injen technology PF8075 User manual

Other injen technology Automobile Part manuals

injen technology

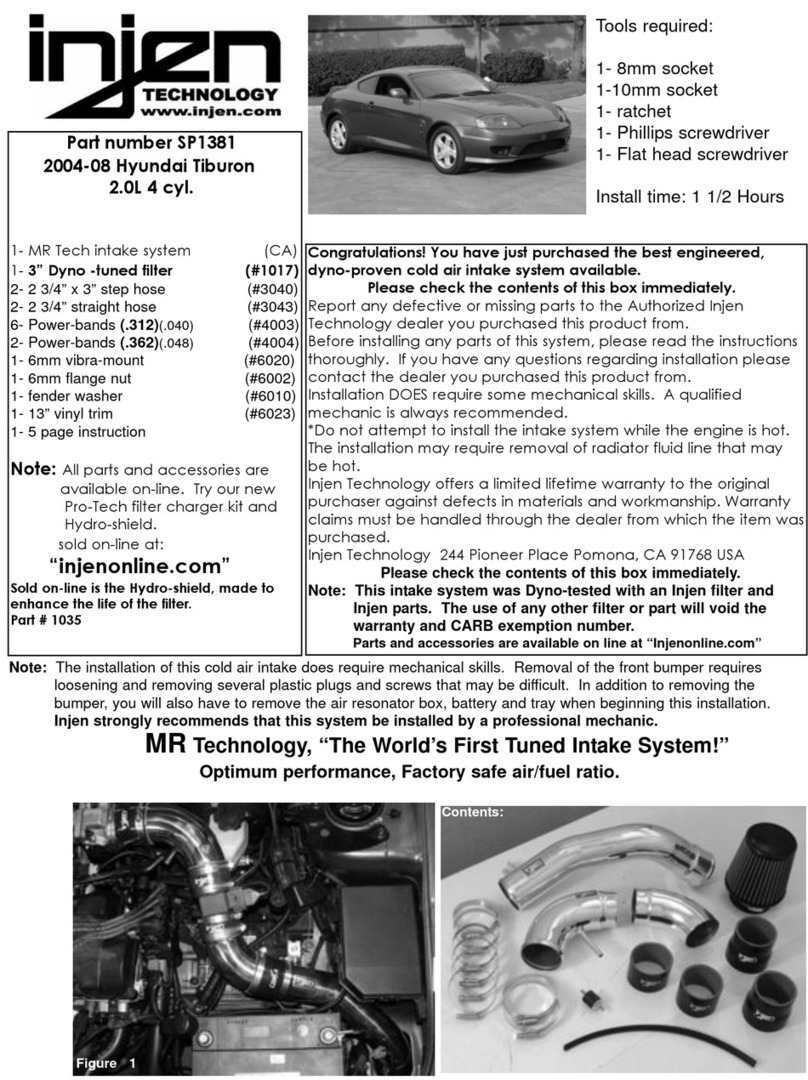

injen technology SP1381 User manual

injen technology

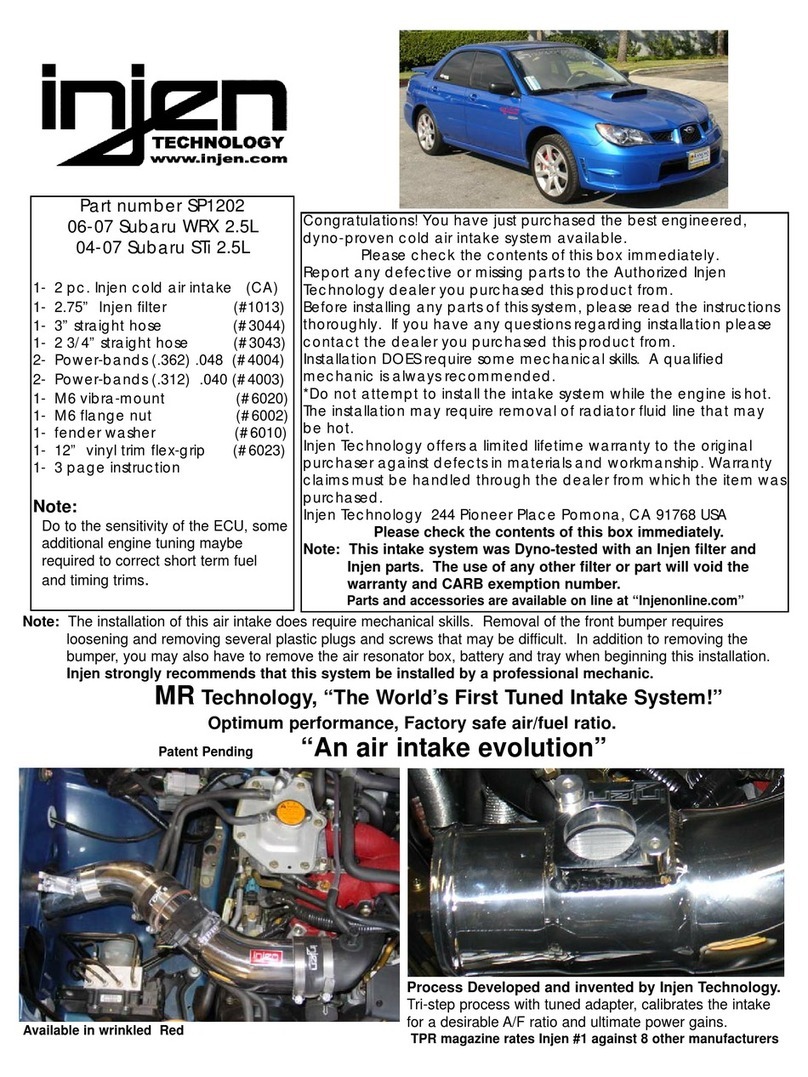

injen technology SP1202 User manual

