Inova Automation NICE1000+ User manual

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

1

Sr No

Subject

Page

1

Safety Information and Precautions

2

2

Product Information

3

1

Connection of peripheral electrical Devices

3

2

System configuration of NICE1000+

4

3

Designation Rules and Nameplate

5

4

Models, Power, Current Rating and DBR requirements

7

5

Physical Appearance and Mounting Dimensions

8

6

Mechanical Installation

9

7

NICE Power terminal & MCTC-MCB-G Main Control Board Details

10

8

Description of the MCTC-KZ-D Extension Card

12

9

Selection and Use of the MCTC-PG Card

14

3

Elevator Hoistway Switches and Sensor Installation

17

1

Terminal floor switches mounting position

17

2

Installation of levelling Plate/Flag and Switches

18

4

Complete Electrical configuration of NICE1000+ all Field Interface

20

5

Initial Start-up Commissioning

21

1

Identify the NICE 1000 control Panel components

21

2

Verification of Controller and Field wiring

21

3

Check list for NICE1000+ Initial Power Up

22

4

Remote MDKE LED Keypad function

23

5

Input and Output functional sequence of Main Control Board (MCTC-MCB-H) of NICE 1000+

24

6

Input terminal LED Sequence for Main Control Board (MCB) while Initial start-Up

25

7

NICE1000+ Start-up Parameterisation

26

8

Commissioning at Inspection Speed

27

9

Inspection Running

30

6

Normal/High Speed Operation

31

1

Elevator Shaft Learning Process

31

2

Door operator commissioning

32

3

Normal Operation & Its Signal Verification

34

4

Floor Level Adjustment

35

5

Car & Landing Calls configuration

35

6

Floor display Setting

36

7

Rescue function using UPS ready on power failure

37

8

Load Weigh Function

38

9

Ride Comfort Fine Tuning

39

7

Function Code Table

40

1

Meaning of each column in Function Code Table

40

2

Function Code Group

40

3

Function Code in details

40

8

Fault Information and Troubleshooting

72

1

Description of Fault Information

72

2

Fault Levels

72

3

Fault Information and Troubleshooting

73

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

2

1. Safety Information and Precautions

DANGER WARNING CAUTION

NICE1000+ Integrated Elevator controller should only be installed, commissioned and maintained by qualified

and competent personnel

Before power is applied to the controller, ensure all covers are fitted to the controller and is fitted in a suitable

enclosure

Dangerous high voltages are present when the input power supply is connected to the controller

Before attempting any work on the controller or motor or power connected other elevator equipment, isolate and

lock off the input power supply

After disconnecting the supply, wait at least 10 minutes to let the controller’s internal capacitors discharge

completely before removing the cover. Prove dead using a voltage tester

Wiring must be performed only by qualified personnel under instructions described in suitable electrical wiring

diagram and user manual

Ensure that the cabling satisfies the EMC requirements and local codes. Use wire sizes recommended in the

manual

Use the shielded cable for the encoder, and ensure that the shield is reliably grounded at one end

Do not touch the rotating part of the motor during the motor auto-tuning or running

Do not start/stop the controller by turning on or off the contactor

When mounting the controller, ensure sufficient cooling is provided in and around

Do not attempt to carry out any repair of the drive. In the case of suspected fault or malfunction, contact your local

supplier

Never connect the mains power supply to the Output terminals U, V, W

The drive must be installed within the limits specified in the technical data section

The motor must be used within the manufacturer’s guidelines

Failure to comply above Safety information and Precautions will result in potential risk of severe or minor personal

