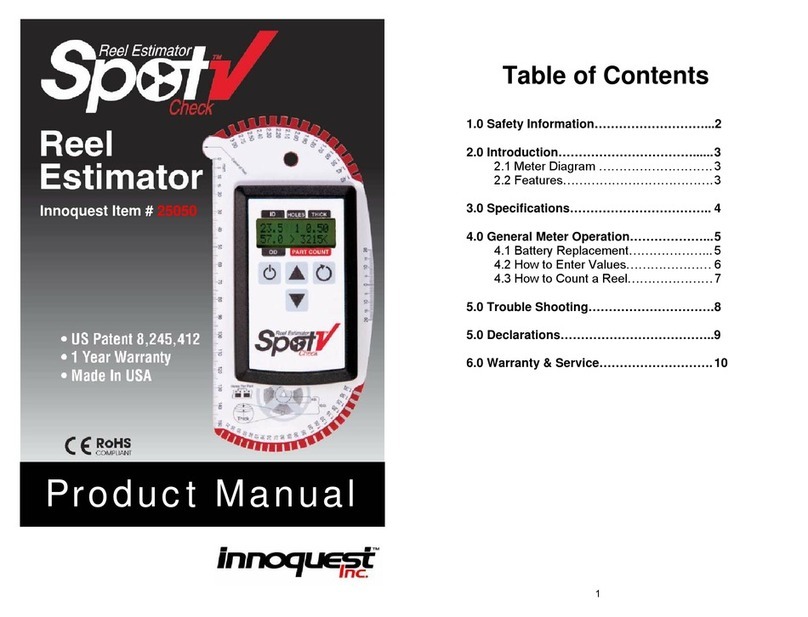

Innoquest SpotOn G2 User manual

Product Manual

Innoquest Item # 23920

1

Table of Contents

1.0 Safety Information………………………...2

2.0 Introduction……………………………......3

2.1 Meter Diagram (Front)………………. 3

2.2 Meter Diagram (Back)………………. 3

2.3 Features……………………………….4

3.0 Specifications…………………………….. 5

4.0 General Meter Operation………………...6

4.1 Battery Installation……………………6

4.2 Meter Modes…………………………. 7

4.3 How to Make a Probing……………...11

5.0 Software Operation……………………….15

5.1 Software Install………………………. 15

5.2 Software Use………………………….16

6.0 Trouble Shooting………………………….21

7.0 Maintenance………………………………. 22

8.0 Warranty & Service……………………….23

2

1.0 Safety Information

Caution should be exercised while using this meter to assure the

safety of the user. This meter is a low voltage battery powered device

which should not cause electrical hazard to the user even when

connected to a computer via a USB cable. However, please use

caution not to service this meter or connect it to a computer in a wet

environment.

It is recommended that this meter be used with an alkaline 9 volt

battery. Such batteries can leak or explode if an attempt is made to

charge them. Do not recharge disposable alkaline batteries.

It is typical for this meter to be used to measure fats and oils which

can be very slippery when on a users hands or if dropped on the

floor. Please use caution when working around these materials due

to a possible slipping hazard.

