innove VP100 Operating and maintenance manual

Vp100 calibration

Suite 5, 56-62 Chandos Street, St. Leonards NSW 2065/PO Box 135 Spit Junction NSW 2088 Australia

Ph (02) 9906 7158 website: www.innovec.com fax (02) 9906 7220 page 1

INSTALLATION PROCEDURE

FOR THE INNOVEC VP100

VALVE POSITIONER

Vp100 calibration

Suite 5, 56-62 Chandos Street, St. Leonards NSW 2065/PO Box 135 Spit Junction NSW 2088 Australia

Ph (02) 9906 7158 website: www.innovec.com fax (02) 9906 7220 page 2

VP100 VALVE POSITIONER CALIBRATION PROCEDURE

Step 1: Electrical Connection.

Before connecting power always check the label for the power supply it has been

configured for.

If the unit you have been supplied with is for 240VAC operation then connect AC

power to:

(a)Terminal 3 is 240VAC supply

(b)Terminal 2 is neutral VAC supply

(c)Terminal 1 is ground supply

If the unit you have been supplied with is for 120VAC operation then connect AC

power to:

(a)Terminal 3 is 120VAC supply

(b)Terminal 2 is neutral VAC supply

(c)Terminal 1 is ground supply

If you require to change an instrument from 240VAC to 120VAC or 120 to 240VAC

operation then there are 3 solder links on the circuit board underneath the transformer.

These links are shown on the component overlay as LK1, LK2 and LK3.

For 240 VAC operation: close link LK2 and open LK1 and LK3

For 120 VAC operation: close link LK1 and LK3 and open LK2

If the unit you have been supplied with is for 24VDC operation then connect DC

power to:

(a)Terminal 3 is 24VDC supply

(b)Terminal 2 is 0VDC supply

(c)Terminal 1 is ground supply

Connect the feedback potentiometer on the valve to:

(a)Terminal 10 is feedback pot left side

(b)Terminal 11 is feedback pot wiper

(c)Terminal 12 is feedback pot right side

The feedback potentiometer can be any value between 100 Ohm to 10,000 Ohms

Connect the milliamp command signal to:

(a)Terminal 8 milliamp loop positive (+)

(b)Terminal 9 milliamp loop negative (-)

Connect the Valve Motor to:

(a)Terminal 4 is Motor One (Forward)

(b)Terminal 7 is Motor Two (Reverse)

(c)Terminal 5 or 6 is the Motor Supply Active

The voltage active supply on terminals five (5) or (6) is switched by the internal relays

on to terminal 4 or terminal 7.

Calibration of the instrument

To gain access to the adjustment potentiometers it is necessary to remove the front

plate of the instrument.

Vp100 calibration

Suite 5, 56-62 Chandos Street, St. Leonards NSW 2065/PO Box 135 Spit Junction NSW 2088 Australia

Ph (02) 9906 7158 website: www.innovec.com fax (02) 9906 7220 page 3

Step 1.

(a) You will see there is a 1mm gap on the right hand side between the front plate and

the case. Insert a thin bladed screwdriver into this gap and gently prise out the front

plate. Access to the calibration potentiometers is now available.

Step 2: Calibrating the feedback potentiometer

The feedback potentiometer is displayed on the two digit LED display at the front of

the instrument as 00 to 99

(a)Drive the motor to its minimum position so that the feedback pot on the motor

gives out its minimum resistance value. Adjust the FEEDBACK ZERO (p2) pot

until the display reads '00' or the minimum required value.

(b)Drive the motor to its maximum position so that the feedback pot on the motor

gives out its maximum resistance value. Adjust the FEEDBACK SPAN (p1) pot

until the display reads '99' or the maximum required value. Repeat until the required

reading has been reached.

Step 3: Calibrating the input current loop.

The instrument can be set up to accept either a 4-20mA or 0-20mA input signal. All

instruments are shipped for 4-20mA operation. If it is intended to use an 0-20mA

input signal then remove the link marked R39 on the electronics board. (There are

two main circuit boards, a power supply/relay board and an electronics board).

(a)Drive the motor to its minimum position and inject 4mA. Adjust potentiometer

COZ CONTROL OUTPUT ZERO (p5) until the relay changes state.

(b)Drive the motor to its maximum position and inject 20mA. Adjust potentiometer

COS [CONTROL OUTPUT SPAN] (p3) until the relay changes state. Repeat the

steps 4 (a) and (b) once for confirmation of the correct operation.

