INNO IFS-15S User manual

Version:V1.00

IFS-15S

Master

User's Manual

Table of Content

PAGE 01

Introduction..................................................................................................................4

Chapter 1 Technical Specifications......................................................................................5

Applicable Fiber Type..........................................................................................................5

Splice Loss..........................................................................................................................5

Splice Mode..........................................................................................................................5

Heat Oven...........................................................................................................................5

Power Supply......................................................................................................................6

Dimensions and Weight.......................................................................................................6

Environment...............................................................................................................6

Other.................................................................................................................................6

Chapter 2 Installation..........................................................................................................7

Safety Warnings and Cautions...........................................................................................7

Safety Warnings...................................................................................................................7

Maintenance and External Care Precautions.....................................................................8

Transport and Storage Precautions....................................................................................8

Installation...................................................................................................................8

Unpacking the Splicer........................................................................................................8

IFS-15S and Accessories..................................................................................................9

Splicer Description and Functions....................................................................................10

Power Supply...................................................................................................................11

Two Ways of Power Supply..............................................................................................11

How to Charge the Battery................................................................................................12

How to Check Remaining Battery Capacity......................................................................12

Battery Refresh................................................................................................................13

Heat Oven........................................................................................................................13

Chapter 3 Basic Operation..............................................................................................14

How to Install Cleaving Table...........................................................................................14

PAGE 02

Turning Splicer "ON"......................................................................................................15

Adjust the Angle of LCD Monitor......................................................................................15

Adjust the Monitor Brightness.........................................................................................16

Preparing the Fibers........................................................................................................16

How to Make a Splice......................................................................................................17

Setting Fiber in the Fiber Holder......................................................................................17

Inspecting the Fibers.......................................................................................................18

Splice.............................................................................................................18

How to Protect the Splice................................................................................................18

Heating Procedure...........................................................................................................18

Chapter 4 Splice Programs.............................................................................................20

Displaying the Active Splice Program..............................................................................20

Selecting a Splicer Program...........................................................................................21

General Splicing Steps....................................................................................................22

Prefusion..........................................................................................................22

Fusion..........................................................................................................22

Splicing Process...............................................................................................................22

Standard Mode.................................................................................................................23

Chapter 5 Splice Option..................................................................................................24

Setting Parameters..........................................................................................................24

Chapter 6 Heater Mode...................................................................................................25

Selecting Heater Mode...................................................................................................25

Editing Heater Mode..........................................................................................................26

Heater Mode Parameters................................................................................................27

Chapter 7 Maintenance Menu.........................................................................................28

Replace Electrodes..........................................................................................................28

Replacement Procedure...................................................................................................28

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 03

Stabilize Electrodes..........................................................................................................29

Operation Procedure........................................................................................................29

Diagnostic Test Function.................................................................................................29

Operation Procedure.......................................................................................................29

Dust Check......................................................................................................................30

Operation Procedure.......................................................................................................30

Motor Calibration..............................................................................................................30

Operation Procedure.......................................................................................................30

Arc Calibration..................................................................................................................30

Operation Procedure.......................................................................................................31

Electrode Setting.............................................................................................................31

Software Upgrading..........................................................................................................31

Chapter 8 Other Function & Utilities................................................................................32

Data Storage....................................................................................................................32

Display Splice Record......................................................................................................32

Clearing Splicing Results in Memory...............................................................................32

Cancel Data Storage........................................................................................................32

System Setting.................................................................................................................32

Change Monitor Position.................................................................................................33

Power Save......................................................................................................................34

System Information...........................................................................................................34

Appendix I........................................................................................................................35

Appendix II.......................................................................................................................36

Appendix III......................................................................................................................38

