InPOWER DBT-MD-01 User manual

© Copyright 2016 InPower LLC

DBT-MD-01 Owner’s Manual

1

Document: OM-194 Version Code: A

Date: August 2016 Date: Sept. 14, 2016

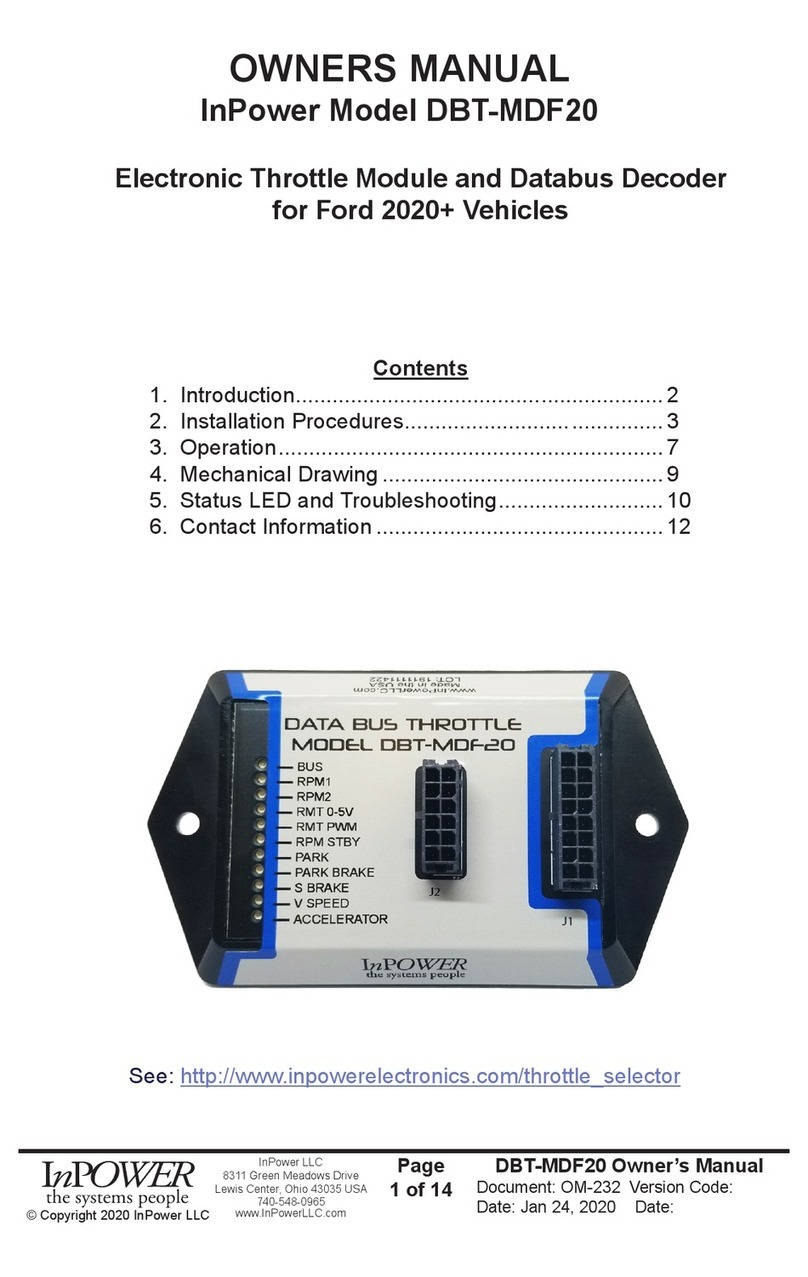

OWNERS MANUAL

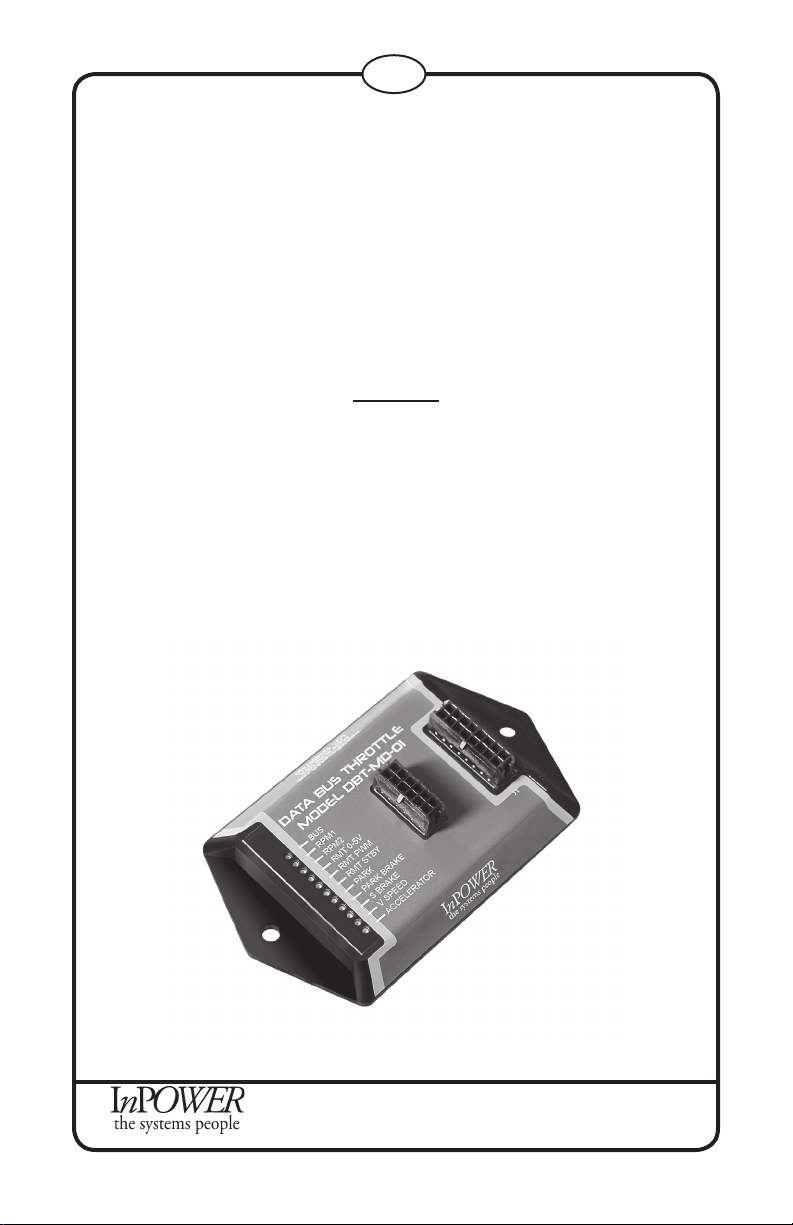

InPower Model DBT-MD-01

Contents

1. Introduction............................................................ 2

2. Installation Procedures.......................................... 3

2.6 Harness Wire Table ........................................ 6

3. Operation............................................................... 7

4. Mechanical Drawing .............................................. 9

5. Status LED and Troubleshooting........................... 10

5.6 Troubleshooting Flowchart ............................. 11

6. Contact Us............................................................. 12

Electronic Throttle Module and Databus Decoder

for Ford 2016+ Vehicles

© Copyright 2016 InPower LLC

DBT-MD-01 Owner’s Manual

2

Document: OM-194 Version Code: A

Date: August 2016 Date: Sept. 14, 2016

1. Introduction

InPower’s DBT-MD-01 Data Bus Throttle both decodes the vehicle data bus

to provide you with the signals you need and provides high idle engine RPM

and PTO control. This product is compatible with 2016+ Ford trucks and vans

equipped with the Ford Stationary Elevated Idle Control (SEIC).

Modules come with four modes of high idle control: one standby mode, two

preset RPM modes, and one variable input RPM mode based on a customer-

supplied remote variable resistor. The standard module also includes four data

bus signal outputs: Park Brake Set, Reverse, Engine Run and Park (note: on

F750 chassis, the output is Neutral) with the capability of additional or alternate

outputs per customer special request. Contact information is located on the

back page of this manual.

Note: The data bus signal outputs will continue to function so long as

the unit has power and vehicle ignition is in the run position. However,

the throttle functions will only operate if the Chassis Ready Conditions

are satised. LED diagnostic indicators are provided to aid in system

troubleshooting. These LEDs are located on the module opposite the

connectors.

The DBT-MD-01 kit includes two cables. The rst cable (J1 Harness) connects

to the module via connector J1 and has three labeled sets of 20-inch blunt cut

wires: ve wires for SEIC, ve wires for inputs, and six wires for data bus signal

outputs. The second cable (J2 Harness) connects to the module via connector

J2 and has both a 16-pin connector plug for the OBDII data link connector

and a set of seven blunt cut wires for remote high idle control and preset RPM

adjustments.

