

DX-(F)18-R-N NONE

DX-(F)18-R-C A

DX-(F)18-R-NL A

DX-(F)18-R-TP B, C (ALL DOORS) + E (WOOD DOORS)

DX-(F)18-R-TP2 A, B, C (ALL DOORS) + E (WOOD DOORS)

DX-(F)18-R-TP(2O.C.) A, B, C (ALL DOORS) + E (WOOD DOORS)

DX-(F)18-R-K B, D (ALL DOORS) + E (WOOD DOORS)

DX-(F)18-R-K2 A, B, D (ALL DOORS) + E (WOOD DOORS)

DX-(F)18-R-K(2O.C.) A, B, D (ALL DOORS) + E (WOOD DOORS)

DX-(F)18-R-L B, D (ALL DOORS) + E (WOOD DOORS)

DX-(F)18-R-L2 A, B, D (ALL DOORS) + E (WOOD DOORS)

DX-(F)18-R-L(2O.C.) A, B, D (ALL DOORS) + E (WOOD DOORS)

D-1400-4Page 3 of 16