Metso NP700/B User manual

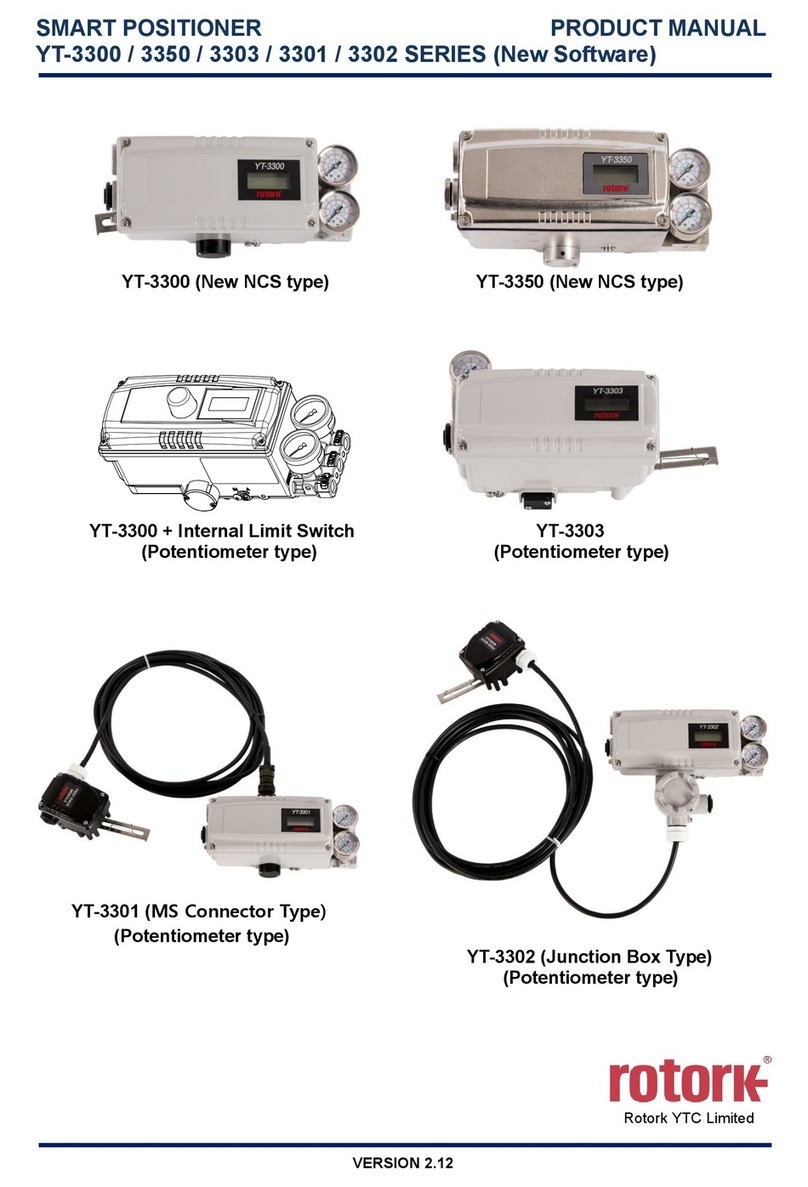

Positioners

Series NP700

Installation, Maintenance and

Operating Instructions

7 NP 72 en • 11/2014

27 NP 72 en

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about safe handling and operation of the positioner.

If you require additional assistance, please contact the manufacturer or manufacturer's representative.

Addresses and phone numbers are printed on the back cover.

SAVE THESE INSTRUCTIONS!

Subject to change without notice.

All trademarks are property of their respective owners.

Table of Contents

1 INTRODUCTION ...................................................3

1.1 General .....................................................................3

1.2 Principle of operation .........................................3

1.3 Marking of positioner ..........................................3

1.4 Technical specifications .....................................4

1.5 Approvals ................................................................4

1.6 Recycling and disposal .......................................4

1.7 Safety precautions ...............................................4

2 MOUNTING ON THE METSO ACTUATOR ............4

2.1 General .....................................................................4

2.2 Installing positioner NP700/S1 on

Metso actuators with VDI/VDE 3845

mounting face ........................................................5

2.3 NP_700/700 positioner/limit switch

combination (Obsolete since 2013)................5

2.4 Piping of supply air ..............................................5

2.5 Instrument air supply ..........................................8

3 INPUT SIGNAL AND DIRECTIONS OF

OPERATION ..........................................................8

3.1 Changeover piece ................................................8

3.2 Cam plate ................................................................8

4 PRELIMINARY ACTIONS FOR THE

ADJUSTMENT .......................................................8

4.1 Position of the changeover piece ...................8

4.2 Pilot valve ................................................................8

4.3 Position of the cam plate ...................................9

5 BASIC ADJUSTMENT ...........................................9

6a

0ADJUSTMENT ..................................................9

7 SPLIT-RANGE ADJUSTMENT .............................10

8 MAINTENANCE ..................................................10

8.1 Supply air filter ................................................... 10

8.2 Pilot valve ............................................................. 10

8.3 Replacement of the diaphragms ................. 11

9 TROUBLESHOOTING .........................................11

10 OPTIONS .............................................................11

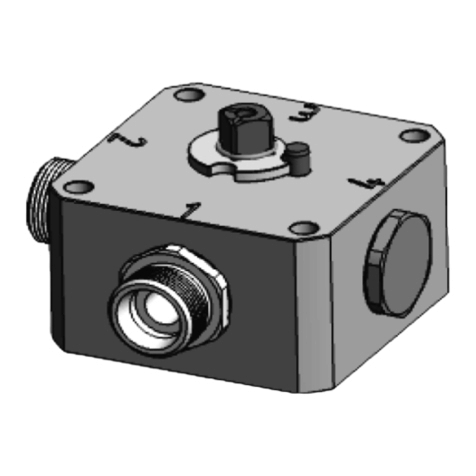

10.1 NP700/B and NP700/B1 ................................... 11

10.2 NP700/GN natural gas construction ........... 11

10.3 NP700/R dust-proof construction (IP65) ... 11

10.4 NP700/A with pressure gauges .................... 11

11 TOOLS ................................................................ 11

12 ORDERING SPARE PARTS ................................. 11

13 DRAWINGS AND PARTS LISTS .......................... 12

13.1 Exploded view and parts list ..........................12

13.2 Mounting parts for B1C6-502 and

B1J8-322 actuators (S1) ....................................14

13.3 Mounting parts for Quadra-Powr®

actuators (S1) .......................................................15

13.4 Mounting parts for B1C6-20 and

B1J8-20 actuators (S2) ......................................16

13.5 Mounting parts for B1C25-502 and

B1J25-322 actuators (S2) .................................17

14 TYPE CODE ........................................................ 18

7 NP 72 en 3

1 INTRODUCTION

1.1 General

The NP700 positioner is used for positioning double or sin-

gle acting actuator.

1.2 Principle of operation

Operation is based on the force balance principle. One force

is caused by the signal pressure (IN) and acts on the dia-

phragm (8), and the other is the compression force caused

by the feedback spring (60.1). The latter is directly propor-

tional to the position of the lower end of the spring, which

is in turn dependent solely on the position of the actuator

shaft via the lever (33), the cam (29), the positioner shaft

(26) and the coupling (52).

When the equilibrium between the forces mentioned

above is disrupted, the beam (5) moves in the direction of

the stronger force. The end of the beam moves the spool

(44.2) in the bore of the body (44.1). When diverted from

the equilibrium position, the spool guides the supply air to

one side of the actuator piston and the air on the other side

of the piston outside.

