INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 yFAX (800) 892-6276 © 2010 CCN 15334006

www.ingersollrandproducts.com

OPERATOR’S MANUAL & SALES AND ENGINEERING DATA

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

INCLUDE MANUAL: AF06XX-XX Air Motor (pn 97999-1467) & S-632 GENERAL INFORMATION (PN 97999-694)

RELEASED: 9-30-10

(REV. 01)

AF060BLXXXXXX-XX-X

PUMP ASSEMBLY

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

6”AIR MOTOR

100:1 RATIO

0 - 10,000 PSI. RANGE

SERVICE KITS

Use only genuine ARO® replacement parts to assure com-

patible pressure rating and longest service life.

637483 packing kit.

637489 for air motor service only.

SPECIFICATIONS

Model Series . . . . . . . . . AF060BLXXXXXX-XX-X.

Type . . . . . . . . . . . . . . . . . Air Operated Grease Pump

Ratio . . . . . . . . . . . . . . . 100:1

Air Motor Diameter. . . . . . . . . . . . . . 6”(15.2 cm)

Stroke. . . . . . . . . . . . . . . . . . . . . . 4”(10.2 cm)

Air lnlet (female) . . . . . . . . . . . . . 1/2-14 N.P.T.F.

Material Outlet (female). . . . . . . 1/2 - 14 N.P.T.F.

Dimensional Data . . . . . . . . . . . . . . . . see chart

PERFORMANCE

Air Inlet Pressure Range. . . . .

0 - 100 p.s.i.g (0 - 6.9 bar)

Fluid Pressure Range . . . . . . . 0 - 10,000 p.s.i.g (0 - 690 bar)

Maximum Delivery/ Min . . . . 2.1 lbs (0.95 kg)

y

y

y

S-632 GENERAL INFORMATION LUBRICATION PISTON PUMPS

(97999-694)