injen technology

injen technology SP1126 User manual

injen technology

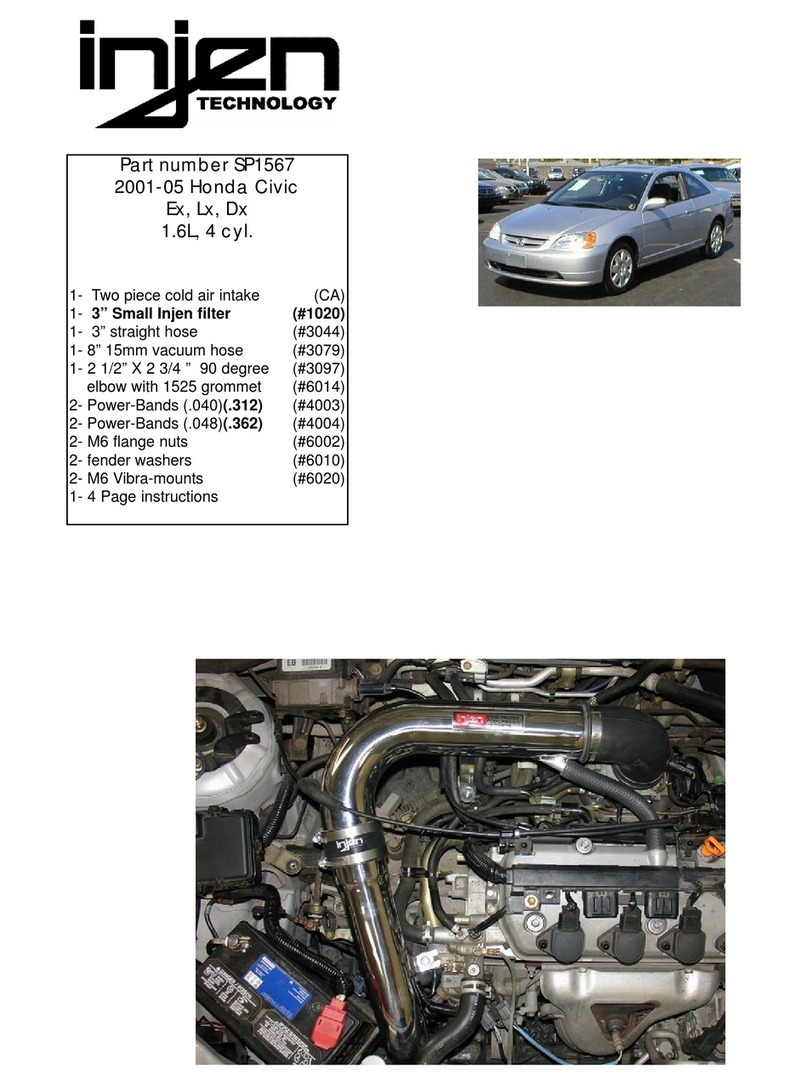

injen technology SP1567 User manual

injen technology

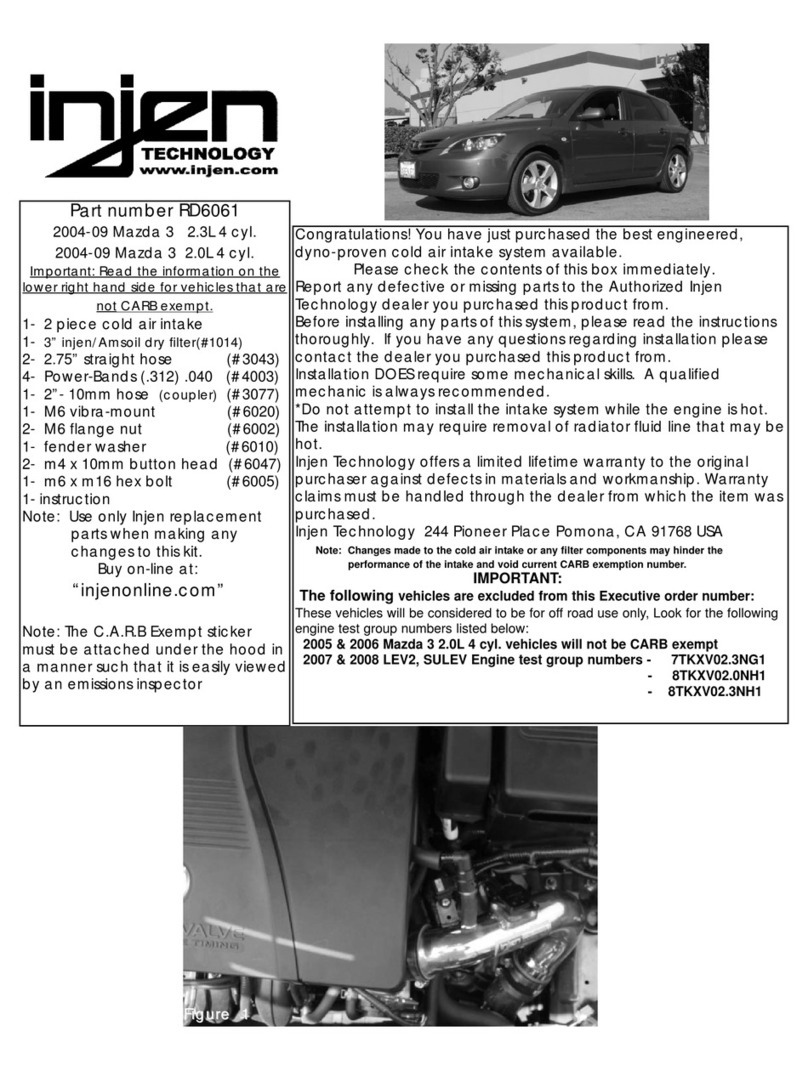

injen technology RD6061 User manual

injen technology

injen technology SP2106 User manual