When the spool is in the equilibrium position the small vol-

ume of leakage past the spool creates an equal pressure on

either side of the unloaded cylinder piston. This pressure is

roughly 0,7 x the supply pressure.

If the signal pressure is altered, the spool moven out of the

equilibrium position and causes a pressure difference in the

cylinder. The piston moves in the direction of the difference

pressure until the compression force of the feedback spring

generated by the change in position is in equilibrium with

the force generated by the signal pressure.

Thus each signal pressure value corresponds to a single

actuator position. If an external force acts on the actuator

shaft, the shaft tends to move in the direction of the torque.

This alters the position of the spool via the feedback system

so that the pressure difference arising in the cylinder offsets

the effect of the external torque.

Parts list for Figure 1:

Item Part

5Beam

8Diaphragmpiston

26 Shaft

29 Cam plate

33 Lever

44.1 Pilot valve body

44.2 Pilot valve spool

46 Changeover piece

52 Coupling

60.1 Feed-back spring

60.3 Range adjustment

67 Zero adjustment

1.3 Marking of positioner

The positioner has an adhesive ID plate, see Fig. 2.

The ID plate contains the following information (from top to

bottom):

Full type designation of the positioner

Input signal

Max. supply presssure

Ambient temperature range

Manufacturing series number

An additional plate, Fig. 3, has markings:

Filter regulator (-K)

Temperature range

Fig. 1 Schematic diagram

Fig. 2 ID plate

Fig. 3 Additional plate

47 NP 72 en

1.4 Technical specifications

Signal pressure ranges 20-100 kPag, 0.2-1.0 barg,

(3-15 psig)

Split ranges 20-60 kPag/60-100kPag,

0.2–0.6 barg/0.6–1.0 barg,

(3–9 psig, 9–15 psig)

Turning angle of feed-back shaft max. 90°

Relation between angle and signal linear

Supply pressure ps 140-1000 kPag, 1.4–10 barg

(20–145 psi)

Effect of supply pressure < 0.2 % / 0.1 bar

(< 0.14 % / 1 psi)

Ambient temperature -40° to +90 °C

(-40° to +185 °F)

Effect of temperature < 0.07 % / °C

(< 0.025 % / °F)

Performance, measured using a cylinder

actuator with 12 % friction load

- dead band < 0.3 %

- hysteresis < 1.2 %

- linearity < 2 %

Effect of vibration (1.5 g, 5–100 Hz) < 1 %

Weight approx. 1.5 kg / 3.3 lb

Construction materials

- case anodized aluminium alloy

- cover polycarbonate (standard model)

- internal parts stainless steel, aluminium

alloy and stainless spring steel

- diaphragm and seals nitrile rubber (standard model)

1.5 Approvals

NP700/B construction has CENELEC EEx d IIC T5/T6

approval.

NP700/B1 construction has CSA Class I, Div. 1, Gr. B, C and

D approval and

FM Class I, Div. 1, Gr. B, C and D approval.

CENELEC = European Committee for Electrotehnical Stand-

ardization

CSA = Canadian Standards Association

FM = Factory Mutual

1.6 Recycling and disposal

Most positioner parts can be recycled if sorted according to

material. Most parts have material marking. A material list is

supplied with the positioner. In addition, separate recycling

and disposal instructions are available from the manufac-

turer. A positioner can also be returned to the manufacturer

for recycling and disposal against a fee.

1.7 Safety precautions

2 MOUNTING ON THE METSO ACTUATOR

2.1 General

When the positioner is supplied together with the valve and

actuator, the tubes are mounted and the positioner adjusted in

accordance with the customer's specifications.

When the positioner is ordered separately, the mounting parts

for the assembly must be ordered at the same time.

Example order: Positioner alone (BC12)-Z-NP724.

The positioner is equipped with VDI/VDE 3845 (S1) mount-

ing face.

This mounting face requires a shaft with the H coupling.

Old Metso Automation mounting face (S2) is no more avail-

able.

For mounting parts for Metso actuators, see Sections

13.2–13.3.

Table 1 Pilot valve alternatives

Positioner

type

Actuator

stroke volume

dm3(litres)

Air

consumption

nm3/h / scfm *)

Max. delivery

nm3/h / scfm *)

NP723 0.3–10 0.6 / 0.3 12 / 7

NP724 1.0–8.0 0.6 / 0.3 12 / 7

NP726 8.0–30.0 0.9 / 0.5 18 / 10.4

NP727 > 30 1.8 / 1.0 32 / 18.6

*) supply pressure 4 bar / 60 psi

CAUTION:

Do not exceed the positioner performance limitations!

Exceeding the limitations marked on the positioner may

cause damage to the posioner, actuator and valve.

Damage or personal injury may result.

CAUTION:

Do not dismantle a pressurized positioner!

Dismantling a pressurized positioner will result in uncon-

trolled pressure release. Always isolate the relevant part of

the pipeline, release the pressure from the positioner and

the piping.

Failure to do this may result in damage or personal injury.

CAUTION:

Beware of the moving parts when positioner is oper-

ated!

