Inovance MDBUN Series Braking Unit User Manual

Page 1 of 24

Preface

Thank you for purchasing Inovance MDBUN series braking unit.

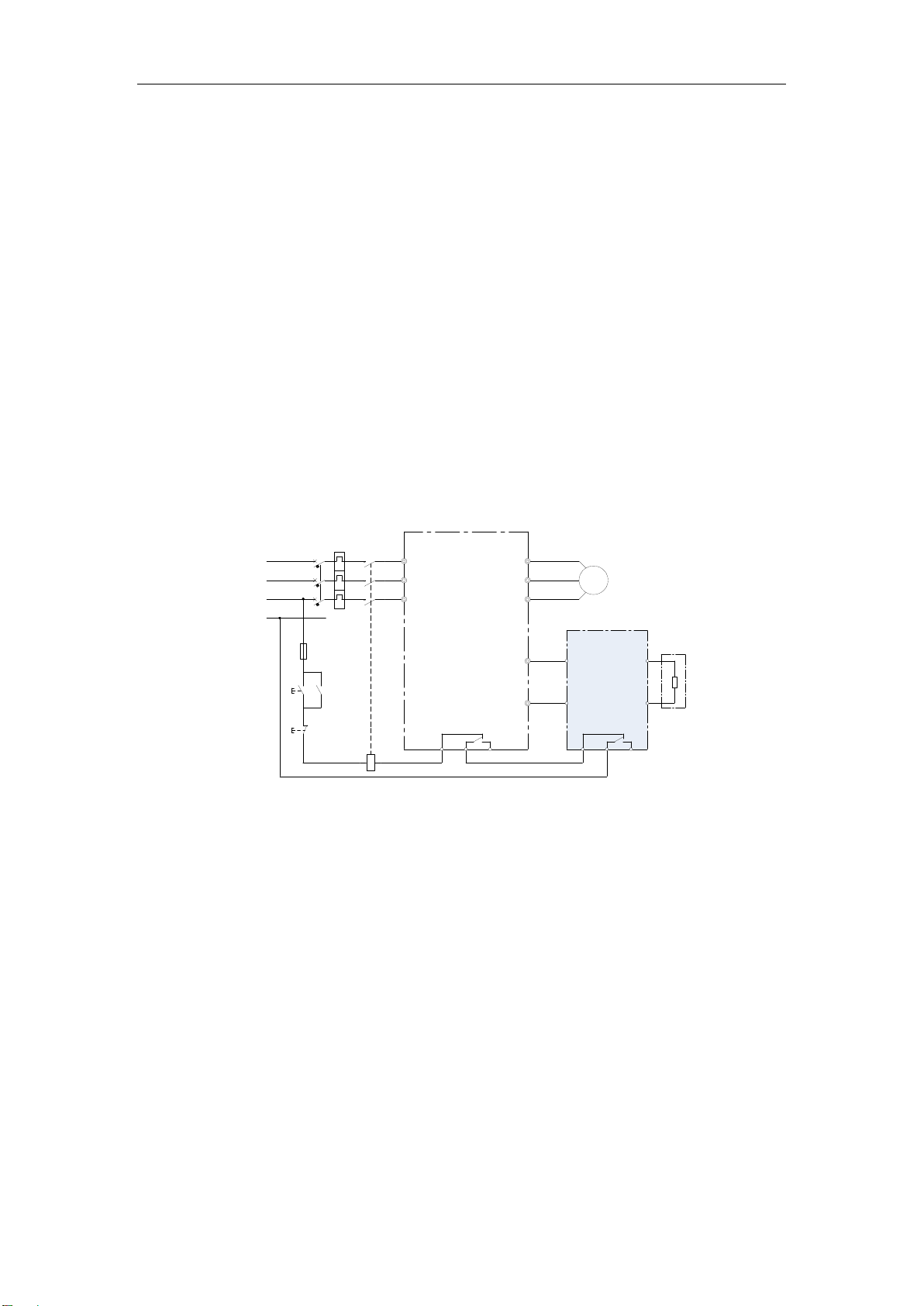

Inovance MDBUN series braking unit applies to the applications where an AC drive or

servo drive (hereinafter referred to as "drive") needs to perform deceleration, positioning

or braking operation. When the drive performs braking, kinetic energy is converted to

electric energy which is fed back to the drive due to the mechanical inertia of the load.

This will cause rising of the DC bus voltage of the drive. Therefore, a braking unit is

required to ensure normal running of the drive. The regenerative energy is consumed by

the braking resistor, preventing the drive from stopping or even being damaged due to

overvoltage protection.

Inovance MDBUN series braking unit provides full protection functions, such as

overcurrent, overheat, and braking unit open-circuit and short-circuit protection. It

supports the setting of parameters including braking start/stop voltage, and braking rate.

Multiple braking units can be deployed in master/slave mode to meet the braking

requirements of high power drive.

Inovance MDBUN braking unit also applies to large-inertia applications that require

sudden stop, for example, such as elevators, textile machines, paper making machines,

centrifuges, wire drawing machines, winding machines, proportional linkage systems, and

crown blocks.

Before performing installation, wiring, operation, maintenance, and inspection, read and

understand this manual thoroughly and follow the instructions. Failure to observe the

instructions may result in personal injury or even death.

The drawings in this manual are sometimes shown without cover or protective guard.

Remember to install the cover or protective guard as specified first, and then perform

operations in accordance with the instructions.

The drawings in this manual are shown for description only and may not match the

product that you have purchased.

The instructions are subject to change due to product upgrade, specification

modification, as well as the efforts to increase the accuracy and convenience of the

manual

Contact the regional agent or customer service center of Inovance if the manual

delivered is lost or damaged.

Contact the customer service center of Inovance if you have problems during the use.