Inivos ULTRA-V Operator's manual

User Instruction Manual

9002 V1/0820

ULTRA-V | USER INSTRUCTION MANUAL

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 3

ALWAYS READ THE INSTRUCTIONS

IN THIS USER MANUAL BEFORE USE

VERSION 1/0820

Ultra-VTM

User Manual

4

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 5

Section 1: Essential safety information Page 6

Section 2: The Ultra-V™ system Page 7

Section 3: Before using the Ultra-V™ system Page 9

Section 4: Using the Ultra-V™ system Page 16

Appendices

Appendix 1: Declaration of Conformity Page 26

Appendix 2: UV-C Light Page 27

Appendix 3: Infection Prevention and Control Page 28

Appendix 4: Ultra-V™ Study Page 30

Appendix 5: Ultra-V™ maintenance Page 32

Appendix 6: Information Page 33

Contents

The aim of this manual is to provide guidance, techniques, best practice and

responsibilities for eective use of the Ultra-V™ system.

Please read and understand this manual. This will ensure you are familiar

with the individual components and their functions of the Ultra-V™ system.

Step by step instructions will ensure optimum performance and results.

All units are tested in our UK manufacturing and test facility by trained

technicians. In the unlikely event of a malfunction or error, you should refer to

this manual to rectify minor faults yourself. In the unlikely event your Ultra-V™

develops a serious fault, then please contact the relevant 24hr helpline

displayed at the bottom of every other page.

Overleaf is a detailed table of contents to help you find your way around this

manual quickly. Enjoy using the Ultra-V™ system!

IMPORTANT: Please keep this manual in a safe place.

It contains safety and operating instructions for your Ultra-V™system.

Welcome

When you see a bracketed letter in bold (B), it corresponds to the

diagram of the Ultra-V™ on the fold out back cover. Please refer to this

to see where items are located on the Ultra-V™ system.

6

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 7

DANGER: Ultra Violet product. These lamps emit high-power

UV radiation that can cause severe injury to skin and eyes.

Avoid eye and skin exposure to unshielded light. Use only in

an enclosed environment which shields users and others from

the radiation.

Only trained and competent operators must use the Ultra-V™

system. Use by untrained personnel can lead to an ineective

decontamination treatment, accidents or personal injury.

Fully read and follow this user manual and follow provided

instructions before attempting to operate the Ultra-V™ system.

Never attempt to use the Ultra-V™ system for any purpose

other than its intended use as a decontamination system.

Never operate the unit outside an enclosed controlled area.

Do not operate the Ultra-V™ system in wet conditions.

Always ensure that the mains cable (D) is fully extended

before use.

Regularly check that the Ultra-V™ system (including its cables

and accessories) are free from damage. Do not use the

system if damaged, please contact Inivos for repair.

It is recommended that the Ultra-V™ system should be

connected to the mains through a 30mA RCD adaptor.

The Ultra-V™ unit must be earthed.

Do not use any other Power Adapter. Using an unapproved

Power Adapter may result in system damage. Call Inivos if

your supplied adapter is lost or damaged.

Do not attempt to open the Ultra-V™ system. There are no

user serviceable parts inside. Opening the Ultra-V™ system

could be dangerous, and will invalidate the warranty.

Do not attempt to replace the lamps (B) of the Ultra-V™

system, please contact Inivos for service.

Section 1: Essential safety information Section 2: The Ultra-V™system

2.1 Ultra-V™system

The Ultra-V™ system is a bio-decontamination system that emits UV-C light, which is a proven

technology for the reduction of biological contamination. The technology used by the Ultra-V™

monitors and adjusts the process to ensure consistent results in the reduction of surface

contamination.

The Ultra-V™ system is intended to be used in enclosed areas only. If an area to be decontaminated

cannot be enclosed and cordoned then please contact Inivos for further advice.

The Ultra-V™ system consist of three major components:

1. The Main Unit – This consists of ten low pressure mercury lamps responsible for the UV-C

light emission and the structure for the lamps and the electrical components.

2. The Process Monitor – This controls the main unit, starts the process, stops the process in

case of an emergency, and informs which stage the process is at.

3. Spectromes – There are 6 Spectromes. In use Spectromes must be located at strategic points

within the treatment area. They monitor the decontamination process, controlling the amount

of UV-C light necessary for an eective decontamination.

2.2 Ultra-V™Safety measures

UV-C light is an electromagnetic

radiation with shorter

wavelength than that of visible

light, in the range of 100-

280nm. This short wavelength

is eective in destroying

the nucleic acids of the

microorganisms so that their

DNA is disrupted by the UV

radiation, leaving them unable to

perform vital cellular functions.

Direct exposure to short

wavelength UV-C light can

cause sunburn and skin cancer.

Direct exposure to the eyes

can cause extremely painful

inflammation of the cornea and

temporary or permanent vision

impairment, up to and including

blindness in some cases. UV-C

light can also damage the retina

of the eyes.

1 2

3

A lamp breaking is extremely unlikely to have any impact

on your health. If a lamp breaks, ventilate the room for 30

minutes and remove the parts, preferably with gloves. Put

them in a sealed plastic bag and take it to your local waste

facilities for recycling. Do not use a vacuum cleaner.

Do not attempt to defeat the safety systems.

Avoid placing the Ultra-V™ adjacent to Air-conditioning

vents, as this could result in incomplete, or termination of the

process.

Always use supplied door barriers to secure all entrances to

the treatment area.

Never enter a space where the Ultra-V™ system is operating,

wait until the process has completed and the process monitor

is displaying process finished.

Always disconnect the system from the mains supply when

not in use.

Do not use harsh or abrasive chemicals to clean the Ultra-V™

system or its accessories. Suitable Solvent free wet wipes

or a damp cloth may be used for cleaning. Always test for

suitability in a small area first.

The Ultra-V™ system must be serviced and PAT (Portable

Appliance Testing) tested for electrical safety every six

months. Note that the system does not have any user

serviceable parts.

Never look directly at the Ultra Violet light source. The system

is designed to produce Ultra Violet radiation which can be

harmful to eyes and skin if directly exposed.

Always carry out a site and location specific risk assessment,

taking into consideration the hazard analysis and risks

reduction identified and implementing suitable control

measures to avoid harm or injury to anyone.