3

2.0 Introduction

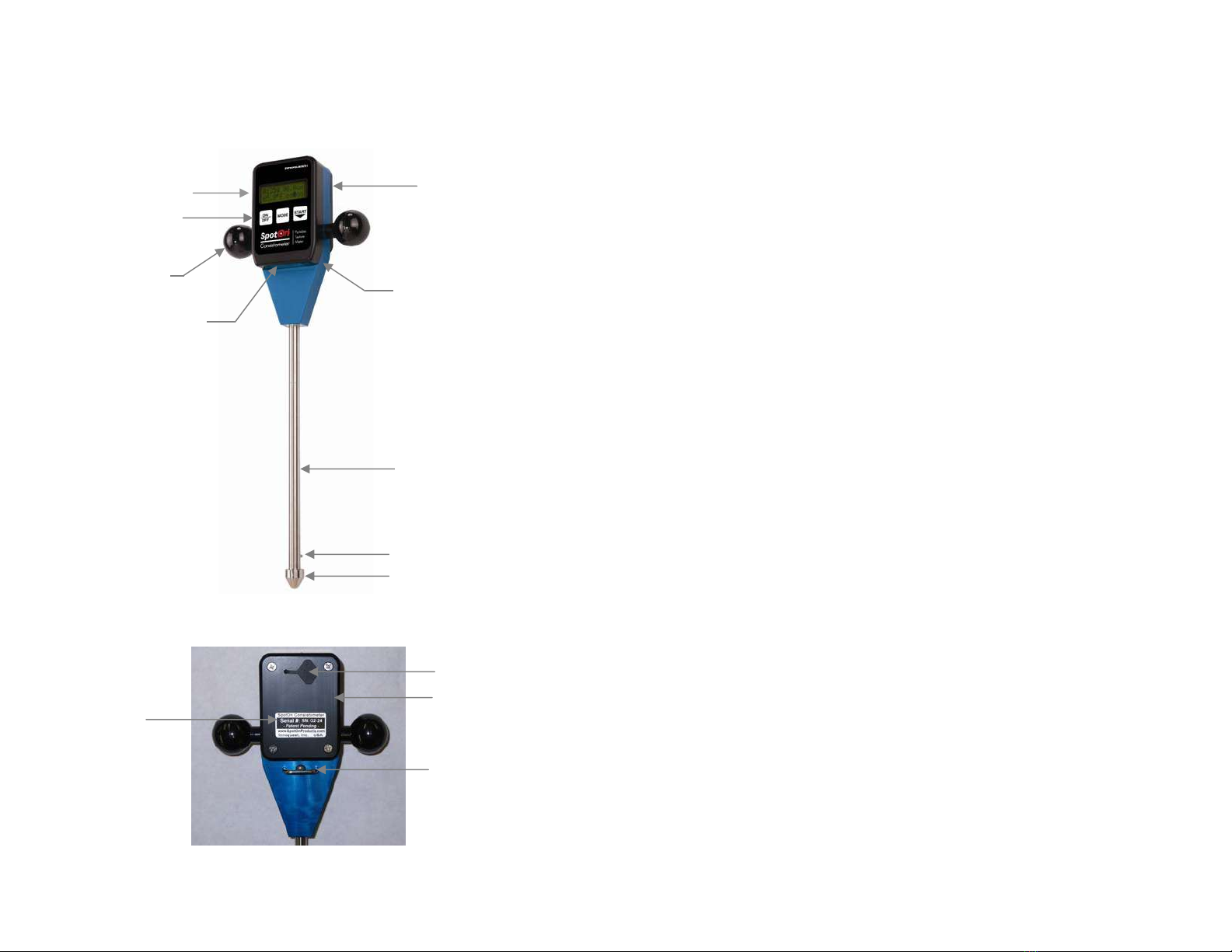

2.1 Meter Diagram (Front)

2.2 Meter Diagram (Back)

Remove

Back Plate

To Replace

Battery

LCD Dis

p

la

y

Ke

y

Pad

Tem

p

erature Sensor

Probe Shaft

Probe Tip

(Remove tip to install

shaft extensions

)

Non-Contact

Infrared Depth

Sensor

Internal Load Cell

Measures Penetration

Force From Shaft

Hand Gri

p

s

Wrist Lanyard

Attachment

Loop

Battery Cover

(Remove Back Plate

to Re

p

lace Batter

y)

Data Port Cover

Serial Number

Label

4

2.3 Features:

●Patent Pending Design

●Quick quantitative measurements of product or ingredient

consistency

●Penetrating consistometer measures entire sample, not just the

surface

●Works on a variety of products and ingredients (shortening, frosting,

dough, butter, cheese…)

●Measurements from 5cm up to 70cm depth (over 28 cm depth

require optional shaft extension)

●Shows readings in either Grams or Pounds

●Integrated Temperature Sensor

●On-board microprocessor calculates and displays:

- the average force of a measurement

- the mean of a group of measurements

- the Standard Deviation of a group of measurements

- the equilibrated temperature of the measured sample

●Precision load cell and non-contact depth sensor simultaneously

measure penetration force and penetration depth, while sample

temperature is also measured

●Displays instantaneous penetration speed to guide operator for

repeatable results

●Included PC software allows configuration for many products by

setting the desired penetration rate, depth of measurement, type of

probe tip and min/max limits; all of which can be preloaded onto the

instrument

●Data can be downloaded as an Excel® file (.CSV) for analysis and

plotting

●Interchangeable probe tips can be used to adapt the instrument to

different products (please contact Innoquest for information on

additional probe tips)

5

3.0 Specifications

Force: 0-22 lbs (0-9,999grams) working range, 0.01 lbs (4 g)

resolution, +/- 2% accuracy, Overload protection to 62 lbs (28

kg)

Depth: 0-28 in (0-70 cm) working range, 0.1 inch (0.1cm) resolution,

+/- 0.25” (0.6 cm) accuracy (Accuracy is much higher at

closer ranges and falls off with distance)