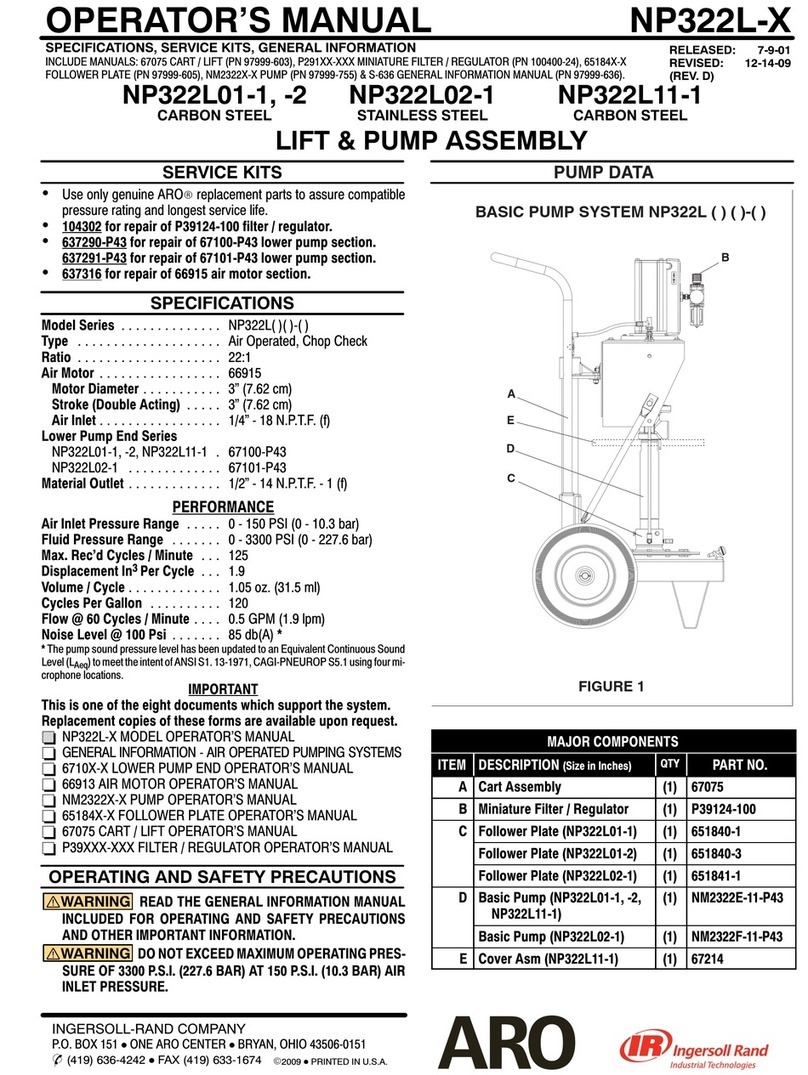

AF060BLXXXXXX-XX-X

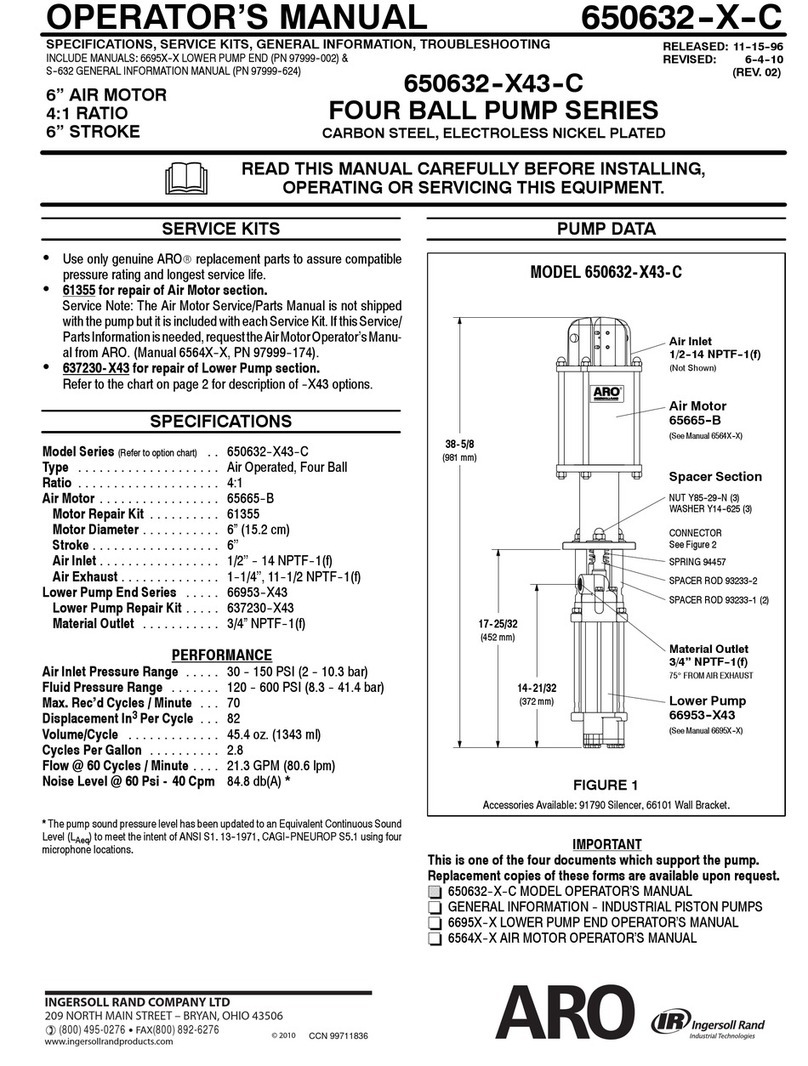

Figure 1

MODELS “A” (mm)

AF060BL4XXXXX

AF060BL5XXXXX

40.010”(1016.3)

49.822”(1265.5)

26.622”(676.2)

36.434”(925.4)

25.466”(646.8)

35.258 (895.6)

“B”(mm) “C”

NOTE: Dimensions are shown in inches and (mm), supplied for reference only.

AF060BLXXXXXX-XX-X MODEL OPERATOR’S MANUAL ( 97999

-1511)

This is one of six documents which support the pump.

Replacement copies of these forms are available upon request.

IMPORTANT

AF066XX-XX AIR MOTOR OPERATOR’S MANUAL (97999-1467)

“B”

“C”

“A”

AF060BL4XXXXX-1

AF060BL5XXXXX-1

42.094”(1069.2)

51.906”(1318.4)

26.622”(676.2)

36.434”(925.4)

25.466”(646.8)

35.258 (895.6)

OPERATING AND SAFETY PRECAUTIONS

WARNING

READ THE GENERAL INFORMATION MAN-

UAL INCLUDED FOR ADDITIONAL OPERATING AND

SAFETY PRECAUTIONS AND OTHER IMPORTANT IN-

FORMATION.

WARNING

EXCESSIVE INLET PRESSURE. Can cause

explosion resulting in severe injury or death. Do not

exceed maximum operating pressure of 10,000 p.s.i.g

(690 bar) at 100 p.s.i.g (6.9 bar) inlet air pressure. Do

not run pump without using a regulator to limit air

supply pressure to the pump.

WARNING

EXCESSIVE MATERIAL PRESSURE. Can cause

equipment failure resulting in severe injury or prop-

erty damage. Do not exceed the maximum material

pressure of any component in the system.

PUMP RATIO X =MAXIMUM PUMP

INLET PRESSURE TO PUMP MOTOR FLUID PRESSURE

Pump ratio is an expression of the relationship between the pump

motor area and the lower pump end area. EXAMPLE: When 100 p.s.i.g

(6.9 bar) inlet pressure is supplied to the motor of a 100:1 ratio pump it

will develop a maximum of 10,000 p.s.i.g (690 bar) uid pressure (at no

ow) - as the uid control is opened, the ow rate will increase as the

motor cycle rate increases to keep up with the demand.

NOTICE

Thermal expansion can occur when the uid in the ma-

terial lines is exposed to elevated temperatures. Example: Material lines

located in a non-insulated roof area can warm due to sunlight. Install a

pressure relief valve in the pumping system.

Per ARO (1/8/2016), use

part #: 63150