5

4

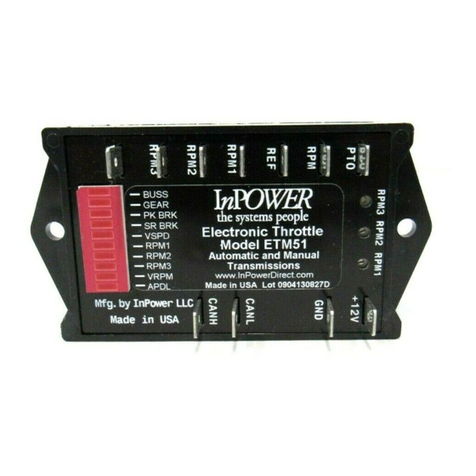

LED Status Indication

RPM1 On Solid RPM1 mode selected, engine at

fast idle

RPM1 Flashing RPM1 mode selected, engine not

at fast

idle ( hassis Ready onditions not

satisfied*)

RPM2 On Solid RPM2 mode selected, engine at

fast idle

RPM2 Flashing RPM2 mode selected, engine not

at fast

idle ( hassis Ready onditions not

satisfied*)

RPM3 On Solid RPM3 mode selected, engine at

fast idle

RPM3 Flashing RPM3 mode selected, engine not

at fast

idle ( hassis Ready onditions not

satisfied*)

HRG On Solid harge Protect mode selected

HRG Flashing harge Protect mode selected,

engine

not at fast idle ( hassis Ready

ondition

not satisfied*)

Note - If all of the LED lights are flashing this indicates either a faulty

DL able connection or that this ETM67A/ETM68A version

Is not compatible with the chassis.

* See hassis Ready onditions on page 2 for required conditions to

allow increased idle speed.

D. Installation

1. Getting Started

The recommended location for the ETM system is under the dash due

to the proximity of the wiring connections and cable length. The unit

should not be located in the engine compartment, or any location that

is not protected. You will need a crimping tool for the 0.25 inch Faston

(blade) terminals, and a wire stripping tool. Be sure to follow the

crimping tool instructions for the proper wire size and terminals.

2. Mount the ETM Module

Mount the ETM module under the dash using the two mounting holes.

Ensure that you have sufficient distance to install the 36 inch long DL

cable. DO NOT EXTEND THE LENGTH OF THIS ABLE OR

WARRANTY WILL BE VOIDED.

D. Installation

3. Install the DL able

onnect the two Faston terminals on the DL cable to the ETM module

terminals (Green wire to ANL terminal and Yellow wire to ANH

terminal). Route the cable to the OBDII (On Board Diagnostic) Data Link

onnector and plug it in. The OBDII connector will be located on the

lower part of the dash on the driver’s side. Using a cable tie, secure the

plug to the OBDII connector so that it will not vibrate out. We

recommend that you route the cable of the plug back across the bottom

of the connector and loop the cable tie around the plug, socket and

cable, thereby keeping the cable out of the way. Also ensure that the

entire cable is routed and secured to keep it out of the way.

4. Wire the Parking Brake Switch Input

Note - Follow this procedure ONLY for the following chassis

configurations:

1. 2006, 2007 Silverado/Sierra lassic 2500, 3500 with 6.6 L

Diesel

2. 2006 - 2008 Kodiac/Topkick 4500, 5500 with 6.6 L Diesel

3. 2007 Express, Savanna with 6.6 L Diesel

The ETM67A/68A systems requires an input to detect that the parking

brake is set before it can go to fast idle (only on the indicated models).

Install a wire from the PK BRK terminal on the ETM module to the

chassis parking brake switch. onnect this wire on the side of the switch

that is not grounded. Verify that the wiring is correct by measuring the

voltage at the PK BRK terminal when the parking brake is operated. The

terminal should be at ground when the brake is depressed and at +

voltage when not depressed.

5. PTO Enable Wiring - Diesel Engines Only

On 2007 and earlier chassis it is necessary to activate the PTOEnable

input function on the Engine ontrol Module (E M) when going to high

idle. There are different methods of activating this function depending on

the chassis configuration. See InPower Technical Bulletin TB-49 for

details.

. Operation ( ontinued)

OM-64G ETM67A & ETM068A

OM-64G ETM67A & ETM068A