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 04

Introduction

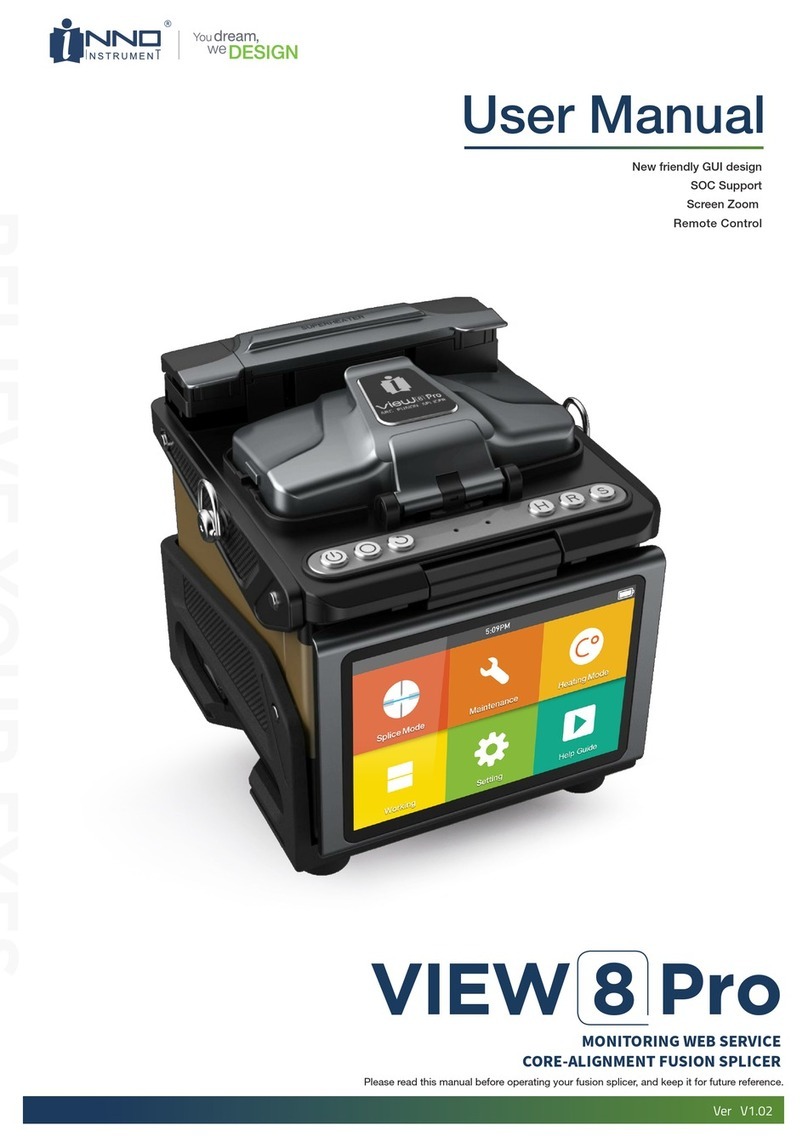

Thanks for choosing IFS-15S FTTx Master from INNO. The IFS-15S with

innovative design and exquisite manufacturing technology bring customers

unprecedented splicing experience.

New technology greatly reduce splicing and heating time. Advanced estimate

method and core alignment technique ensure the accuracy of splice loss

estimation. Its small size, compact design and reliable protection shell make it

suitable for any operating environment. Dynamic operation interface and automatic

splice mode give the customers great convenience.

For more information, please contact your local distributor or visit our web:

www.innoinstrument.com

www.innoinstrument.cn

Model: FH-K5

All-in-one Fiber Holder

This manual explains the features, specifications, operation, maintenance and

warnings about IFS-15S. The primary goal of this manual is to make the user as

familiar with the splicer as possible.

Important!

INNO Instrument recommends all users to read this manual carefully before

operating IFS-15S.