7 NP 72 en 5

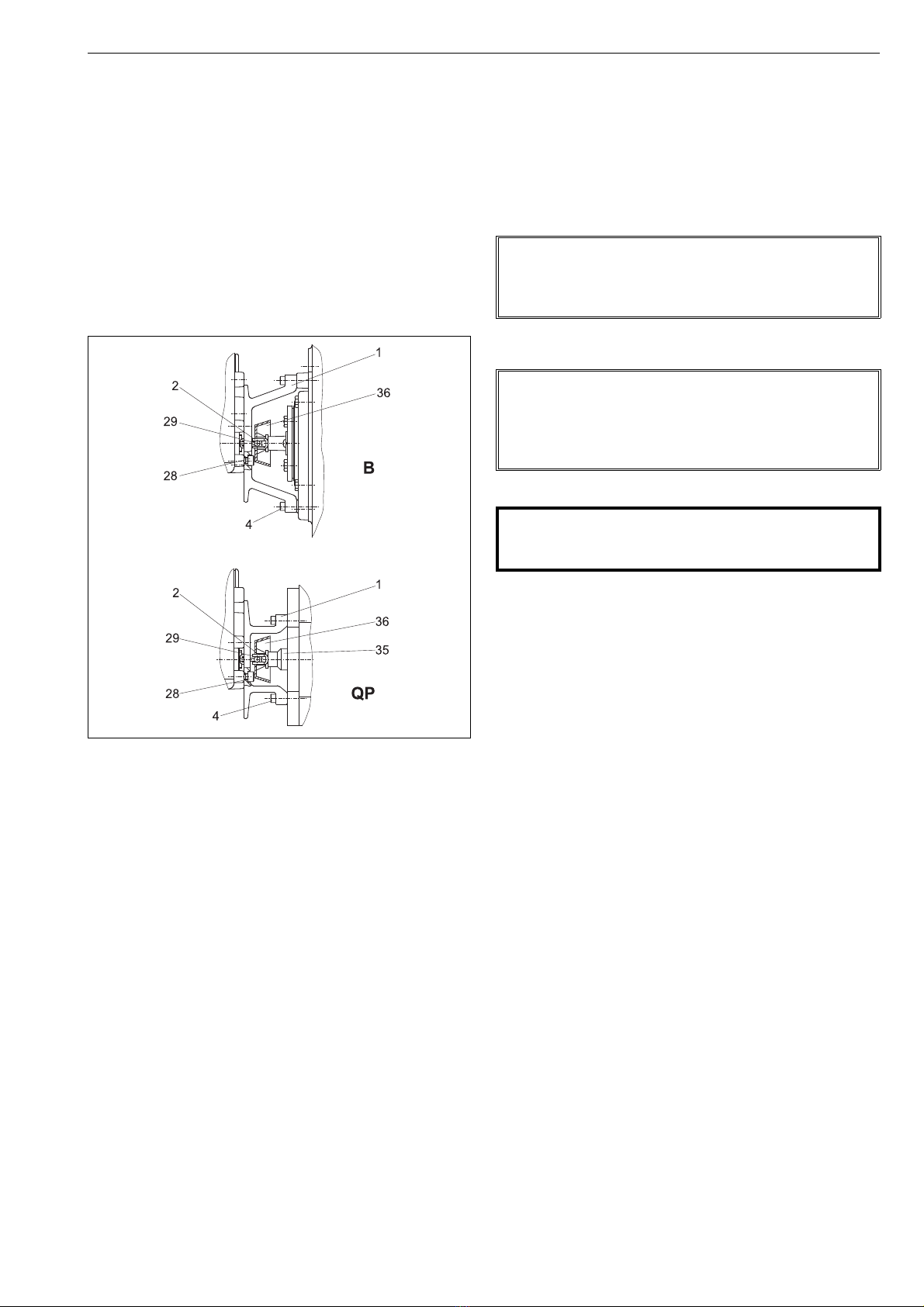

2.2 Installing positioner NP700/S1 on

Metso actuators with VDI/VDE 3845

mounting face

1. The actuator piston must be in the up position (in spring-

return actuators as determined by the spring).

2. Install the pointer (only B_U) parallel with the valve clo-

sure member and fasten the draught piece (2) with a

screw (29) to the pointer cover (B_U) or to the coupling

(QP), as shown in Fig. 4. Secure the draught piece fasten-

ing screw with a sealant (e.g. Loctite) and tighten it

properly.

3. Fasten the mounting bracket (1) to the positioner.

4. Fasten the mounting bracket (1) to the actuator.

2.3 NP_700/700 positioner/limit switch

combination (Obsolete since 2013)

The bottom of the limit switch acts also as the cover for the

positioner. Remove the limit switch before the adjustment

of the positioner.

1. Loosen the cover screws. Note the position of the shaft

relative to the positioner when removing the limit switch.

2. When the adjustment of the positioner is done, operate

the actuator until the valve is in the closed or open posi-

tion.

3. Note the position of the actuator and valve when

mounting the limit switch on the actuator. Make sure

that the position of the shaft is unchanged relative to

the positioner.

4. Place the limit switch on the positioner so that the

shafts are correctly engaged.

5. Fasten the cover screws.

6. Check the adjustment of the limit switch. See the

instruction manual of the limit switch for details.

2.4 Piping of supply air

Table 2 provides the recommended pilot valve and tube

sizes in accordance with the actuator sizes. Tube sizes are

minimum values allowed.

Connect air supply to S (1/4 NPT).

Connect C1 and C2 (1/4 NPT) to the actuator according to

Fig. 5. See also Chapter 3.

Connect signal air to IN (1/4 NPT).

For pipe threads are liquid sealants, e.g. Loctite, recom-

mended.

2.5 Instrument air supply

The supply air must be clean, dry and oil-free instrument air,

e.g. according to standard ISA S7.3-81. Supply pressure is

1.4–10 bar (20–140 psi).

Fig. 4 Installing on a Metso actuator (S1)

NOTE:

A single action connection alone is permitted for position-

ers mounted on the spring actuator!

Place a plug in connection C1 or C2. See Figure 5.

NOTE:

Exessive sealant may cause faulty operation of the posi-

tioner.

Sealing tape is not recommended.

Ensure the cleaness of the air piping.

CAUTION:

Do not exceed the permitted actuator supply air pres-

sure!

67 NP 72 en

Table 2 Piping and operating times

Actuator

NPT

Piping Operating time / stroke (s)

pilot valve

Plastic/Cu/SS (mm) Plastic/Cu/SS (")

B1C Stroke vol.

dm3/in36/4 10/8 12/10 1/4 3/8 1/2 ø4LC ø4 ø6 ø6 HC

6 0.3/20 1/4 x x 1 1

9 0.6/37 1/4 x x 1.5 1.5

11 1.1/67 3/8 x x 2 2

13 2.3/140 3/8 x x 4

17

20

4.3/262

5.4/330

1/2 x

x

x

x

7

8.5

(6)

(5.5)

25

32

10.5/640

21/1282

1/2

3/4

x

x

(x)

(x)

x

x

(x)

(x)

10

17

(8.5)

(16)

40

50

43/2624

84/5130

3/4

1

x

x

(x)

(x)

x

x

(33)

(60)

31

57

502 195/11900 1 x x

B1J

B1JA

Stroke vol.

dm3/in3NPT 6/4 10/8 12/10 1/4 3/8 1/2 ø4LC ø4 ø6 ø6 HC

6 0.47 / 28.7 1/4 x x 1 1

8

10

0.9/55

1.8/111

3/8 x

x

x

x

1.5/3 1.5/3

2.5/5.5

12

16

3.6/225

6.7 / 415

1/2 x

x

x

x

4.5/11

8/18

(3.5/6)

(4.5/11)

20

25

13/795

27 / 1642

3/4 x

x

(x)

(x)

x

x

(x)

(x)

8.5/21

17/38

(7.5/19)

(15/33)

32

322

53 / 3231

106 / 6480

1x

x

(x) x

x

(33/74) 30/64

60/130

QP Stroke vol.

dm3/in3NPT 6/4 10/8 12/10 1/4 3/8 1/2 ø4LC ø4 ø6 ø6 HC

1C 0.62/38 3/8 x x 1.5/2 1.5/2 - -

2C 1.08/66 3/8 x x 2/3.5 2/3.5 - -

3C 2.18/133 3/8 x x - 3/5 2/3 -

4C 4.34/265 3/8 x x - 6/10 4/6 -

5C 8.7/531 3/8 x x - - 7/10

6C 17.5/1068 3/4 x x - 12/18 10/15

Times in parenthesis are achieved by changing pilot valve alone or pilot valve and tube size.