Temperature: 32.0-99.9*F (0.0-37.7*C) range, 0.1*F (0.1*C)

resolution, +/-0.5*F (0.3*C) accuracy, time constant approx

20 sec

Data Measurement: Records and displays force reading for every 1

cm (0.4in) of depth up to 70cm (27.6in). (Depending on shaft

length used)

Memory Capacity: Up to 99 probings

Multi Reading Average: Up to 6 probings can be averaged on the

meters display (also calculates standard deviation)

Computer Interface: USB port with special data interface cable

(included)

Battery: Standard 9 volt alkaline battery, 25 hrs continuous use

expected battery life (the meter will automatically shutoff after

2.5 minutes of non-use to save battery life)

Environmental: 35-120*F (2-49*C) / 0-95% RH / Indoor operational

conditions (meter is dust tight but not waterproof)

6

4.0 General Operation

Note: See Demo Video on www.YouTube.com

(Search SpotOn Consistometer)

4.1 Battery Installation

The meter requires a standard 9 volt alkaline battery. Use of

rechargeable batteries is not recommended since the meter won’t

read their remaining life correctly due to voltage differences. The

battery compartment is under the meter’s back cover. Remove the

back cover by first removing the (4) four Philips screws located in its

corners. Changing the battery does NOT erase any of the meter’s

memory; data or settings.

7

4.2 Meter Modes

Once power is turned on to the meter the user has the option to scroll

through and select 4-5 operating modes. (Review Mode does not

show if Data Logging is turned off) Use the MODE button to cycle

through the meter’s modes. The meter will automatically shut off after

2.5 minutes if no buttons are pressed.

Probe Mode – Use this mode to make readings. The meter

defaults to this mode when turned on.

Calibrate Mode – Use this mode to calibrate the meter.

Calibration is required when changing tips or shaft

configurations and recommended at the start of each day for

best accuracy.

Setup Mode – Use this mode to change meter settings for

units of measure or to turn data logging on or off.

Raw Mode – Use this mode to see raw sensor data. This

mode is primarily used for trouble shooting and not needed

for normal operation.

Review Mode – Use this mode to review a previous probing.

This mode only shows and works when data logging is turned

ON.