injen technology

injen technology SP1360 User manual

Popular Automobile Part manuals by other brands

Murphy

Murphy Diagnostic Display PV10 Specifications

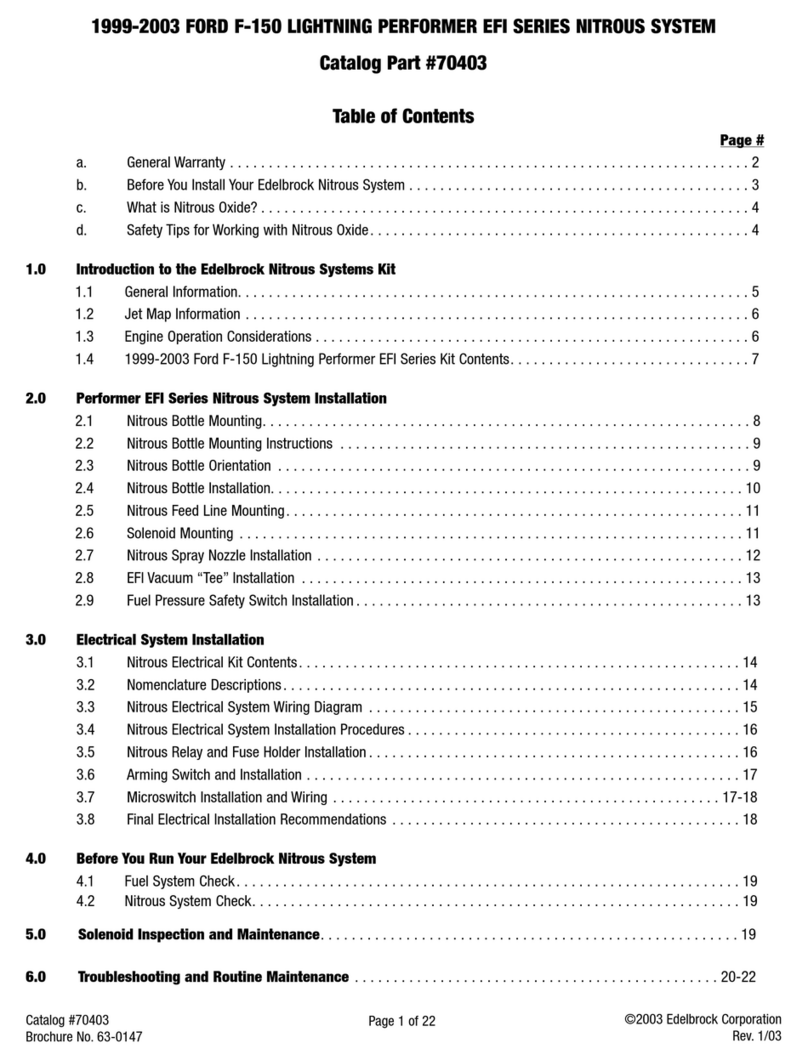

Edelbrock

Edelbrock 70403 installation manual

