613201-3-CPage 2 of 4

OPERATION

WARNING DO NOT EXCEED MAXIMUM INLET AIR PRES-

SURE OF 120 P.S.I. (8.3 Bar). OPERATING PUMP AT HIGHER

PRESSURE CAN CAUSE PUMP DAMAGE.

CONTROL VALVE OPERATION

TO FILL - TURN CONTROL VALVE LEVER COUNTER-CLOCKWISE.

TO EVACUATE - TURN CONTROL VALVE LEVER CLOCKWISE

(back 90_).

To purge the system of air:

1. Place the hose / screen assembly into barrel or drum of material.

2. Supply air to pump and adjust the air regulator to a few pounds and

cycle pump slowly to prime system while holding gun in the fluid con-

tainer.

3. Allow the pump to continue cycling until the pump primes and the air

has been eliminated from the system.

SYSTEM OPERATION - FILLING TIRE

Jack up the vehicle and rotate the tire until the valve stem is located at

top of the wheel. NOTE: Adapter (19d) and core remover (19b) are used

only for 1-piece valves.

CAUTION: Disconnect air supply to the pump while making con-

nection to valve stem.

CONNECTING TO VALVE STEM

To connect to 2-piece valve stem:

1. Remove the (19c) adapter from the gun assembly.

2. Thread the (19c) adapter onto the valve stem, finger tight.

3. Thread the swivel nut on the (19c) adapter onto the gun. The (19a)

handle should be pulled back from the (19c) adapter. (Make sure the

gasket in the (19c) adapter is in place.)

REMOVING THE VALVE CORE & FILLING TIRE

1. Push the (19a) handle in until it makes contact with valve core.

2. Hold the gun assembly with one hand and hit the (19a) handle with

the other, driving the core remover onto the valve core.

3. Turn the (19a) handle counter-clockwise and completely unthread

the core from valve stem.

4. Pull the (19a) handle all the way back from valve stem. Move the

handle of the siphon valve to “FILL” position, fill tire. NOTE Periodi-

cally check pressure in tube. The tube will be about 2/3 full when

pressure reaches 30 lbs.

5. Move the handle of the siphon valve to “EVACUATE” position (clock-

wise) until air bubbles stop coming up in liquid container. Continue

filling the tire until recommended volume or weight is reached.

DISCONNECTING AFTER FILLING TIRE

1. Shut pump off. Place valve core into valve stem with (19a) handle.

2. Turn (19a) handle of gun to the right, or clockwise, threading valve

core into valve stem tightly.

3. Pull the (19a) handle back from valve stem. Then turn handle of si-

phon valve to “EVACUATE” position. Remove gun assembly and

(19c) adapter from valve stem.

PROPER TIRE PRESSURE

Inflate tire to 8 - 10 p.s.i. (0.55 - 0.69 bar) above recommended tire pres-

sure.

With valve stem at top, bleed until it is 1 or 2 p.s.i. (0.07 - 0.14 bar) above

recommended tire pressure.

Let vehicle off jack. With valve stem located at bottom of the wheel,

check pressure with an air-water gauge.

REMOVING FLUID FROM TIRE

1. Jack up the vehicle, rotate the tire so that the valve stem is at the

bottom of the wheel.

2. Connectthe gun to the valve stem (see “ConnectingtoValve Stem”).

3. After connection has been made, remove the valve core (see “Filling

Tire” instructions).

4. Start pump, turn handle of siphon valve to “EVACUATE” position.

Continue to run pump until fluid level in container no longer in-

creases, then shut pump off.

5. Place valve core into valve stem and remove the gun (see “Discon-

necting After Filling Tire”).

MAINTENANCE

The air line should be disconnected from the air motor if the pump sets

idle for long periods of time.

Periodically clean and inspect the material screen assembly.

