INIM Electronics PREVIDIA MAX Quick guide

Configuration manual

1

FIRE DETECTION AND EXTINGUISHANT SYSTEM MANUAL FOR

SYSTEM CONFIGURATION,

COMMISSIONING AND

MAINTENANCE

EN 54-2

EN 54-4

EN 54-21

EN 12094-1

0051

0051-CPR-1863

cert. N.991K

2Warranty

Fire detection and extinguishant system

Warranty

INIM Electronics s.r.l. (Seller, Our, Us) warrants the original purchaser that this product shall be free from defects in

materials and workmanship under normal use for a period of 24 months. As INIM Electronics s.r.l. does not install this

product directly, and due to the possibility that it may be used with other equipment not approved by Us; INIM

Electronics s.r.l. does not warrant against loss of quality, degradation of performance of this product or actual damage

that results from the use of products, parts or other replaceable items (such as consumables) that are neither made nor

recommended by INIM Electronics. Seller obligation and liability under this warranty is expressly limited to repairing or

replacing, at Seller's option, any product not meeting the specifications. In no event shall INIM Electronics s.r.l. be liable

to the purchaser or any other person for any loss or damage whether direct of indirect or consequential or incidental,

including without limitation, any damages for lost profits, stolen goods, or claims by any other party caused by defective

products or otherwise arising from the incorrect or otherwise improper installation or use of this product.

This warranty applies only to defects in parts and workmanship relating to normal use. It does not cover:

• damage arising from improper maintenance or negligence

• damage caused by fire, flood, wind or lightning

•vandalism

• fair wear and tear

IINIM Electronics s.r.l. shall, at its option, repair or replace any defective products. Improper use, that is, use for purposes

other than those mentioned in this manual will void the warranty. Contact Our authorized dealer, or visit our website for

further information regarding this warranty.

Limited warranty

INIM Electronics s.r.l. shall not be liable to the purchaser or any other person for damage arising from improper storage,

handling or use of this product.

Installation of this Product must be carried out by qualified persons appointed by INIM Electronics. Installation of this

Product must be carried out in accordance with Our instructions in the product manual.

Copyright

The information contained in this document is the sole property of INIM Electronics s.r.l.

No part may be copied without written authorization from INIM Electronics s.r.l.

All rights reserved.

Configuration manual

Table of contents 3

Table of contents

Warranty.......................................................................................................................... 2

Limited warranty........................................................................................................... 2

Copyright........................................................................................................................ 2

Table of contents ......................................................................................................... 3

Chapter 1 General information ....................................................................................................5

1.1 Manufacturer's details .....................................................................................................................5

1.2 About this manual ............................................................................................................................5

1.3 Description of the configuration and programming procedures .......................................6

1.4 Operator classification - Access Levels ......................................................................................6

Chapter 2 Configuration ................................................................................................................ 7

2.1 Access to programming.................................................................................................................8

2.2 Setting the IP network address.....................................................................................................8

2.3 Accessing the configuration menu .............................................................................................8

2.4 Addressing IFM and FPM modules ..............................................................................................9

2.5 Setting the Hornet+ network address (IFMNET) ....................................................................10

2.6 Addressing the repeaters..............................................................................................................10

2.7 Enrolling loop devices (IFM2L).................................................................................................... 11

2.8 Acquiring the configuration.........................................................................................................13

2.9 Signal check and fault search .....................................................................................................13

2.10 Factory data .....................................................................................................................................13

2.11 Setting the date and time.............................................................................................................13

2.12 Firmware revision ...........................................................................................................................14

2.13 Registration of the control panel to Inim Cloud....................................................................15

Chapter 3 Commissioning........................................................................................................... 16

3.1 Testing the Control panel ............................................................................................................16

3.2 Testing to detectors and manual activations.......................................................................... 17

3.3 Testing signalling and activations .............................................................................................. 17

3.4 Testing the extinction system ..................................................................................................... 17

3.5 Maximum time settings. Normative restrictions .................................................................... 17

Chapter 4 Maintenance................................................................................................................ 18

4.1 Testing the control panel.............................................................................................................18

4.2 Testing the detectors ....................................................................................................................18

4.3 Manual activation test ...................................................................................................................18

4.4 Testing signalling and activations ..............................................................................................18

4Table of contents

Fire detection and extinguishant system

Configuration manual

General information 5

Chapter 1

General information

1.1 Manufacturer's details

Manufacturer: INIM ELECTRONICS S.R.L.

Production plant: Centobuchi, via Dei Lavoratori 10

Municipality: 63076, Monteprandone (AP), Italy

Tel.: +39 0735 705007

Fax: +39 0735 704912

E-mail: [email protected]

Web: www.inim.biz

The personnel authorized by the manufacturer to repair or replace the parts of this system have authorization to work on

INIM Electronics brand devices only.

1.2 About this manual

Manual code: DCMCINE0PREVIDIA

Revision: 1.51

This manual describes the procedures for the configuration, commissioning and maintenance of the Previdia Max fire-

detection system.

1.2.1 Terminology

Control panel, System, Device: The main supervisory unit or any constituent part of the fire detection system.

Left, Right, Behind, Above, Below: Directions as seen by the operator when directly in front of the mounted device.

Qualified personnel: Personnel whose training, expertise and knowledge of the products and laws regarding security

systems, are capable of creating, in accordance with the requirements of the purchaser, the most suitable solution for

the protected premises.

Select: Click on a specific item on the interface (drop-down menu, options box, graphic object, etc.).

Press: Push a button/key or tap on a video button on a touchscreen or display.

1.2.2 Graphic conventions

Following are the graphic conventions used in this manual.

Note: The notes contain important information relating to the text.

Attention: The “Attention” prompts indicate that total or partial disregard of the procedure could damage the

device or its peripherals.

Conventions Example Description

Text in italics

Refer to paragraph

1.2.2 Graphic

conventions

Directs you to the title of a chapter, section,

paragraph, table or figure in this manual or

other published reference.

<text> <AccountCode> Editable field

[Uppercase letter] or

[number] [A] or [1] Reference relating to a part of the system

or video object.