8

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9

2.3 Ultra-V™Process Safety

In order to avoid these potential risks of the UV-C light the Ultra-V™ system comes with a

number of safety and security features that are designed to minimize the potential risk of

accidental UV-C exposure:

1. The operator must secure all the entrance/exit points to the treatment area and

display visual warning signs at all the entrance points to the space. Use Inivos tape

to block any potential UV-C Light leakage.

2. In case of emergency, a “Stop Process” soft button is available during the process on the

screen of the Ultra-V™ Process Monitor (BB), pressing it will switch o the lamps immediately

and carry out safety checks. Do not enter room while the Process Monitor is performing safety

checks.

3. The Ultra-V™ Process Monitor communicates with the Ultra-V™ main unit by Wi-Fi, this

communication is checked every 10 seconds, in the case that the communication is lost,

Ultra-V™ automatically switches o the lamps.

4. As a last resort, Ultra-V™ units are equipped with a movement sensor system (C) that

automatically switch o the lamps when any movement is detected. Therefore, if someone

inadvertently enters the treatment area, Ultra-V™ will automatically switch o the lamps to

minimise exposure to UV-C light. This safety feature is last resort, putting any person very

close to the hazard, and therefore must not be used to switch o the Ultra-V system light.

5. UV-C Light emitting lamps (B) feature a polymer coating sleeve which is designed to safely

contain any glass in case of breakage.

6. The lamps of the Ultra-V™ system are provided with special lamp glass that filters out the

wave-lengths which produce ozone, therefore the amount of ozone produced during the

decontamination is negligible. If possible, allow the room to be ventilated before entering after

the decontamination process.

7. Site specific risk assessment must be carried out taking into account hazards identified in this

manual and the hazard analysis and reduction report.

3.1 Pre-operation checks

Remove soft cover and stow away safely. Position the system in the

room to be decontaminated.

Each Ultra-V™system is individually tested for full functionality and

calibrated before despatch. There is a small amount of machine set

up required before use.

Check the Ultra-V™system for damage after unpacking. Do not

connect the electrical supply if any damage is identified. Check each

bulb for damage.

Check the spectormes LED’s light up, if not replace the batteries.

Section 3: Before using the Ultra-V™ system

Likelihood

5510 15 20 25

44 8 12 16 20

33 6 9 12 15

22 4 6 8 10

11 2 3 4 5

1 2 3 4 5

Consequence

3.2 Hazard Analysis and Risk Reduction Report

This document follows a standard risk evaluation and preventative action process to

understand hazards and minimise risk to operators and to ensure process eiciency.

Through a process of implementation and audit of standard operating procedures, risk

associated with Ultra-V™Decontamination Process can be minimised independent of

operator ability, ensuring safe operation of the Ultra-V™System within the healthcare setting.

Quantitative Risk Assessment scoring

Likelihood scoring:

1. Rare - Will probably never happen or recur

(unlikely to occur /may happen sometime in 5 to 25 years)

2. Possible (under unfortunate circumstances) - Unlikely - Not expected to happen or

recur, but possible (Possible to occur in time; may happen sometime in 2 to 5 years)

3. Possible - Might Happen or recur occasionally (Possible to occur in time; may happen

sometime in 2 to 5 years)

4. Probable - Likely - Will probably happen or recur, but is not a persisting issue or

circumstance (Probably will occur in time; may happen sometime in 1 to 2 years)

5. Almost Certain - Very Likely - Very likely to happen or recur: possibly frequently (likely to

occur immediately or within a short period of time; may happen several times in one year)

10

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 11

Descriptor Consequence

1Very Low • Minor reduction in quality of service

• No or minimal eect for customers or patients

• Minor Injury, First Aid not required

2Low • Single failure to meet acceptable standards of quality or service

• Low eect for small number of customers / patients if unresolved

• Minor Injury, First Aid required

3Moderate • Repeated failure to meet acceptable standards of quality or service

• Moderate eect for multiple customers or patients if unresolved

• Injury requires Doctor or hospital attendance

4High • Ongoing noncompliance with standards of quality or service

• Significant eect for numerous customers / patients if unresolved

• Major Injury resulting in Disability

5Very High • Gross failure to meet standards with totally unacceptable levels of quality

or service

• Very significant eect for a large number of customers / patients

if unresolved

• Fatality

In the interest of corporate responsibility, Specialist Inivos Will not

participate in activities that are categorised as Very High Risk.

3.3 Hazard and Risk reduction associated with personnel

IDENTIFIED HAZARD EXISTING CONTROLS

Likeli-

hood

Impact

Score

PREVENTATIVE ACTION

Exposure to UV-C Light

radiation when personnel

inadvertently enter the area

being treated during the

process. Direct exposure

to UV-C light. (This is Class

3 equipment as per BS

EN 62471:2008 Standard)

can cause eye and/or skin

damage1. Daily UV-C light

exposure limits can be

exceeded within seconds.

In case of emergency, a “Stop Process” soft button is

available during the process on the screen of the Ultra-V™

Process Monitor. Ultra-V™UV-C light hazard and caution

signs are displayed. Ultra-V™units are equipped with a

movement sensor system that automatically switch o the

lamps when any movement is detected.

Ultra-V™radiation will switch o when movement is

detected within the Artificial Optical Radiation Directive

Guidance limits2.

Ultra-V™system is provided with a User Manual.

Operators are provided with an accredited training

qualification.

3 1 3 • The operator must secure all the entrance/exit points to the

treatment area using the supplied door barriers and display

visual warning signs at all the entrance points to the space.

• Never look directly at the Ultra-V™light source.

• In addition to the hazards identified in this report, a Site-

specific risk assessment must be carried out.

• The Ultra-V™system is intended to be used in enclosed areas

only.

• Operator or any other personnel must not enter the room

while the decontamination process is in progress.

Leakage of UV-C light

during the treatment cycle to

adjoining areas

Only trained operators use the Ultra-V™ system. The

process can be started only with the unique authorization

card which is only issued to trained sta.

3 2 6 • All gaps should be blocked using supplied tape.

Strain or injury to the operator

during moving and handling

of the Ultra-V™equipment

and setting up Ultra-V™

equipment before and after

the decontamination process

Secured on four fully steering castors, with a 360-degree

handle, allowing Operator to maneuver system without

the need for heavy lifting.