Step 4: Calibrating the Dead band

Dead band of the relay switching operation can be set between 1 to 25%. This is

accomplished by adjusting the DEADBAND POTENTIOMETER (P4)

AUTO MANUAL SELECTION

The instrument also includes auto/manual control of the final element. The three push

buttons that protrude through the front of the instrument are:

(a)CENTRE BUTTON - Auto/manual selection

(b)LEFT BUTTON - ramp down

(c)RIGHT BUTTON - ramp up

The instrument is in AUTO when the centre button is extended and in MANUAL

when the centre button is pushed in.

In AUTO the VP100 tracks the 4-20mA signal driving the motor to a position relative

to the 4-20mA signal.

In MANUAL the VP100 ignores the 4-20mA signal and the motor can be manually

driven by using the RAMP UP/RAMP DOWN push buttons which switch voltage

directly onto the motor bypassing the internal electronics.

Vp100 calibration

Suite 5, 56-62 Chandos Street, St. Leonards NSW 2065/PO Box 135 Spit Junction NSW 2088 Australia

Ph (02) 9906 7158 website: www.innovec.com fax (02) 9906 7220 page 4

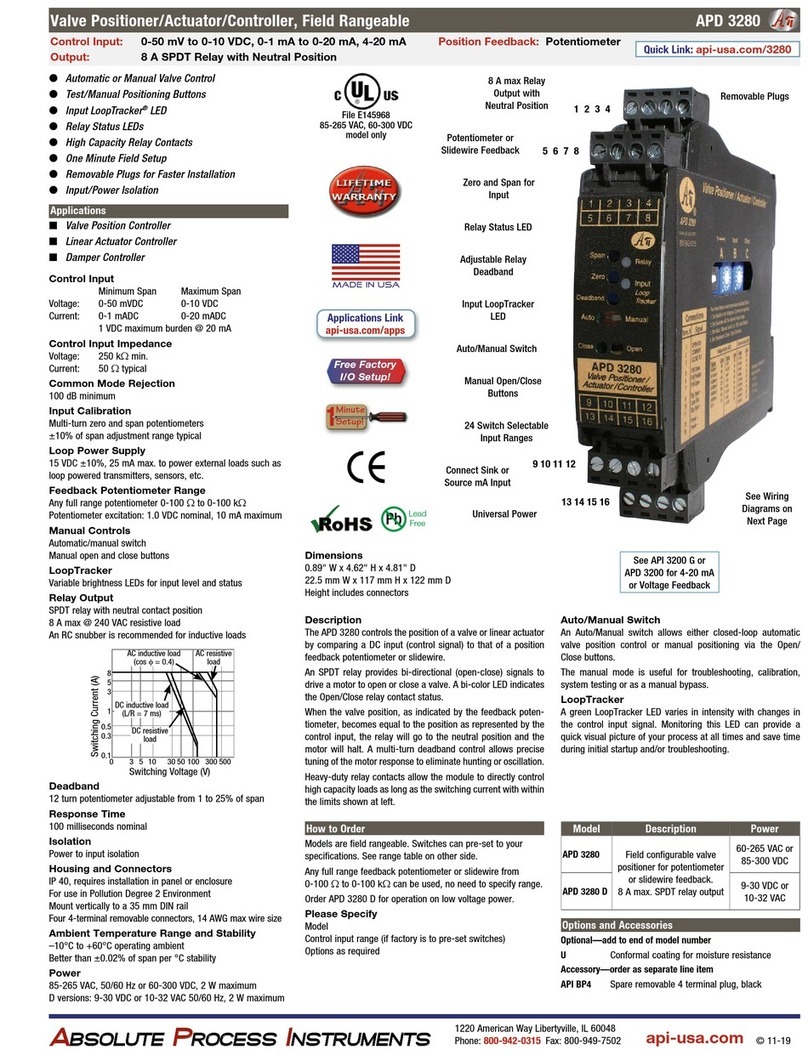

Table 1 showing electrical connection

Terminal number

Description

1

Ground supply

2

Neutral supply/0VDC supply

3

VAC active /24VDC active supply

4

Motor one

5

Motor common

6

Motor common

7

Motor two

8

mA input positive (+)

9

mA input negative (-)

10

Feedback potentiometer left

11

Feedback potentiometer wiper

12

Feedback potentiometer right

VP100 Layout with front view showing potentiometers and rear terminal connections

Vp100 calibration

Suite 5, 56-62 Chandos Street, St. Leonards NSW 2065/PO Box 135 Spit Junction NSW 2088 Australia

Ph (02) 9906 7158 website: www.innovec.com fax (02) 9906 7220 page 5

Control board

Vp100 calibration

Suite 5, 56-62 Chandos Street, St. Leonards NSW 2065/PO Box 135 Spit Junction NSW 2088 Australia

Ph (02) 9906 7158 website: www.innovec.com fax (02) 9906 7220 page 6

Power and relay Board

Table of contents