Note: Ford vehicle wire colors and locations may vary substantially

between different models and even different model years. Please obtain

and consult the SEIC information for your specic vehicle prior to

installing the module. Documentation may be obtained from Ford’s

Truck Body Builder Advisory Service (www.eet.ford.com/truckbbas/).

© Copyright 2016 InPower LLC

DBT-MD-01 Owner’s Manual

3

Document: OM-194 Version Code: A

Date: August 2016 Date: Sept. 14, 2016

2. Installation Procedures

2.1 Safety Precautions

This electronic throttle product has been designed and manufactured to meet

the intended application requirements and specications. Any modications

to the product or to the installation procedure can be dangerous and will void

InPower’s warranty.

• Read and understand the instructions in this manual and other manuals

before starting the installation.

• Make sure that the vehicle battery power is disconnected during installation

of the throttle module.

• Reconnect the battery when the system installation is complete.

• Wear appropriate safety equipment, such as protective eyeglasses, face

shield and clothing when installing equipment and handling the battery.

• Be careful when working near a battery. Make sure that the area is well

ventilated and that there are no ames near the battery. Never lay objects

on the battery that can short the terminals together. If battery acid gets in

your eyes, immediately seek rst aid. If acid gets on your skin, immediately

wash it off with soap and water.

2.2 Getting Started

IMPORTANTNOTE: Please obtain the specic SEIC installation instructions

for your vehicle make and model from Ford. Wire colors and locations may

vary from model to model and even between different years for the same

model.TheguidemaybeobtainedfromFord’sBodyBuilderAdvisoryService.

We recommend installing the DBT-MD system under the dash due to the

proximity of the wiring connections and cable length. The unit should not be

located in the engine compartment or any other location that is not protected.

You will need tools to splice wires together. For each xed preset mode, you

will need a high idle On/Off switch. For Variable RPM control, you will need a

potentiometer. We recommend a 10 Kohm 3, 5, or 10-turn potentiometer such

as those available from Digikey. If using PWM for Variable RPM control, refer

to PWM instructions.

Do not lengthen the cable from the module to the OBD-II connector.

Disconnect the battery before making any electrical connections.

WARNING

!