The center of gravity of the main system unit is very

low, which makes it very stable and easy to move. The

Ultra-V™User Manual indicates the correct system

maneuvering information. Setting up equipment for the

decontamination process does not require heavy lifting

and is quick, simple and safe.

2 3 6 • Operators of the unit should always maintain an upright

posture and avoid lowering their shoulders to push the

machine as this can put undue pressure on the lower back

area.

• Never attempt to lift the Ultra-V™.

• Avoid any drops like steps, kerbs and loading bays - do not

attempt to wheel the Ultra-V™down steps.

• Always follow best manual handling techniques and

practice.

• The Ultra-V™Systems should only be used by trained and

competent operators.

• Training sessions allow operators to follow the correct room

decontamination procedure

The operator is exposed to

high electrical voltage.

No exposed live parts are accessible to the operator

under normal conditions. The electronics box requires a

tool to open and for a service personnel warning label is

placed on the electronics box door to warn of the danger.

1 5 5 • Operators must carry out standard visual electrical safety

checks before using the equipment. The system must not be

used if damage to cables or system is identified.

• All Ultra-V™equipment should be periodically serviced and

electrically checked in accordance with relevant Electrical

Safety Regulations.

Fire All heat sources are adequately enclosed in metal

compartment.

Warning signs are present and visible to identify potential

heat hazards.

1 3 3 • Site specific risk assessment must be carried out taking into

account hazards identified in this report.

• Ultra-V™system must not be used in the proximity of

flammable or explosive materials.

12

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 13

3.3 Hazard and Risk reduction associated with personnel

IDENTIFIED HAZARD EXISTING CONTROLS

Likeli-

hood

Impact

Score

PREVENTATIVE ACTION

Injury in case of UV-C lamp

breakage.

The UV-C emitting lamps are housed

securely in the main unit and feature a

polymer sleeve which is designed to safely

contain any glass in case of breakage.

1 3 3 • Operators must follow best safe handling practice.

• When maneuvering the Ultra-V™decontamination system, only use

the handle. Care should be taken to avoid sharp knocks and bumps

particularly on the lamps of the Ultra-V™system.

Mercury release for Ultra-V™lamp

breakage

All lamps have a polymer sleeve to

minimize breakage due to minor knocks.

A lamp breaking is extremely unlikely to

have any impact on your health.

2 1 2 • Handle Ultra-V™system with care.

• If a lamp breaks, ventilate the room for 30 minutes and remove

the parts, preferably with gloves. Put them in a sealed plastic bag

and take it to your local waste facilities for recycling. Do not use a

vacuum cleaner.

Trip hazards associated with the

set-up and use of the Ultra-V™

equipment.

The Decontamination system is equipped

with a 4-meter length of cable, which in

most cases, will stay with-in treatment area.

The process monitor is supplied with

1.5-meter length power adaptor, which

could be extended using the supplied

extension cable.

3 3 9 • Operators should be trained in cable management.

• The cable in most cases, will stay with-in the treatment area.

• Routing cables safely and if necessary use of covers.

• Decontamination process should not proceed If the unit cannot be

used safely.

Injuries or hazards related to

misuse and defeat of safety

features

The system is designed with several safety

features including PIR sensors, software

safety and a “one fault should not present

a hazardous situation” design rational

2 3 6 • The operator must follow the User manual. Only trained operators

should use the system. Trained operators are issued their own time

limited operator card to use the system until refresher training is

due and in built system reporting helps identify misuse.

Ref 1. Photobiological safety of lamps and lamp systems (BS EN 62471:2008)

RISK GROUP Maximum Permissible UV Light

Eective Irradiance (Ee) At 20 Cm.

180 Nm – 400 Nm

Mpe Time At 20 Cm For

Uprotected Skin And Eye Within

An 8 Hour Period Per Day

Exempt 0.001 W/m2 8.33 hours

1 (Low) 0.003 W/m2 2.77 hours

2 (Moderate) 0.03 W/m2 16.66 minutes

3 (High) > 0.03 W/cm2 < 16.66 minutes

Table 1 Risk group classification

Limitations

Classification is determined by UV light irradiance values at 20 cm distance – relates to the

UV light emission of the source rather than characterising the exposure of a person – may

not be appropriate for many applications.

Applies to normal operation only – may be not applicable to maintenance, service or

abnormal operation (e.g. with broken filter glass). Relates to a single product – doesn’t

account for accumulative exposure from multiple sources.

Exempt group regarding the un-weighted UV-A limit is based on the ACGIH integration

duration of 1,000 seconds – exposure to such lamps at a distance of 20 cm for longer than 16

minutes could lead to exceeding the ICNIRP ELV, where the integration duration is 8 hours.

Ref 2. AORD Exposure Limits for UV-C Disinfector

DISTANCE

/ meter

Angle Between Emitter

& Detector ()

Time To Exceed Aord

Limit For Uv-C (Seconds)

LB(Wm-2sr-1)

1 0 5.5 0.0111

2 0 14.3 0.0057

190 246.4 0.0027

1180 797.6 0.0025

Table 2. AORD exposure limit with respect to the UV-C hazard. LB for an 8-hour shift is 100

Wm-2sr-1

The Control of Artificial Optical Radiation at Work Regulations 2010 SI No. 1140. Lower

exposure limits may apply to Young persons. Specific young person’s risk assessment must

be carried out.

14

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 15

3.4 Manoeuvering the Ultra-V™equipment

The Ultra-V™is designed to be operated by a

single person. Secured on four fully steering

castors with a 360 degree handle (F) the

Ultra-V™unit is very easy to turn left or right.

Most of the weight is at the bottom of the unit,

which makes it very stable and easy to move,

although care must be taken while pushing

the Ultra-V™, especially up gradients. Maintain

an upright posture and avoid lowering your

shoulders to push the machine as this can put

undue pressure on the lower back area. Never

attempt to lift the Ultra-V™.

Take particular care when manoeuvring the

equipment outside. Avoid any drops like steps,

kerbs and loading bays - do not attempt to

wheel the Ultra-V™down steps! Always follow

best manual handling techniques and practice.

Care should be taken to avoid sharp knocks

and bumps, particularly on the lamps of the

Ultra-V™. For your safety, the lamps of the

Ultra-V™(B) are provided with a polymer

coating sleeve which is designed to safely

contain any glass in the case of a breakage.