6General information

Fire detection and extinguishant system

1.3 Description of the configuration and programming procedures

Following is a flow chart which summarizes the operations to be carried out during the installation and commissioning

phases of the Previdia Max system and indications regarding the manuals to refer to for each operation:

1. Installation and cabling (refer to the Installation Manual)

2. Initializing (refer to the Installation Manual)

3. Configuration from the front plate (operations described in this manual)

4. Troubleshooting (operations described in this manual)

5. Connection to a PC and reading (refer to the Programming Manual)

6. Configuring the parameters (editing data, refer to the Programming Manual)

7. Writing data on the control panel and test (refer to the Programming Manual)

8. Commissioning (operations described in this manual)

9. System handover

10. Maintenance (operations described in this manual)

1.4 Operator classification - Access Levels

The control panel has 4 distinct access levels:

Level 1: Public level - this is the normal access level of the control panel and is the access level for building inhabitants

who are neither authorized to use the system nor instructed in its use.

At this level it is possible to view the information on the display and on the signalling LEDs, to interact using the buttons

and the touch screen to scroll through the information. The only operations allowed are:

• mute buzzer

• test signalling LEDs

• activate alarm signalling when an early-warning process is running

Level 2: Authorized users - this access level is for the system supervisors and is for authorized personnel who are

adequately instructed in the use of the system and its functions.

Access requires the use of a key or entry of a valid access code with sufficient access rights. In addition to the operations

described for level 1 it is also possible to carry out the following operations:

• mute alarm signalling devices

• rearm the control panel

• activate alarm signalling devices manually

• disable control panel elements

• place in test status one or more of the system elements

The system provides two additional sub-levels of authorized user:

-Superuser level as for the previous one, with the added possibility of replacing a loop device and registering control

panels to their account with the Inim Cloud service

-Maintenance level as for the previous level, with the possibility to terminate the valve pulse, for models that support

the extinction functions

Level 3: Programming - this access level is for specialized technical operators who carry out system configuration,

commissioning and maintenance.

Access requires entry of a valid access code with sufficient access rights after inserting a jumper which enables

programming. Refer to the manual for system configuration, commissioning and maintenance.

ONLY authorized technicians, appointed by the Manufacturer can, by means of special tools, carry out repair work on

the motherboard.

Level 4: ONLY authorized technicians, appointed by the Manufacturer can, by means of special tools, carry out repair

work on the motherboard.

Configuration manual

Configuration 7

Chapter 2

Configuration

Once the installation and cabling procedures have been completed (refer to the Installation Manual of the Previdia Max

system) the system is ready for first startup.

In the case of first start-up, the selection of the control panel languages is requested, a compulsory main lnaguage and

an optional secondary language (see paragraph 2.10).

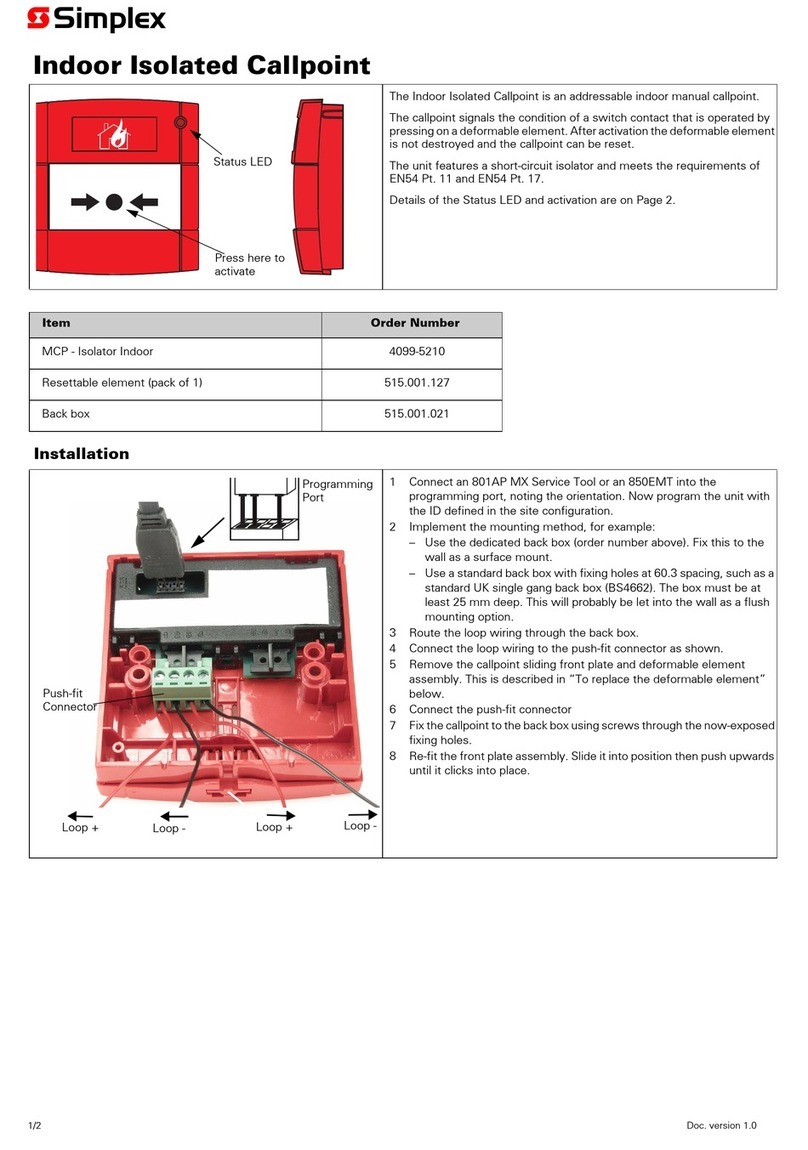

The control panel screen will be as follows:

In this condition the control panel has no acquired configuration, all the modules connected to the CAN drive bar or

front plate have the same address and are not included in the configuration.

The configuration status icon on the status bar indicates a fault condition, due to the fact that modules have been

detected but are not present in the configuration saved in the memory.