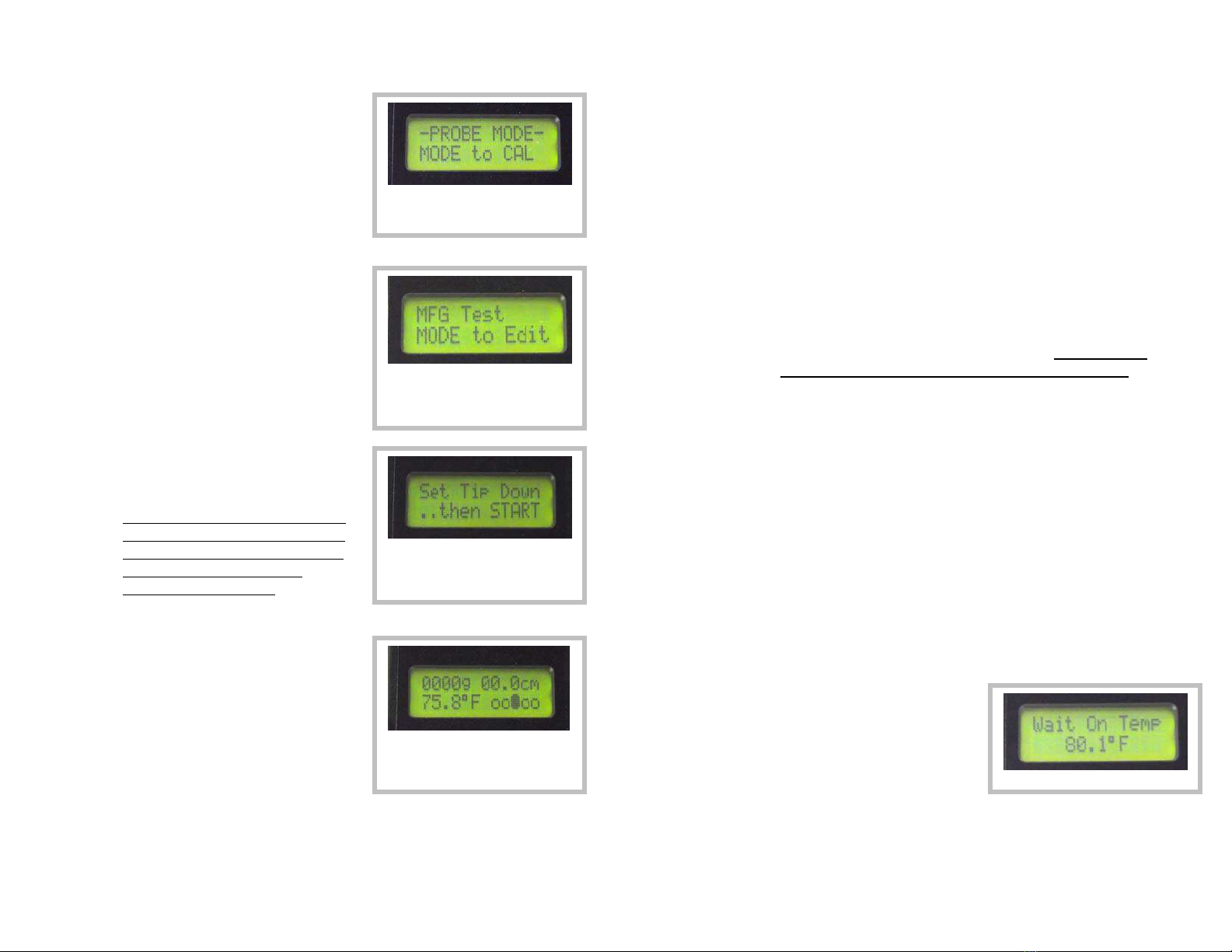

4.2.1 PROBE MODE

Probe mode is for taking readings with the meter and is

detailed below in section 4.3. The meter can operate

with or without saving readings to a data file. This

logging function is set as described in Setup Mode

section 4.2.3. If the logging is turned OFF then the meter

can still take readings and calculate multi-probe averages

but none of the data is stored for later download or for

review in Review Mode. When logging is turned ON the

meter tracks probings in its data file with an “N” number.

This number is consecutively assigned to each probing

while the logging function is on and is reported on the

meters LCD and later in the data file so the user can

track where the probing came from with his/her notes.

When the logging function is off, the “N” number will only

show as “- -“. It is possible to turn the logging function on

and off as many times as desired during a days work but

only readings taken while logging is on will be in the data

file. Turning off the logging function does not delete

previously recorded data.

8

Step 2

4.2.2 CALIBRATE MODE

This mode is used to calibrate the meter’s internal load

cell for drift which can occur due to temperature changes

or impact to the meter’s shaft. It is required that

calibration be done when ever a probe tip is changed or

shaft extensions are added or removed since the weight

of the shaft assembly is determined during calibration. It

is recommended that calibration be done at the start of

each day for best meter accuracy.

Select the CALIBRATE Mode and then press the START

button to begin calibration.

The meter goes through a 2 step

process to calibrate the load cell and

measure the weight of the shaft and tip

currently installed. First the meter asks

for the user to “Hang Shaft” this means

to hold the meter up by the handles and

allow the shaft to hang freely down

without touching anything (see Step 1

photo). Press the START button and

wait for the meter to finish. The meter

then asks for “Shaft Up Now” this

means that the meter must be place up-

side-down on a flat stable surface so

that the shaft is pointing straight up in

the air (see Step 2 photo). This will

allow the meter to measure only the

weight of the shaft and tip as

configured. With the meter sitting on it’s

“head” press and release the start

button and wait for the meter to finish

calibration. Note that the meter will

automatically ask for a calibration if it

detects a change in the shaft length

being used.

Step 1

9

4.2.3 SETUP MODE

Once in Setup Mode press the START button to select

which parameter to change.

a. UNITS screen allows the user to change the

measurement units of the meter between Metric

and Imperial. Press the MODE button to enter

the units screen and then change the units with

the START button. Note there are two units

screens; one for force/depth and one for

temperature. When done press the MODE

button to exit Setup Mode. The measurement

units can also be changed with the PC software.

Either method has the same effect.

b. DATA LOGGING screen allows the user to select

if the meter is configured to save probing data to

its memory for later download to a computer or

review. Press the MODE button to enter the data

logging screen and then change the setting with

the START button. When done press the MODE

button to exit setup mode. Unless no PC is

available or desired for operation it is best to set

data logging ON.

10

4.2.4 RAW MODE

This mode allows the user to see the raw readings from

the different sensors on the meter. While in this mode

the user can press the START button to scroll through

several other screens used for diagnostic or

troubleshooting work. All of these screens are read only

so no parameters can be accidentally changed. Exit raw

mode at anytime by pressing the MODE button.

4.2.5 REVIEW MODE

This mode allows the user to see data from previous

probings (only available if data logging is turned on).

Pressing the START button again will allow the user to

scroll down through the previous probings. Once the

probing of interest is reached then press the MODE

button to select it. At this point the START button will

allow the user to see the data from this probing including

each 1 cm of recorded data by continuing to press the

START button. When done press the MODE button to

return to the review mode.