injury or even death and/or equipment damage

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

3

2. Product Information

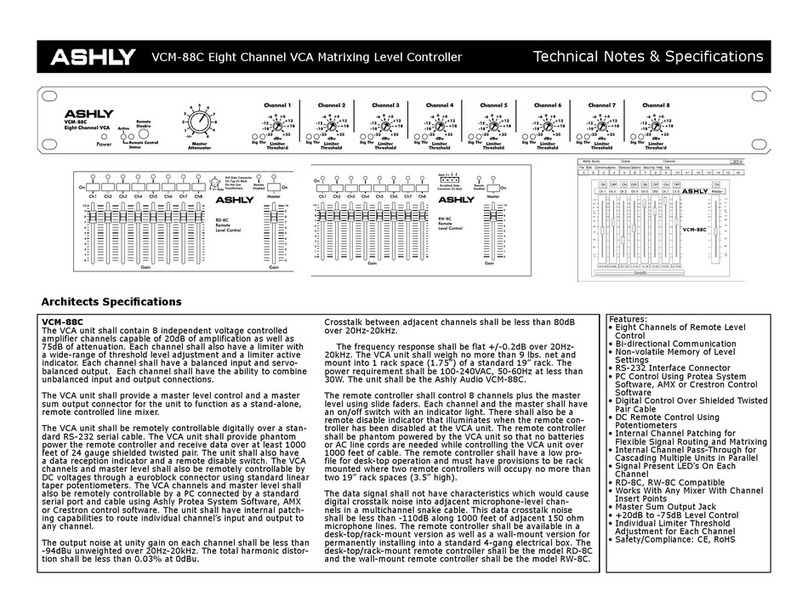

2.1. Connection of peripheral electrical Devices

Ground

AC input reactor

Electromagnetic

contactor

Molded case circuit

breaker (MCCB) or

earth leakage circuit

breaker (ELCB)

Three-phase AC

power supply

Braking resistor

Noise filter on

input side

To guarantee safety, use an

electromagnetic contactor. Do not

use it to start or stop the controller

because such operation reduces

the service life of the controller.

Select a proper breaker to

resist large in-rush current

that flows into the controller

at power-on.

Use within the allowable

power supply specification of

the controller.

Reliably ground the

motor and the

controller to prevent

electric shock.

Reduce the

electromagnetic

interference on

the input side.

P(+)

BR

Braking

unit

+

-Motor

MF.K

RUN STOP

RES

QUICK

PRG ENTER

RUN LOCAL/REMOT FED/REV TUNE/TC

RPM %

A VHz

External operation panel

Output

reactor

Ground

Ground

Operation box

Hall display

board

Bottom floor

Top floor

Hall display

board

2

4

5

78

6

3

1

Suppress the high order harmonic

to improve the power factor.