BAD POSTURE GOOD POSTURE

NOTE: When manouvering the Ultra-V™decontamination system, only use the handle.

3.5 Setting up the treatment area

The system does not require the use of chemicals to disinfect, unlike other

technologies. The pre-treatment set up required is therefore minimal compared

to other disinfection technologies. However, the use of the Ultra-V™technology

requires you to follow a protocol to ensure the maximum eiciency of the

process:

Exposed surfaces - Ensure the maximum

number of elements and surfaces are going

to be exposed to the UV-C light. The Ultra-V™

technology relies on the UV-C light to reduce

the surface contamination, the surfaces that

are directly exposed to the UV-C light will

receive the highest dose of UV-C light while

the surfaces that are exposed to indirect

UV radiation will present a lower grade of

decontamination.

Cleaning – Ensure the room has been manually

cleaned to remove gross soiling, dust and dirt.

Dirt and dust interfere in the eectiveness of

the decontamination process by shielding the

microorganisms and not allowing the UV-C

light to directly irradiate the surface to treat.

In this context cleaning is:

The removal of organic matter

The removal of adhesive residues

and films and spills

The removal of dust and visible dirt

Free from waste materials

Free from loose or compromised surfaces

Block possible UV-C leaking areas – UV-C

light must not be transmitted to any adjacent

area. In order to avoid this, the operator must

ensure that all the openings are closed and

gaps are sealed o to block the transmission of

UV-C light from one area to another.

Location of the Spectromes around the

treatment area – Spectromes monitor the

amount of UV-C light they are receiving

from the main unit. This helps them control

the process and ensures an eective

decontamination process. Therefore,

Spectromes must be located around the

treatment area (see section 4.6), ensuring that

all the surfaces receive a suicient amount of

UV-C light for an eective decontamination.

The Ultra-V™process lasts for a maximum of

45 minutes. In the case that one or more of the

Spectromes have not received enough UV-C

light after the 45 minutes of treatment, the

process monitor will indicate which areas have

not been properly decontaminated, allowing

the operator to relocate the Ultra-V™system

and rerun the decontamination process.

16

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 17

IMPORTANT: The Ultra-V™system should only be used by trained & competent operators.

4.11 Identify, Cordon

and Secure the area to be

treated against general

access. Stick “NO ENTRY –

decontamination in progress”

signs on every access door.

Fill all required entries on the

Warning sign sheet. Enter the

area location, room name,

date, time, operator, etc

4.12 Wheel the Ultra-V™

main unit into the centre of

the treatment area & apply

brakes.

4.13 Unhook the process

monitor from the main unit by

lifting it and placing it outside

the room.

4.14 Take the Spectromes

out of the storage tray

and place them within the

treatment area as far from the

Main Unit as possible. Make

sure The Spectromes sensor

eye is facing the Main Unit.

By doing so, the Ultra-V™unit

will automatically calibrate

to the size of the treatment

area and will ensure that the

right amount of UV-C light is

emitted. (Refer to Spectrome

placing diagrams page 23)

4.15 Fully extend the main

cable (D) of the unit by

grasping the main plug and

pulling. Plug the main cable

into a convenient socket, using

an extension lead if necessary.

If an extension lead is used,

it must be in accordance

with site rules, approved CE

marked 13A extension lead

and must be fully unwound,

not left in a coil.

4.16 Connect the Process

Monitor to the convenient

mains socket by using

supplied Power Adapter

(AA). If required, use supplied

Cable Extension for extra

cable length. Use ONLY Inivos

approved Power Adapters

and Cable Extensions.

4.17 Process Monitor will

connect to Ultra-V™System.

You will be prompted with the

confirming message on the

screen (BB).

4.18 Close the door of the

area to be treated. Ensure the

warning signs are displayed

at all entrances to the space.

Use Supplied Door barriers

to secure all entrances to

the treatment area. Block

any gaps using Inivos Tape

provided.

4.19 When asked - If you

are satisfied that it is safe to

start the decontamination

process then present your

key card. (CC). Ultra-V™

Process Monitor will now ask

if you are ready to start the

decontamination process.

4.20 Check to ensure that

the entrance/exit points

to the treatment area are

closed locked and sealed

so that no UV-C light is

going to irradiate outside the

treatment area, then press

“YES (start process)” on the

process monitor screen.

4.21 The system will

now perform a Baseline

calibration.

4.22 Once the Baseline

calibration has finished, the

process monitor will show

the status of each Spectrome.

Thumbs up symbol would

mean that Spectrome is

working and communicating

with the system. Thumbs

down symbol would mean

that Spectrome is not working

or communication is lost.

Low battery sign would

mean that the batteries need

replacing. If either of the

last two symbols appear,

re-enter the room, replace

the batteries, or reset the

Spectrome by placing it back

into the holder. Press ‘’NO

(start again)’’ button on the

process monitor. Process

monitor will reset the system

and will repeat the Baseline

calibration – Steps 4.17 to

4.22. The Ultra-V™system can

be used with fewer than 6

Spectromes if necessary.

4.23 If all in use Spectromes

appear with the thumbs up

symbol, Baseline Calibration

has been successful. Now,

press ‘’YES (ready to start)’’

on the process monitor

screen. Decontamination

process will start after 30

seconds. You will hear a

warning sound prior to the

UV-C lamps activating.

4.1 Ultra-V™user instructions

Section 4: Using the Ultra-V™system

Ultra-V™warning sign

The Ultra-V™warning signage is a simple and highly

visible single use sign to inform personnel of the Ultra-V™

process.

The sequentially numbered signs come in pads of 50,

glued and stitched at the spine and perforated to remove

the sign before use. The ‘proof of process sign stub’

retained in the spine of the book has space to complete

process time, date, location and operator details and

can be retained as proof of process for later reference.

There is space for the operator to complete the predicted

process times and contact details in case of emergency.

There is also a handy pre-process checklist on the

reverse to ensure all necessary preparations are carried

out prior to the process in order to achieve maximum

eicacy of decontamination and safety in operation.

