Page 10 Insinger Machine Company 2005

OPERATION

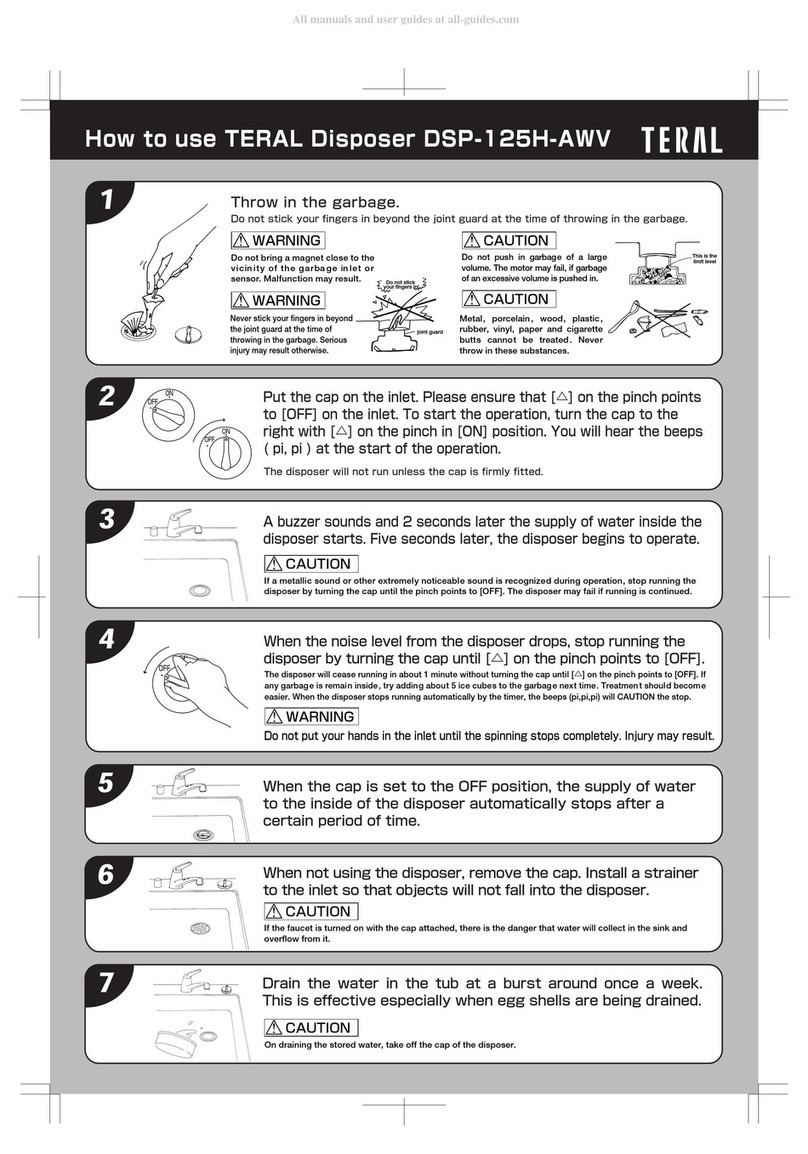

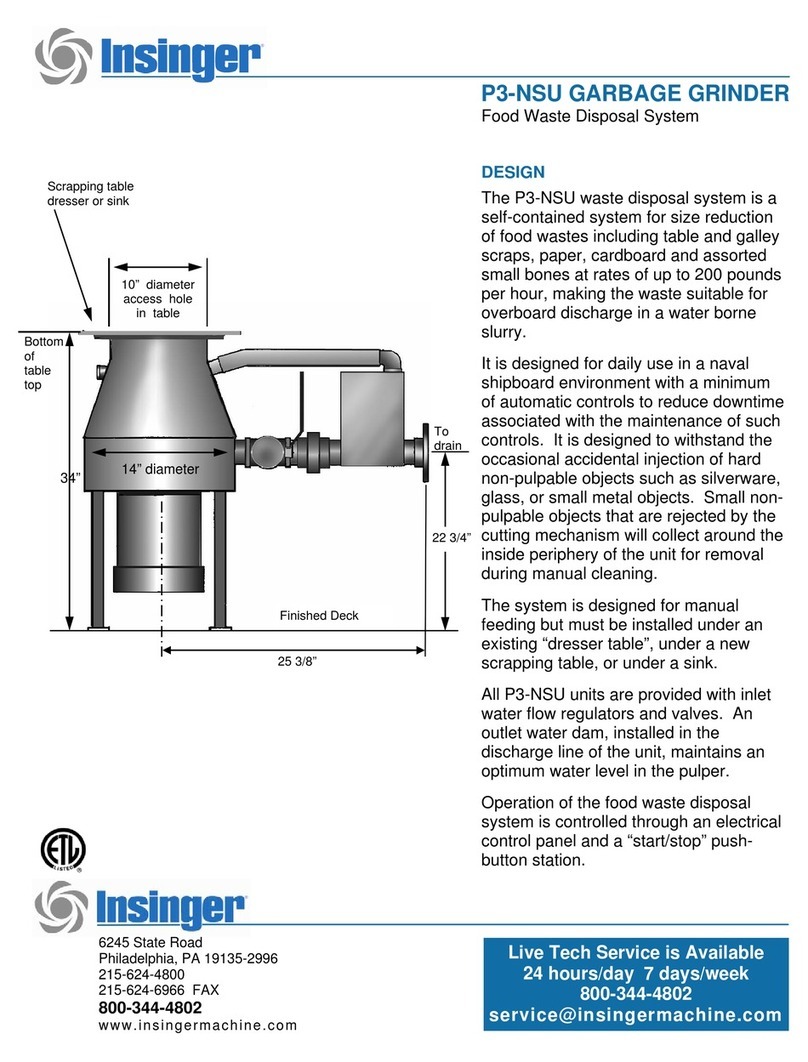

1. Check that disposer is empty and clean from previous use.

2. Check that vinyl silver trap scrapping ring is in place and properly seated over throat opening in cone or sink.

3. Turn disposer ON. Note that water is flowing into top cone or into sink via the water swirl fitting.

WARNING: Never feed waste by hand past vinyl silver trap ring or reach inside running disposer.

NOTE: Do not feed metal, wood, cloth, rubber, corn husks, plastics, plastic sheets of bags, styrofoam, or other foreign

matter. A periodic clean out of such material from the disposer is advisable.

4. Proceed with dish cleanup, feeding waste gradually. DO NOT pack waste into disposer waste chamber.

5. After each use, if disposer is wired with manual controls, allow disposer to run (motor and water) for at least 2

minutes. This clean-out cycle will empty the disposer and flush the waste line, preventing potential drain

stoppage.