In order to configure the control panel it is necessary to work through the following procedure:

1. Access programming (paragraph 2.1)

2. Set the IP network address (paragraph 2.2)

3. Access the configuration menu (paragraph 2.3)

4. Assign addresses to the system modules (paragraph 2.4)

5. Enroll loop devices on IFM2L modules and respective troubleshooting procedure (paragraph 2.7)

6. Set the defined configuration (paragraph 2.8)

7. Check eventual signalling and search for faults (paragraph 2.9)

8. Set the date and time (paragraph 2.11)

Note: Once the configuration operations have been completed correctly, the control panel will be ready to

operate.

The control panel is configured to consider each input point (detector, module, terminal) as a fire-alarm

point. Therefore, in the event of a fire alarm it will activate all the outputs available on its loops or

terminals.

At this point it is necessary to proceed with eventual changes to the configuration data for the

distribution of points in zones, edit descriptions of the various system elements, define specific

activation sequences, etc.

Refer to the Programming manual.

[A]

Buttons to access the

events logs, system

status and programming.

[B]

Status bar (always

present) shows essential

information regarding

the system.

[C]

Button for changing the

language of the control

panel, if a secondary

language is provided

[D]

Configuration status

icon (system

configuration and faults)

Log

System status

Programming

L: 1 01/01/2020

18:23

C

B

A

D

8Configuration

Fire detection and extinguishant system

2.1 Access to programming

To access the programming phase of the Previdia Max control panel, it is

necessary to work through the following procedure:

1. Insert the programming jumper on the back of the FPMCPU module

(see opposite, [D]).

2. Tap on the Programming button on the screen (see above, [A]).

3. A keypad will appear (see opposite, [E]) for the entry of a code with

installation privileges.

Note: The default access code to level 3 is “00004”.

4. You access the programming menu, where the following items are

available:

-Configuration

-Network

- Factory data

2.2 Setting the IP network address

If an Ethernet network connection is used, it will be necessary to set up the IP address and parameters of the network.

This operation must be done for anyone of the following devices:

• The Previdia Max control panel, via the main FPMCPU module

• the backup FPMCPU module, via the FPMCPU module itself

• the FPMCPU repeater module, when connected to an Ethernet network, via the FPMCPU module itself

In order to set the network parameters, it is first necessary to access the

programming phase of the control panel (paragraph 2.1) and then tap on the

Network button which appears on the screen.

The network parameters screen will be shown [F].

Beside these there is the Backup panel option [G]. If enabled, the FPMCPU

module you are using will be set as control panel backup CPU unit. In this

case, the network parameters must be the same as the parameters set for

the main FPMCPU module.

Once set, it will be necessary to tap on the Ok button and save the data.

If the module has been set as a backup CPU unit, the message "In backup" will appear on the display

In the same section you have the tools to register the control panel to the installer profile at the Inim Cloud service [H]

(refer to paragraph 2.13 Registration of the control panel to Inim Cloud).

2.3 Accessing the configuration menu

To access the configuration menu it is necessary to first access the programming phase of the control panel (paragraph

2.1) and then tap on the Configure button which appears on the screen.

Alternatively, it is possible to tap directly on the configuration status icon (see above, [C]).

Entry of a valid access code is necessary In both cases.

Once the configuration menu has been accessed, the control panel screen will provide a layout of the control panel and

its parts.

D

00004

1 2 3 A B

4 5 6 C D

7 8 9 E F

C 0 OK

E

Net-

work IP

192 192 1 1

Backup panel

Netmask

Cloud enabled

255 255 255 0EnrollGateway

192 111 EscPort

6001 Ok

Access

level:3 01/01/2020

18:23

G

F

H

Configuration manual

Configuration 9

Selection of one of the cabinets from the control panel layout ([E]) will show it both on the left ([A]), where the installed

IFM modules with their addresses and firmware revision are shown, and on the right ([F]), where the installed FPM

external modules are shown. From this section you can access the configuration phase of each module by tapping on

the icon which represents it.

2.4 Addressing IFM and FPM modules

In order for the control panel to identify each module individually, it is

necessary to assign an address to each one. It is possible to assign the same

address to modules of different types, however, modules of the same type

must have different addresses.

To assign an address to a module, it is necessary to tap on the module

shown in the section it belongs to (internal IFM modules on the left [A]; FPM

front-plate modules on the right [F]).

A window will open ([H]), select the desired address in the programming

field, then tap on Set.

Note: Addresses which exceed the maximum number of modules supported by the control panel will not be

considered valid.

