nInitial Winch Operating Checks

Winchesaretestedforproper operationpriortoleavingthe factory.Beforethewinch

is placed into service the following initial operating checks should be performed.

1. When first running the motor inject a small amount of light oil into the inlet

connection to provide initial lubrication.

2. Check oil level in motor, reduction gear assembly and disc brake are correct. Top

off levels as required before operation as described in

“LUBRICATION” on page 9.

3. Operate winch in both directions with no load for one to two minutes.

4. New brake band Lining Run-in Procedure: All new brake band linings require a

‘run-in’ period. Operate the winch without load in the payout direction while

gradually applying the brake. Allow the brake to slip for approximately one

minute. Winch motor may stall as drum brake band lining fully engages. Do not

allow brake to overheat.

5. Check operation of brakes. Adjust if necessary as described in “MAINTENANCE”

section in the Product Maintenance Information Manual.

6. Check operation of limit switches, locking mechanisms and all safety devices

when equipped.

7. Check foundation mounting fasteners are secure.

8. Install drum guard when provided.

For winches that have been in storage, the following start-up procedures are

required:

1. Give the winch an inspection conforming to requirements of

‘Winches Not in Regular Use’ on page 9.

2. Pour a small amount of ISO VG 32 (SAE 10W) oil in motor inlet port.

3. Operate motor for 15 seconds in both directions to flush out any impurities.

4. The winch is now ready for normal use.

OPERATION

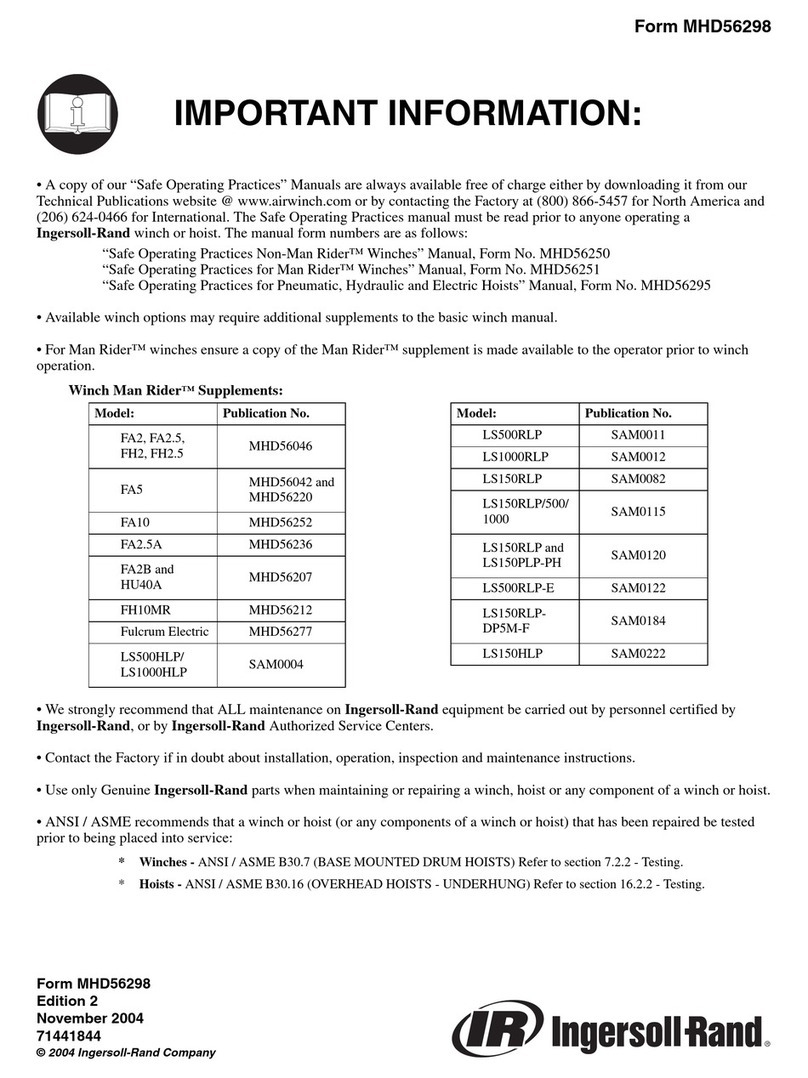

It is recommended that the user and owner check all appropriate and applicable

regulationsbeforeplacingthis product into use. RefertoProductSafety Information

Manual before operating product.

The four most important aspects of product operation are:

1. Follow all safety instructions when operating the product.

2. Allow only people trained in safety and operation of this winch to operate this

equipment.

3. Subject each product to a regular inspection and maintenance procedure.

4. Be aware of product capacity and weight of load at all times.

WARNING

• Do not lift loads over people.

NOTICE

• Refer to Product Parts Information Manual for drawings unless specified

elsewhere.

nWinch Controls

The spring loaded, motor mounted, live air manual throttle control valve is supplied

as a standard feature on this winch. Optional remote throttle controls are available.

Reference model code on the winch data (name) plate and compare it to

“SPECIFICATIONS” on page 3, to determine your configuration. The throttle controls

provide operator control of motor speed and direction of drum rotation.

nWinch Mounted Air Throttle

Refer to Dwg. MHP1809 on page 12, A. Haul-In; B. Exhaust Port; C. Lift Slider Handle

UP to Unlock; D. Payout; E. Air Inlet Port; F. Brake Release Port.