11

4.3 How to Make a Probing

4.3.1 Turn the meter on and select

PROBE MODE if not already on

the screen as shown. (At power

on wait for the splash screens for

battery % and memory full to

finish displaying.)

4.3.2 Press START to begin a reading

once in PROBE MODE, if the

meter was just turned on then the

Product Type last used will be

displayed. If the product type

needs to be changed then press

MODE.

4.3.3 Once the START button is

pressed again the meter will

configure itself for a probing.

Turning the meter OFF and then

back ON will allow selection of a

new Product Type and will reset

all averages and standard

deviation calculations.

4.3.4 Place the meter’s tip on the

surface of the sample and press

START again. The meter will

measure the distance to the

surface for use in calculating

depth during the probing and for

checking probe length for

reporting in the data file. If the

probe length measured does not

match the currently calibrated configuration the meter may

suggest a new calibration is required. Once this screen

appears the user can then proceed by pushing the probe into

the sample.

Defaults to PROBE MODE after

power on, press START to

continue

Select Product Type, START to

continue, MODE to change

Product Type (“MFG Test” is the

Product Type shown here)

When this screen shows set the

meter’s tip on the surface of the

product but DO NOT start

p

enetratin

g

y

et.

When this screen appears the

probe may be inserted into the

product.

12

i. While pushing the probe into the sample watch the

speed indicator in the lower right of the screen. For the

selected insertion speed the indicator must be centered

(ooOoo). If the speed is too fast then the indicator

moves to the right (oooOo). If the speed is too slow

then the indicator moves to the left (oOooo). For

reference: (Ooooo)= 60% of target speed,

(oOooo)=80%, (ooOoo)=100%, (oooOo)=120%,

(ooooO)=140%.

ii. During the probing the force measured and the depth

will be continuously updated on the screen. The meter

will record a force reading at each 1 cm of depth and

save them to calculate a probing average and also for

later review or download to a computer if the logging

function is enabled. Probe averages discard the first 3

cm and the last 1 cm of probing depth. Therefore the

minimum probing depth is 5 cm for a valid reading.

4.3.5 For the meter to allow a probing to be considered complete

the penetration depth must be at least 5 cm. Once the

probing has gone to 5 cm or deeper then the probing reading

can be completed in two ways.

i. The downward penetration can be stopped and the

probe pulled out of the sample, once it has been

withdrawn 4 cm the meter will complete the probing

and then take the temperature that is currently sensed

by the temp sensor and then show FINISHED on the

LCD as shown on the next page.

ii. OR the downward penetration can be stopped at any

depth beyond 5 cm and the meter is left to sit without

further penetration or significant withdrawal for 4

seconds. After this 4 second wait the meter will

recognize that the user

intends to stop the probing

and will automatically enter

a temperature stabilization

mode (looks for less than

0.1*F change every 3

seconds). Once in this

mode it will monitor the temp sensor and only complete

the reading once the temperature measurement has

stabilized. Once stabilized the meter will complete the

probing and show FINISHED on the LCD.