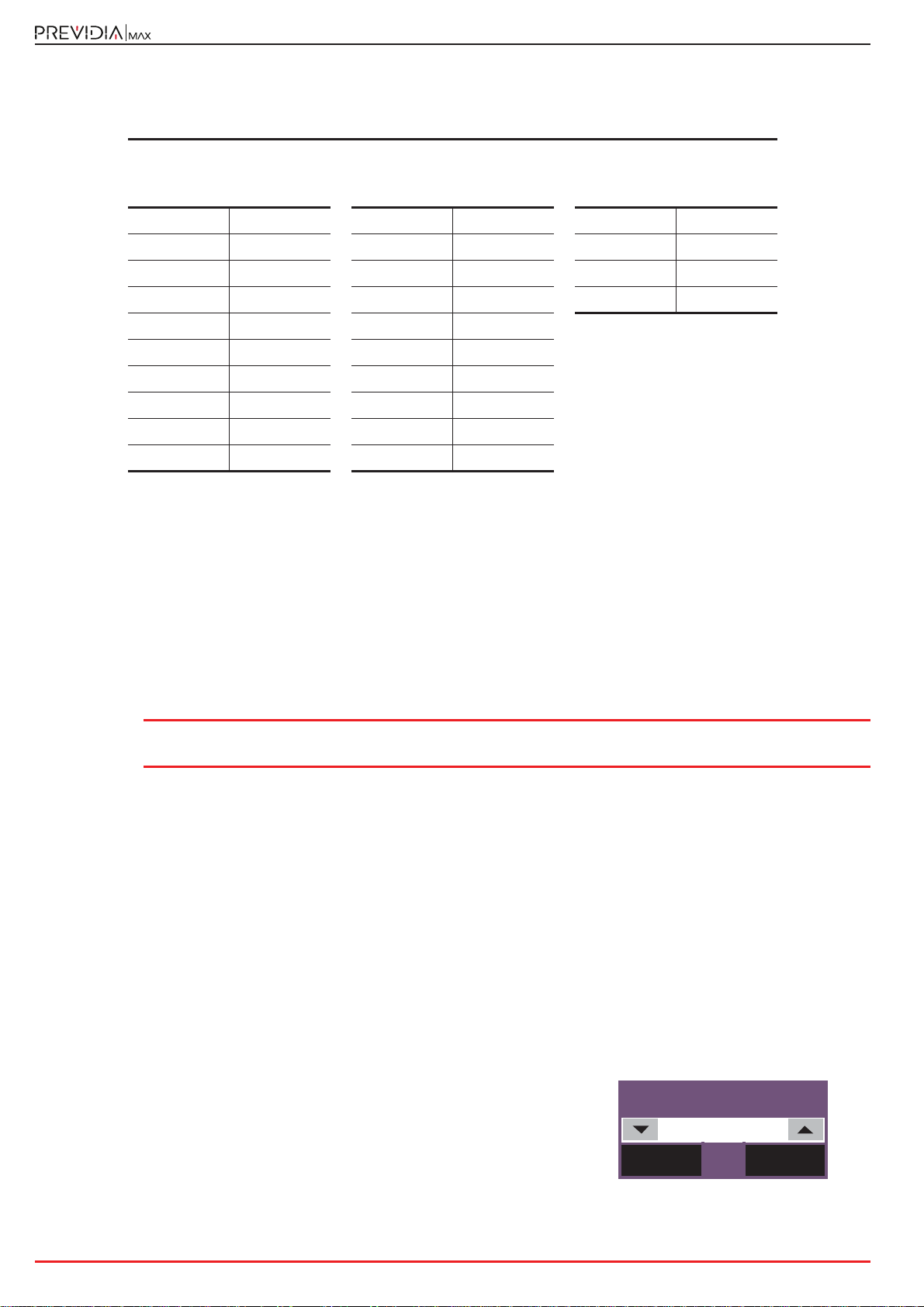

Following is a table containing the addresses allowed for each type:

[A] Internal layout of the

selected cabinet

[B] Internal module

detected

[C] Position empty

[D]

Address and firmware

revision of detected

module

[E] Map of the entire

control panel

[F] Layout of the selected

cabinet

[G]

Buttons to carry out

setting changes or to

exit without saving

FPM Module

Maximu

m

number

Address

IFM Module

Maximu

m

number

Address

fro

mto fro

mto

FPMLED 7 1 7 IFM24160 4 1 4

FPMLEDPRN 1 / IFM2L 8 1 8

FPMEXT 5 1 5 IFM4R 16 1 16

IFM4IO 16 1 16

IFMDIAL 1 /

IFM16IO 4 1 4

IFMNET 1 /

IFMLAN 1 /

IFMEXT 24 1 24

N.01 FW:1.0.0.

N.02 FW:1.0.0.

N.12 FW:1.0.0. Set

Esc

Access level:3 01/01/2020

18:23

B

A

C

D

E

F

G

C

C

C

C

B

B

D

D

Module xxx

Address

12

Esc Set

H

10 Configuration

Fire detection and extinguishant system

Due to the fact that each FPMEXT front plate module is associated automatically with 5 internal IFMEXT modules at

precise addresses, the FPMEXT modules must have an address which respects the IFMEXT - FPMEXT module association

table which follows:

On returning to the control-panel configuration section, the assigned address ([D]) will be shown at the side of the

previously selected internal module.

2.5 Setting the Hornet+ network address (IFMNET)

If the installation has control panels connected in a Hornet+ network, it will be necessary to assign the network address

to each control panel.

Select the IFMNET module in the section on the left containing the internal layout of the cabinet ([A]). In the section

which appears, enter the network address and the bit rate.

Note: Each control panel in the same Hornet+ network must be set with the same bit rate and univocal

address.

2.6 Addressing the repeaters

The procedure to configure the FPMCPU modules as repeaters depends on the type of connection between the

modules and the control panel.

Connection via Ethernet network

The Ethernet connection needs network parameters setting. The procedure must be done via the display of the module

itself, following the indications described in the paragraph 2.2 Setting the IP network address.

Connection via RS485 BUS

The BUS connection needs the addressing of any repeater in configuration,

in order for the control panel to identify each module individually.

To assign an address to a repeater, it is necessary to enter the configuration

procedure starting from the display of the module itself, as described in the

paragraph 2.3.

A window will open, select the desired address in the programming field,

then tap on Set. The available addresses are from 1 to 14.

Addressing the extinction module

IFMEXT FPMEXT IFMEXT FPMEXT IFMEXT FPMEXT

11 113 215

21 123 225

31 133 235

41 143 245

51 153

62 164

72 174

82 184

92 194

10 2 20 4

Address

14

Esc Set

Configuration manual

Configuration 11

Attention: The “0” address is reserved to the main FPMCPU module. Do not use.

2.7 Enrolling loop devices (IFM2L)

The operations required for the configuration of the IFM2L network modules involve the configuration of the devices

connected to the loops.

The selection of the module from the internal layout section of the cabinet (paragraph 2.1 Access to programming,[A])

will access the configuration section which, in addition to providing the change address button (at the top) also provides

two identical sections for each of the two loops (connected to the Loop-A and Loop-B terminals). The present

document describes the operations necessary for the configuration of a single loop, however, it is implicit that the

operations be repeated for each of the two loop.

[A] Button to access the section for IFM2L module address assignment (paragraph 2.4 Addressing IFM

and FPM modules).

[B] Sections containing the configuration menu of the single loops.

Section on the left for the loop connected to the Loop-A terminals, on the right for the Loop-B terminals.