IFS-15S

Master

IFS-15S

Master

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 05

Chapter 1-Technical Specifications

Applicable Fiber Type

Splice Loss

ζSM(ITU-TG.652) / MM(ITU-TG.651) / DS(ITU-TG.653) / NZDS(ITU-TG.655) /

ITU-TG.657

ζFiber count: Single

ζApplicable fibers:

0.25mm/0.9mm/2.0mm/2.4mm/3.0mm/Indoor cable

ζApplicable fiber diameter: Cladding diameter: 80~150μm, Coating diameter:

100~1000μm

Measured by cut-back method relevant to ITU-T standard:

ζSM:0.02dB

ζMM:0.01dB

ζDS:0.04dB

ζNZDS:0.04dB

ζG.657:0.02dB

Splice Mode

ζPreset 12 splice mode

ζInternal splice data storage: 2000

ζSplicing time: SM FAST mode: 7s

Heat Oven

ζApplicable protection sleeve: 40mm, 60mm

ζHeating time: 20~900s

ζCooling time: 0~ 180s

ζTypical heating time: 35s

ζHeater mode: 2 heater modes

ζHeat oven: IFS-15S Special Heat Oven(Detachable heater part for splice-on connector)

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 06

Dimensions and Weight

Power Supply

ζInput power: AC 100~240V, 50~60HZ./ DC9~14V

ζLi-ion battery input: DC 11.1V . Completely charging time is about 3 hours.

ζSize: Length×Width×Height = 164mm×143mm×139mm

ζWeight: 2.1kg (battery included)/1.8kg

Environment

ζOperating condition: 0~5000m above sea level, 0~95% relative humidity, -10~50đ,

15m/s wind.

ζStorage condition: 0~95% relative humidity, -40~80đ; Battery: -20~30đfor long

time storage.

Other

ζViewing Method: two camera and 4.3 inch color LCD monitor (with high strength

protection shield on the top)

ζ300× magnification for single X or Y view. or 180× for both X and Y view.

ζTensile test: 1.96~ 2.25 N.

ζTerminals: USB2.0 for upgrading.

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 07

Safety Warnings and Cautions

As IFS-15S is designed for fusion splicing silica glass optical fibers, it is very important that

the splicer should not be used for any other purpose. The splicer is a precision instrument

and must be handled with caution. Therefore, you must follow all safety rules and general

precautions in this manual. Any behavior that not follow the warnings and cautions will break

the safety standard about the fusion splicer and may result in electric shock, fire, and/or

serious injury. INNO will not take the responsibility for those results caused by misuse!

Chapter 2 - Installation

Safety Warnings

ŚNever operate the splicer in an environment where flammable liquids or vapors exist.

śDo not touch the electrodes when the splicer is on and power is supplied to the unit. The

electrodes generate high voltage and high temperatures that may cause a severe shock or burn.

③Do not disassemble or modify the splicer, AC adapter, battery or battery charger. In particular,

do not remove or bypass any electrical or mechanical device (e.g. a fuse or safety switch)

incorporated into the design and manufacture of this equipment. The equipment must be r

epaired or adjusted by an authorized technician or engineer. Unauthorized repair may result in

fire or electric shock.

④Properly connect the AC power cord to the splicer(inlet) and wall socket (outlet). When inserting

the AC plug, make sure there is no dust or dirt on the terminals. Engage by pressing the female

plug into the splicer (inlet) and the male plug into the wall socket (outlet) until both plugs are fully

seated. Incomplete engagement may cause fuming, electric shock, or equipment damage and

may result in injury, death, or fire.

⑤Never operate the splicer in an environment where flammable liquids or vapors exist. Risk of

dangerous fire or explosion could result from the splicer's electrical arc in such an environment.

Do not operate splicer near hot objects, in high temperature environments, in dusty/humid

atmospheres, or when water-condensation is present on the splicer. This may result in electric

shock, splicer malfunction, or poor splicing performance.

⑥Safety glasses should always be worn during fiber preparation and splicing operation. Fiber

fragments can be extremely dangerous if they come into contact with the eye, skin, or are

ingested.

⑦Disconnect the AC power cord from the AC adapter inlet or the wall socket (outlet) immediately

if user observes the following or if the splicer receives the following faults:

- Fumes, bad smell, noise, or over-heating occurs.

- Liquid or foreign matter falls into cabinet.

- Splicer is damaged or dropped.

If any of these faults occurs, ask our service centre for repair. Leaving the splicer in a damaged

state may cause equipment failure, electric shock, or fire and may result in injury or death.