Operating times for spring return actuators B1J/B1JA and QP:

against the spring / direction of the spring

Actuator without valve:

ps= 0.4–0.5 bar / 58 - 72 psi

Step of input signal:

pi= 0-100 % and 100-0 %

7 NP 72 en 7

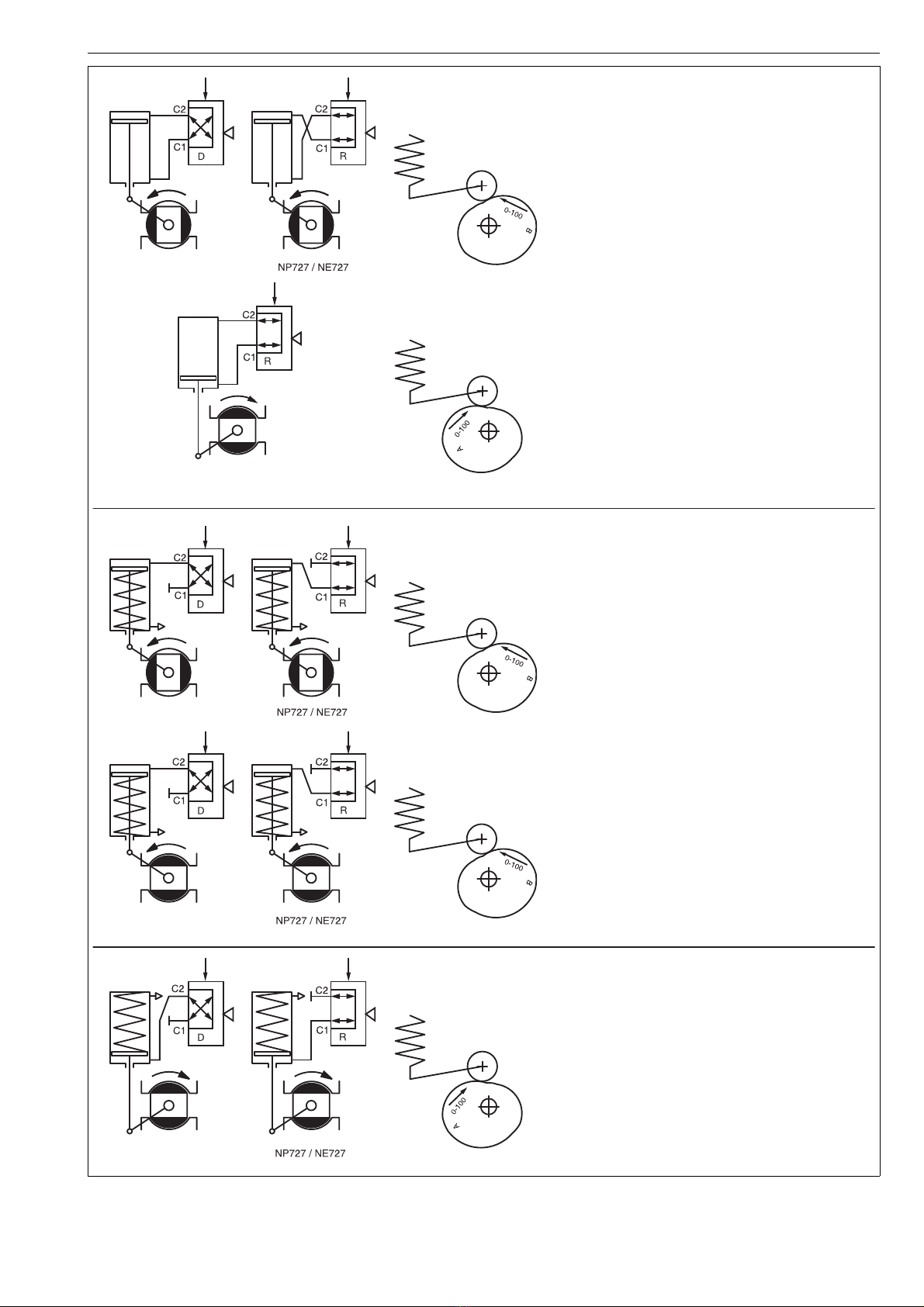

Fig. 5 Positioner actions

NOTE: In positioner NP727 the changeover piece can be used in position R only.

DOUBLE-ACTING

1. Increasing input signal to open valve.

Cam segments:

B/0-100, A/0-50, A/50-100

2. Increasing input signal to close valve.

Cam segments:

A/0-100, B/0-50, B/50-100

NOTE:

Reverse piping for ST actuators.

SINGLE-ACTING

(SPRING TO CLOSE)

3. Increasing input signal to open valve.

Spring to close valve.

Cam segments:

B/0-100, A/0-50, A/50-100

4. Increasing input signal to close valve.

Spring to open valve.

Cam segments:

B/0-100, A/0-50, A/50-100

WARNING:

Valve closes exceptionally counterclockwise.

Unsuitable for Q, R, T5, F and L series valve

NOTE:

Reverse piping for ST actuators. Spring and

piston in the opposite position from shown.

SINGLE-ACTING

(SPRING TO OPEN)

5. Increasing input signal to close valve.

Spring to open valve.

Cam segments:

A/0-100, B/0-50, B/50-100

NOTE:

Reverse piping for ST actuators. Spring and piston in

the opposite position from shown.

87 NP 72 en

3 INPUT SIGNAL AND DIRECTIONS OF

OPERATION

Figure 6 assists in choosing the right segment for the cam

plate (29) and position for the changeover piece (46).

3.1 Changeover piece

The function of connection C1 and C2 can be altered by

turning the changeover piece (46). The diagram D (or R)

shown on the protective plate (48) functions when the sym-

bol D (or R) is visible in the lower lefthand corner of the

changeover piece (46).

D = direct, R = reverse.

External changes in the tubes are not needed. Positioner

NP727 is an exception (DIA6HC pilot valve). Then the

changeover piece must always be in position R and the

external tubes mounted in accordance with Fig. 5.

3.2 Cam plate

The figures marked on the cam plate (29) are the signal

ranges expressed as percentages, for example 0-100 corre-

sponds to 0.2–1.0 bar (3-15 psi), or 50-100 to 0.60-1.0 bar (9-

15 psi), see Fig. 6.

The arrows on the cam show the direction it must turn

when the input signal is rising in the cam segment in ques-

tion.

The non-rising segments between the rising segments are

roughly 15-20°.

4 PRELIMINARY ACTIONS FOR THE

ADJUSTMENT

Set the valve’s open and closed limits with the actuator lim-

iter screws; see the valve instruction manual. The changeo-

ver piece (46) and the cam (29) must be in correct positions.

Check the pilot valve size from Table 2.

The adjustment must always be carried out when the sup-

ply pressure has been changed.

Please note that operating of the valve is required during

the adjustment.

4.1 Position of the changeover piece

Choose the position of the changeover piece, D or R, from

Fig. 7 in accordance with the function desired.

Turn the changeover piece (46) when necessary.

Loosen the nuts (49) and remove the protective plate (48).

Pull out the changeover piece (46). Check the O-rings (47, 2

pcs.) and apply silicone grease lightly if needed. Place the

changeover piece (46) and the protective plate (48) in the

case. Tighten the nuts (49) evenly, one after the other.

4.2 Pilot valve

Removal of the pilot valve is unnecessary when the change-

over piece is turned around. For instructions of removal, see

Section 8.2.

4.3 Position of the cam plate

Choose the side, A or B, and the rising segment of the cam

plate from Fig. 7 in accordance with the function desired.

Move the actuator piston to the end where the input signal

has its lower value. Shut off the supply pressure or move the

pilot spool by deflecting the beam (5) gently so that the pis-

ton strokes to the desired limit. The input signal should be

zero or at the lower limit.

Fig. 6 Input signal ranges, the cam plate (29).

50 - 100

0 - 100

0 - 50

B

~ 15°

~ 15°

~ 15°

~ 15°

~ 15°

~ 15°

segment C

segment E

segment D

segment C

segment E

0.2–0.6 bar (3–9 psi)

rising signal opens

0.20–1.0 bar (3–15 psi)

rising signal opens

0.2–1.0 bar (3–15 psi)

rising signal closes

0.60–1.0 bar (9–15 psi)

rising signal closes

0.6–1.0 bar (9–15 psi)

rising signal opens

0.2–0.6 bar (3–9 psi)

rising signal closes

CAUTION:

Do not dismantle a pressurized positioner!

NOTE:

Check that the changeover piece is mounted correctly:

Symbol D or R is visible in the lower left hand corner.