Update Esc

Access

level:2 01/01/2020

18:23

001

002

003

004

005

006

007

008

009

010

013

014

015

016

017

018

K

023

024

025

Loop1: Loop1

Loop O terminal: OK

Loop I terminal:

Loop consumption (mA): 15

LOOP CLOSED

Generic: 1

Detectors: 44

IN Modules: 12

OUT Modules: 5

IN/OUT Modules: 0

Sounder/flashers: 3

Call points: 8

Loop reset Scan Show topology Esc

Access

level:2 01/01/2020

18:23

Loop module Change address

Loop 1 Loop 2

Diagnostics Diagnostics

Parameters Parameters

Auto-configure Auto-configure

Esc

Access

level:2 01/01/2020

18:23

A

B

C

D

B

E

FG

IH J

J

C

D

E

C

Acquire

Readdress

Update

Add/Change

Esc

E

L

M

N

O

Procedure in progress

Procedure completed

Found: 73 100%

1 Generic

44 Detectors

12 IN modules

5 OUT modules

0 IN/OUT modules

3 Detectors

8 Call points Diagnostics

Esc

Access

level:3 01/01/2020

18:23

Found: 72

N. SN Type Description SN Type

1010EE4D4 Opt. det. Opt. det. 01 010EE4D4 Opt. det.

2010EE4E0 Opt. det. Opt. det. 02 010EE4E0 Opt. det.

3010EE0AB IN IN Input module 01 010EE0AB Opt. det.

4 010C7CAC Call

point Button 01

5010E1CE0 Opt. det. Opt. det. 03 010E1CE0 Opt. det.

6010EE6F2 Opt. det. Opt. det. 04 010EE6F2 Opt. det.

Esc

7010ECC90 Opt. det. Opt. det. 05 010ECC90 Opt. det.

8010EFF12 IN IN

Ok

9010E122C IN IN Input module 03 010E122C IN IN

Access

level:3 01/01/2020

18:23

Delete

N. SN Type Description

1010EE4D4 Opt. det. Opt. det. 01

Add/Change

2010EE4E0 Opt. det. Opt. det. 02

3010EE0AB IN IN Input module 01

Program

4 010C7CAC Call point Button 01

5010E1CE0 Opt. det. Opt. det. 03

6010EE6F2 Opt. det. Opt. det. 04

7010ECC90 Opt. det. Opt. det. 05

Esc

8010EFF12 IN IN Input module 01

Access

level:3 01/01/2020

18:23

O

L

M

N

C

Change address

12 Configuration

Fire detection and extinguishant system

[C] Button to access the section for loop diagnosis.

[D]

Button to access the section for the selection of the type of devices installed on the loop.

It provides a check box for option selection “4 wires” (if the cabling has been completed as a ring

circuit, as required by the fire control standards).

Tap on Ok to confirm and exit.

[E] Button to access the automatic loop-configuration procedure.

[F]

Section which provides data regarding the electrical status of the loop circuit:

-Loop status: indicates whether the loop is a closed ring circuit or open

-Loop O Terminal: indicates eventual short-circuits or anomalies instantly on the “OUT” terminals

-Loop I Terminal: indicates eventual short-circuits or anomalies instantly on the “IN” terminals

-Loop Consumption: indicates the current absorbed by the loop

-Cable resistance: indicates the cable resistance value

[G] Section which provides the number and type of devices currently in the configuration.

[H]

Button to rearm the loop and reassess the status.

In the event of a “Loop open” fault, it will be necessary to tap on this button in order to check

whether or not the interruption has been cleared.

[I]

Button to start a check on an already enrolled loop.

The procedure verifies whether there are any connected devices which are not in the configuration,

if devices have been lost or if there are any other anomalies.

The result of the scan can be viewed in the section on the right ([G]).

[J]

Button which passes to the map of the devices in the configuration of the enrolled loop.

The display provides an exact diagram of the device connections. Any devices in alarm or fault status

will be outlined in red or yellow.

The selection of a device will access its management page (refer to the Device management section

in the Installation manual).

[K] Button to refresh the screen by updating the alarm and fault indications of the devices shown

(restored fault events will not be shown).

[L]

Button to perform a scan which will search the loop for devices and their serial numbers and place

those found in the configuration.

A report of the devices will be shown when the scan terminates. The “Diagnostics” button will allow

you to pass to the technical report, as shown in the previous points ([C]).

For loops operating with Inim or Argus protocol, it is possible to use this procedure only after

completion of an automatic or manual addressing procedure by means of a programmer

(EDRV1000 for Inim loops and VPU100 for Argus).

[M]

Button to perform a scan which will search the loop for devices and their serial numbers and assign

automatically an address to each of those found in order of their connection to the loop. This

operation may take several minutes depending on the size and composition of the loop.

A report of the devices will be shown when the scan terminates. The “Diagnostics” button will allow

you to pass to the technical report, as shown in the previous points ([C]).

For Apollo devices, where the address is assigned by means of the microswitch on the device, these

operations coincide with those previously described (“Acquire”).

[N]

Button to start the procedure which is to be performed after changes have been carried out on a

previously configured loop (add, remove or replace devices).

The control panel will provide a table with the previously acquired configuration in the columns on

the left, and the newly detected configuration in the columns on the right. Positions in which

changes have not been detected will be outlined in green. Changes will be indicated in white. This

operation may take some minutes depending on the size and composition of the loop.

The OK button will allow you to accept the new configuration which will become the configuration

saved to the memory.

Procedure available for loops with Inim protocol only.

Diagnostics

Parameters

Auto-configure

Loop reset

Scan

Show topology

Update

Acquire

Readdress

Update

Configuration manual

Configuration 13

2.8 Acquiring the configuration

Once the previously described operations have been completed, it will be necessary to save the defined configuration to

the control panel memory. This operation can be done via the configuration screen, by means of the “Set” button

(paragraph 2.3 - [G]).

A progress bar will confirm data saving in course.

Once this operation has been completed and valid addresses have been assigned to all the devices, the

configuration status icon will turn green. Any successive changes to the hardware configuration (for example,

the loss of a module or addition of a new module) will turn the icon yellow to signal that the control panel

configuration is different to the one saved to the memory.

2.9 Signal check and fault search

Once the configuration setup has been completed, the control panel will check the status of the devices and input/

output terminals.

Eventual faults on these elements will be shown on the screen. In this case, it is necessary to remove the causes of the

fault until you return to the stand-by screen that shows no fault messages (refer to the Previdia Max system installation

manual).

2.10 Factory data

The Factory data button from the programming menu (paragraph 2.1)

deletes all the configuration data and resets the control panel to the

factory default settings.