NICE1000new

integrated elevator

controller

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

4

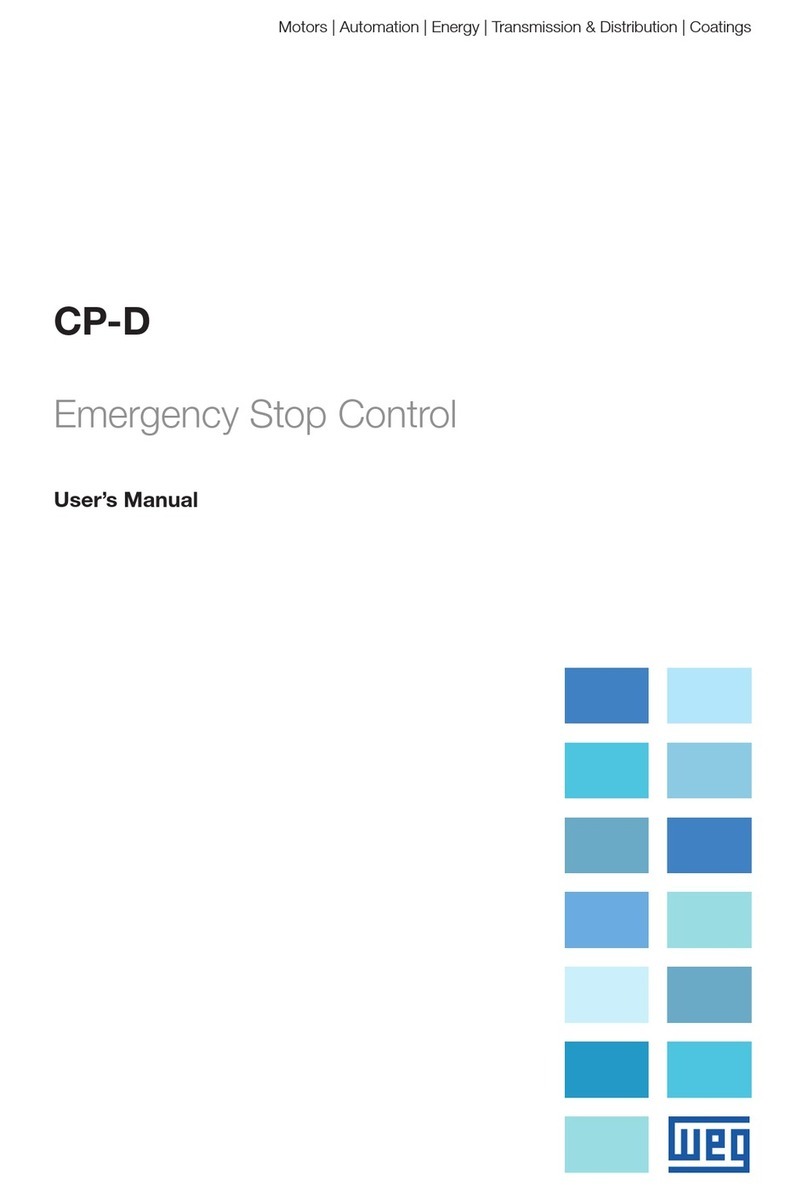

2.2. System configuration of NICE1000+

The NICE1000+ Integrated Elevator Control Solution combines the functions of both Elevator control and High

performance vector AC Drive.

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

5

2.3. Designation Rules and Nameplate

NICE

-

L

-

H

-

40

07

2.4. Technical Specifications

Basic Specifications

Maximum Frequency

99Hz

Carrier Frequency

2-16 kHz, adjusted automatically based on the load features

Motor control mode

Sensor-less vector control (SVC)

Closed-loop vector control (CLVC)

Voltage/Frequency (V/F) control

Start-up torque

0.5 Hz: 180% (SVC)

0 Hz: 200% (CLVC)

Speed adjustment range

1:100 (SVC)

1:1000 (CLVC)

1:50 (V/F)

Speed stability accuracy

±0.5% (SVC)

±0.05% (CLVC)

Torque control accuracy

±5% (CLVC)

Overload

60s for 150% of the rated current,

1s for 200% of the rated current

MODEL: NICE-L-H-4007

INPUT: 3PH AC 380~440V 36A 50/60HZ

OUTPUT: 3PH AC 0~440V 33A 0~90HZ 15KW

S/N: 010150602803825403

Suzhou MONARCH Control Technology Co. Ltd

Nice Series

Specialized For Door

Machine

H –Synchronous

H1 - Asynchronous

20 –Single Phase 220VAC

40 –Three Phase 415VAC

Motor Power

02

2.2KW

03

3.7KW

.

.

37

37KW

45

45KW

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

6

Motor auto-tuning

With-load auto-tuning; no-load auto-tuning

Distance control

Direct travel ride mode in which the levelling position can be

adjusted flexibly

Basic Specifications

Acceleration/

Deceleration curve

N curves generated automatically

Slow-down

New reliable slow-down function, automatically identifying

the position of the slow-down shelf

Shaft auto-tuning

32-bit data, recording the position in the shaft accurately

Levelling adjustment

Flexible and easy levelling adjustment function

Start-up torque compensation

Load cell start-up pre-torque compensation

No-load-cell start-up pre-torque self-adaption

Test function

Easy to implement multiple elevators commissioning functions

Fault protection

Solutions to different levels of elevator faults

Intelligent

management

Remote monitoring, user management, and group control

adjustment

Security check of

peripheral devices

after power-on

Security check of peripheral devices, such as grounding and

short circuit, after power-on

Status monitor

Monitoring the state of feedback signals to ensure that the

elevator works properly

I/O feature

Digital input (DI)

24 x DI - Input specification: 24 V, 5 mA

3 higher-voltage detection input terminals of safety circuit and

door lock circuit Input specification: 95−125 V

Floor input/output

50 floor button inputs/outputs; functions set flexibly

Analog input (AI)

AI (voltage range: –10 V to +10 V)

Communication

port

1 CANbus communication ports

1 Modbus communication port

Output terminal

block

27 relay outputs

The terminals can be allocated with different functions.