© Copyright 2016 InPower LLC

DBT-MD-01 Owner’s Manual

4

Document: OM-194 Version Code: A

Date: August 2016 Date: Sept. 14, 2016

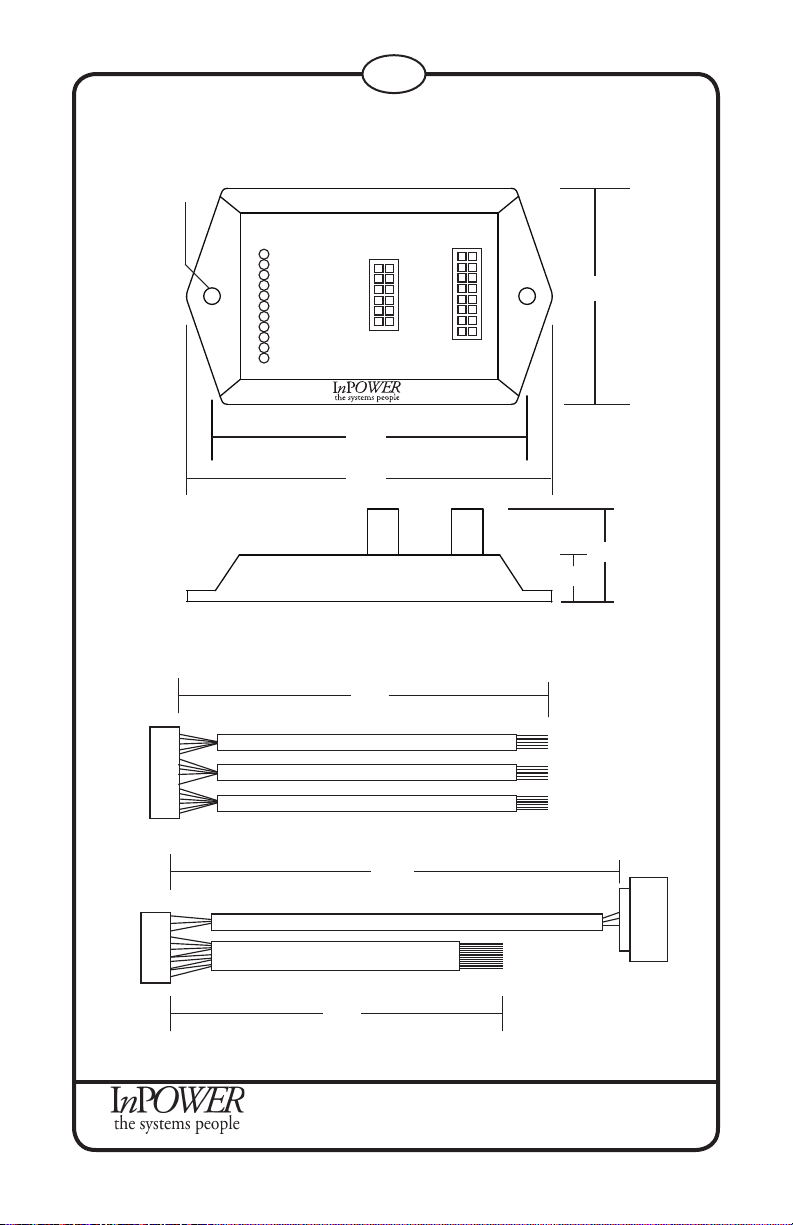

2.3 Mounting

Mount the DBT-MD module under the dash or on a at surface using the two

mounting holes. Ensure that you have sufcient distance to install the 36 inch

OBD-II cable that is part of the J2 harness.

Plug the J1 cable into the J1 connector (20 pin connector) and plug the J2

cable into the J2 connector (12 pin connector). The J2 cable will be used

for the OBD-II connection, power input, RPM adjustment and hooking up

either remote RPM or PWM. The J1 cable will be used for hooking into the

SEIC circuit, high idle on/off or mode select switches and for providing output

signals.

2.4 Wiring

Ensure the J1 cable and the J2 cables are both connected to the module.

Note: So long as the vehicle is on and the unit has power, even if the

High Idle Throttle function is not engaged, the Databus Decoder signals

will continue to operate. If the Databus Decoder signals will not be used,

properly secure the Output wire group on the J1 harness.

A. OBD-II connector

Locate the red connector on the J2 harness. Route this portion of the cable

to the OBD-II Data Link Connector and plug it in. The OBD-II connector is

usually located on the lower part of the dash on the driver’s side. Using a

plastic cable tie, secure the plug to the OBD-II connector so that it will not

vibrate out. We recommend routing the DLC cable across the bottom of the

plug and looping the cable tie around the plug, socket and cable to keep it out

of the way.

B. SEIC

Locate the SEIC group of blunt cut wires on the J1 harness. Install wires

between the blunt cut wires provided on the J1 harness and the respective

inputs and outputs of the Ford SEIC as shown in the wiring diagrams.

C. High Idle Mode Selection Controls

Determine the combination of high idle speed modes you will need (standby

high idle, variable RPM control and/or up to two additional xed preset

speeds).

© Copyright 2016 InPower LLC

DBT-MD-01 Owner’s Manual

5

Document: OM-194 Version Code: A

Date: August 2016 Date: Sept. 14, 2016

You will need to supply your own switches for turning on or off RPM modes,

and for the variable RPM, you will need to provide your own 0 to 5V

potentiometer. We recommend a ten-turn potentiometer such as those found

at Digikey and other similar vendors.

Please refer to section 2.6 on page 6 for a complete chart of input and output

wires. All mode selection switches should be wired to the INPUTS wire group

in the J1 Harness. The variable remote should be wired to the appropriate

wires in the J2 Harness.

D. Decoded Data Bus Signal outputs

Note: As long as the unit has power (connected via the Red wire on the J2

harness) and the vehicle is on (data bus signals are not transmitted when the

vehicle is off), the DBT-MD will provide these output signals, regardless of the

status of the throttle controls and engine RPM.

All decoded signal output wires are located in the J1 harness in the bundle

marked Outputs. Each wire corresponds to a different signal and all wires

give a 600mA current when connected. (Note: The pink wire and the gray

wire are unused in the standard model but may be given a custom signal at

customer request.) Tape or otherwise properly secure any unused wires out.

Please see 2.6 on page 6 for chart.