⑧Do not use compressed gas or canned air to clean the splicer. They may contain flammable

materials that could ignite during the electrical discharge

⑨Use only the AC adapter designed for this splicer. Using an improper AC power source may

cause fuming, electric shock, or equipment damage and may result in injury, death, or fire.

Proper AC power source is AC 100~240v, 50~60Hz. Check the AC power source before use.

ţUse the supplied AC power cord. Do not place heavy objects on the AC power cord. Keep the

power cord away from heat source. Use of an improper cord or a damaged cord may cause

fuming, electric shock, or equipment damage and may result in injury, death, or fire.

Note: Only use specified electrodes for the fusion splicer. Select [Replace

Electrodes] option to replace electrodes. Turn the splicer off and disconnect the

AC power cord or remove battery before replacing electrodes. Discharging is

prohibited before the electrodes are placed as a pair.

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 08

Maintenance and External Care Precautions

ŚAlways avoid using hard objects to clean V-grooves and electrodes.

śDo not use any chemical other than pure alcohol (99% or greater) to clean the

objective lens, V-groove, LEDs, LCD monitor, etc., of the splicer.

ŜUse a dry cloth to remove dust and dirt from the splicer.

ŝIf the outside of the splicer is dirty, plunge a soft cloth into diluted neutral washing

up liquid, wring out the cloth and clean. Dry the splicer with a dry cloth but DO

NOT use furniture polish or other cleaning agent.

ŞAlways follow the maintenance instructions in this manual.

Transport and Storage Precautions

ŚWhen the splicer is moved from cold to warm environment, you should allow the

splicer to warm up gradually. Otherwise, the condensation inside will be harmful for

the splicer.

śPack the fusion splicer for long time storage.

ŜKeep the splicer clean and dry.

ŝThe fusion splicer is precision adjusted and aligned. Always keep the slicer in its

carrying case to protect from damage and dirt. Put cushion package outside the

carry case for long distance transporting.

ŞAlways avoid leaving the splicer in direct sunlight or expose to excessive heat.

şDo not store the splicer in dusty/humid atmospheres. This may result in electric

shock, splicer malfunction, or poor splicing.

ŠKeep the humidity to a minimum level where the splicer is stored. The humidity

must not exceed 95%.

Installation

Important!

Please carefully follow the instructions below.