Encoder interface

Supporting different encoders by using an optional PG card

Operation and

display

Keypad

Used for shaft auto-tuning

LED operation

panel

5-digit LED display, querying/modifying most parameters and

monitoring the system state

NEMS software

Connecting the control system and the host computer,

convenient for querying/motoring the system state.

Environment

Altitude

Below 1000 m (de-rated 1% for each 100 m higher)

Ambient

temperature

–10°C to 50°C (de-rated if the ambient temperature is above

40°C)

Humidity

Maximum relative humidity 95%, non-condensing

Vibration

Maximum vibration: 5.9 m/s2 (0.6 g)

Storage

temperature

-20°C to 60°C

IP level

IP20

Pollution degree

PD2

Power distribution

system

TN, TT

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

7

2.4. Models, Power, Current Rating and DBR requirements

Model

Power

Capacity

(KVA)

Input

Current

(A)

Output

Current

(A)

Adaptable

Motor Power

(KW)

DBR

Resistance

( to )

DBR

Power

(Watts)

Braking Unit

Single phase 220VAC, Range -15% to 20%

NICE-L-H/H1-2002

2.0

9.2

5.2

1.1

145~125

≥300

Built-in

NICE-L-H/H1-2003

2.9

13.3

7.5

1.5

105~90

≥450

220-NICE-L-H/H1-4007

3.9

17.9

10.3

2.2

72~63

≥600

220-NICE-L-H/H1-4011

5.9

25.3

15.5

3.7

43~37

≥1100

220-NICE-L-H/H1-4015

7.3

31.3

19

4.0

40~35

≥1200

220-NICE-L-H/H1-4018

8.6

34.6

22.5

5.5

29~25

≥1600

220-NICE-L-H/H1-4022

10.6

42.6

27.7

11

18~16

≥3500

220-NICE-L-H/H1-4030

13.1

52.6

34.6

15

13~13

≥4500

Three phase 220VAC, Range -15% to 20%

NICE-L-H/H1-2002

4.0

11.0

9.6

2.2

72~65

≥600

Built-in

NICE-L-H/H1-2003

5.9

17.0

14.0

3.7

54~50

≥1100

220-NICE-L-H/H1-4007

7.0

20.5

18.0

4.0

40~35

≥1200

220-NICE-L-H/H1-4011

10.0

29.0

27.0

5.5

29~25

≥1600

220-NICE-L-H/H1-4015

12.6

36.0

33.0

7.5

26~22

≥2500

220-NICE-L-H/H1-4018

15.0

41.0

39.0

11.0

14.5~13

≥3500

220-NICE-L-H/H1-4022

18.3

49.0

48.0

15.0

13~12.5

≥4500

220-NICE-L-H/H1-4030

23.0

62.0

60.0

18.5

12.5~12

≥5500

Three phase 380 to 480VAC, Range -15% to 10%

NICE-L-H/H1-4002

4.0

6.5

5.1

2.2

290~230

≥600

Built-in

NICE-L-H/H1-4003

5.9

10.5

9.0

3.7

170~135

≥1100

NICE-L-H/H1-4005

8.9

14.8

13.0

5.5

115~90

≥1600

NICE-L-H/H1-4007

11.0

20.5

18.0

7.5

85~65

≥2500

NICE-L-H/H1-4011

17.0

29.0

27.0

11.0

55~43

≥3500

NICE-L-H/H1-4015

21.0

36.0

33.0

15.0

43~35

≥4500

NICE-L-H/H1-4018

24.0

41.0

39.0

18.5

34~25

≥5500

NICE-L-H/H1-4022

30.0

49.5

48.0

22.0

24~22

≥6500

NICE-L-H/H1-4030

40.0

62.0

60.0

30.0

20~16

≥9000

NICE-L-H/H1-4037

57.0

77.0

75.0

37.0

16~13

≥11000

MDBUN-60-T

NICE-L-H/H1-4045

69.0

93.0

91.0

45.0

14~11

≥13500

NICE-L-H/H1-4055

85.0

113.0

112.0

55.0

12~10

≥16500

MDBUN-90-T

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

8

2.5.Physical Appearance and Mounting Dimensions

L structure between 2.2 –15 KW L structure between 18 –37 KW

L structure between 45 –55 KW

Controller Model

A

(mm)

B

(mm)

H

(mm)

W (mm)

D

(mm)

Hole

Diameter

(mm)

Gross

Weight