2.5 Calibration

All four RPM modes come with Factory Calibrations but may be adjusted by

the user if so desired once the module is installed.

1. Activate the mode you wish to adjust. Note: If the Adjustable RPM

mode is activated, this process will adjust the maximum RPM setting.

2. Locate the grey wire in the J2 harness. Apply +12V to this wire to

raise the RPM or ground the wire to lower it to the desired RPM. Note:

A minimum of 910 RPM is required for PTO to activate, so we do not

recommend lowering the Standby RPM.

3. To permanently store the changed RPM, disconnect from all RPM

modes but maintain power. If you disconnect the power without rst

deactivating all modes, it will not store the changes.

© Copyright 2016 InPower LLC

DBT-MD-01 Owner’s Manual

6

Document: OM-194 Version Code: A

Date: August 2016 Date: Sept. 14, 2016

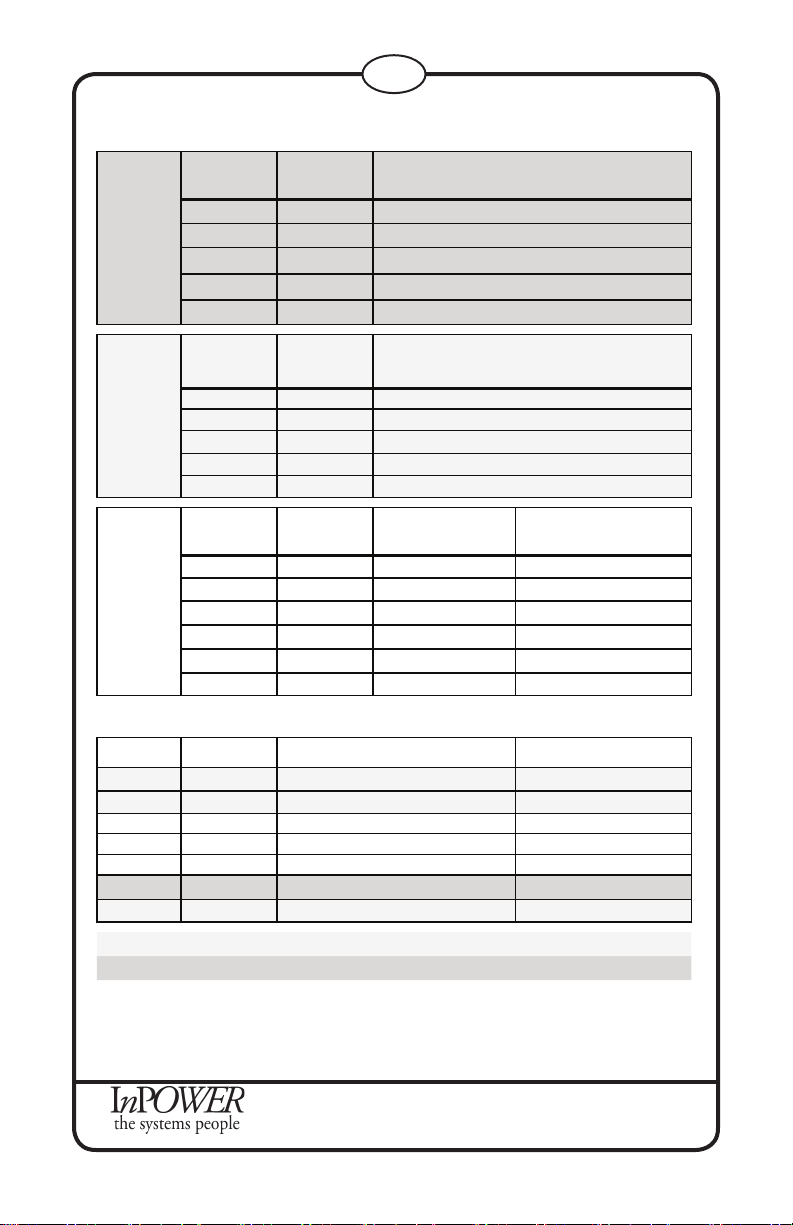

J1 Harness

SEIC

GROUP

Wire Color Connector

Pin Number Function

White 2 Input from PTO Relay / PTO Indicator

Brown 8 Input from PTO VREF

Orange 13 Output to PTO-REQ2 for gas engines

Yellow 14 Output to PTO-REQ1

Green 16 Output to PTO-RPM

INPUTS

GROUP

Wire Color Connector

Pin Number Function

Brown 3 Not Used

Pink 4 Input RPM1

Tan 5Input RPM2

Violet 6Input RPM STBY

Dark Blue 7 Input RPM Remote

OUTPUTS

GROUP

Wire Color Connector

Pin Number Function Signal Output

Dark Green 1 Park Brake Set Ground

Pink 9 Not used Positive

Tan 10 Reverse Positive

Violet 11 Engine Run Positive

Dark blue 12 Park (750: Neutral) Positive

Gray 15 Not Used Ground

J2 Harness

Wire Color Pin Number Function

Black 2 Ground out to Remote *

Orange 3 Input from 0-5V Remote *

Red 7 12V Power Input

Violet 8Not Used

Gray 9 RPM Adjust

Pink 10 Input from PWM Remote **

White 11 5V Output to Remote *

* These three wires are for use with remote variable RPM

** The Pink PWM Remote wire is for use with PWM only

Note: Pins 1, 4 and 5 of J2 connect to OBD-II Connector Wires

12V Power must be supplied to the Red Power Input Wire for unit to function

J2 gray wire may be used to adjust calibration for all RPM settings. See section 2.5

2.6 Harness Wire Chart

© Copyright 2016 InPower LLC

DBT-MD-01 Owner’s Manual

7

Document: OM-194 Version Code: A

Date: August 2016 Date: Sept. 14, 2016

3. Operation

When the vehicle is parked and Chassis Ready Conditions are satised, the

engine idle speed may be controlled by selection of one of the four available

modes: standby, two presets and one variable RPM. The preset RPM modes

may be adjusted via the grey RPM adjust wire (see Adjusting RPM Values,

page #).

Chassis Ready Conditions:

• No vehicle speed

• Parking brake set

• Shift selector in Park (or Neutral on F750)

• Accelerator not pressed

• Service brake not pressed

• Engine running and below 1000 RPM

• No Diagnostic Trouble Code (DTC). Check Engine light must be off.

NOTE: While the engine is in high idle, should the throttle be deactivated

by one of the Chassis Ready Conditions changing, the engine will return

to normal speed. The throttle will ash the diagnostic LEDs to indicate the

cause of the deactivation for ten seconds after Chassis Ready Conditions

are restored. Then it will reset and return the vehicle to high idle.

Modes of Operation:

Standby Mode

Function: Increase idle to minimum required to activate PTO

Activation: Apply +12V to Violet Wire on J1 Harness Input Group

Factory Calibration: 950 RPM

NOTE: A minimum of 910 RPM is required to enable PTO on 2017+

vehicles, so we do not recommend adjusting the Standby set-point below

the Factory Calibration.

Preset RPM Modes

Function: Increase idle to preset RPM values

Activation: RPM1: Apply +12 V to Pink Wire on J1 Input Group

RPM2: Apply +12V to Tan Wire on J1 Input Group

Factory Calibration: RPM1: 1500 RPM RPM2: 1200 RPM

Calibration Range: Varies based on vehicle model. Generally, 900 RPM

to 2200 RPM (gas) or 2800 RPM (diesel)

© Copyright 2016 InPower LLC

DBT-MD-01 Owner’s Manual

8

Document: OM-194 Version Code: A

Date: August 2016 Date: Sept. 14, 2016

Variable RPM Mode

Function: Varies RPM as a function of voltage from customer-supplied

remote variable control

Activation and Adjustment:

1. Activate Standby Mode: Apply +12V to Pink Wire on J1 Harness Input

Group (J1 Pin4)

2. Activate Remote Mode: Apply +12V to Dark Blue Wire on J1 Harness

Input Group (J1 Pin7)

The module will then look for a signal from either PWM or remote

potentiometer. Both RMT 0-5V and RMT-PWM LEDs will ash until it

receives a remote signal. At that point, the corresponding LED will turn

solid and the other one will shut off.

3. To adjust RPM with the potentiometer, start at zero and then turn

potentiometer up slowly until desired RPM is reached. To adjust with

PWM, contact InPower for PWM specications.

Minimum RPM: Equal to Standby Mode RPM

Maximum RPM: Preset Adjustable. Factory Default: 1500 RPM

Mode Priorities:

If more than one mode is selected at a time, the modes take the following

priorities:

RPM1 Highest - overrides all other modes

RPM2 Second - overrides lower modes

Variable RPM Third - overrides lower mode

Standby Lowest

NOTE: When using module with PTO on 2017+ gas vehicles, rst engage

Standby High Idle Mode before engaging PTO.

