2.3 Steamer Functions

6

English

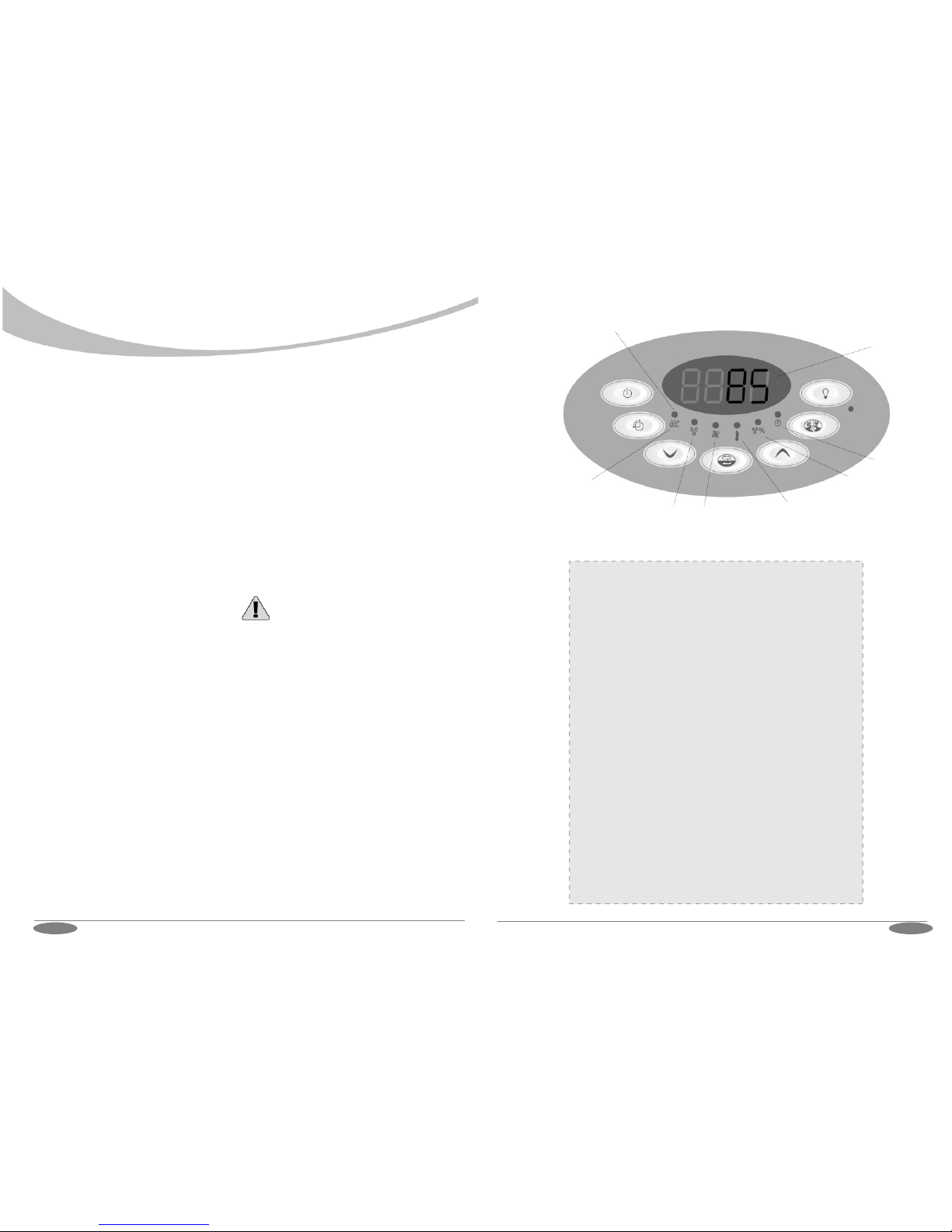

2.2.4 Setting Mode

Long press the toggle button to activate

setting mode. It can be used to select and

adjust the fan*, temperature, humidity* and

the session time (*not all models have all

the same features). Corresponding LEDs

will be blinking on each selected features.

Change values by pressing the up and down

buttons.

Save the settings by long pressing the

toggle button, a high beep will confirm it. If

no keys are pressed within 5 seconds, the

control unit will save the settings.