Fig. 7 Mounting the changeover piece

47 49 48

46

45

44

43

7 NP 72 en 9

Loosen the screw (57), remove the indicator (32), loosen the

screw (31) and the locking wheel (30). Turn the cam plate

(46) to the desired side.

In case of α0adjustment proceed acc. to Sections 6.1 and

6.2.

Place the roller so that its contact point is 1 mm (0.04") from

the beginning of the rising segment. Then tighten the lock-

ing wheel (30) and the screw (31).

5 BASIC ADJUSTMENT

Basic adjustment is made to rotary and butterfly valves.

Please note the procedures in Chapter 4 before the adjust-

ment.

1. Switch on the supply pressure (S) and the input signal

(IN).

2. Set the input signal at the closed limit of the valve so

that it is 2 % i.e. 0.02 bar (0.2 psi) higher or lower than

the limit value, e.g. 0.2 + 0.02 = 0.22 bar (3 + 0.2 = 3.2 psi)

or 1.0 - 0.02 = 0.98 bar (15 - 0.2 = 14.8 psi). Loosen the

screw (56). Turn the zero adjustment screw (67) so that

the actuator comes slowly to the closed limit. Tighten

the screw (56) always after the zero adjustment. The

valve should open slightly with a 4 % change in signal,

that is 0.03 bar (0.5 psi), e.g. 0.2 + 0.03 = 0.23 bar (3 + 0.5

= 3.5 psi) or 1.0 - 0.03 = 0.97 bar (15 - 0.5 = 14.5 psi). See

Figures 8 and 9.

3. Set the input signal to the other limit value. The valve

should be entirely open at 100 %, i.e. 1.0 bar (15 psi) or

0.2 bar (3 psi). The valve should start to operate to

closed direction at 98 %, i.e. 0.98 bar (14.0 psi) or 0.22

bar (3.2 psi). The range, i.e. turning angle, changes when

the effective lenght of the spring (60) is increased or

decreased by turning the range adjustment nut (60.3).

See Fig. 9.

4. The zero and range adjustments affect each other, so

stages 2 and 3 must be repeated a few times.

5. Screw on the pointer (32) into place so that the yellow

line is in the direction of the valve closing member.

Tighten the screw (57).

6α0ADJUSTMENT

α0adjustment is made to segment and ball valves. This

adjustment takes into account the "dead angle" α0of the

ball valve. The entire signal range is then used for effective

The same adjustment method can be applied to butterfly

valves in papermills for pulp flow control to avoid the dewa-

tering of the pulp near the closed position of the disc.

Table 3 shows the shift on the circumference of the cam

equal to the "dead angle" of the valve, Figure 11, in various

cam segments (C, E, D).

Please note the procedures in Chapter 4 before the adjust-

ment.

1. Mark the shift in question on the edge of the cam, Fig. 11

and Table 3. Dimensions do not have to be measured if

the dead angle can be reliably noticed from position of

the closing member.

2. Lock the cam so that the roller touches the edge of the

Fig. 8 Basic and

α

0adjustments

POSITION %

Rising input signal closes valve Rising input signal opens valve

max 2 %

INPUT SIGNAL %

safety range 2 %

Basic adjustment α0adjustment

Fig. 9 Zero and range adjustments

Fig. 10 Dead angle

Fig. 11 Shift on circumference of cam equal to dead angle

range increases

range

range decreases

screw (56)

zero adjustment (67)

adjustment (60.3)

α0= dead angle

segment D

segment C

segment E

shift

Roller contact point when

the ball is completely closed

10 7 NP 72 en

cam plate at the mark. Tighten the locking wheel (30)

and the screw (31).

3. Switch on the supply pressure (S) and the input signal

(IN).

4. Set the input signal at the closed limit of the valve so

that it is 2 % i.e. 0.02 bar (0.2 psi) higher or lower than

the limit value, e.g. 0.2 + 0.02 = 0.22 bar (3 + 0.2 = 3.2 psi)

or 1.0 - 0.02 = 0.98 bar (15 - 0.2 = 14.8 psi). Loosen the

screw (56). Turn the zero adjustment screw (67) so that

the actuator comes slowly to the closed limit. Tighten

the screw (56) always after the zero adjustment. The

valve should open slightly with a 4 % change in signal,

that is 0.03 bar (0.5 psi), e.g. 0.2 + 0.03 = 0.23 bar (3 + 0.5

= 3.5 psi) or 1.0 - 0.03 = 0.97 bar (15 - 0.5 = 14.5 psi). See

Figure 9.

5. Set the input signal to the other limit value. The valve

should be entirely open at 100 %, i.e. 1.0 bar (15 psi) or

0.2 bar (3 psi). The valve should start to operate to

closed direction at 98 %, i.e. 0.98 bar (14.0 psi) or 0.22

bar (3.2 psi).

The range, i.e. turning angle, changes when the effective

lenght of the spring (60) is increased or decreased by turn-

ing the range adjustment nut (60.3). See Fig. 9.

6. The zero and range adjustments affect each other, so

stages 4 and 5 must be repeated a few times.

7. Screw on the pointer (32) into place so that the yellow

line is in the direction of the valve closing member.

Tighten the screw (57).

7 SPLIT-RANGE ADJUSTMENT

In principle, split range adjustments are made in the same

manner as for a normal signal range. Select a split range,

20-60 kPag / 0.2–0.6 barg / 3–9 psig or 60-100 kPag /

0.6–1.0 barn / 9–15 psig, from the cam plate. See Figure 6.

8 MAINTENANCE

Regular maintenance is not necessary.

The need for maintenance depends on the quality of the

instrument air. See also Section 2.5.

If there is need for servicing proceed according to the fol-

lowing sections.

8.1 Supply air filter

The supply air filter (50) is located in the supply air connec-

tion (S); the filter can be removed for cleaning.

8.2 Pilot valve

Remove the pilot valve (44) by first loosening the nuts (49),

and then by lifting off the protective plate (48), the change-

over piece (46) and the gasket (45).

Table 3 Dead angle in degrees

Valve

size

Valve series

MBV

QMBV

1)

MBV

QMBV

2)

D

3)

T5,

QT5 QXT5 T25,

QT25 QXT25 R,

QR

mm mm Dead angle in degrees

25 1 12.5 - - 23.0 17.5 - - 14

40 1 1/2 11.0 - - 22.0 11.0 - - 11

50 2 9.0 8.0 12.0 22.0 11.0 16.0 7.0 15

6521/28.0------11

80 3 9.0 7.0 11.0 16.0 7.0 15.0 8.0 8

100 4 9.0 7.0 11.0 15.0 7.5 14.5 8.0 7

125511.0----11.06.07

150 6 9.0 7.0 10.5 14.5 8.0 12.0 7

200 8 8.0 6.5 7.5 11.0 6.0 8.5 6

250 10 8.0 6.5 7.0 12.0 8.5 6

300 12 7.0 5.5 5.5 8.5 7.0 5

350 14 5.4 5.5 - 4

400 16 4.5 5.0 8.5(14") 4

450 18 5.0 7.0 (16")

500 20 5.5

600 24 5.0

650 26 6.0

700 28 6.0

750 30 5.5

800 32 -

900 36 4.5

1) Seat supported 2) Trunnion 3) S/G seat

Table 4 Shift caused by dead angle, mm/inch

α0Segment C Segment E Segment D

20° *) 6.1/0.24 8.1/0.31

19° *) 5.8/0.22 7.7/0.30

18° *) 5.5/0.21 7.3/0.28

17° *) 5.2/0.20 6.9/0.27

16° *) 4.9/0.19 6.5/0.25

15° 3.1/0.12 4.6/0.18 6.1/0.24

14° 2.9/0.11 4.3/0.16 5.7/0.22

13° 2.7/0.10 4.0/0.15 5.3/0.20

12° 2.5/0.09 3.7/0.14 4.9/0.19

11° 2.3/0.09 3.4/0.13 4.5/0.17

10° 2.1/0.08 3.1/0.12 4.1/0.16

9° 1.9/0.07 2.8/0.11 3.7/0.14

8° 1.7/0.06 2.5/0.09 3.3/0.12

7° 1.5/0.05 2.2/0.08 2.9/0.11

6° 1.3/0.05 1.9/0.07 2.5/0.09

5° 1.1/0.04 1.6/0.06 2.1/0.08

4° 0.9/0.03 1.3/0.05 1.7/0.06

*) Segment C: α0max. 15°

CAUTION:

Do not dismantle a pressurized positioner!