I am aware of the infection risk in this room or area Yes

I have observed the relevant local protocols for the use of the Ultra-V system Yes

I have observed local infection control protocol for access to the room or area Yes

I have identified specific room requirements for the safe use of the Ultra-V system Yes

I have set-up the Ultra-V decontamination equipment in the room Yes

I have sealed the air ventilation and extraction Yes

I have isolated fire alarms Yes

I have checked that the room is safe to run decontamination process Yes

I have checked to ensure that the room is safe to re-enter Yes

I have handed the room or area back to the clinical sta Yes

Operator:Date:Location:

Operator:Date:Location: Process number:

Process number:

Start time:

Start time:

Finish time:

Finish time:

DO NOT ENTER

DECONTAMINATION IN PROGRESS

FOLLOW THE LOCAL RULES AND

USER MANUAL FOR CORRECT

USE OF THIS EQUIPMENT

THIS PROCESS PRODUCES

NON-IONIZING RADIATIONS

Is the infection risk known in this room or area? Yes/No If yes, what is the Infection:

PLEASE REFER TO LOCAL RULES FOR DEFINITIONS AND RESPONSIBILITIES

Ultraviolet-C light Decontamination

Ultra-V™ is a UV-C light decontamination device. It emits light specifically at the

wavelength 254nm through 10 powerful lamps.

UV-C light has been proven to kill vegetative bacteria by destroying the nucleic

acid in DNA.

4.24 The decontamination

process will now run for a

maximum time of 45 minutes.

The duration time of the

process and Spectromes

status will appear on the

process monitor screen.

4.25 At any time during the

decontamination process,

the Ultra-V™process can be

Stopped and/or paused.

4.26 Once the process

is complete, the process

monitor will show the final

status of in use Spectrome.

Process is considered

successful when all in use

Spectromes are indicating

Thumbs Up. If there are any

thumbs down for the in use

Spectromes, then the success

of the decontamination of the

room needs to be evaluated

by a competent person.

Inivos can provide guidance if

necessary.

4.27 Once the Ultra-V™

decontamination process has

completed successfully, enter

the room, switch o at the

wall sockets and unplug the

process monitor and the main

unit. Give a light pull on the

unit’s cable to disengage the

ratchet and allow the cable to

retract. Store process monitor

power adapter neatly in the

Storage box provided (AA).

4.28 Collect all Spectromes

and place them back in the

storage tray (E), stow Process

Monitor back on the main

unit, and wheel Ultra-V™

system out of the treatment

area. When the area is ready

for patients, inform the sta

involved and ensure the room

is clear.

Ultra-V™Plug Guard

You should always ensure

that your Ultra-V™unit

is allowed to complete

its cleaning process un-

interrupted. Our Ultra-V™plug

guard has been specifically

designed to prevent the

accidental removal of the

unit’s power supply from

the mains wall socket . The

unit features high visibility

warning messages, and is

produced in durable non-tear

synthetic paper. The plug

guard simply fits over the

mains plug of your Ultra-V™

unit, creating a highly visual

barrier to help prevent the accidental removal of the plug.

DO NOT UNPLUG

During Decontamination Process

IN PROGRESS

DO NOT UNPLUG

IN PROGRESS

Ultra-V™Door Barrier

You should always ensure that your Ultra-V™unit is

allowed to complete its Decontamination process

uninterrupted. Our Ultra-V™Door Barrier Kit has

been specially designed to prevent accidental

access to rooms being treated. This is achieved

by preventing access to the door handle. The unit

features a Telescopic pole, Door Barrier Sign Clip,

and a Door Barrier Sign. The telescopic pole has

been designed to fit securely into the door frame.

The door bar sign is then slotted into the door bar

clip, and then this in turn is clipped to the pole at a

height which obscures access to the door handle.

The barrier also features a write on/wipe clean

section for the details of the process running, and

of all other emergency and technical helplines.

DEPROXTM / ULTRA-VTM CLEAN

Inivos sealant tape

To operate the Ultra-V™system safely within your organisation,

you will require appropriate sealant tapes to prevent possible

UV-C light leakage and visually mark the areas during the

decontamination cycles for safety reasons. Our branded

sealant tapes have been validated for the eective containment

of UV-C light during the Ultra-V™decontamination cycles.

These 75mm wide tapes are designed for the easy sealing

of doors, windows etc. They are specially developed to

ensure successful adhesion without leaving a residue

or removing paintwork from surfaces.

18

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 19

4.2 Ultra-V™Process Log

Each time an Ultra-V™process is completed, a log file detailing the Date, Time and Operator

ID of the process is created. Other process parameters such as the UV-C Light readings from

each Spectrome, including their target value and process duration time, will be logged on

the same file. The process report file will hold all the relevant information required to validate

and track the decontamination process. Any failed attempts to run a UV-C decontamination

process will also be logged accordingly.

The Ultra-V™system can send process validation reports directly to an email address using

its internal mobile broadband connection. The service is dependent on a mobile broadband

signal. If a WiFi signal is not available, the Ultra-V™will store reports and send them the next

time it is plugged in and a signal is available.

If you would like to enable this service, please contact Inivos using the contact details

provided.

Company No. 07183 575 | © SHS 2016

Ultra-V Decontamination Process Report

USA 1855 372 6800

www.hygienesolutionsus.com

United Kingdom 0845 270 6690

www.hygienesolutionsuk.com

Australia 1800 689 533

www.hygienesolutionsau.com

New Zealand 0800 652 2689

www.hygienesolutionsnz.com

Ultra-V System No:

Process ID:

Process Location:

Process Start Time:

Process Authorised by:

Spectrome Target Value:

Pro cess Time out :

Process Duration:

Decontamination Process Validation

Spectrome Baseline Target Achieved Success

1

2

3

4

5

6

UltraV 0017

21720171422

ward16 sideroom7

7/21/2017 14:22:44 PM

Paul Smith

Logspec: 100

45 minutes

6 minutes total (UV exposure 3 minutes)

Process Successful

0.2782 100%

0.2940 100%

0.2706 100%

0.2967 100%

0.3112 100%

0.2842 100%

A typical decontamination process report

showing that all Spectromes have received the

required amount of UV-C light to decontaminate.

1UNIT LOADING

Process monitor loads software

4.3 The Ultra-V™Process Monitor

2SPECTROME PLACEMENT

Screen shows optimal placement of Spectromes

The Process Monitor is placed outside of the treatment area, it controls

the main Ultra-V™unit and it is supported by an advanced but easy-to-use

piece of software that clearly indicates the steps you must follow in order

to carry out the decontamination. It gives continuous on-screen indication

of the process progress.