The winch control throttle valve is spring loaded, full flow air and mounts to the

motor rotary housing.

To operate control valve, place palm of hand on control knob and wrap fingers

around flange of sliding handle. Squeeze fingers, lifting sliding handle up to unlock

control handle. Shift control handle in desired direction to payout or haul-in wire

rope. As viewed from air motor end, move control throttle handle to the right

(clockwise) to payout wire rope and to the left (counterclockwise) to haul-in wire

rope. Avoid sudden movements of handle to ensure smooth operation of winch.

When released, handle will return to neutral or center position, sliding handle will

drop down to engage and lock control handle in place.

nRemote Full Flow Air Throttle

Refer to Dwg. MHP2043 on page 12, A. To Brake; B. Threaded Ports.

Provides for remote mounting of winch control at a fixed location at up to 20 feet (6

metres) away from winch motor. Air hoses connect throttle to winch motor to

provide winch operation.

Move control throttle handle to the right (clockwise) to payout wire rope and to the

left (counterclockwise) to haul-in wire rope. Avoid sudden movements of control

valve to ensure smooth operation of winch.

nRemote Pilot Pendant Throttle

Refer to Dwg. MHP2398 on page 11, A. Red - Air Supply; B. Green; C. Yellow; D.

Payout load; E. Haul-In Load.

Provides for remote winch control at distances of up to 66* feet (20 metres) away

from winch. The pilot pendant control throttle is a two function movable control

station for winch operation. Pilot pressure from pendant control activates winch

control valve. The winch control valve, located on winch motor, controls motor

speed and direction of drum rotation. Direction of drum rotation is determined by

the pendant lever/button depressed.

nRemote Pilot Lever Throttle

Provides for remote winch control at distances of up to 66* feet (20 metres) away

from winch. The lever pilot control throttle is a fixed mounted lever control station

for winch operation. Pilot pressure from lever pilot control throttle activates winch

control valve. The winch control valve, located on winch motor, controls motor

speed and direction of drum rotation. Direction of drum rotation is determined by

the direction in which lever is shifted.

* For distances greater than 50 feet (15 metres) contact Ingersoll Rand Technical

Sales for control suitability.

nUnderwound Operation (optional feature)

Underwound operation allows wire rope haul-in or payout off the bottom of drum.

This is a special operation and requires a winch specifically designed for this usage.

nEmergency Stop and Overload System

Emergency Stop and Overload System are standard on -CE winches.

Refer to Dwg. MHP2619 on page 12, A. Emergency Stop Button; B. Push Down to

StopWinch Movement;C.OverloadValveResetButton;D.TwistRed Buttonto Reset;

E. Overload Valve Adjustment Screw.

When emergency stop or overload valve is activated, winch drum rotation will

immediately cease.

CAUTION

• If winch continues to move (payout load) after emergency stop activates,

brake(s) are not holding load and may require adjustment or repair.

When control valve senses a preset pressure difference between ports, a pilot signal

is sent to stop flow of air, winch drum rotation will immediately cease.

nEmergency Stop

Emergency stop device is located on the control valve. When activated, winch drum

rotation will immediately cease. To activate emergency stop, depress (push down)

red palm valve, located on top of control valve.

NOTICE

•Ifwinchoverload occurs, overloaddevice,ifequipped, also stopswinch.To

operate winch after an overload, reduce load and reset overload.

Emergency Stop Reset:

1. Rotate red stop button, in (counterclockwise) direction until red stop button

‘pops’ up.

2. Winch is ready to resume operation.

Pendant Control:

Refer to “Emergency Stop” section and Dwg. MHP1892 on page 12, A. Pendant

Handle; B. “Emergency Stop” Button; C. “ON” Button; D. Winch Control Levers.

nOverload System (CE Models only)

The winch utilizes a direct acting load limiter to limit the maximum line pull to 160%

of the rated line pull. The limiter is a pressure regulator that limits the supply air to

a pressure that will not allow the winch to pull beyond 160% of the rated line pull.

Checking Overload Valve Setting:

Proper test and adjustment of overload should only be performed by an

Ingersoll Rand trained technician. The winch shall not be able to lift a load greater

than 160% of the rated utility load. If this is possible, adjustment is required.

1. Attach load line to a load that is calibrated to maximum rated load for winch.

2. Move control lever to haul-in position. If winch does not lift load, adjust the

adjustment screw. Refer to ‘Overload Valve Adjustment’ in the Product

Maintenance Information Manual.

Setting the Overload:

Attach load line to a load that is calibrated to 160% of winch rated capacity. Shift

control lever to haul-in position.

1. If overload valve activates, reset overload valve. Winch is ready for normal

operation.

2. If winch lifts higher than 160% of rated load, lower load. Turn jam nut

(counterclockwise) in 1/4 turn increments until overload valve activates when

control lever is shifted to haul-in position. After each 1/4 turn, retest winch.

nGuideline System (optional feature)

Refer to Dwg.MHP1349 on page 13, A. Guideline Position; B. Normal Position.

1. Place selector lever in NORMAL position.

Form MHD56438 Edition 3 7