NOTE:

Ensure the cleanness of the air piping.

7 NP 72 en 11

The pilot valve spool (44.2) should slip easily in the pilot

valve body (44.1).

If the pilot valve sticks, wash the body and spool with sol-

vent.

See the exploded view for the correct installation position

of the pilot valve. The size code for the pilot valve on the

body, for example DIA 4.0, must be visible on the right side.

Check the condition of the O-rings (43, 47) and of the gas-

ket (45). The end of the leaf spring on the beam must be on

top of the pilot valve spool, Figure 7. Make sure that the end

of the beam (5) goes into the spool groove without side-

ways deflections. After tightening the nuts (49), check the

beam once again by hand to see that the pilot valve moves

readily.

8.3 Replacement of the diaphragms

Remove the feedback spring (60), loosen the screws (23)

and remove the screw (15). Replace the diaphragm (14).

Note the correct installation position for the diaphragm,

with the convolution downward. See Figure 12.

Check the condition of the washer (55) when assembling

and secure the upper spring plate (16) with e.g. Loctite.

Check that the O-ring (11) is in place. Tighten the cover

screws (23) evenly. The positioner adjustment should be

checked after replacement of diaphragm.

Note. O-ring (11) in the old construction only (manufac-

tured before 12/94)

9 TROUBLESHOOTING

1. Signal pressure change does not affect actuator position

supply pressure too low

signal pressure tubes leak

diaphragm damaged

pilot valve sticks

changeover piece seals leak

tube installations between positioner and actuator

changeover piece or cam position wrong, see Fig. 6.

actuator or valve jammed

2. The actuator reaches final position with a small signal

pressure change

the tube installation between positioner and actua-

tor, the changeover piece or the cam position wrong.

3. Inaccurate positioning

pilot valve dirty

beam (5) pushes pilot valve spool sideways

diaphragm damaged

actuator torque too low

supply pressure too low

valve torque requirement increased

4. Overshooting or too slow positioning

pilot valve dirty or wrong size, see Table 2

supply air tube too small or supply air filter dirty

valve sticks

10 OPTIONS

10.1 NP700/B and NP700/B1

Equipped with a flameproof enclosure I/P converter.

To be adjusted like for standard posioners. Do not make any

adjustments for the I/P converter!

10.2 NP700/GN natural gas construction

For clean "sweet" natural gas instead of compressed air. Like

standard construction but with 3/4 NPT exhaust port.

Please note: do not remove the exhaust port (4).

10.3 NP700/R dust-proof construction (IP65)

For extremely dusty environments. The protective cover (3)

behind the standard posioner is replaced with an exhaust

port. The port has a 3/4 NPT filter.

Please note: do not remove the exhaust port (3).

10.4 NP700/A with pressure gauges

A standard positioner can be equipped with a pressure

gauge block.

The block (70) is attached with tree sef-tapping screws (72).

The O-rings (71, 3 pcs.) must be in position before mount-

ing. Check tightness after mounting.

For all other constructions see Type Code, Chapter 14.

11 TOOLS

In addition to standard general tools, you need the follow-

ing equipment:

calibration device for adjustments

12 ORDERING SPARE PARTS

When ordering spare parts, always include the following

information:

type code, sales order number, serial number

number of the parts list, part number, name of the

part and quantity required

This information can be found from the identification plate

or documents.

NOTE:

The pilot valve body and spool constitute a pair, and must

not be replaced separately.

Fig. 12 Replacement of diaphragms

NOTE:

gap required

11 14 55 15 22 23

5

16

60

12 7 NP 72 en

13 DRAWINGS AND PARTS LISTS

13.1 Exploded view and parts list

65

26

26

88 87 86

NP700/J

4

68, 99

64, 101

3, 69,98

NP700/S1

NP700/R

NP700/GN

43

4

3

27 28

50

62

77 78 79

72

70

71

73

74

76

NP700-K

NP700/A

100

43

44

45

47

46

48

49

109

110

2

29

30

31

32

57

105

58

5

6

59

16

60

51

34

33

56

67

14

15

55

10

8

7

22 23

22 75

54

18

22

23

37

115

116

NP700/B, -/B1

NP700/B-L

NP700/A

1

7 NP 72 en 13

Spare part category 1: Parts for basic maintenance. Delivered as a set.

Spare part category 2: Parts for spool valve and cover replacement.

Spare part category 3: Parts for shaft replacement.