PROCESS LOCATION

Operator enters location process is taking place

READY TO START

Ultra-V™ is ready to commence process.

Operator must confirm

PREPERATION

Ultra-V™ is preparing to start the process

CALIBRATION

Ultra-V™ has completed calibration of the

Spectromes

DECONTAMINATION STARTING

Monitor displays process information to

operator

DECONTAMINATION IN PROGRESS

Monitor displays process information to

operator

20

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 21

ULTRAV ™ROOM DECONTAMINATION

TASK SEQUENCE DURATION

Location set up Position the room contents for optimal decontamination

performance

Set up equipment

Placing warning elements (Door Bar, Door Warning Sign)

Approx. 5

minutes

Decontamination

process

N/A Up to 45

minutes

Post-process

requirements

Checking a successful decontamination process

Remove Ultra-V™equipment

Approx. 5

minutes

DECONTAMINATION STOPPING

Monitor displays process information to

operator

10 RESUME AFTER PAUSE

Operator has option to resume process after

pausing

11 RESUME AFTER PAUSE CONFIRM

Operator has option to resume process after

pausing

12 PROCESS STOPPING COMPLETE

Ultra-V™process has ended

13 PROCESS REPORT SENDING

Ultra-V™process report is sending to the

designated recipient

14 PROCESS COMPLETE

Ultra-V™process has completed

4.4 Method summary

4.5 Should the power fail during a process

If the electrical supply to the unit fails during a decontamination process, it must be assumed that

the decontamination process has not been finished successfully. Entering the room is safe and

the system will be automatically reset. The decontamination process should be carried out again

once the power has returned.

22

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 23

Ultra-V™system includes 6 Spectromes that are designed to monitor the

decontamination process while actively responding to the amount of

UV-C light they receive. Spectromes are responsible for the verification of

necessary UV-C light exposure for an eective decontamination process.

In order to get best results and a complete successful decontamination process, Spectromes

must be located at strategic points within the treatment space, ensuring that all surfaces receive

the right amount of UV-C light. Always make sure that the Spectromes sensor eye is clean and

free from debris, and is facing the Main Unit. By doing so, the Ultra-V™unit will automatically

calibrate to the size of the treatment area.

4.6 The Spectrome

Rectangular Room

Key

Spectrome

Ultra-V ™Main Unit

Square Room Corner Room

Spectromes placing diagrams:

We advise using all 6 spectromes, however if necessary less spectromes may be used. In this

case the spectromes used needs to map out the room space at the furthest points.

Rectangular Room

Key

Spectrome

Ultra-V ™Main Unit

Square Room Corner Room

Spectromes placing diagrams:

For larger areas, such as bays, communal areas, corridors etc, you can use two or more separate

systems at the same time. You would still follow the same treatment area setup procedure and

deploy Spectromes as you would when using one Ultra-V™unit.

4.7 Process Pause

Process Pause summary:

If you observe on the process monitor screen that the Spectromes are not receiving enough UV-C

light you may also wish to pause the process to re-configure the room set up and placement of

the Ultra-V

™

Main Unit it may be that some of the Spectromes are in shadowed areas. Pressing

the ‘Tap to Pause’ Icon on the process monitor screen will allow you to deactivate the Ultra-V

™

and enter the room safely to change the position of the Ultra-V

™

Main Unit. In some instances

your Spectromes and Ultra-V

™

may be in optimum positions for the room layout, in this case you

may find it easier, where possible, to re-configure the furniture. Never change location of the

Spectromes as this will not guarantee the required UV-C Light exposure to surrounding surfaces.

Any time during the process

you can stop the unit by

pressing the ‘Stop Process’

Icon on the process

monitor screen. You should

only use in the case of

an EMERGENCY or for

stopping a process.

4.8 Ultra-V™System message - Process Stop

24

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 25

This message is triggered

when communication

between Ultra-V™main

unit and Process Monitor

has been lost. For safety

reasons the Process

Monitor of the Ultra-V™

checks the communication

with the Ultra-V™main unit

every ten seconds. If the

communication is lost the

decontamination process is

automatically stopped and

displayed on the Process

Monitor screen.

4.9 Ultra-V™System message - Communications lost

This message is triggered

when the sensors placed

on the Ultra-V™main unit

(C) detect movement.

For safety reasons the

Ultra-V™will automatically

switch o, it does this in the

event that someone may

have inadvertently entered

the room.

The sensors are passive

infra red and will detect heat

movement. Air conditioning

systems and electronic

equipment which change

the heat patterns within

the decontamination room

will also trigger the sensors

resulting in the process

requiring a restart.

When the safety sensors are

triggered, for safety reasons,

the decontamination process

cannot be restarted for

60 seconds.

4.10 Ultra-V™System message - Safety sensor triggered

After 60 Seconds

When a faulty Lamp(s) is

displayed on the Process

Monitor, the Ultra-V™

Main Unit will continue to

operate, but the time taken

to achieve a successful

decontamination, can

be longer. The Ultra-V™

system lamps are not user

replaceable parts and

Inivos, service Engineer

must be contacted.

Any other messages are

due to a system fault and

a Inivos service Engineer

must be contacted.

4.11 Ultra-V™System Message - Faults

26

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 27

Appendix 1: Declaration of Conformity

Exposure to UV light occurs from both natural and artificial sources. The

sun is the principal source of UV light. Solar UV undergoes significant

absorption by the atmosphere. UV is one of the non-ionizing radiations in the

electromagnetic spectrum and lies within the range of wavelengths 100 nm to

400 nm, and is invisible to human eyes. UV can be classified into UV-A (315

- 400 nm), UV-B (280 - 315 nm) and UV-C (100 - 280 nm) regions, although

other conventions for UV-A, UV-B and UV-C wavelengths bands are in use.

A strong germicidal eect is provided by the Light in the short-wave UV-C

band. UV-C works using a photolytic eect whereby the radiation destroys or

inactivates the micro-organism so that they can no longer multiply. For DNA,

it does this by causing adjacent thymine bases to form a chemical bond, thus

creating a dimmer. If a suicient number of these are created, DNA cannot

replicate.