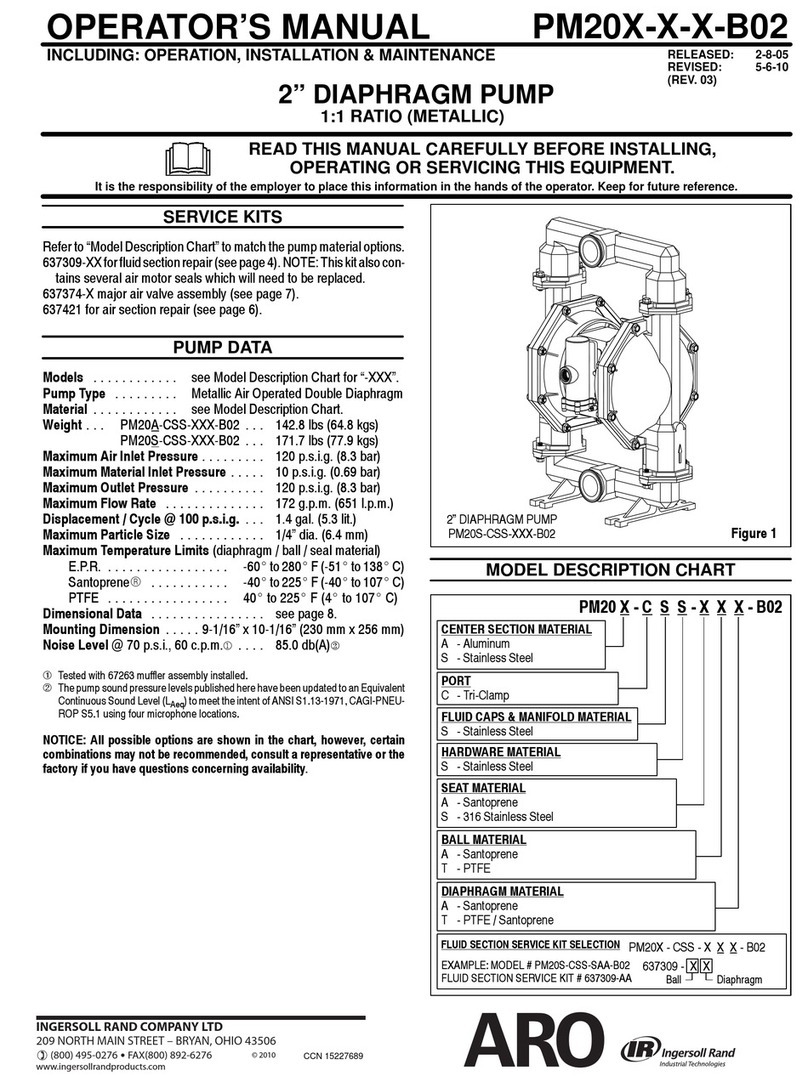

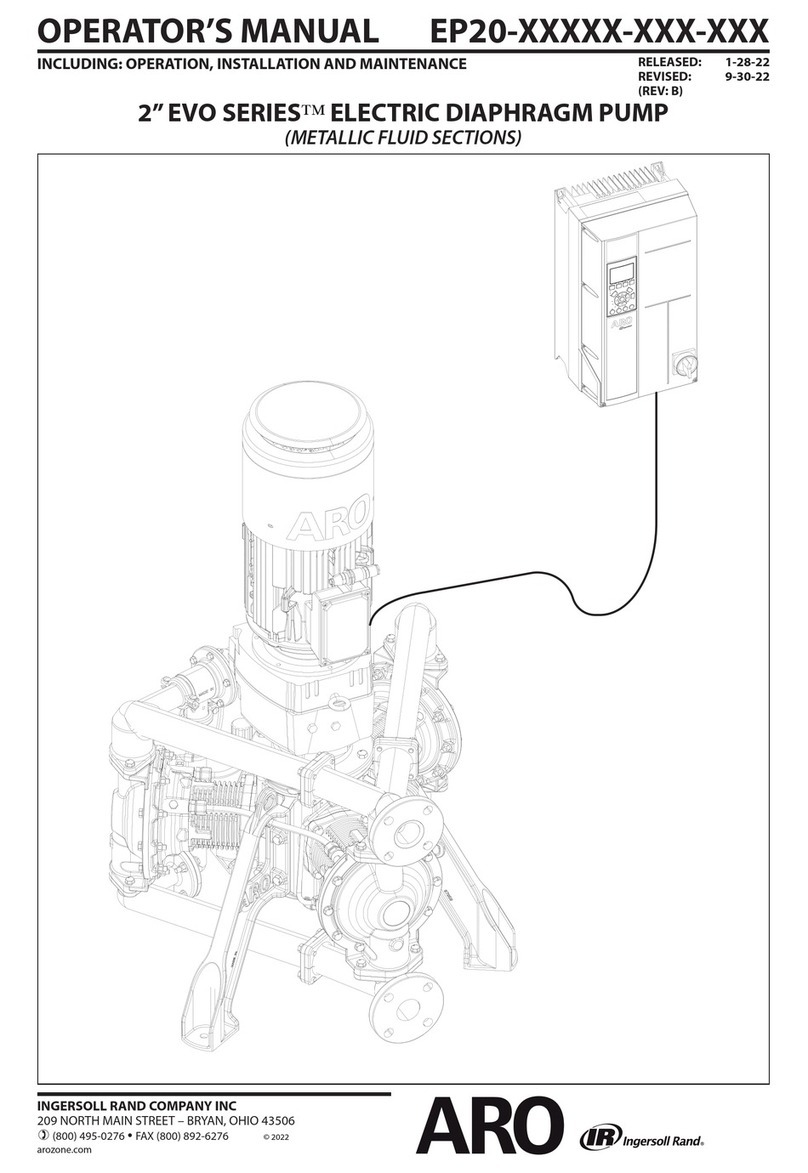

19a 19b * 19c 19d

19b *

(19) GUN ASSEMBLY

* Choose the proper core remover to fit the valve core.Figure 2