Temp Stabilization Mode

13

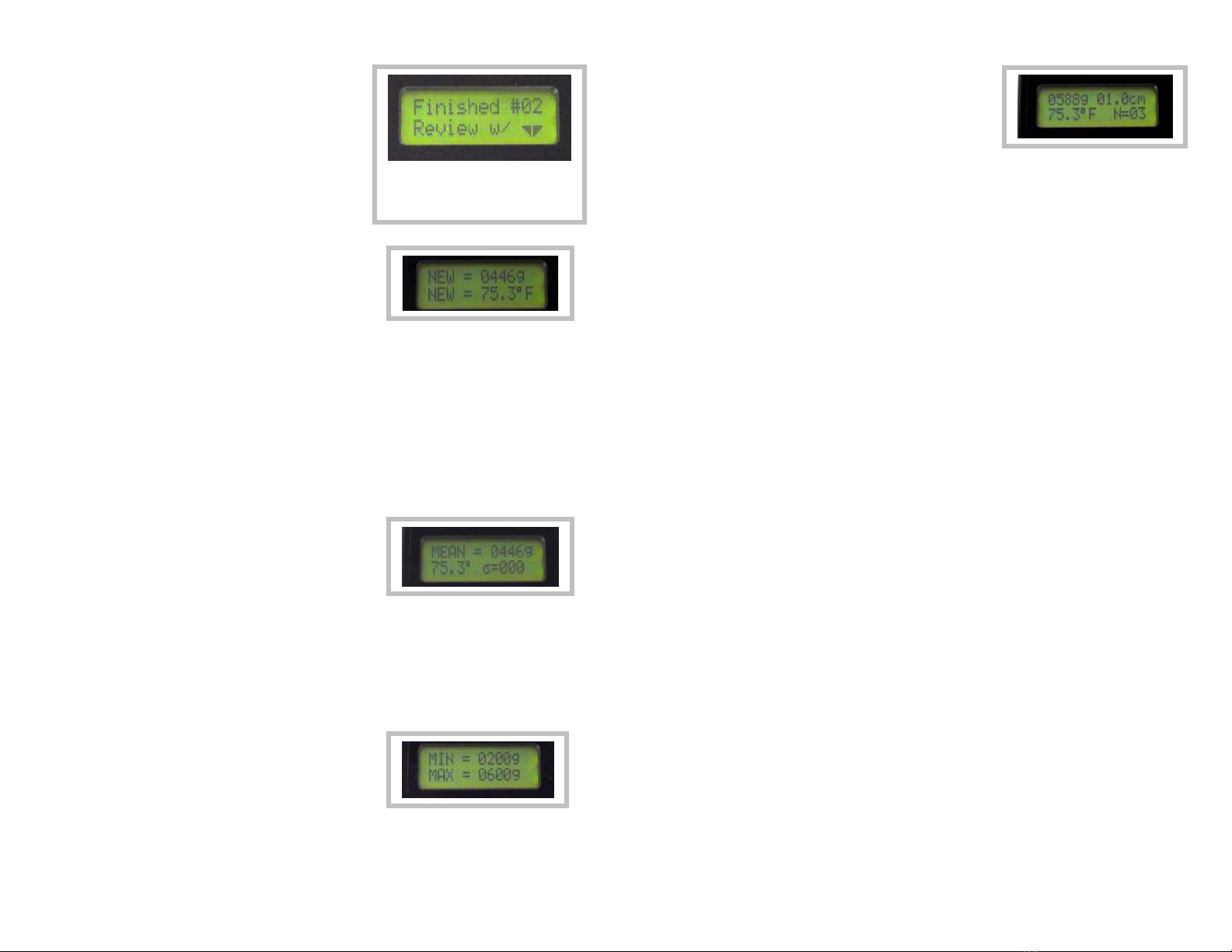

4.3.6 Once the meter has just finished

a probing (before starting a new

probing) the user can see 3-4

types of data. Pressing the

START button will show the data

in the following order. If data

logging is enabled then this data

can also be viewed later through

the use of Review Mode.

SCREEN 1 - The probing force

average and temperature for the

current reading called “NEW”. The

first 3cm and last 1cm of data are

not used in computing this average.

If more than 50% of the recorded force readings for the

probing profile were at speeds greater or less than the middle

three speedometer display segments (greater then +/- 20% of

target speed) then the entire probing is rejected and the user

is instructed to take a new one. This keeps operator error

from producing bad data sets. If a Max Depth was set

through the PC software for this product type then the

average as described above will only be calculated on data

points up to the set Max Depth.

SCREEN 2 - The multi-probe mean

of both force and temperature for all

probings since the meter was

turned ON. The standard deviation

is also displayed for all readings

included in the mean (shown as the Greek symbol sigma).

The meter will only calculate the mean and std dev for up to 6

probings. If more than 6 probings are taken without turning

the meter off/on then the mean will show as 0. To reset this

multi-probe averaging function turn the meter OFF then back

ON.

SCREEN 3 - The min and max

values are displayed as set through

the PC software for the currently

selected product type. If the min

and max are set to 0 and 9999

respectively then this min/max screen will not show.

This screen shows when the

probing is completed. (whether by

stopping the insertion and waiting or

immediately withdrawing the probe)

14

SCREEN 3/4 & Up - Pressing the

START button additional times will

allow the user to cycle through the

readings held in temporary memory

for each 1 cm of probing depth.

These readings are only recorded for computer download if

the logging function is ON. Once the max probing depth has

been displayed the display will cycle back to the SCREEN 1

in a continuous loop. In this way you can always get back to

a reading if you accidentally pressed the start button too

many times.

Pressing the MODE button at anytime will exit the review

mode and ready the meter for another probing. Once this is

done the data described above is no longer available to view

unless data logging was ON.

15

5.0 PC Software

The SpotOn Consistometer PC software is used for the following:

- Before the meter can communicate with the PC a correct com

port must be selected. (see 5.2.1)

- Transfer of data from the meter to a file on the PC (see 5.2.2)

- Clearing the data memory on the meter (see 5.2.3)

- Configuring settings on the meter (see 5.2.4

5.1 Software Install

Software Installation:

Insert the SpotOn Consistometer Software CD in the computer’s CD

drive. This should automatically start a software install wizard on the

PC. Follow the steps on the install wizard to install the software.