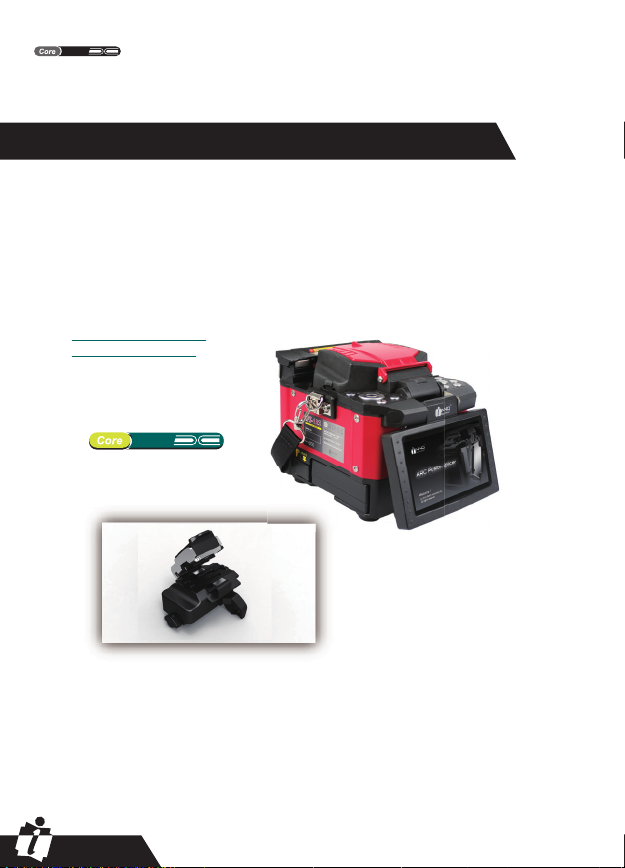

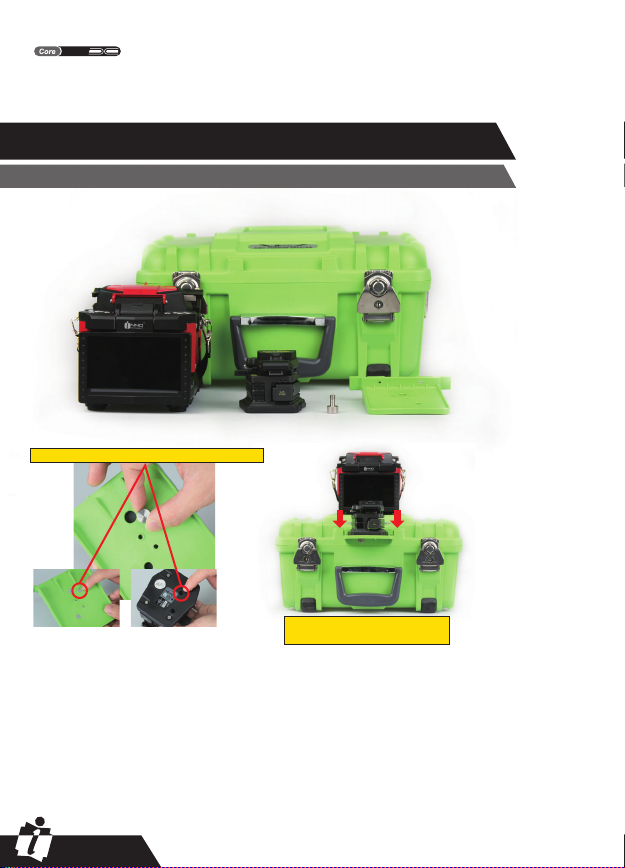

Unpacking the Splicer

Check the belt and hooks for damage before taking the splicer out. Lift the splicer

by the lifting belt as show below:

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 09

IFS-15S and Accessories

Name Quantity

1.Fusion Splicer

2.High Precision Fiber Cleaver

3.Large-capacity Battery

4.Battery Charger and Power Cord

5.User's CD

6.Spare Electrodes

7.Carrying Case

8.Cooling Tray

9.All-in-one Fiber Holder

10.Kevlar Stripper

11.Auto Collector for Fiber Debris (option)

12.Cleaver Working Table (option)

13.AC Adapter(option)

14.Aerial Working Table (option)

15.Splice-on Connector Holder (option)

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1 2 3 4 5

6 7 8 9

11 12 13

10

1514

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 10

Splicer Description and Functions

Operating button Heat oven

Power ON/OFF

Lifting belt

LCD monitor Battery

USB port

Serial port

Power supply connector

Side

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

Power Supply

Two Ways of Power Supply

PAGE 11

Take out battery/AC Adapter

Release button

Inserting the

battery/AC Adapter

Inserting the battery into the

power unit dock until you hear "click".

Power off the splicer.

Press the release button,

and take out the battery.

The first way: battery operation

Insert the Battery into the power unit dock. Check and make sure the

remaining battery capacity is 20% or greater before operation.

Install the battery as below.

The second way: AC operation

Power the splicer by AC/DC adapter. Insert the AC/DC adapter into the

power unit dock in the same way with battery installation. Connect the

power cord to the AC/DC adapter as below.

Detaching the battery Inserting the battery

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 12

Charging progress is indicated by five lit LEDs continuously sweeping from 20% to

100% on the battery indicator (see below).

As charging proceeds, one LED is lit when 20% charged. When it’s fully charged,

all five LEDs are lit (i.e. 100%).

Attaching Detaching

Note: 1. Check and make sure the remaining battery capacity is 20% or greater

before splicing. If the battery capacity is less than 20%, please use AC/DC

adapter to power the splicer.

2. Heat will be generated during the charging process. Do not stack the battery

on top of AC/DC adapter while charging.