(kg)

Single-phase/Three-phase 220 VAC, range: -15% to 20%

NICE-L-H-2002

150

334.5

347

223

143

6.5

5.5

NICE-L-H-2003

220-NICE-L-H-4007

150

334.5

347

223

173.5

6.5

7

220-NICE-L-H-4011

220-NICE-L-H-4015

220-NICE-L-H-4018

195

335

350

210

192

6

9.1

220-NICE-L-H-4022

220-NICE-L-H-4030

230

380

400

250

220

7

17

Three-phase 380 to 480VAC, range: -15% to 10%

NICE-L-H-4002

150

334.5

347

223

143

6.5

5.5

NICE-L-H-4003

NICE-L-H-4005

NICE-L-H-4007

150

334.5

347

223

173.5

6.5

7

NICE-L-H-4011

NICE-L-H-4015

NICE-L-H-4018

195

335

350

210

192

6

9.1

NICE-L-H-4022

NICE-L-H-4030

230

380

400

250

220

7

17

NICE-L-H-4037

NICE-L-H-4045

245

580

525

300

275

10

35

NICE-L-H-4055

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

9

2.6. Mechanical Installation

Pay attention to the following points when designing the control cabinet:

The temperature inside the cabinet must not rise to 10°C higher than the temperature outside the cabinet

A closed control cabinet must be equipped with a fan (or other air cooling device such as air conditioner) to

ensure air circulation

The air from the fan must not blow directly to the drive unit because this can easily cause dust adhesion and

further a fault on the drive unit

A vent must be available at bottom of the control cabinet to form bottom-up air flow, which prevents heat island

effect on the surface of components or partial thermal conductivity effect

If the fan does not meet the cooling requirements, install an air conditioner in the cabinet or in the equipment

room. Note that the temperature inside the cabinet must not be too low; otherwise, condensation may occur,

causing short-circuit of components

For special environment where the temperature is high but cannot be reduced effectively, de-rate the controller

during use.

Power

Clearance Requirement

1.1 to 18KW

A ≥ 10 mm

B ≥ 100 mm

22 to 55KW

A ≥ 50 mm

B ≥ 100 mm

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

10

2.7. NICE Power terminal & MCTC-MCB-G Main Control Board Details

Actual NICE1000+ unit with Encoder PG card NICE1000+ Unit Terminal Details

2.7.1 Description of Power Terminal of NICE

Terminal

Name

Description

R,S,T

3-Phase power input terminal

Input 3-phase AC380 to 480V

(+), (-)

Positive and Negative terminals of

DC bus

Connect the external braking unit and energy feedback unit for

models of 37 kW and above

(+), PB(P)

Terminals for brake resistor

(+), PB: Connect the braking resistor for models of below 37 kW

(+), (P): Connect the DC reactor for models of 37 kW and above

At delivery, the (+) and P terminals are shorted with the jumper

bar. If you need not connect the DC reactor, do not remove the

jumper bar.

U,V,W

Controller Output Power Terminal

Connect to the three phase Hoist Motor

PE

Grounding Terminal

Must be connected with Earth/Ground Bus bar

2.7.2 Description of indicators on the MCB

Mark

Terminal Name

Function Description

ER

Fault indicator

When a fault occurs on the controller, this indicator is ON (red).