Once the software is installed the CD will run a program that installs

the driver for the USB cable. This will be seen as a small “command

prompt” window that will flash on the screen for a few seconds. When

this is finished the install process is complete and the software and

USB cable should be ready to use.

Note: If there is a problem installing the software then locate the

SpotOn Setup.exe on the CD and right click on it, then select

windows compatibility mode and run as XP compatible.

USB Cable Installation:

The meter has a data port for connection to a computer via a special

USB cable that was provided with the meter. This cable requires a

driver be installed on the computer for proper operation. The

software CD that comes with the meter will automatically install this

driver when installing the meter’s software as described above.

PLEASE NOTE: Don’t plug this USB cable into the computer until

after the software has been installed. If it is plugged in before the

install please remove it and CANCEL all requests by the “New

Hardware Wizard”.

16

5.2 Software Use

5.2.1 Port Selection

1. Make sure the meter has a battery installed. The meter should be

turned off. Attach the Special USB cable to a USB port on the

computer and to the data port on the meter.

2. After opening the SpotOn Meter Software enter the Port Select

menu and click on AUTO DETECT. This will cause the software to

search the computer to find the port the data cable is plugged into.

The com port will be automatically located and saved for future use.

(Note: only works when the meter is connected to the computer with

the USB cable) The com port can also be manually selected.

17

5.2.2 Transferring Meter Data

Enter the Meter menu and select GET DATA FROM METER to

download all data on the meter. This will create a .CSV (comma

separated variable) file which can be read by any spread sheet

program. Note: All data stays on the meter even after a download or

after changing the meters battery. The ONLY way to clear the data

from memory is described in section 5.2.3.

Data File Example Opened in a Spread Sheet Program:

18

5.2.3 Clearing Meter Memory

Clear the meters memory when desired by entering the Meter menu

and selecting CLEAR METER MEMORY. This will clear all data from

the meter’s memory. Note that this does not affect settings or stored

Product Type names.

19

5.2.4 Configuring the Meter

A list of Product Types can be generated by entering the Meter menu

and selecting CONFIGURE PRODUCT LIST. The Product Types

entered will automatically be saved and redisplayed when the

software is re-opened. Only the Product Types which have been

selected with a check mark will be sent to the meter. The user can

then scroll through the transferred Product Types while using the

meter in the field to select the one desired before a reading is taken.

Product Types -

Send Check Box – If this box is checked then its associated

product type will be sent to the meter. By checking or un-

checking this box the number of product types to scroll through

on the meter is limited while still allowing all data to be store in

the PC file. All the data is stored in the file: SpotOn Settings.cfg.

This file can be copied to other computers to eliminate the need

to re-enter all the settings for each computer if desired.

Product Name – Enter up to 12 characters or numbers to create

a unique name that will display on the LCD of the meter once

uploaded.

20

Min – The value entered here will show on the meter’s LCD to

remind the user what the minimum acceptable value is. Set min

to 0 and max to 9999 if no min/max is desired to show on the

meter. Valid ranges are 25 to 9998 grams or 0 to 22.00 lbs.

Max – The value entered here will show on the meter’s LCD to

remind the user what the maximum acceptable value is. Set min

to 0 and max to 9999 if no min/max is desired to show on the

meter. Valid ranges are 25 to 9998 grams or 0 to 22.00 lbs.

Configuration – This is a pull down menu that allows the user to

select one of the custom named “configurations” as defined in the

Set Up Configuration section. A configuration MUST be selected

for each product type.

Set Up Configuration -

Configuration Name – This is a custom name the user can enter

up to 15 characters to describe the configuration (i.e.

“shortening”, “dough”, “icing”…). This name will show in the pull

down menu in the product types section above.

Penetration Speed – Select the penetration speed the meter will

use. The default is 3 cm per second.

Tip Type – This is a pull down menu that allows the user to select

from tip numbers 1 to 99. The tip number does not affect the

meter’s operation but is passed on to the data file for ease in

tracking the use of different tips. The default tip is Tip #1.

Max Depth – This sets the maximum depth that will be used to

calculate a probing average on the meter. This setting allows all

data to be calculated to a given depth regardless of the users

actual penetration (provided penetration at least to the Max

Depth).

Select Units -

Units - Select what measurement unit the meter and software will

function in. This setting is not changed on the meter until the

UPDATE METER button is pressed.