© Copyright 2016 InPower LLC

DBT-MD-01 Owner’s Manual

9

Document: OM-194 Version Code: A

Date: August 2016 Date: Sept. 14, 2016

3.8

0.2 dia.

4.4

2.6

J1

J2

0.4

0.8

www.InPowerLLC.com

Made in the USA

LOT: 1234567890

36

20

20

to J1

to J2

MODULE

CABLES

All Dimensions in Inches

Not to Scale

Sensors &

Power

PTO

Inputs

Outputs

Diagnostic

LEDs

4. Mechanical Drawing

© Copyright 2016 InPower LLC

DBT-MD-01 Owner’s Manual

10

Document: OM-194 Version Code: A

Date: August 2016 Date: Sept. 14, 2016

5. Status Indicators and Troubleshooting

5.1 For new installations. The throttle automatically checks to see if its

software revision code supports the chassis. The DBT-MD detects the vehicle

type during the rst ignition turn-on after installation. If the Park LED is on

solid and all other LEDs are off, the truck is not supported by this model.

Please refer to the Throttle Selector Guide found on our website for the most

up-to-date compatibility information.

(www.inpowerdirect.com/electronicthrottlecontrols_selector.php)

5.2 Check all wiring and make sure all connectors are plugged in rmly.

Refer to the Harness Wire Chart in section 2.5 on page 5 when checking that

wires are connected to appropriate inputs and outputs.

Ford vehicle wire colors and locations may vary substantially between different

models and even different model years. Please obtain and consult the SEIC

information for your specic vehicle. Documentation may be obtained from

Ford’s Truck Body Builder Advisory Service (www.eet.ford.com/truckbbas/).

5.3 A series of 11 LEDs on top of the module provide diagnostic information

for troubleshooting purposes. The LEDs are

labeled and correspond to RPM modes, Databus

status and safety interlocks necessary to bring the

vehicle to high idle. If no LEDs are illuminated, the

unit does not have power.

See LED Troubleshooting Flowchart on Page 9.

5.4 While engine is in high idle, if one of the

Chassis Ready Conditions changes states, the

engine will return to factory idle. The throttle will

ash the diagnostic LEDs to indicate the cause

of the high idle deactivation. Then, once conditions are restored, after a ten

second delay it will return the vehicle to the preset high idle speed. This

feature may be used to troubleshoot intermittent problems.

BUS

DBT-MD LED INDICATORS

ACCELERATOR

RPM1

RPM2

RMT 0-5V

RMT PWM

RMT STBY

PARK

PARK BRAKE

S BRAKE

V SPEED

© Copyright 2016 InPower LLC

DBT-MD-01 Owner’s Manual

11

Document: OM-194 Version Code: A

Date: August 2016 Date: Sept. 14, 2016

Unit has no power

Unit has power but

no databus RPM

message

BUS Only

Multiple LEDs

Are Any LEDS on?

Unit has power and

data bus RPM

message received,

but no modes

selected. Decoder

functions are active

but throttle is off.

Bus on.

Mode LED flashing

One or more Chassis

Condition LED

flashing

Park On

Solid

No

Yes

Bus On Solid

RMT 0-5V Flash

RMT PWM Flash

RPM1,RPM2,STBY off

All others On Solid

Bus OFF

RPM1 through RPM STBY

Flashing

Truck Not

Supported.

Second device is

connected to SEIC

wirings and

controlling RPM

operation

Operating at

Standby Speed,

waiting on remote

input to control

RPM

Mode Selected.

Chassis Ready Condition Not Met.

Check flashing interlock.

(e.g. if Park is flashing, make sure

vehicle is in Park)

Bus On

Single Mode LED

On Solid

Mode Activated.

Unit working

normally.

Flashing

On Solid

5.5 LED Troubleshooting Flowchart

© Copyright 2016 InPower LLC

DBT-MD-01 Owner’s Manual

12

Document: OM-194 Version Code: A

Date: August 2016 Date: Sept. 14, 2016

Contact Us

InPower LLC

8311 Green Meadows Drive

Lewis Center, Ohio 43035

740-548-0965

www.InPowerLLC.com

Table of contents

Other InPOWER Media Converter manuals