OK

Normal running indicator

When the controller is in normal running state, this indicator is ON

(green).

CAN

Parallel control

communication indicator

This indicator is steady ON (green) when communication for parallel

control is enabled, and blinks when the running in parallel mode is

normal.

L1 to L26

Button input indicator

This indicator is ON (green) when the button input is active.

X1 to X27

Input signal indicator

This indicator is ON (green) when the external input is active.

Y0 to Y22

Output signal indicator

This indicator is ON (green) when the system output is active.

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

11

2.7.3 Description of Main Control Board (MCB) Terminals

Mark

Code

Terminal

Name

Function Description

Terminal Arrangement

CN2

CN4

24V/COM

External 24

VDC power

supply

24 VDC power supply for the entire

board

L1 to L26

Button

function

selection

Button input and button indicator

output, 24 V power for button

illumination

CN1

CN6

24V/COM

External 24

VDC power

supply

24 VDC power supply for the entire

board

X1 to X24

DI

Input voltage range: 10–30 VDC

Input impedance: 4.7 kΩ Opto-

coupler isolation

Input current limit: 5 mA

Functions set in F5-01 to F5-24

AI-M/AI

AI

Used for the analog load cell device

CN7

X25 to X27/

XCM

Higher-

voltage

detection

terminal

Input voltage range: 110 VAC±15%

110 VDC±20% for safety circuit and

door lock circuit, function set in F5-25

to F5-27

Y0/M0 to

X27

Y3/M3

Relay output

Normally-open (NO),

maximum current and

voltage rating: 5 A, 250 VAC Function

set in F7-00 to F7-03

CN8

CN9

Y6 to Y22

Relay output

NO, maximum current and voltage

rating: 5 A, 250 VAC

or 5 A, 30 DC

Function set in F7-06 to

F7-22

YM1 to

YM3

COM for

relay

output

YM1 is COM for Y6 to Y9;

YM2 is COM for Y10 to Y16;

YM3 is COM for Y17 to Y22

CN3

MOD+/-

Reserved

-

CAN+/-

CAN bus

differential

signal

CAN bus communication

interface, used for parallel control

GND

Ground

Must be grounded

CN5

Interface for extension board MCTC-KZ-D

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

12

CN10

USB

interface

Communication

•• Used to connect the

external Bluetooth module for

commissioning via

Android cell phone

(not supporting English version

currently)

•• Used to burn the MCB program

•• Used for residential

monitoring

CN12

RJ45

interface

Interface for

operation panel

Used to connect the

operation panel

J12

Interface for connecting the PG card

J9/

J10

Factory reserved. Do not short them randomly. Otherwise, the

controller may not work properly

2.8. Description of the MCTC-KZ-D Extension Card

The extension card is mainly used for extension of floor call button inputs and relay outputs.

2.8.1 Appearance and installation of the MCTC-KZ-D

Actual Appearance of MCTC-KZ-D NICE1000+ connected with MCTC-KZ-D

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

13

2.8.2 Mounting dimensions of the MCTC-KZ-D

2.8.3 Function description of terminals

Mark

Code

Terminal

Name

Function Description

Terminal Arrangement

CN3

CN4

L27 to L38

Button

function

selection

Button input and button

indicator output, 24 V power for

button

illumination

L39 to L50

Button

function

selection

Button input and button

indicator output, 24 V power for

button

illumination

CN1

YM/Y4/Y5/Y2

3 to Y27

Relay output

Normally-open (NO),

maximum current and

voltage rating:

5 A, 250 VAC

Function set in F7-03 to

F7-27

CN2

Interface for connection to the MCB

2.8.4 Description of indicators on the MCTC-KZ-D

Mark

Terminal Name

Function Description

L27 to L50

Extension button signal

collection/feedback

indicator

When the extension floor button input signal is active and the response

signal is output, this indicator is ON (green).

Y4, Y5,

Y23 to Y27

Extension relay output

signal indicator

When the extension relay output of the system is active, this indicator is

ON (green).