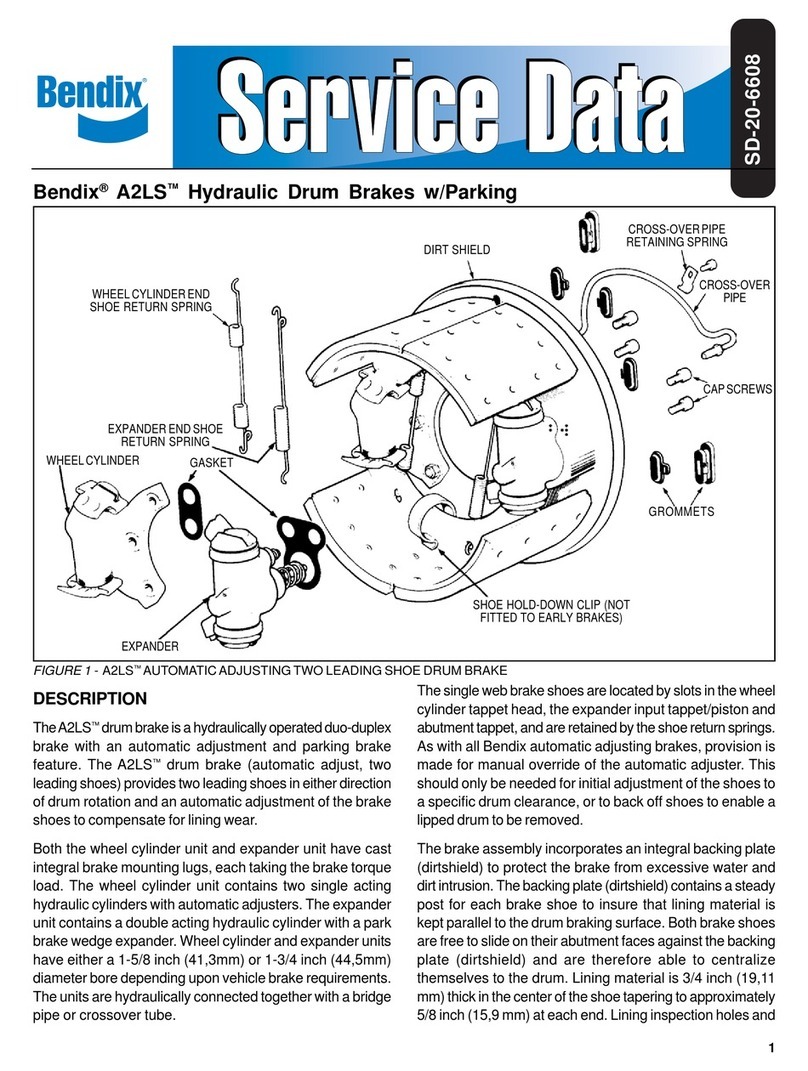

BENDIX

BENDIX A2LS HYD DRUM BRAKES W-PARKING manual

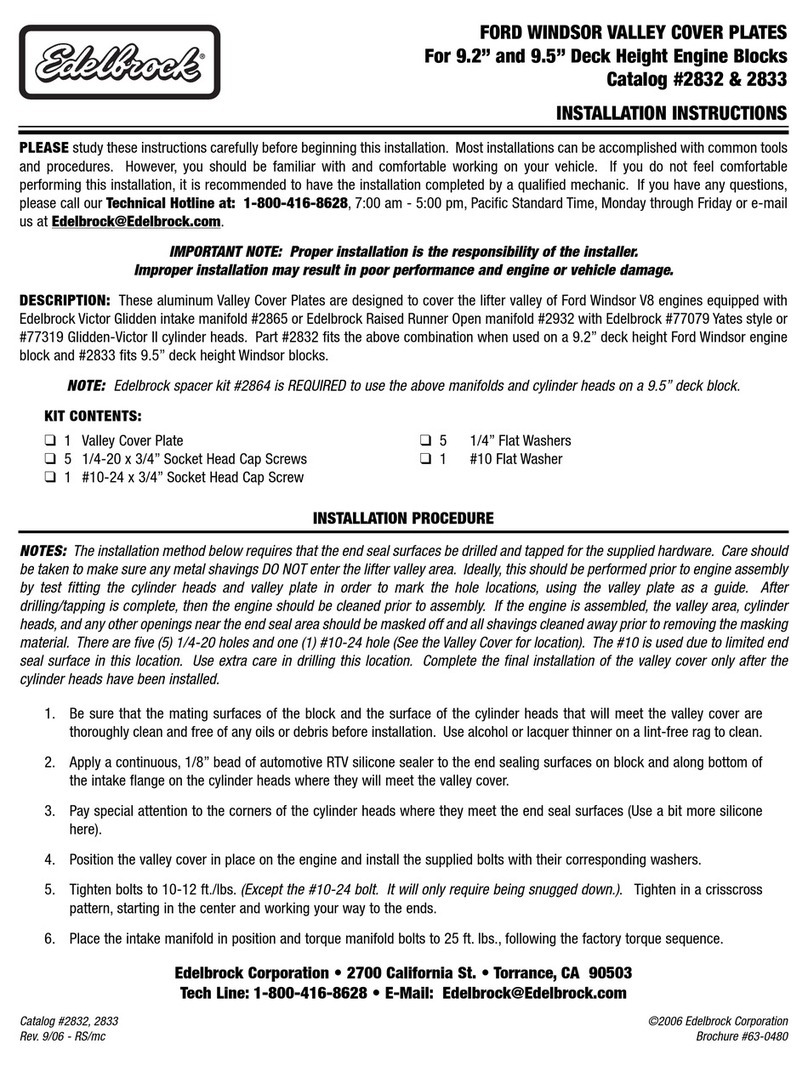

Edelbrock

Edelbrock 2832 installation instructions

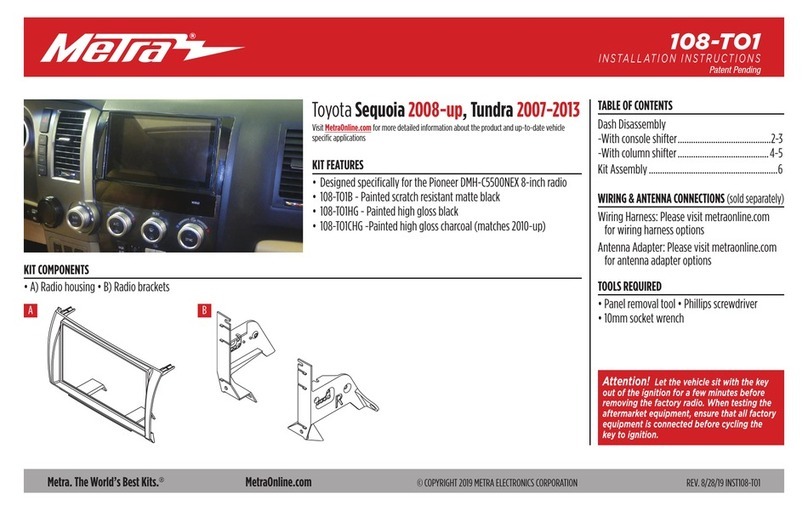

Metra Electronics

Metra Electronics 108-TO1 Series installation instructions