The most eicient source for generating UV-C are the low-pressure mercury

discharge lamps. The radiation is generated almost exclusively at 254 nm

viz. at 85% of the maximum germicidal eect. Lamps used with the Ultra-V™

system have an envelope of special glass that filters out ozone-forming

radiation, in this case the 185 nm mercury line.

Self-evidently, people should avoid direct exposure to UV-C. Fortunately this

is relatively simple as it is absorbed by most products, even standard flat 4mm

glass blocks all UV-C. However, you should take every necessary action to

prevent direct UV-C light exposure to your skin and eyes.

Direct UV-C light exposure to eyes could cause serious eye damage which

may result in permanent loss of sight.

Direct UV-C light exposure to skin could cause solar erythema, “sunburn”,

which, if severe enough, may result in blistering and destruction of the surface

of the skin with secondary infection and systemic eects, similar to those

resulting from a first or second degree heat burn.

In the unlikely event of being exposed to UV-C light, DO NOT look directly

at the UV-C light source. Close, or shield your eyes and leave the area

immediately and seek medical advice.

The Ultra-V™unit has three layers of safety and security to prevent accidental

UV-C exposure, which are designed to automatically deactivate the unit

should it sense a change in its operational environment. The residual risks are

detailed in the Ultra-V™Hazard analysis and risk reduction report.

Appendix 2: UV-C Light

Ref: Environmental Health Criteria 160, World Health Organisation Geneva 1994

28

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 29

Section 1 – Objectives

Barnsley Hospital NHS Foundation Trust has been using a

hydrogen peroxide vapour (HPV) system to decontaminate the

environment. However, this introduces a significant downtime of

several hours which the Trust is working to reduce. This has led

to an evaluation of UV-C decontamination as a new technology

to reduce environmental contamination. The purpose of this

evaluation was to assess the eicacy of UV-C decontamination

(Ultra-V™) on surfaces both directly and indirectly exposed to

UV-C radiation, using a Total Viability Count (TVC) method to

culture aerobically forming colonies.

Section 2 – Materials and Methods

The resources used in this study where:

•Ultra-V™decontamination System

•Rodac Agar Plates x300 - Pro-Tect TWI (Contact Plate) -

Product Code PO0678D

•List of Surface Sampling Points for each room

•Sterile Gloves

Testing was carried out in the following steps:

1On discharge of a patient, 5 samples were taken from the

room prior to cleaning from the following locations: inside of

chair arm; under bed; windowsill; mattress; and door handle.

See ‘Method of Sampling’ below.

2The room was then cleaned and allowed to dry.

3Samples were taken from the same locations post-cleaning

4The Ultra-V™decontamination system was then deployed

and the process time recorded.

5Another 5 samples were taken from the standard sample

sites

Section 3 – Method of Sampling

1The agar plate was numbered with an indelible marker

2The agar was placed on the surface to ensure contact.

3The plate was lifted from the surface and lid replaced

4The plate was placed in an insulated box.

5The plate number and surface contacted were recorded in

the table

6The process was repeated at all sample sites through all

stages

Sterile gloves were worn and care was taken not to

contaminate the samples at any point.

Section 4 – Results

Mean average process time of 21.4 minutes. Range 12-30

minutes.

20

40

60

0

Before Cleaning After Ultra-V

80

Average TVC

After Cleaning

73.60

39.90

1.06

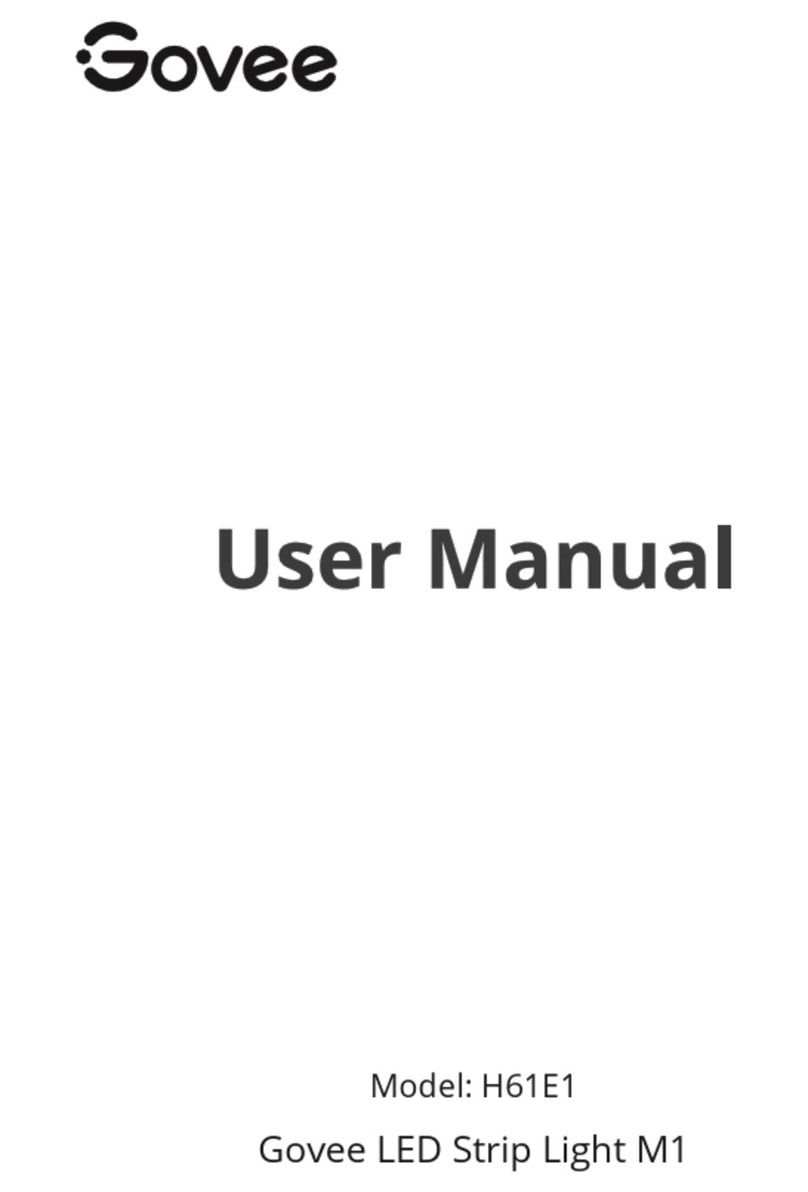

Figure 1. Average Total Viability Count (TVC) by Stage

Appendix 3: Ultra-V™study

Evaluation of Ultra-V™decontamination as an adjunctive

to manual cleaning at Barnsley Hospital

Denise Gibson, Dr Jyothi Rao, Susan Burns, Lynn Wright

Discussion

Figure 1 shows the averages from the sample sites, and the

corresponding total viability counts cultured at the varying

stages of the process. This showed on average, cleaning

led to a reduction in the overall bio-burden, (73.6 - 39.902),

but with a significant level of contamination still remaining.

