Table of Content

i) Notice............................................................................................................................................................1

ii) Safety Information ........................................................................................................................................4

iii) Safety Regulations .......................................................................................................................................5

1. GENERAL .......................................................................................................................................................6

1.1 Model Specification ...................................................................................................................................6

1.2 Operating Specification..............................................................................................................................7

1.3 Type of Interface ........................................................................................................................................7

1.4 Main Components ......................................................................................................................................7

2. OVERVIEW .....................................................................................................................................................9

2.1 Dimension (in mm) .......................................................................................................................................9

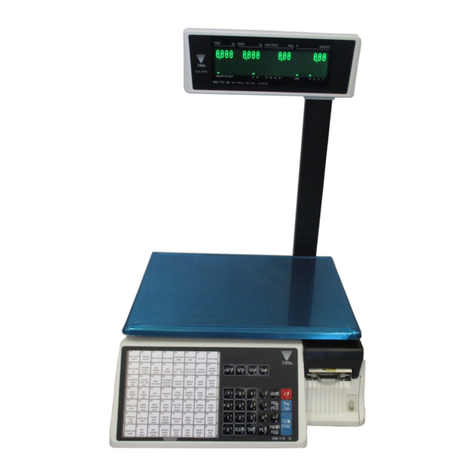

2.1.1 SM-720 DP ........................................................................................................................................9

2.1.2 SM-720 EB ........................................................................................................................................9

2.1.3 SM-720 EV ......................................................................................................................................10

2.1.4 SM-720 TDP....................................................................................................................................10

2.1.5 SM-720 TEB ....................................................................................................................................11

2.1.6 SM-720 TEV ....................................................................................................................................11

2.1.7 SM-720 H ........................................................................................................................................12

2.1.7 SM-720 BS ......................................................................................................................................12

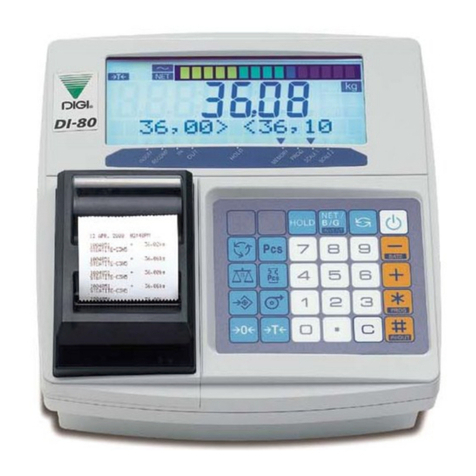

2.2 Key sheet Layout .......................................................................................................................................13

2.3 Panel Layout ..............................................................................................................................................16

3. SPAN SWITCH..............................................................................................................................................18

3.1 Span Switch Jumper Setting Changing Procedure...................................................................................18

3.2 Span Switch located in Main Board ..........................................................................................................18

4. INITIAL SETUP .............................................................................................................................................19

4.1 Pole, Bench and Elevated Type................................................................................................................19

4.1.1 Scale Assembly ...............................................................................................................................19

4.1.1.1 Display Pole Kit Mounting.....................................................................................................19

4.1.1.2 Level Adjustment ..................................................................................................................19

4.1.2 Default Country Spec Setting ..........................................................................................................19

4.1.3 Calibration .......................................................................................................................................23

4.1.4 User Spec Setup Procedure............................................................................................................24

4.1.5 Weigh & Measurement Spec Setup Procedure ..............................................................................26

4.2 Touch Pole, Touch Bench and Touch Elevated Type...............................................................................28

4.2.1 Default Country Spec Setting ..........................................................................................................28

4.2.2 Calibration .......................................................................................................................................29

4.2.3 User Spec Setup Procedure............................................................................................................30

4.2.4 IP Address Setting...........................................................................................................................30

5. HARDWARE TESTING & MAINTENANCE .................................................................................................32

5.1 For Pole, Bench and Elevated Type .........................................................................................................32

5.1.1 Hardware Testing ............................................................................................................................32

5.1.1.1 RAM Read and Write Test....................................................................................................32

5.1.1.2 SIO Loop Back Test .............................................................................................................33

5.1.1.3 ROM Checksum Test ...........................................................................................................33

5.1.1.4 PLU Generator Test .............................................................................................................33

5.1.1.5 Internal Count .......................................................................................................................34

5.1.1.6 Span Switch Status ..............................................................................................................35

5.1.2 Adjustment.......................................................................................................................................35

5.1.2.1 Location of Gap Sensor And Peel Sensor............................................................................35