Safety Information and Precautions

- 2 -

Disclaimer

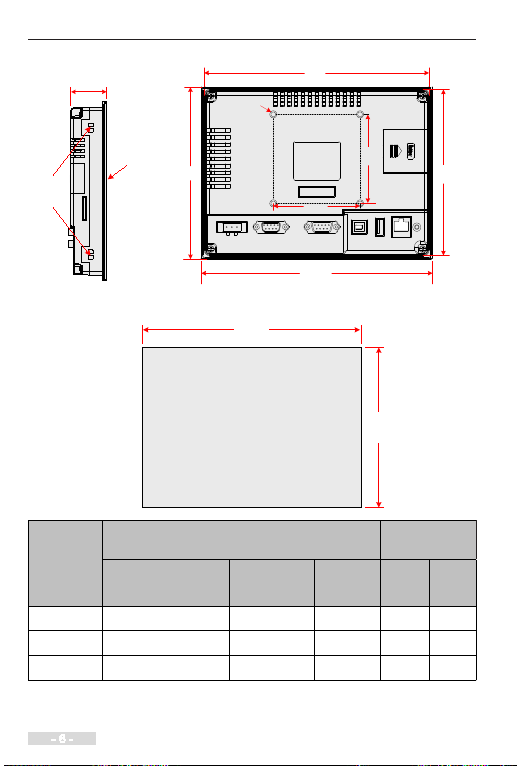

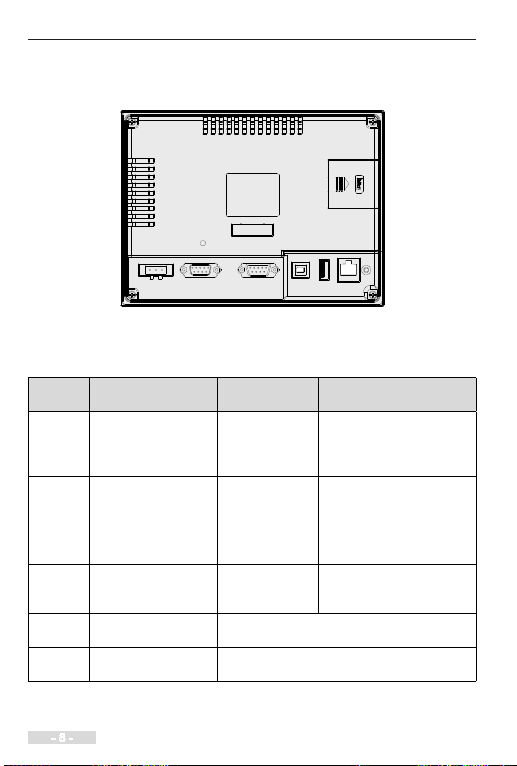

•The drawings in the manual are shown for description only and may not

match the product you purchased.

•The instructions are subject to change, without notice, due to product or

software upgrade, specication modication as well as efforts to increase the

accuracy and convenience of the manual.

•Contact our agents or customer service center if you have problems during

the use.

Approvals

Certification marks on the product nameplate indicate compliance with the

corresponding certicates and standards.

Certication Mark Directives Standard

CE

EMC directives 2014/30/EU EN61131-2

LVD directives 2014/35/EU EN 61010-1,

EN61010-2-201

RoHS directives 2011/65/EU EN 50581

TUV - EN 61010-1,

EN61010-2-201

Note

•The above EMC directives are complied with only when the EMC electric

installation requirements are strictly observed.

•Machines and devices used in combination with this drive must also be CE

certified and marked. The integrator who integrates the drive with the CE

mark into other devices has the responsibility of ensuring compliance with CE

standards and verifying that conditions meet European standards.

•The installer of the drive is responsible for complying with all relevant

regulations for wiring, circuit fuse protection, earthing, accident prevention

and electromagnetic (EMC regulations). In particular fault discrimination

for preventing re risk and solid earthing practices must be adhered to for

electrical safety (also for good EMC practice).

•For more information on certification, consult our distributor or sales

representative.