As an alternative to using the Factory data button, it is possible to reset

the factory default settings by means of the buttons on the back of the

FPMCPU front-plate module. Press and hold the “Factory data” button [A]

and press and release the “Reset” button [B].

Following confirmation of the request to reset to the factory data, the

selection of the control panel languages will be requested (a mandatory

main language and an optional secondary language).

A progress bar will confirm factory data resetting in course.

2.11 Setting the date and time

When setting this parameter, it is necessary to tap on the respective field in the bottom right-hand corner of the screen,

enter an access code with either supervisor or installer capabilities then, by means of the scroll keys, navigate through

the programming fields and set the desired date and time.

[O]

Button to access a section which will allow you to select a specific address and change, remove or

add a device manually.

At the side of the loop device list are a series of buttons which will allow you to work on the device

selected by a screen tap gesture, as follows:

-Delete: button to delete the selected device.

-Add/Change: button to change or add a device manually.

After completing the connection of a new device or replacing an old device, it is necessary to

select the address involved then tap on the Add/Replace button.

When using Inim protocol, it is necessary to enter the serial number of the new device.

-Program: button to access a section where it is possible to change some of the device

parameters.

Once this operation has been completed the control panel will communicate with the new device.

The appearance of the type of device detected is the confirmation of its presence.

Arrow buttons

Button to step back

Add/Change

Esc

B

A

14 Configuration

Fire detection and extinguishant system

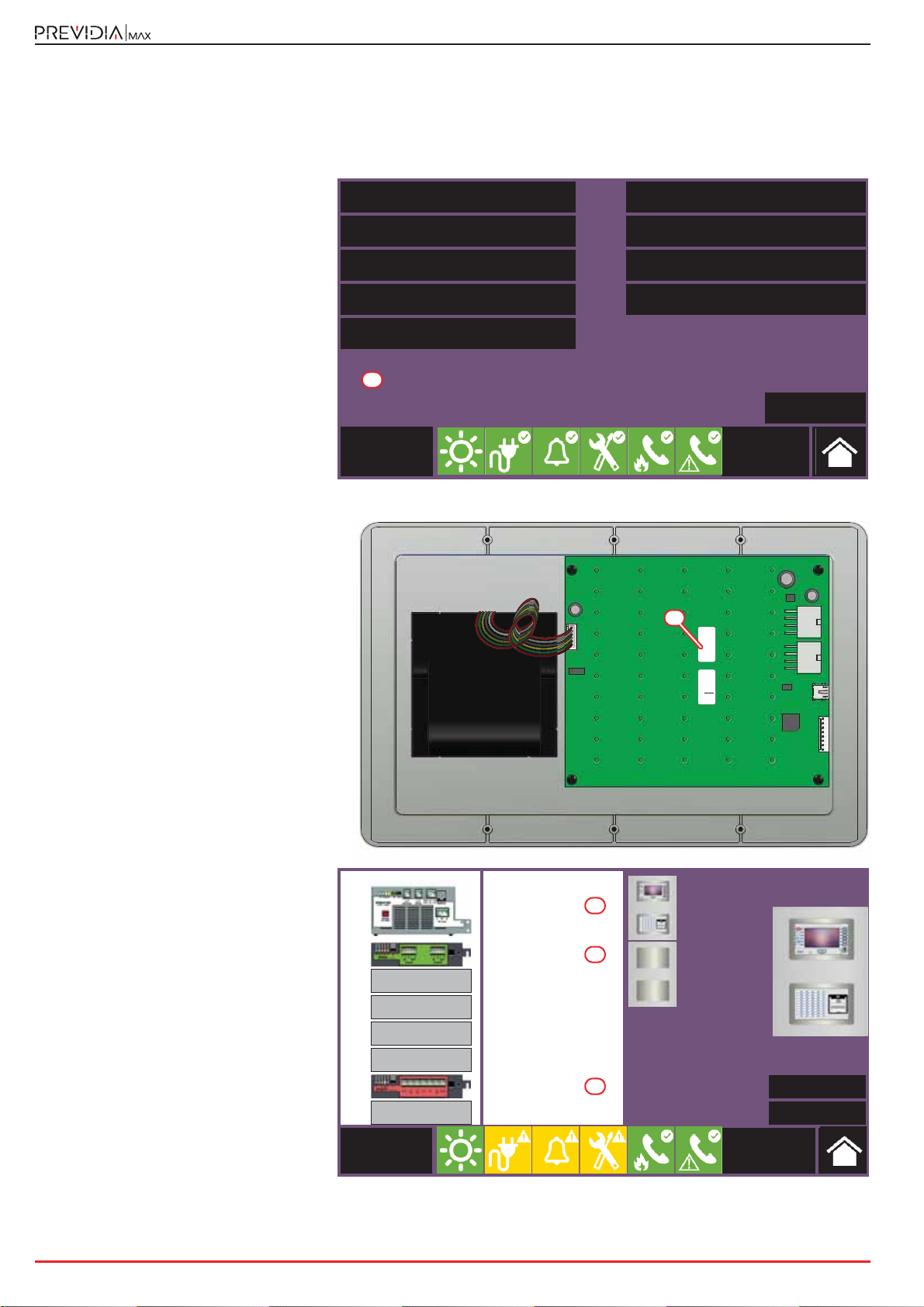

2.12 Firmware revision

The installer of Previdia Max system can see the firmware revision of each control panel module in order to facilitate any

upgrade or configuration procedure.

Such information can be achieved depending on the type of the module:

FPMCPU front-plate module: by means

of the System status button on the

display in the stand-by condition, you

can access a section where it is possible

to view the status of the various system

elements.

In the lower left corner of this section [A]

you can see:

• serial number of the FPMCPU module

• counter of the number of alarms

starting from system installation

• firmware version of the FPMCPU

module (FW, both the main and the

emergency backup CPU.)

• minimum required revision of Previdia/

STUDIO configuration software (SW)

• site specific data release (Data),

progressive number of system

configuration upgrades

FPMLED, FPMPRN, FPMEXT front-plate

modules: the module firmware revision is

written on a label on the back of the module

[B]; the label can be seen by opening the

cabinet door when the module is already

installed.