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

14

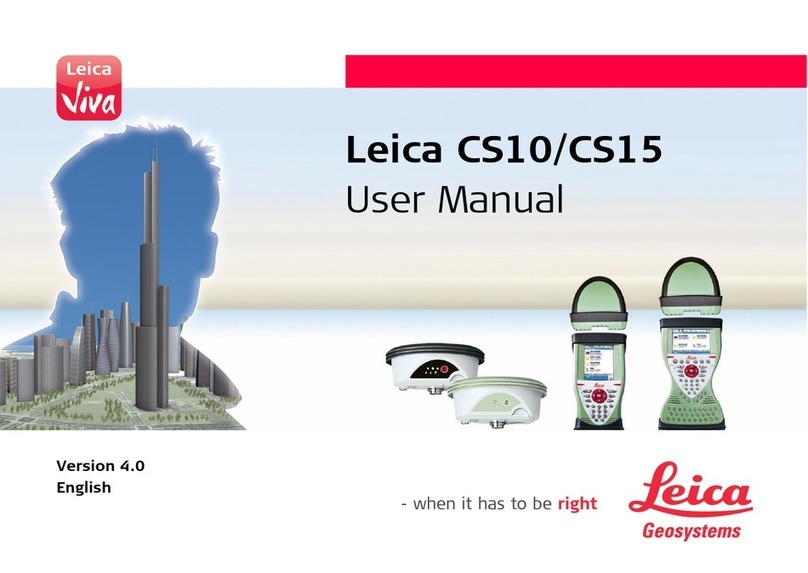

2.9 Selection and Use of the MCTC-PG Card

The NICE1000new can implement CLVC only with use of the MCTC-PG card

Directly insert the J1 terminal of the MCTC-PG card into the J12 terminal of the controller

2.9.1 Appearance of the MCTC-PG card and its installation on the controller

2.9.2 Selection of the MCTC-PG card models

Encoder Type

Adaptable PG Card

Appearance

Push-pull encoder

Open-collector incremental

Encoder

MCTC-PG-A2

UVW encoder

MCTC-PG-D

SIN/COS encoder

MCTC-PG-E

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

15

Absolute encoder

(ECN413/1313)

MCTC-PG-F1

2.9.3 Details on Different Encoders wiring configuration with different PG Cards

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

16

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

17

3. Elevator Hoistway Switches and Sensor Installation

3.1 Terminal floor switches mounting position

In the formula, "L" indicates the slow-down distance, "V" indicates the F0-04 (Rated elevator speed), and "F3-08"

indicates the special deceleration rate.

The default value of F3-08 (Special deceleration rate) is 0.5 m/s2. The slow-down distances calculated based on

different rated elevator speeds are listed in the following table:

Rated Elevator Speed (F0-04) m/s

0.4

0.5

0.63

0.75

1.0

1.5

1.75

Distance Slow-down switch (m)

0.5-0.6

0.6-0.8

0.8-1.0

0.9-1.2

1.2-1.6

1.8-2.5

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

18

3.2 Installation of levelling Plate/Flag and Switches

NICE1000+ supports below three combinations of Door Zone and Up/Down levelling sensor/switches for elevator floor

stopping at floor level

Third method of having Up/Down levelling switches and Door Zone switches are used mainly for Re-levelling and

Advance floor levelling functions. While using these functions, need three or four switches along with MCTC-SCB-A

board.