Item Qty Description Spare part

category

1 1 Housing assembly

21Cover 2

31Protectivecover

1Exhaustport

41Screw

5 1 Beam assembly

61Plate

72Screw

81Lowerdiaphragmplate 1

10 1 Upper diaphragm plate

13 *) 1 O-ring

14 1 Diaphragm 1

15 1 Screw

16 1 Upper spring plate

18 3 O-ring

22 1 Diaphragm cover

23 3 Screw

26 1 Shaft assembly 3

27 1 Washer

28 1 O-ring 1

29 1 Camplate

30 1 Locking wheel 1

31 1 Screw

32 1 Pointer

33 1 Lever assembly

34 1 Retaining ring 1

37 1 I/P converter

43 1 O-ring 1

44 1 Pilot valve assembly 2

45 1 Gasket 1

46 1 Changeover piece

47 2 O-ring 1

48 1 Protective plate

49 2 Hexagon nut

50 1 Filter

51 2 Bearing

Item Qty Description Spare part

category

55 1 Gasket 1

56 1 Screw

57 1 Grub screw

58 1 Support plate

59 2 Barrel nut

60 1 Spring

62 1 Hexagon plug

64 1 Body

65 1 Lock ring

67 1 Zero screw

68 2 Spring

69 2 Guide

70 1 Pressure gauge block

71 3 O-ring

72 3 Screw

73 1 Pressure gauge

74 2 (1) Pressure gauge

75 1 Pressure gauge

76 1 Double fitting

77 1 Filter regulator

78 1 Reduction fitting

79 1 Pressure gauge

86 1 Adapter plate

87 2 Washer

88 2 Screw

98 2 Screw

99 2 Spring plate

100 1 Additional plate

101 2 O-ring

105 1 ID plate

109 1 Seal

110 4 Screw

115 2 Washer

116 2 Screw

*) Only in positioners manufactured before 12/94

14 7 NP 72 en

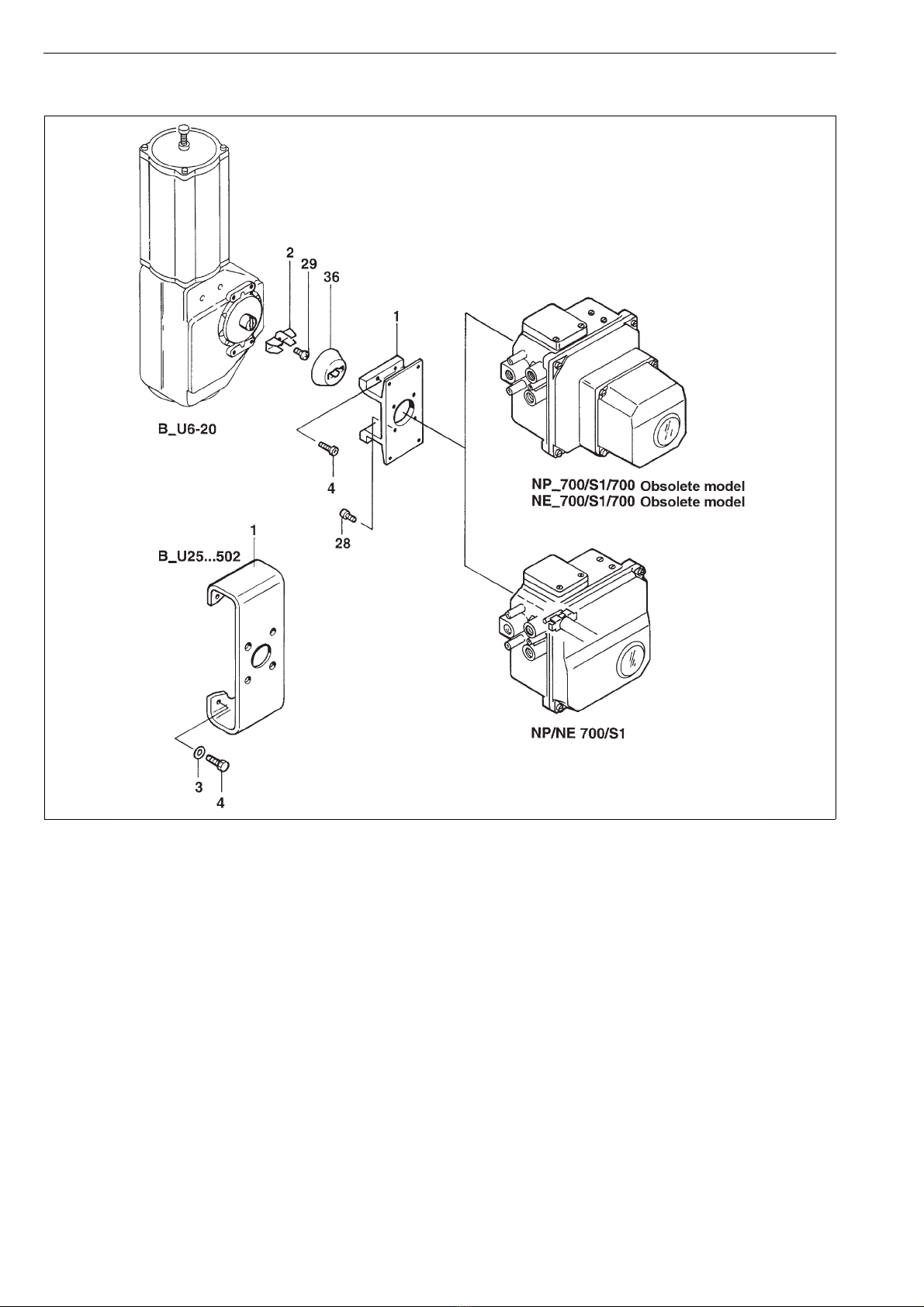

13.2 Mounting parts for B1C6-502 and

B1J8-322 actuators (S1)

Item Qty Description

1 1 Mounting bracket

21Draughtpiece

34Washer

44Screw

28 4 Screw

29 2 Screw

36 1 Coupling jacket

7 NP 72 en 15

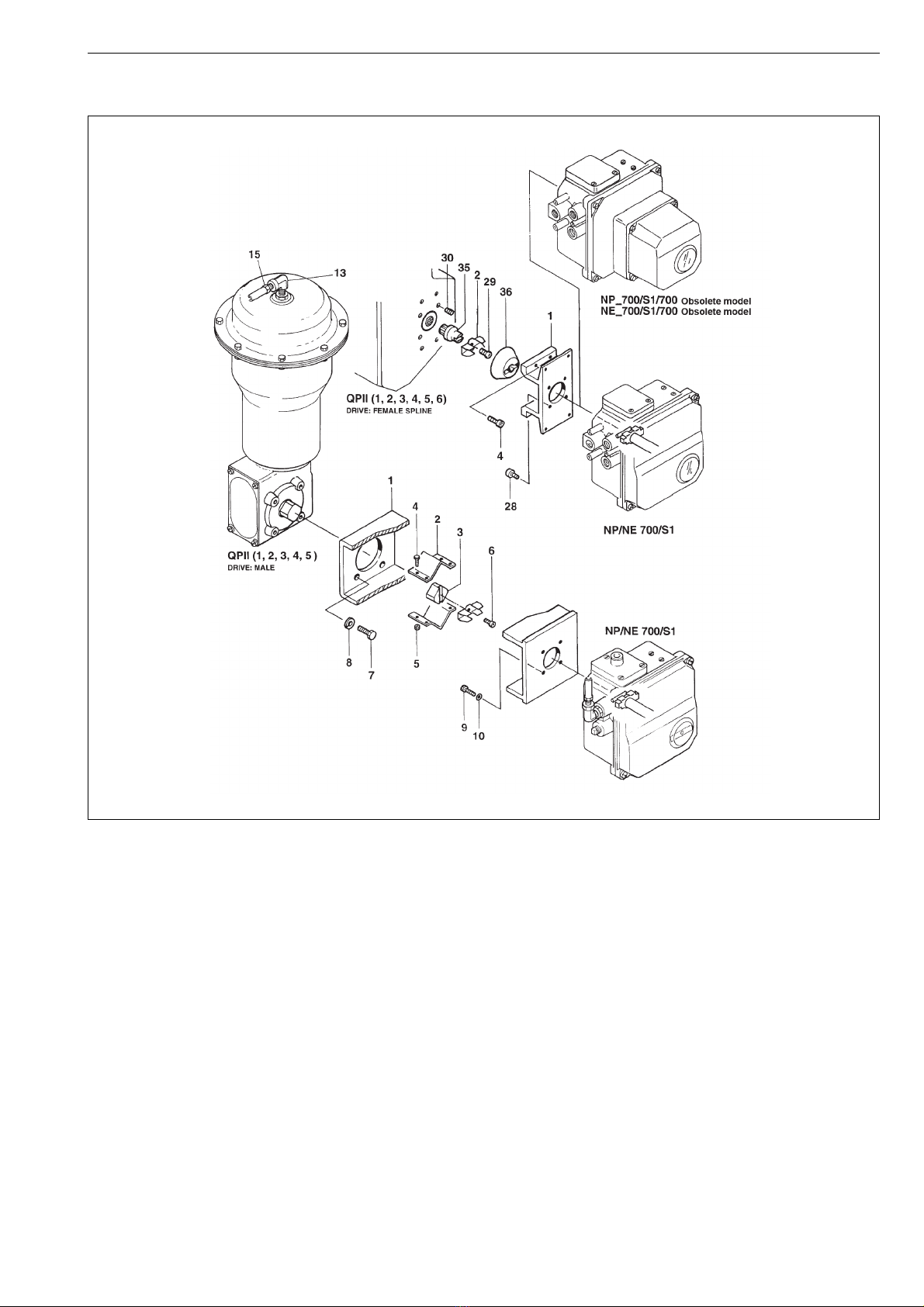

13.3 Mounting parts for Quadra-Powr®

actuators (S1)