2.2.7 Cabin Light Button

Cabin light can be switched on, even when

the heater or pre-run timer are off. Short

press the button and the lights will be

switched on/off.

LED for the light indicates if the light is

switched on or off.

2.2.5 Dimmer light (optional)

When the lights are switched off, short

press the light button to activate the

dimmer.

If the lights are on and the cabin light

button is pressed for long, it will toggle the

dimmer light state. Then the cabin lights

can be adjusted with the arrow buttons

from 0% to 100%. Confirm the settings

with the toggle button.

The steamer function can only be activated

if the heater has a steamer and the steamer

feature is present on the controller. When

there is no steamer present, all the

functions and settings regarding the

steamer are not available.

Press the mode button for less than 3

seconds to activate the steamer. Once

activated, the steamer is switched on,

unless the temperature or the relative

humidity inside the sauna room is too high.

High humidity and high temperature are not

allowed, “HOT” will be displayed in the

control unit and the steamer will not be

activated.

Lock the key pad by pressing the up and

down arrow keys at the same time for more

than 5 seconds. A high beep will confirm the

activation and the deactivation.

When key lock is activated only heater on/off

and cabin light functions can be used. Toggle

button is enabled only to see actual values. If

other buttons are pressed, “----“ is shown in

the display.

Unlock the buttons by pressing up and down

arrow keys at the same time for more than 5

seconds. A high beep will confirm it.

The key lock function is set automatically if it

was activated during the previous operation.

2.2.8 Key pad lock

(to prevent unauthorised use of

control unit)

2.3.1 Steamer

2.2.6 Fan (optional)

If the model installed has a fan, its speed

can be regulated. Switch it on or off by

pressing the mode button, LED light for fan

will indicate if the fan is turned on or off.

The speed of the fan can be set in the

settings mode.

Please note: If the used heater is a Combi

with a steamer, the button needs to be

pressed for longer than 3 seconds to

activate the fan. Long press it again to turn

off the fan.

5English

2.2.1 Heater on

Press the Power button to activate the

heater. The heater LED is illuminated

indicating that the heater is turned on.

The sauna will heat up to the temperature of

the previous setting and operate for the

length of previous session time. Session

time is saved for next session only if session

time is changed within 5 minutes after

switching the heater on.

2.2.2 Heater off

Turn the heater off by pressing the Power

button. This button will turn off all the active

functions, including the pre-run session.

However, the sauna room light will not be

switch off. Light button can be used even the

heater is off.

2.2 Directions of use

2.2.3 Pre-run button

Pre-run button is enabled only when the

heater is turned off. During the pre-run

parameter values can be changed.

Set the pre-run time by pressing the

pre-run button. Pre-run time will be

displayed indicating countdown time after

which the sauna is ready for use. The up

and down arrow keys can be used to change

the pre-run time.

Next, temperature, fan*, steamer* and

session time (*not in all models). can be

changed if preferred. Finally press the

toggle button for long to confirm.

When the control unit is in the pre-run state,

it will display the remaining time of the

pre-run. The confirmed pre-run settings are

saved for the next session.

When the pre-run function is used for the

first time control unit estimates the time that

the heater needs to reach the set tempera-

ture. For example, if the pre-run time is set

to 2 hours, the heater will be switched on in

1.5 hours.

If the sauna has not reached the set

temperature by the time it is meant to be

ready, in this case 30 minutes, it will remem-

ber this. Next time the pre-run function is

used, the heater will be switched on earlier,

for example 50 minutes before the end of

the pre-run time.

Alternatively, if the heater reaches the set

temperature too quickly, it will adjust itself to

be switched on later. The control unit

teaches itself to switch the heater on at the

ideal time in order to reach the set tempera-

ture when wanted.

The pre-run function has different default

settings, depending on the installation

location. For domestic use, the default time

is 6 hours, including the pre-run time as well

as the session time. See more details in the

installation section of the manual.

Always check that there is no combustible material,

like towels, above the heater, nor inside the safety

distances, before switching the heater on! The

safety distances are stated in the heater manual.

Warning

Always check that there is no combustible

material, like towels, above the heater, nor inside

the safety distances, before switching on the

heater or pre-run mode. The safety distances are

stated in the heater manual.

Warning