How to Charge the Battery

How to Check Remaining Battery Capacity

You have two ways to check remaining battery capacity.

ŚIf the battery is connected to the slicer, then its charging level appears. The

power source which is used to charge the splicer is indicated by a special icon on

the top left corner of the monitor (see below)

<5%

<20%

<20-40%

<40-60%

<60-80%

<80-100%

Connect the battery charger to the battery.

If the splicer is powered through AC/DC adapter, there will be a sign on the top left

corner of the monitor. (see below)

ADAPTER

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 13

śIf the battery is detaching from the splicer. Press "PUSH" button on the battery, battery

power is indicated by LEDs. As shown below:

100% 80% 60% 40% 20%

LED

Battery Refresh

In order to prevent the aging effect of

the battery, the battery need to be

refreshed periodically. Turn the splicer

on and discharging until it consume all

the battery capacity and the splicer turn

off automatically. Fully recharge the

battery and redo discharging.

2 1

Heat Oven

Open the heater lid

Cooling tray

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 14

How to Install Cleaving Table

Chapter 3 - Basic Operation

Insert the cleaving table

into the slot on the carrying case.

Fix the cleaver on the Cleaving Table by matching screw.

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 15

Turning Splicer "ON"

Press ON/OFF button on left operation panel. The ready screen is displayed after

the motors rest to their initial positions.

Adjust the Angle of LCD Monitor

Adjust the monitor angle to comfortably watch the screen.

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 16

Adjust the Monitor Brightness

In the initial interface, press "ĭ" or "į"to change the monitor brightness until it is

clear enough.

Note: The LCD monitor of IFS-15S manufactured in a

quality-controlled factory environment. However, some black dots

may appear, or red/blue/green dots may remain on the screen. The

screen brightness may not appear uniform, depending on the viewing

angle. Note that these symptoms are not defects, but are natural on

LCDs.

Preparing the Fibers

3 steps for preparing fibers:

Step 1: Strip the fiber

①Remove at least 50mm of secondary coating

(valid for both tight and loose tube secondary

coating) with an appropriate stripper.

②Remove approximately 30mm of primary

coating with an appropriate stripper.

Step 2: Clean the fiber

Clean the bare fiber thoroughly with alcohol

impregnated gauze or lint-free tissue.

Step 3: Cleave the fiber

Cleave the fiber by high precision fiber cleaver.

In order to get excellent splice result, high

precision fiber cleaver should be used, such as

INNO VF- fiber cleaver. And the cleave length also

should be precisely controlled (shown below).

Note:

Always remember to slip a

heat-shrink sleeve onto either end

of the fibers at the beginning of

each fiber preparations.

Examples of cleaving length

≥10mm ≥10mm

Important!

From this point, you must be very

careful with the fibers to ensure that

they do not become dirty again.

- avoid putting them down on a dusty

working surface

- avoid waving them around in the air.