Drive: male

Item Qty Description

1 1 Mounting bracket

2 2 Coupling half

31Adapter

44Screw

54Hexnut

61Screw

74Screw

84Washer

94Screw

10 4 Washer

Drive: female spline

Item Qty Description

1 1 Mounting bracket

21Ear

44Screw

28 4 Screw

29 1 Screw

30 (4) Screw

35 1 Coupling

36 1 Coupling jacket

16 7 NP 72 en

13.4 Mounting parts for B1C6-20 and

B1J8-20 actuators (S2)

Item Qty Description

1 1 Mounting bracket

21Draughtpiece

32Washer

42Screw

51Bracket

61Washer

71Screw

82Washer

10 1 Rod

11 2 Bushing

12 2 Screw

13 2 Stud (B1C6 only)

14 2 Hexagon nut (B1C6 only)

26 2 Locking nut

27 2 Washer

28 2 Screw

7 NP 72 en 17

13.5 Mounting parts for B1C25-502 and

B1J25-322 actuators (S2)

Item Qty Description

1 1 Mounting bracket

21Draughtpiece

32(4)Washer

42(4)Screw

82Washer

92Screw

10 1 Rod

11 2 Bushing

12 2 Screw

26 2 Locking nut

27 2 Washer

28 2 Screw

18 7 NP 72 en

14 TYPE CODE

PNEUMATIC POSITIONER NP 700

1. 2. 3. 4. 5. 6.

NP724 /S1–K

1. PRODUCT GROUP

NP Pneumatic positioner

2. SERIES CODE

3. INPUT SIGNAL RANGE

04-20 mA, only with options B and B1 (6th sign).

220-100 kPag /0.2-1.0 barg / 3-15 psig.

4. PILOT VALVE SIZE CONNECTIONS

S, C1, C2

3Ø4 mm LC 1/4 NPT

4Ø4 mm 1/4 NPT

6Ø6 mm 1/4 NPT

7Ø6 mm HC 3/8 NPT

5. ACTION

Suitable for Double and Single action, without sign.

A

Single action, linear motion. Applicable ONLY to D/R series

spring diaphragm linear actuators, max. stroke size 57 mm

(2-¼ in).

6. OPTIONS

If several options below are needed to the same positioner,

the codes shall be marked in presented order from top.

Temperature range for various options shall be considered

carefully.

-Standard, (IP 54 enclosure). 6. sign S1 always to be defined

Temperature range -40 °C... +90 °C/ -40 °F...+194 °F.

B

Flameproof enclosure I/P-converter (IP65), ATEX EEx d IIC T6.

Input signal range 4-20 mA. M20x1,5 conduit entry.

3. sign always 0.

Temperature range -40 °C... +55 °C / -40 °F...+131 °F.

B1

Explosion proof enclosure I/P-converter (IP65), FM/CSA-

approval. Class 1, Div. 1, Groups B, C, D. Input signal range

4-20 mA. 1/2 NPT conduit entry. 3. sign always 0.

Temperature range -40 °C... +55 °C/ -40 °F...+131 °F.

GN For natural gas. Exhaust adapter, 3/4 NPT thread.

Not usable inside with options B and B1.

RWater and dustproof enclosure IP65/NEMA 4 and 4X.

Not available with option GN.

H

High temperature construction. Viton diaphragm and seals.

Not available with options B, B1, A, A1 and K.

Temperature range -10° to +120 °C/ +14° to +248 °F.

S1

Positioner with attachment face acc. to standard

VDI/VDE 3845, equipped with H-clip. When positioners are

separate deliveries, VDI/VDE ear is supplied.

Not applicable to globe valve actuators (5th sign A).

A

Pressure gauges, scale bar/psi/kPa, basic material brass, nickel

plated, housing stainless steel, glycerine filled. 5. sign always

to be defined.

Temperature range -40 °C... +70 °C / -40 °F... +158 °F.

Y2 Brass bearing of small lever arm.

J30 Square shaft and special mounting kit.

YSpecial construction.

-□ACCESSORIES

K

Filter regulator for supply air. Pressure gauge, scale bar/psi/

kPa, basic material brass, nickel plated, housing stainless steel,

glycerine filled.

Temperature range -40 °C... +82 °C / -40 °F... +180 °F.

Filter size 5 μm. Not available with HC-pilot (4. sign 7). Will be

specified in the option sticker.

In connection with the Ø6 HC-pilot valve (4. sign 7) must be

used large capacity filter regulator (not K) for actuator bigger

than BC 40 and BJ 32. Installation with mounting bracket.

CE01 PG11 / 1/2 NPT conduit entry nipple. Will be specified in the

option sticker.

CE02 PG11 / M20x1.5 conduit entry nipple. Will be specified in the

option sticker.

CE03 PG11 / R1/2 (PF1/2) conduit entry nipple. Will be specified in

the option sticker.

7 NP 72 en 19

Metso Flow Control Inc.

Europe, Vanha Porvoontie 229, P.O. Box 304, FI-01301 Vantaa, Finland. Tel. +358 20 483 150. Fax +358 20 483 151

North America, 44 Bowditch Drive, P.O. Box 8044, Shrewsbury, M A 01545, USA. Tel. +1 508 852 0200. Fax +1 508 852 8172

South America, Av. Independéncia, 2500-Iporanga, 18087-101, Sorocaba-São Paulo, Brazil. Tel. +55 15 2102 9700. Fax +55 15 2102 9748

Asia Pacic, Haw Par Centre #06-01, 180 Clemenceau Avenue, Singapore 239922. Tel. +65 6511 1011. Fax +65 6250 0830

China, 11/F, China Youth Plaza, No.19 North Rd of East 3rd Ring Rd, Chaoyang District, Beijing 100020, China. Tel. +86 10 6566 6600. Fax +86 10 6566 2583.

Middle East, Roundabout 8, Unit AB-07, P.O. Box 17175, Jebel Ali Freezone, Dubai, United Arab Emirates. Tel. +971 4 883 6974. Fax +971 4 883 6836

www.metso.com/valves

20 7 NP 72 en

This manual suits for next models

12

Table of contents

Other Metso Valve Positioner manuals

Popular Valve Positioner manuals by other brands

KMC Controls

KMC Controls CMC-1001 installation guide

Westlock

Westlock 793 Installation, setting, operation

Samson

Samson 3780 series Mounting and operating instructions

Samson

Samson 3730-2 Mounting and operating instructions

Parker

Parker 401XE Series product manual

Pepperl+Fuchs

Pepperl+Fuchs PGV -F200 -B6-V15B Series manual

cam

cam PL Series operating manual

VAC

VAC V200 Series Installation,operation and maintenance instruction

Balluff

Balluff BIP ED2-B 03-S75 Series user manual

Rotex

Rotex Posidapt Series Installation, operation and maintenance

Nanosonics

Nanosonics trophon CPP user manual

Flowserve

Flowserve ARGUS MW 8 Installation and operating instructions