The introduction of Ultra-V™decontamination led to a further

reduction in the total count (39.902 – 1.06). It should be noted

that these results from UV-C are from sites both directly and

indirectly exposed to the UV-C rays.

40

80

120

0

Inside of

chair arm

Under bed Mattress Window ledge Door handle Handrail Toilet roll

holder

Before Cleaning

After Cleaning

Average TVC

101.1

69.9

2.3

0.7

3.7

0.1 7

0.5

1

2

32

44.5

37. 937. 6

39.8

25.3

18.9

88.4

29.6

7 7. 4

136

30

After Ultra-V

20

60

100

140

Figure 2. Average TVC by Site at Each Stage

Discussion Continued

Figure 2 shows the average total viability counts at each stage

of the process, at the dierent sites that were sampled around

the room. The patient hand rail was the site on which most

contamination was found, with the average before and after

counts of 136 and 44.5 respectively. However, after Ultra-V™it

had an average colony count of only 1. The Inside of Chair Arm,

Mattress and Door Handle were all identified to be sites with

high contamination both before and after cleaning, suggesting

that manual cleaning as a process still leaves significant

risk to the next patient. This clearly highlights that manual

cleaning alone does not fully remove the risk of environmental

organisms to our patients. However, after Ultra-V™, all of these

sites showed low levels of contamination (2.3, 3.7 and 0.5 on

average respectively), significantly reducing that risk. The data

also shows us that although there is generally a reduction

after cleaning, a significant bio-burden is still detected in the

room (average 39.902 Figure 1), but after Ultra-V™there were

consistently low counts, even on sites in the en-suite which we

would not expect to be directly exposed to the UV-C rays due to

obstructions in the direct line of sight.

Conclusion

Owing to the fact that the Ultra-V™requires no vapour-

impermeable sealing and is a rapid process, this technology

may be particularly suited to high-pressure environments for

example ED, ICU and theatres and would enhance any bed

management programme. Pressure to release beds for new

patitents is a continual concern and needs to be balanced with

providing a safe and clean environment. The Ultra-V™could be

an integral part of securing patient safety whilst optimising bed

flow.

Section 5 – Further Work

This evaluation assesses viable aerobically-forming organisms

and does not evaluate eicacy against spores

30

inivos.com

9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 9002_ULTRA-V_INSTRUCTION MANUAL_V1/0820 31

A4.1 Regular care

Once a week wipe down the case, lamps (B) of the Ultra-V™

system, the Process Monitor, and the Spectromes to remove

any dust. Never use any wet substance to clean the parts of

the system.

Regularly check the mains lead and the Process Monitor for

damage, paying particular attention to the points where they

emerge from the connectors. The wheels of the Ultra-V™system

(A) should be periodically cleaned.

Appendix 4: Ultra-V™ maintenance

A4.2 Machine servicing

The lamps of the Ultra-V™system have a working life of 9000

hours and begin to reduce their intensity and performance

after this time, therefore they will need to be changed. The

lamps must be changed by Inivos, failure to change the

lamps after 9000 hours may lead to longer process times

and frequent process failures.

When Spectrome status appears with a low battery sign,

all four batteries should be replaced with new AA size

Alkaline batteries. The Ultra-V™system must be serviced

every 6 months for optimum performance. There are no user

serviceable parts.

Moreover, the Ultra-V™system must be PAT (Portable

Appliance Testing) tested for electrical safety. Inivos can

provide this service. The system will flash up a warning

message for 30 seconds at power up every six months when

this service is due.

Appendix 5: Information

External dimensions (mm)

1880·660·610 without Process Monitor

1880·660·720 with Process Monitor

Operational temperature range 0-30°C

Operational humidity range 0-95% RH

Power consumption 1430W @ 230V

Supply voltage range 220-240V AC

Supply frequency 50Hz

Plug fuse 13A

8.1 FAQs

Q: How Does Ultra-V™Work?

A: Ultra-V™system emits UV-C light, which destroys the nuclei

acids of the microorganism, leaving them unable to reproduce.

Q: Is UV-C light dangerous to people?

A: Yes, direct exposure to UV-C light can cause serious damage

to skin and eyes.

Q: Would simple glass filter the UV-C light?

A: Yes, UV-C light is absorbed by most products.

Q: Can I replace the bulbs by myself?

A: No, call Inivos for service

Q: How long does the process take?

A: Average side room would normally take 20 min to complete.

Q: How do I stop the process?

A: Process can be stopped by pressing ‘Process Stop’ button

on the screen.

Q: What is Spectrome?

A: Spectromes monitor decontamination process to ensure the

right UV-C light exposure.

Q: How do I start the process?

A: Process can be started by using a unique key card.

Q: Do I need to have any training to use Ultra-V™system?

A: Yes, only trained operators can use the Ultra-V™system.

Q: Should the room be cleaned before using the Ultra-V™

system?

A: Yes, room has to be manually cleaned to remove gross

soiling, dust and dirt.

The Ultra-V™unit

B

A

D

AA

BB

CC

PROCESS

MONITOR

E

F

Diagram 1

C

For more information on our infection prevention

and control services or products:

inivos.com

@InivosGroup /inivos-group

United Kingdom

307 Euston Road,

London NW1 3AD,

UK

USA

1740 Broadway, 15th Floor,

New York, 10019,

USA

Australia

Australia Square Plaza,

95 Pitt Street, NSW, 2000,

Australia

New Zealand

6 Clayton Street,

Newmarket, Auckland,

1023, New Zealand

Netherlands

Schipol Rijk, Beech Avenue,

Het Poortgebouw 54-62,

1119 PW Schiphol, Netherlands