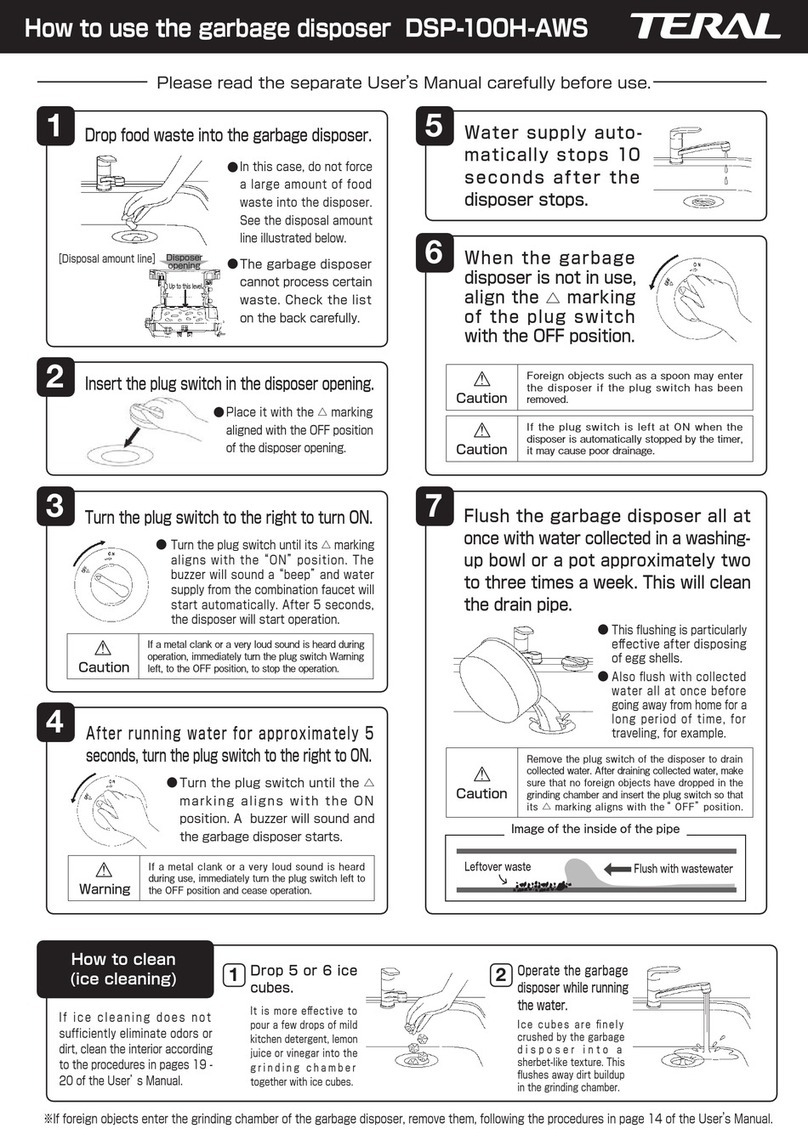

6. Should motor stop during use cycle, SHUT OFF POWER IMMEDIATELY, via ON-OFF switch. If disposer is

connected to Model RAC2 Control Center, shut OFF power at black emergency disconnect handle; on manual

switches, turn branch circuit disconnect to OFF.

A. Remove vinyl silver saver scrapping ring and check waste chamber through top opening and remove foreign

objects that may have caused stoppage.

B. Check to see if rotor turns freely.

C. If rotor turns freely, replace vinyl silver saver scrapping ring and turn disposer ON.

If disposer fails to start and run, an obstruction may still be binding the rotor.

A. Turn disposer OFF. Using a wooden bar or wooden handle, pry and push against the impact bars on the

rotor to break it free; then remove object.

B. Turn disposer ON and if motor fails to start, the thermal protector, either in the motor (“H” and “A” Series) or

in the controls, may have tripped.

C. Push reset button on thermal protector.

If disposer still fails to start, check for blown fuses or tripped circuit breakers in the branch circuit (especially on

three-phase installations) to be sure that all power legs are feeding motor.

TROUBLESHOOTING

DISPOSER DOES NOT START WHEN NEW

Manual reset button of thermal protector is tripped. On “I” and “N” Series, reset button is on motor; on “S” and “G”

Series, reset button is in control box.

Fuses or circuit breaker on branch circuit feed line have tripped.

Electrical connectionf on motor, in panel or feed lines not tight.

Headers have not been installed in starter, if starter is used in circuit.

DISPOSER DOES NOT START AFTER STANDING UNUSED FOR A PERIOD OF TIME

Clean out cycle too short. When disposer is stopped too early, the remaining water slowly drains out carrying the

shattered waste particles into the very close clearance opening between sizing ring and rotor, where it hardens and

solidifies, acting as a binding agent between the two parts. The motor at start-up is unable to overcome the dried

blockage (usually on low horsepower disposers).

DISPOSER STALLS WHEN IN OPERATION

Large quantities of foreign material (rags, wood pieces, rubber bands, strings, pieces from floor mops, cellophane

and polyethylene) which will not disintegrate, cause the motor to overheat and the thermal protector to trip.

Not enough water volume flow (GPM) causing thermal protector to trip.

Thermal protectors (heaters) sized too small, causing nuisance tripping.