- check if the V-grooves are clean, if

not, wipe them clean

- check if the fiber clamps are clean, if

not, wipe them clean

Tight secondary coating

Primary coating

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 17

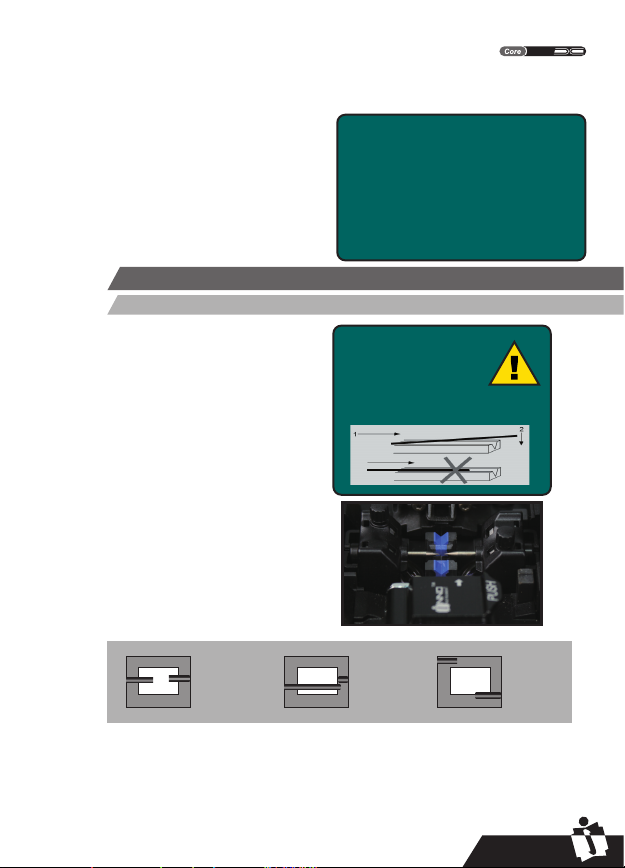

How to Make a Splice

Setting Fiber in the Fiber Holder

Note:

Make sure to avoid sliding

the fibers along the

V-grooves, but rather

position them over the

V-grooves and then tilt

them down into place (see

picture below).

ŚOpen the wind shield.

śRaise the fiber clamps.

ŜPlace the fibers into V-grooves.

ŝMake sure the fiber ends are visible on

the monitor.

(4a) If the fiber ends are not visible, the

splicer will try to find them by moving the

fibers horizontally. The ends will be found

if the fibers are placed within the

mechanical movement range of the

horizontal motors.

(4b) If not, an error message will be

displayed. The splicer will not find fiber

ends that are placed above or below the

imaging area.

(4c) Normally, this should only happen if

the V-grooves or the fibers are dirty, or if

the splicer is not well adjusted.

ŞClamp the fiber in position by lowering both sets of fiber clamps.

şClose the safety shield.

As previously stated preparing the fibers

for splicing is one of the most important

factors in the splicing process and must

be carried out with the utmost care to

minimize splice loss. Therefore, consult

the check-list backwards to ensure that

these steps should be carried out.

Fiber preparation checklist

ȏThe correct V-grooves are selected (See

Chapter 7 "Maintenance ")

ȏThe fiber clamps and V-grooves are

clean

ȏA heat-shrink sleeve is in place

ȏThe fibers are stripped

ȏThe fibers are clean

ȏThe end-faces are well-cleaved

ȏThe cleaving lengths are correct

a.

Imaging area Fibre ends

visible on

the monitor.

b. Imaging area Fibre ends

outside

monitor.

c.

Imaging area

Fibre ends

above and

below

monitor, not

possible to

find

automatically.

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 18

To change between Front

View and Back View, press

ĬorĮ.

If you find any defects as illustrated above, remove

the fibers and prepare again.

Before continuing with splicing, you should visually check the fibers in the monitor

to make sure they are clean and well-cleaved.

Note: The fibers are checked automatically when you press "Set"

button. The splicer automatically focuses the fibers and checks for

damage or dust particles.

Splice

ŚSelect the appropriate splicing mode. (described in detail in Chapter 4 "Splice

programs"- "Selecting a splice program")

śPress "SET" to start splicing.

Note: If the splicer set as "Auto Mode", the fibers splice once the

protection shield closed.

Heating Procedure

Inspecting the Fibers

How to Protect the Splice

After splicing, protect the joint by using a heat-shrink sleeve and the heat oven

which is mounted onto the splicer.

①Open the heat oven lid.

②Lift the left and right fiber clamps on the splicer.

Holding the heat-shrink tube (previously placed onto the fiber), lift the spliced fibers

and holding them taut, move the heat-shrink tube so that it is centered over the

splice point.

③Move both the fibers and the heat-shrink tube over to the heat oven and place

them in the oven clamps.

④Press "HEAT" to start. After heating, the led indicator will go out with buzzing.

Dust on fiber Tag

Chip Large cleave

angle

Front View

Back View

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

PAGE 19

Opening the heater lid Splice

Moving the fibers and protection

sleeve to the heat oven.

Heating Indicator Heat Button

User’s Manual

INNO Instrument, Inc.

IFS-15S

Master

Table of contents

Other INNO Industrial Equipment manuals