IFM internal modules: the firmware of

each internal module (already installed)

can be seen by accessing to the

configuration menu (paragraph 2.3).

The address and the firmware revision of

the detected modules are shown in the

proper section [C].

Control panel Dialer

Zones I/O Lines

Points Extinction modules

Groups Cloud

Timer

SN:SNSNSNSN Alarm counter: ccc

FW001FPMCPU - FW:xxxxxxxxxxxxx - SW:yy.yy.yy - Data:zzz Esc

Access level:1 01/01/2020

18:23

A

FW0000FPMxxx

1.00

SBQC0000INxxx

QC

PASSED

NNNN

NNN-NN

MMMM-MM

DD/MM/YYYY

B

N.01 FW:1.0.0.

N.02 FW:1.0.0.

N.12 FW:1.0.0. Set

Esc

Access

level:3 01/01/2020

18:23

C

C

C

Configuration manual

Configuration 15

2.13 Registration of the control panel to Inim Cloud

The registration of a control panel is an operation that allows its accessibility to all Inim Cloud service users. It is therefore

necessary that the registration is carried out first by the installer, registered with the Inim Cloud service, so that later users

can add the already registered control panel to their own account.

1. Access the programming phase of the control panel (paragraph 2.1) and then press the Network button on the

menu that appears on the screen.

2. Enable the "Cloud enabled" option.

3. Access the "Enroll” section via the button that appears below.

4. Enter the 8-digit ID-installer number contained in the confirmation email received during registration to the Cloud as

an installer.

In this section you can activate the "Installer Property" option. If activated, the installer reserves the management of

accesses to the system by the Cloud. If not activated, this property is assigned to the first user enrolled

5. Press the Register button. The control panel will carry out the registration of the control panel on the Cloud and the

display will show the "WAIT" message.

If the control panel date/time differs by more than 15 minutes from the exact date/time, the registration process may

result negative.

6. The screen will show the outcome of the procedure via one of the following messages:

• “Account created!”: the control panel has been successfully registered to Cloud

• “Communicat.Error”: generic communication error.

The possible causes may be:

- no Internet connection

- date of manufacture of the control panel is earlier than dd/mm/yyyy

- date/time of control panel different, ahead of or behind the exact date/time by more than 15 minutes

• “Already enrolled”: the control panel is already registered to Cloud

• “Panel notEnabled”: the control panel cannot be registered to Cloud.

16 Commissioning

Fire detection and extinguishant system

Chapter 3

Commissioning

The commissioning phase is a set of tests and inspections which are necessary to ensure the full efficiency and proper

functioning of the system as specified in the system project. This phase is essential and must be performed in a

scrupulous way in accordance the regulatory requirements of the country where the system is installed and in full

respect of the recommendations in the following section.

Ensure the test and inspection procedures are performed only after checking the safety of the system and after having

verified that any device activations controlled by the system will not cause any conditions of danger, and that all the

building occupants who can be reached by the audible and visual signalling have been informed.

Ensure that the person who is responsible for the security of the building where the tests and inspections are to be

carried out has taken countermeasures to avoid any situations of panic or distress for the building occupants.

3.1 Testing the Control panel

It is necessary to check the functionality status of the frontplate by first checking the information supplied on the screen

and LEDs and then by inspecting the efficiency of the command devices (user-interface buttons, access keys, etc.):

• Check the functionality status of the screen and ensure that the information provided is clear.

• Ensure that the descriptions of the various zones, points and system elements entered during the data-entry phase are

correct, and that the information provided on the screen clearly indicates any detectable conditions of danger.

• Check that there are no indications present of faults, alarms or anomalies of any type whatsoever. In the event of such

indications, proceed with the removal of the causes of faults and anomalies.

• Check the status the functionality of the LEDs and buzzer. The front panel provides a button for the simultaneous

activation of all the LEDs and buzzer thus allowing evaluation of their efficiency (refer to the description of the User

Interface).

• Check the efficiency of the front-plate buttons and keys.

• Check the status of the power-supply sources (mains and batteries) and the consumption conditions of the control

panel. The power-supply parameters can be checked by accessing the configuration menu (refer to paragraph 2.3

Accessing the configuration menu) and selecting the configured IFM24160 modules.

The sections show the voltages, currents and temperatures of the various elements:

[A] Button for addressing the

module

[B] Section containing a list of

current faults

[C] Voltage and output current

of the IFM24160 module

[D]

Battery parameters (internal

resistance, voltage, status

and current)

[E] Internal temperature and

battery charge voltages

Low battery voltage

Mains fault

PSU 1 Module

Change address

Exit

27.0 V

0.225 A

150 mOhm

26.2 V

28°C

Charging

0.222 A

33°C

37°C

27.2 V Esc

Access

level:3 01/01/2020

18:23

B

A

C

E

D

Configuration manual

Commissioning 17

3.2 Testing to detectors and manual activations

All the installed detectors must be tested during the commissioning phase. It is necessary to check the capacity of each

detector to react to a simulated condition of fire, and to check the precision of the signals transmitted to the control

panel in response to its activation (description of the point and zone).

For this purpose it is possible to use the Test button of the control panel ([A])

on the “Zone status” screen, accessible via the “System status” menu on the

home page.

By tapping this button it is possible to place one or more zones in test status.

The activation of a detector which belongs to a zone in test status will not

generate any alarm signalling or activate the outputs or signalling devices.

However, the control panel will activate the signalling LEDs on the detectors

and will perform automatic reset after a few seconds without any need of

further intervention by the operator on the control panel.

The activation of a point which belongs to a zone in test status will be recorded in the events log. Therefore, on

completion of the test on all the zone devices, the operator can check the congruence of the various indications by

means of the log.

The activation of all the manual call points (alarm buttons) must be tested in the same way as described for the detectors.

3.3 Testing signalling and activations

The functionality and efficiency of all the signalling devices must be checked

thoroughly.

It is possible to test such devices by activating the relative LEDs and outputs

manually at the control panel via the respective management page ([B]).

To reach this page you must access the “Points” section via the “System

status” menu on the homepage. Select the desired loop and point to be

tested from the lists shown then, by means of the relative View buttons go

to the management screen where you will find the Turn On output and Turn

On LED buttons.