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

20

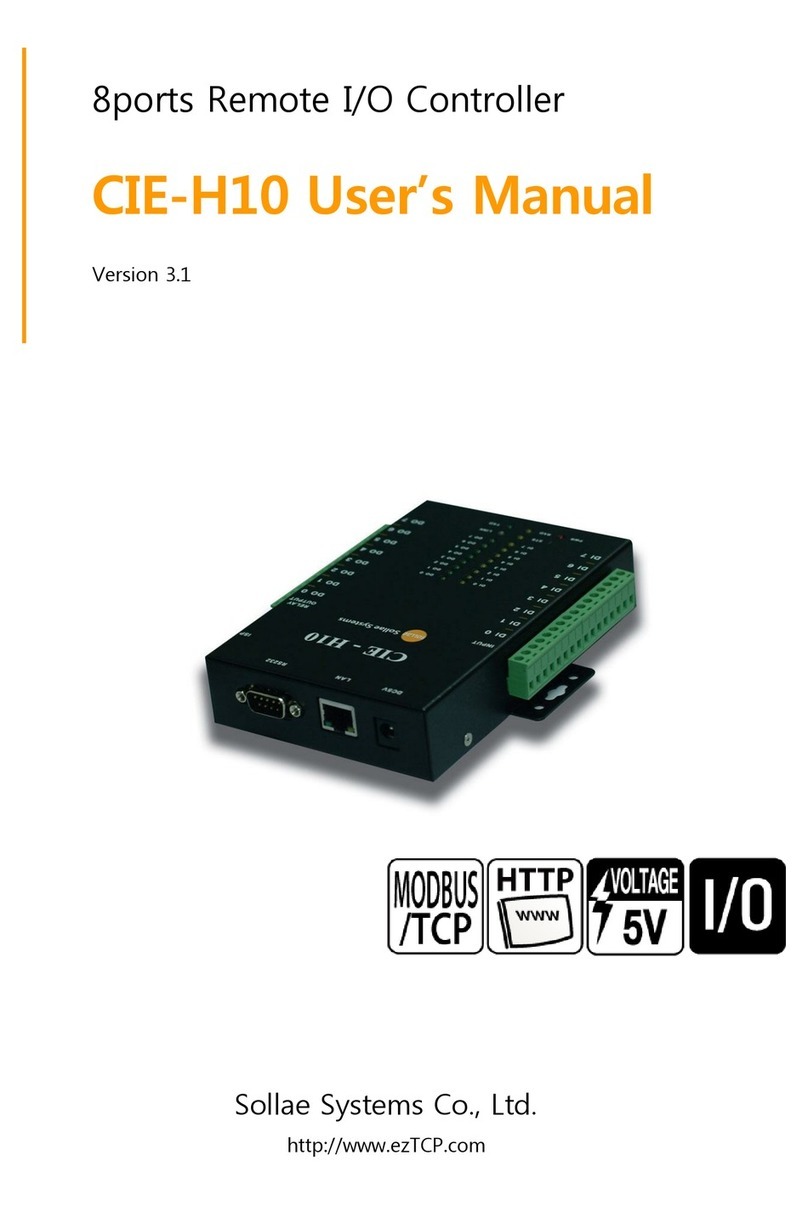

4. Complete Electrical configuration of NICE1000+ all Field Interfaces

INOVA AUTOMATION NICE Series Integrated Elevator Solution –NICE1000+ Quick Start-Up Guide V1.0

21

5. Initial Start-up commissioning

5.1. Identify the NICE 1000 control Panel components

5.2. Verification of Controller and Field wiring

For safety, make sure that the all Moulded Case

Circuit Breakers (MCCB) are turned OFF before

wiring the main circuit power input terminals located

at machine room and elevator controller

Select the ‘Controller INS ’ selector switch to

inspection mode

Check control panel wiring are proper and well

tightened

Check the field wiring are proper and well tightened

at controller

Check all Field Wiring (Machine Room, Controller,

Hoist-way, Car top, COP and LOP) are connected as

per the suitable Electrical Drawing

Check control panel wiring for short circuit or

grounding using Multi meter

Verify the below power points with respect to Earth

point

R S T with respect to Earth (PE)

U V W with respect to Earth (PE)

±24VDC with respect to Earth (PE)

Encoder power supply with respect to Earth

(PE)

Safety circuit and Door Lock circuit with

respect to Earth (PE)

All other Field Control circuit with respect to

Earth(PE)

Check Controller power terminal U V W are correctly

connected corresponds to the Motor U V W terminal

Check the Machine Brake wiring is done correctly as

per the requirement

INS

NOR

OFF

Table of contents