Update Meter Button -

Pressing the UPDATE METER button will send all the current

selected product types and units selections to the meter. All of

the settings showing on the screen will be saved to a PC data file

named “SpotOn Settings.cfg” when the software is closed.

Therefore any changes will show the next time the software is

opened.

21

6.0 Trouble Shooting

Why do I get an ERROR after making a probing?

If 50% of the speed readings for a given probing (measured at each 1

cm depth increment) were not within one dot of the center point of the

speedometer then the meter rejects the reading as invalid and show

ERROR on the LCD which requires the user to make the probing

again. With experience the user will get better at producing

consistent penetration speeds that do NOT generate errors. (see

4.3.4)

Why do I get a 0 for mean while the probe average is not 0?

The mean is calculated for up to 6 readings after power on. If the

user takes more than 6 readings the mean and standard deviation will

show as 0’s. Turning the meter OFF then back ON will reset the

counter for up to 6 new readings for which it will calculate mean and

standard deviation. The probe average will always be correct

regardless of the number of readings since power on.

Why don’t I get accurate temperature measurements?

First make sure you are keeping the probe inserted in the product for

4 seconds rather than withdrawing it immediately to end the probing.

If the temperature readings are still not accurate the try withdrawing

the probe 1-2 cm after your full depth is reached. This will help to

insure the temp sensor is in good contact with the product and should

cause it to read better. Note: the probe requires 4 cm of withdrawal

to make it end the probing without waiting for temp stabilization,

therefore it is ok to withdraw 1-2 cm since this won’t break the entry to

temp stabilization mode.

Why does the Speedometer seem “stuck” at the start of the

probing?

The speedometer will automatically show a centered position until the

probe tip reaches a depth of 2 cm. This allows time for the user to

enter the surface of the product and then develop some consistency

to their speed before the speedometer starts showing real values.

Why am I having trouble taking readings near the edge of a

product container?

The meter uses a non-contact infrared sensor which shines an

invisible beam of light out the bottom of the meter front. Make sure its

clear window is clean and that the probe tip is at least 1.5 (3.8 cm)

inches back from the edge of the container so the light beam does not

miss the surface of the product.

22

7.0 Maintenance

- Remove the battery from the meter if it will be stored without

use for a long period of time (like 3 months or more)

- Clean the meter with a soft cloth using soapy water or mild

cleaning agent like Windex®. The meter is sealed against

moisture, dust, and oils but it is not considered water tight and

must NOT be submerged.

- Check the clear window on the bottom edge of the front of the

meter. This is the window over the Infrared depth sensor and

must be kept clean for best performance. Use only soft cloths

for cleaning this window so it does not get scratched.

- Note the purpose of the small o-ring around the threaded end of

the shaft is to provide a self-locking feature to the probe tip so

that it does not come loose during use. The o-ring is

compressed when the probe tip is tightened by hand and

should be sufficient to keep the tip from coming loose. The o-

ring is not designed to form a seal nor is it required for

operation.

- If during normal use an alkaline battery leaks in the meter

please clean the meter immediately and wash hands to remove

any caustic battery electrolyte. The battery electrolyte is water

soluble so please use a wet towel to clean the battery

compartment.

23

8.0 Warranty & Service

One Year Warranty

Innoquest, Inc. warrants this product to be free from defects in

materials and workmanship under normal use and service for a period

one (1) year from date of purchase. This warranty extends only to the

original purchaser and shall not apply to any product which, in

Innoquest’s sole opinion, has been subject to misuse, alteration,

abuse, or abnormal conditions of operation or handling. Innoquest’s

obligation under this warranty is limited to repair or replacement of the

product which is returned to Innoquest. Innoquest accepts no liability

for whatever damages may be caused by a malfunctioning product.

Repair & Service Policy

Product returned to Innoquest for repair or service must follow the

guidelines set forth as follows: Return of the product for warranty or

service repair will be the responsibility of the purchaser (Innoquest

does not pay inbound shipping charges). All returns must receive an

RMA number by calling Innoquest prior to return of the product. The

RMA number must be clearly marked on the outside of the shipping

carton. If the customer is returning product for non-warranty related

repair or service, a minimum charge will apply for accessing the

product’s repair needs and further work will not be completed without

the customer’s approval.

910 Hobe Road

Woodstock, IL 60098

Toll Free: 800-637-1623

Phone: 815-337-8555

Fax: 815-337-8556

www.InnoquestInc.com

© 2012 Innoquest, Inc. USA P/N 27580 Rev. 4 (Revised 10/25/12)

Table of contents

Other Innoquest Measuring Instrument manuals