Note: Testing devices by means of manual activation does not test functionality and efficiency of the cause/

effect association which determines their activation (programming coherence of groups), therefore, it is

necessary to perform real functionality tests.

3.4 Testing the extinction system

Particular attention must be paid to the testing of eventual fire extinction systems.

Special attention must be paid to the functionality and safety of the extinguishing-agent release devices before

proceeding with the testing of all activation and stop-extinction procedures in accordance with the requirements of the

executive project.

3.5 Maximum time settings. Normative restrictions

During programming via the Previdia/STUDIO software you can set the time length or delay of many control panel

functions. The normative reference standards require maximum duration for the following parameters:

•Prealarm time, the maximum delay time is 10min (EN 54-2 - clause 7.11.1 (c)).

•Verification time OFF (s), if the verification function is enabled for an input device, the time for which the device

remains deactivated after the first activation must be 60 seconds maximum (EN 54-2 - clause 7.12.1 [b]).

•Verification time (s), if an input device has the alarm verification option enabled, the maximum verification time is 30

minutes (EN 54-2 - clause 7.12.1 [c]).

•Lock reset time after released (min), the maximum time is 30 minutes (EN 12094-1:2003 - clause 4.12.2).

•Pre-extinction time on automatic/manual activation, the maximum time is 60 seconds (EN 12094-1:2003 - clause

4.17.2).

•Valve ON time, the maximum time is 300 seconds (EN 12094-1:2003 - clause 4.21).

Refer to the Previdia/STUDIO software programming manual for more details about the parameters listed above.

Zone status

N. Description Status

1 Zone 01 Stand-by

2 Zone 02 Fault

3Zone 03 Stand-by

4 Zone 04 Stand-by

5 Zone 05 Alarm

6 Zone 06 Stand-by

Disable Test Esc

Access

level:2 01/01/2020

18:23

A

Loop module: 03 Point: 03 SNSNSNSNSN

Optical heat det.

Zone 02

Detector lost Replace Info

Turn On output Real-time

Turn On LED Camera

Disable point Map

Disable zone Esc

Access

level:2 01/01/2020

18:23

B

18 Maintenance

Fire detection and extinguishant system

Chapter 4

Maintenance

For correct and efficient management of the system it is necessary to carry out periodic maintenance in accordance

with the regulatory requirements of the country where the system is installed and in full respect of the recommendations

contained in this section.

For the frequency of the maintenance operations it is necessary to adhere to the applicable regulations. However, the

manufacturer recommends that tests are performed on each point, component and element of the system at least once

a year.

4.1 Testing the control panel

Work through the steps for control-panel test procedure as described in the commissioning section (paragraph 3.1

Testing the Control panel).

Additionally, consult the events log and check for the presence of fault or alarm conditions which must be investigated.

4.2 Testing the detectors

As well as the tests which must be performed during the commissioning phase (paragraph 3.2 Testing to detectors and

manual activations), it is also necessary to check the contamination level in smoke detectors.

The management and configuration software provides a loop diagnostic function which allows you to gather the

contamination values of the various devices in such a way to decide when cleaning is necessary.

Refer to the Programming manual for details regarding the diagnostic function and the detector manual for the

instructions regarding cleaning operations.

4.3 Manual activation test

Work through the same tests as recommended in the commissioning section (paragraph 3.2 Testing to detectors and

manual activations).

4.4 Testing signalling and activations

Work through the same tests as indicated in the commissioning section (paragraph 3.3 Testing signalling and activations).

Configuration manual

19

20

Fire detection and extinguishant system

Centobuchi, via Dei Lavoratori 10

63076 Monteprandone (AP) Italy

Tel. +39 0735 705007 _ Fax +39 0735 704912

ISO 9001 Quality Management

certified by BSI with certificate number FM530352

DCMCINE0PREVIDIA-151-20210128

Other manuals for PREVIDIA MAX

3

Table of contents

Other INIM Electronics Fire Alarm manuals

Popular Fire Alarm manuals by other brands

Dorgard

Dorgard DG1328-FP operating guide

Kentec Electronics

Kentec Electronics Taktis Vision Installation and operation manual

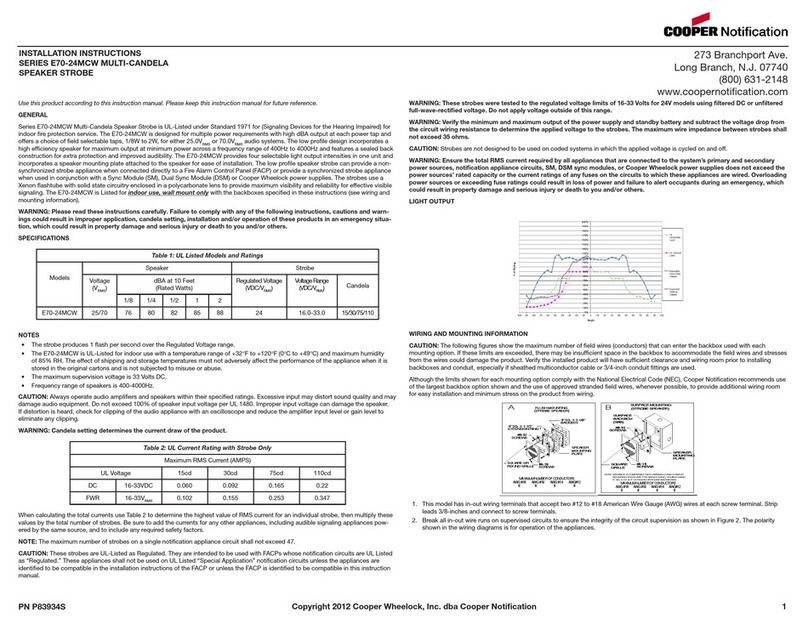

Cooper Notification

Cooper Notification E70-24MCW Series installation instructions

CWSI

CWSI CP-3000DA Operating and installation instruction manual

SILENT KNIGHT

SILENT KNIGHT 5860 Installation quick reference

Honeywell

Honeywell Silent Knight 6820EVS Basic operating instructions