KTM Power Parts

KTM Power Parts 6130795800049 Information

Toyota

Toyota Radiator Hose Replacement guide

Edelbrock

Edelbrock 1713 installation instructions

LG

LG ARNU48GBRZ4 manual

Dakota Digital

Dakota Digital VHX-49F installation manual

AUTOTECH

AUTOTECH 10.297.400K-402K 410K-412K installation instructions

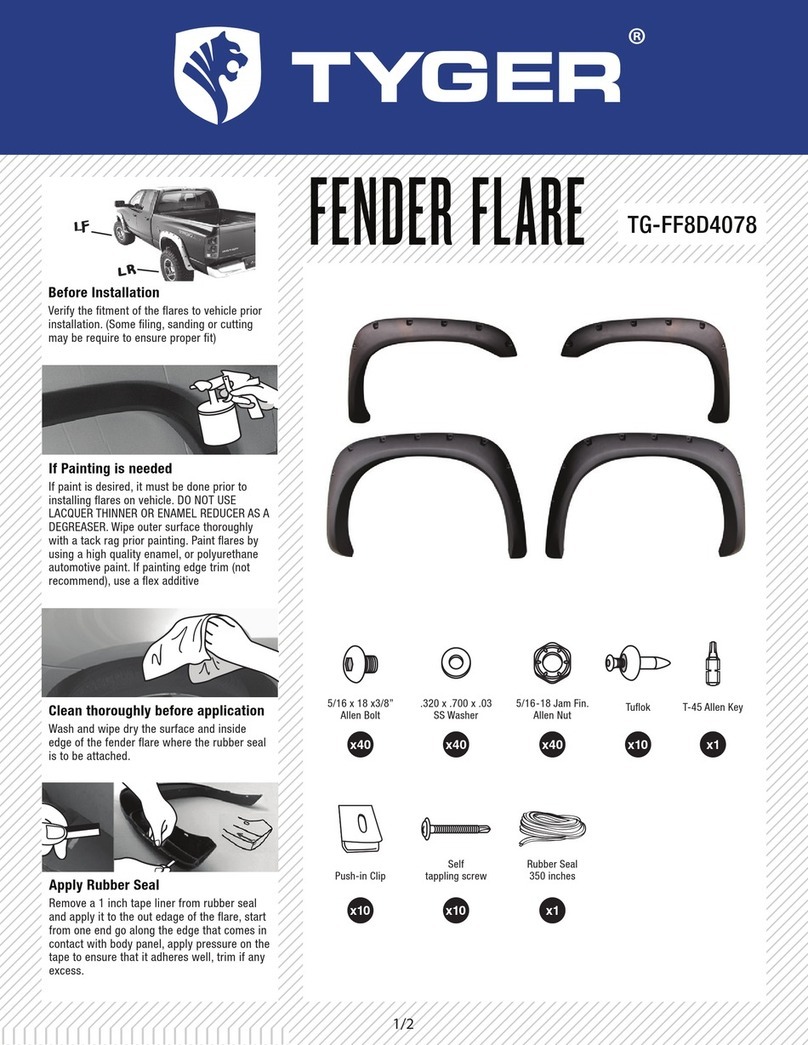

Tyger

Tyger FENDER FLARE TG-FF8D4078 installation instructions

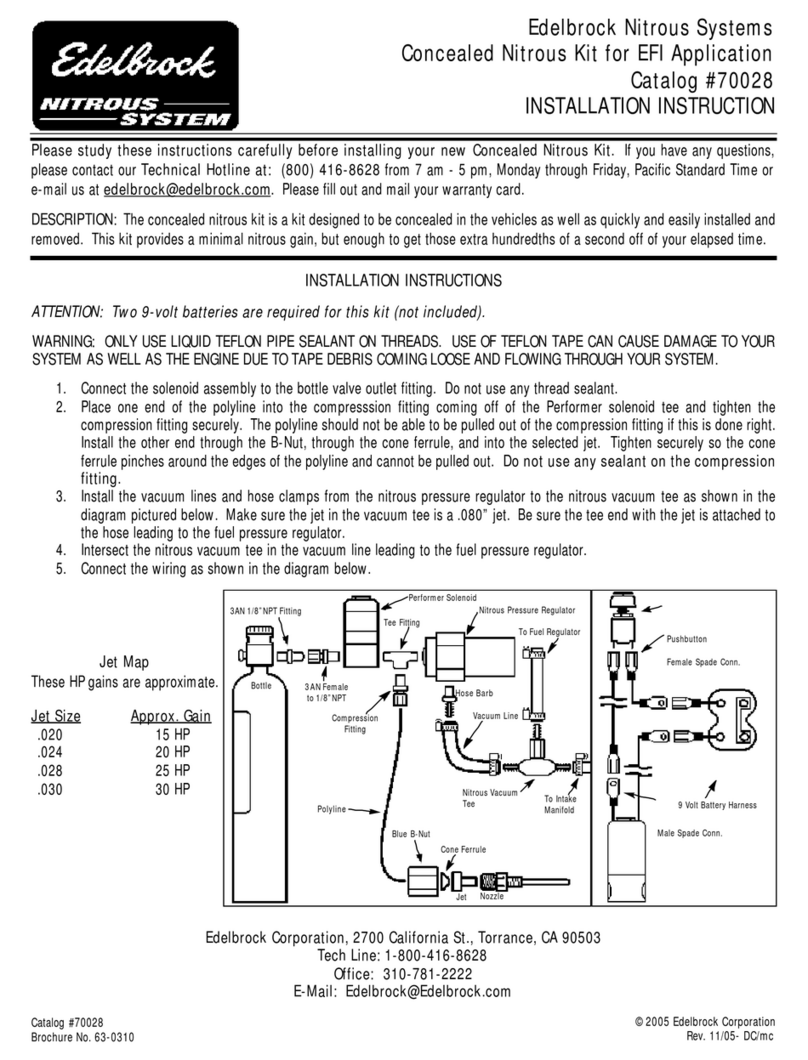

Edelbrock

Edelbrock 70028 installation instructions

DefenderCab

DefenderCab Yamaha Wolverine Vision Cab kit owner's manual

Edelbrock

Edelbrock Performer 60039 installation instructions

Holley

Holley 0-7448 INSTALLATION, TUNING, AND ADJUSTMENT MANUAL

Edelbrock

Edelbrock 3844 (65mm) installation instructions

Edelbrock

Edelbrock 66662 installation instructions